Review on Contactless Power Transfer for Electric Vehicle Charging

Abstract

:1. Introduction

2. Different Technologies in Contactless Power Transfer

2.1. Capacitive CPT

2.2. Inductive CPT

2.3. Radiant CPT

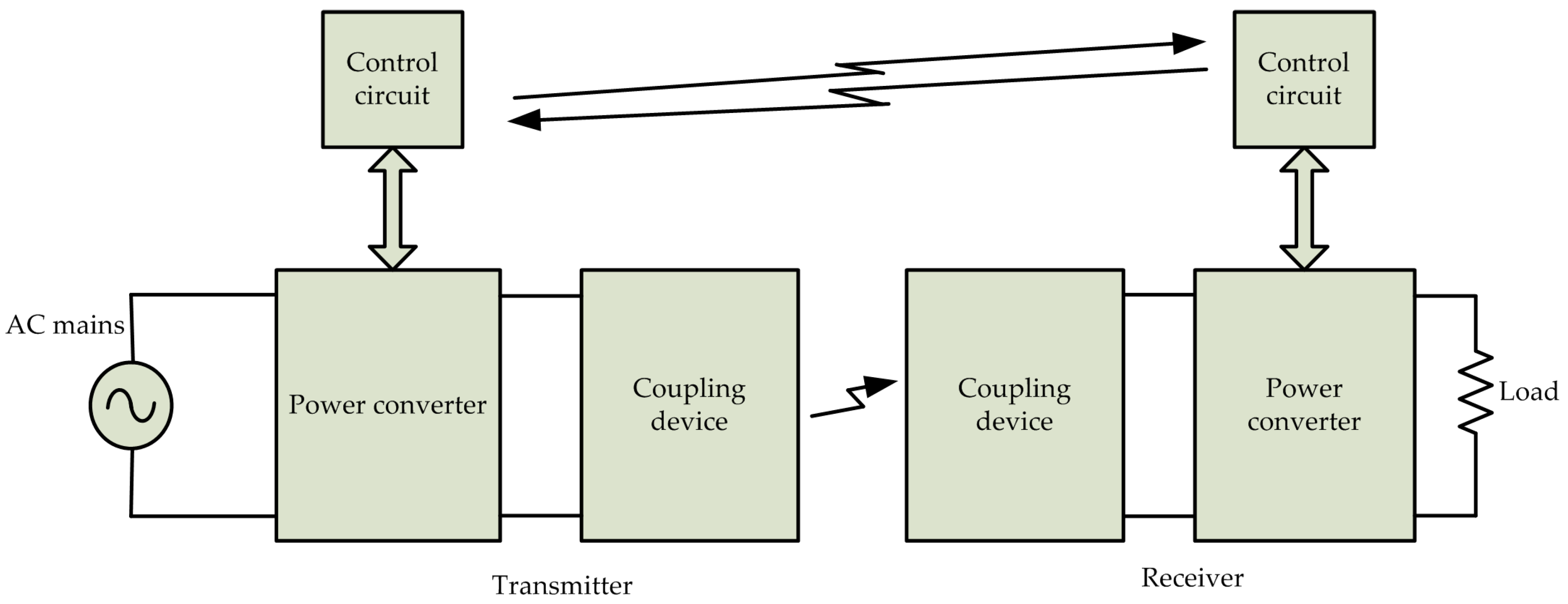

3. Inductive Power Transfer

Need of Compensation in Inductive Power Transfer

4. Outline of Issues in Inductive Coupled CPT Based on Existing Literature

5. Development of Inductive Coupled CPT for EV Charging

5.1. Compensation Topologies

5.1.1. Calculation of Compensation Capacitor for the Basic Topologies

5.1.2. Some of the New Topologies Reported until Now

5.2. Design of the Coil System

6. High Frequency Converter and Its Control Strategies

Future Recommendations

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Wm | Energy density in magnetic field |

| We | Energy density in Electric field |

| B | Magnetic flux density |

| E | Electric field intensity |

| r1 | Resistance of the transmitting coil |

| r2 | Resistance of the receiving coil |

| L1 | Self-inductance of the transmitting coil |

| L2 | Self-inductance of the receiving coil |

| M | Mutual inductance between transmitting and receiving coil |

| RL | Equivalent load resistance on the AC side |

| V1 | Voltage fed to the transmitting coil |

| I1 | Current flowing through transmitting coil |

| I2 | Current flowing through receiving coil |

| Ω | Angular frequency of the voltage fed to the transmitting coil |

| ω0 | Angular frequency at resonance |

| Z2 | Equivalent impedance at receiving side |

| Zt | Total impedance when seen from transmitter side input terminals |

| Zr | Reflected impedance from receiving side to transmitting side |

| Zro | Reflected impedance from receiving side to transmitting side at resonance |

| K | Coefficient of coupling between transmitting and receiving coil |

| PLmax | Maximum load power |

| SSC | Short circuit power |

| SPR | Sizing power ratio for voltage source |

References

- Chau, K.T.; Wong, Y.S.; Chan, C.C. An overview of energy sources for electric vehicles. Energy Convers. Manag. 1999, 40, 1021–1039. [Google Scholar] [CrossRef]

- Chan, C.C. The State of the Art of Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Miller, J.M. Hybrid electric vehicles: Architectures and motor drives. Proc. IEEE 2007, 95, 719–728. [Google Scholar] [CrossRef]

- Ashique, R.H.; Salam, Z.; Aziz, M.J.; Bhatti, A.R. Integrated photovoltaic-grid DC fast charging system for electric vehicle: A review of the architecture and control. Renew. Sustain. Energy 2016. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Mohamed, A.; Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renew. Sustain. Energy 2017, 69, 771–789. [Google Scholar] [CrossRef]

- Ul-Haq, A.; Cecati, C.; Al-Ammar, A. Modeling of a Photovoltaic-Powered Electric Vehicle Charging station with Vehicle-to-Grid Implementation. Energies 2017, 10, 4. [Google Scholar] [CrossRef]

- Jin, C.; Sheng, X.; Ghosh, P. Optimized Electric Vehicle Charging With Intermittent Renewable Energy Sources. IEEE J. Sel. Top. Signal Process. 2014, 8, 1063–1072. [Google Scholar] [CrossRef]

- Keshri, R.; Bertoluzzo, M.; Buja, G. Integration of a Photovoltaic Panel with an Electric City Car. Electr. Power Compon. Syst. 2014, 42, 481–495. [Google Scholar] [CrossRef]

- Su, W.; Eichi, H.; Zeng, W.; Chow, M.Y. A Survey on the Electrification of Transportation in a Smart Grid Environment. IEEE Trans. Ind. Inform. 2012, 8, 1–10. [Google Scholar] [CrossRef]

- Covic, G.A.; Boys, J.T. Modern Trends in Inductive Power Transfer for Transportation Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 28–41. [Google Scholar] [CrossRef]

- Wu, H.H.; Gilchrist, A.; Sealy, K.; Israelsen, P.; Muhs, J. A review on inductive charging for electric vehicles. In Proceedings of the IEEE International Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, USA, 2011; pp. 143–147. [Google Scholar]

- Khaligh, A.; Dusmez, S. Comprehensive Topological Analysis of Conductive and Inductive Charging Solutions for Plug-In Electric Vehicles. IEEE Trans. Veh. Technol. 2012, 61, 3475–3489. [Google Scholar] [CrossRef]

- Lukic, S.; Pantic, Z. Cutting the Cord: Static and Dynamic Inductive Wireless Charging of Electric Vehicles. IEEE Electr. Mag. 2013, 1, 57–64. [Google Scholar] [CrossRef]

- Zaheer, A.; Hao, H.; Covic, G.A.; Kacprzak, D. Investigation of Multiple Decoupled Coil Primary Pad Topologies in Lumped IPT Systems for Interoperable Electric Vehicle Charging. IEEE Trans. Power Electron. 2015, 30, 1937–1955. [Google Scholar] [CrossRef]

- Ni, W.; Collings, I.B.; Wang, X.; Liu, R.P.; Kajan, A.; Hedley, M.; Abolhasan, M. Radio Alignment for Inductive Charging of Electric Vehicles. IEEE Trans. Ind. Inform. 2015, 11, 427–440. [Google Scholar] [CrossRef]

- Aditya, K.; Williamson, S. A Review of Optimal Conditions for Achieving Maximum Power Output and Maximum Efficiency for a Series-Series Resonant Inductive Link. IEEE Trans. Transp. Electr. 2016. [Google Scholar] [CrossRef]

- Li, H.L.; Hu, A.P.; Covic, G.A.; ChunSen, T. A new primary power regulation method for contactless power transfer. In Proceedings of the IEEE International Conference on Industrial Technology, Churchill, Australia, 10–13 February 2009; pp. 1–5. [Google Scholar]

- Chao, Y.H.; Shieh, J.J.; Pan, C.T.; Shen, W.C.; Chen, M.P. A Primary-Side Control Strategy for Series-Parallel Loosely Coupled Inductive Power Transfer Systems. In Proceedings of the 2nd IEEE Conference on Industrial Electronics and Applications, Harbin, China, 23–25 May 2007; pp. 2322–2327. [Google Scholar]

- Wang, C.S.; Covic, G.A.; Stielau, O.H. Power transfer capability and bifurcation phenomena of loosely coupled inductive power transfer system. IEEE Trans. Ind. Electron. 2004, 51, 148–157. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Kong, S.; Kim, H.; Suh, I.S.; Suh, N.P.; Cho, D.H.; Kim, J.; Ahn, S. Coil Design and Shielding Methods for a Magnetic Resonant Wireless Power Transfer System. Proc. IEEE 2013, 101, 1332–1342. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.A.; Boys, J.T.; Huang, C.Y. Development and evaluation of single sided flux couplers for contactless electric vehicle charging. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 2011; pp. 614–621. [Google Scholar]

- Mude, K.N.; Dashora, H.K.; Bertoluzzo, M.; Buja, G. From Wired to In-Moving Charging of the Electric Vehicles. In Proceedings of the WSEAS International Conference on Development, Energy, Environment, Economics (DEEE), Lisbon, Portugal, 30 October–1 November 2014; pp. 33–42. [Google Scholar]

- Sallan, J.; Villa, J.L.; Llombart, A.; Sanz, J.F. Optimal design of ICPT systems applied to electric vehicle battery charge. IEEE Trans. Ind. Electron. 2009, 56, 2140–2149. [Google Scholar] [CrossRef]

- Bertoluzzo, M.; Naik, M.K.; Buja, G. Preliminary investigation on contactless energy transfer for electric vehicle battery recharging. In Proceedings of the IEEE 7th International Conference on Industrial and Information Systems (ICIIS), Chennai, India, 2012; pp. 1–6. [Google Scholar]

- Kim, J.; Bien, F. Electric field coupling technique of wireless power transfer for electric vehicles. In Proceedings of the IEEE TENCON Spring Conference, Sydney, Australia, 17–19 April 2013; pp. 267–271. [Google Scholar]

- Theodoridis, M.P. Effective Capacitive Power Transfer. IEEE Trans. Power Electron. 2012, 27, 4906–4913. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C. A Double-Sided LCLC-Compensated Capacitive Power Transfer System for Electric Vehicle Charging. IEEE Trans. Power Electron. 2015, 30, 6011–6014. [Google Scholar] [CrossRef]

- Dai, J.; Ludois, D.C. Capacitive Power Transfer through a Conformal Bumper for Electric Vehicle Charging. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1015–1025. [Google Scholar] [CrossRef]

- Aditya, K.; Williamson, S.S. Design considerations for loosely coupled inductive power transfer (IPT) system for electric vehicle battery charging—A comprehensive review. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 15–18 June 2014; pp. 1–6. [Google Scholar]

- Rituraj, G.; Joy, E.R.; Kushwaha, B.K.; Kumar, P. Analysis and comparison of series-series and series-parallel topology of contactless power transfer systems. In Proceedings of the IEEE TENCON Conference, Bangkok, Thailand, 22–25 October 2014; pp. 1–6. [Google Scholar]

- Jiwariyavej, V.; Imura, T.; Hori, Y. Coupling Coefficients Estimation of Wireless Power Transfer System via Magnetic Resonance Coupling Using Information from Either Side of the System. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 191–200. [Google Scholar] [CrossRef]

- Mude, K.N.; Bertoluzzo, M.; Buja, G. Design of a contactless battery charging system. Proceedings of IEEE International Conference of AFRICON, Pointe-Aux-Piments, Mauritius, 9–12 September 2013; pp. 1091–1096. [Google Scholar]

- Stielau, O.H.; Covic, G.A. Design of loosely coupled inductive power transfer systems. Proceedings of International Conference on Power System Technology, Perth, Australia, 23–24 October 2000; pp. 85–90. [Google Scholar]

- Villa, J.L.; Sallan, J.; Llombart, A.; Sanz, J.F. Design of a high frequency Inductively Coupled Power Transfer System for electric vehicle battery charge. Appl. Energy 2009, 86, 355–363. [Google Scholar] [CrossRef]

- Wang, C.S.; Stielau, O.H.; Covic, G.A. Design consideration for a contactless electric vehicle battery charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1313. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.A.; Boys, J.T. Design and Optimization of Circular Magnetic Structures for Lumped Inductive Power Transfer Systems. IEEE Trans. Power Electron. 2011, 26, 3096–3108. [Google Scholar] [CrossRef]

- Villa, J.L.; Sallan, J.; Sanz Osorio, J.F.; Llombart, A. High-Misalignment Tolerant Compensation Topology For ICPT Systems. IEEE Trans. Ind. Electron. 2012, 59, 945–951. [Google Scholar] [CrossRef]

- Zheng, C.; Ma, H.; Lai, J.S.; Zhang, L. Design Considerations to Reduce Gap Variation and Misalignment Effects for the Inductive Power Transfer System. IEEE Trans. Power Electron. 2015, 30, 6108–6119. [Google Scholar] [CrossRef]

- Buja, G.; Bertoluzzo, M.; Mude, K.N. Design and Experimentation of WPT Charger for Electric City Car. IEEE Trans. Ind. Electon. 2015, 62, 7436–7447. [Google Scholar] [CrossRef]

- Miller, J.M.; Onar, O.C.; Chinthavali, M. Primary-Side Power Flow Control of Wireless Power Transfer for Electric Vehicle Charging. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 147–162. [Google Scholar] [CrossRef]

- Eftekhar, M.G.; Ouyang, Z.; Andersen, M.A.E.; Andersen, P.B.; Ribeiro, L.A.; Schaltz, E. Efficiency Study of Vertical Distance Variations in Wireless Power Transfer for E-Mobility. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Ibrahim, M.; Pichon, L.; Bernard, L.; Razek, A.; Houivet, J.; Cayol, O. Advanced Modeling of a 2-kW Series–Series Resonating Inductive Charger for Real Electric Vehicle. IEEE Trans. Veh. Technol. 2015, 64, 421–430. [Google Scholar] [CrossRef]

- Kim, H.; Song, C.; Kim, D.H.; Jung, D.H.; Kim, I.M.; Kim, Y.I.; Kim, J.; Ahn, S.; Kim, J. Coil Design and Measurements of Automotive Magnetic Resonant Wireless Charging System for High-Efficiency and Low Magnetic Field Leakage. IEEE Trans. Microw. Theory Tech. 2016, 64, 383–400. [Google Scholar] [CrossRef]

- Samanta, S.; Rathore, A.K. A New Current-Fed CLC Transmitter and LC Receiver Topology for Inductive Wireless Power Transfer Application: Analysis, Design, and Experimental Results. IEEE Trans. Transp. Electr. 2015, 10, 357–368. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A Double-Sided LCC Compensation Network and Its Tuning Method for Wireless Power Transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, L.; Liao, C. Compensate Capacitor Optimization for Kilowatt-Level Magnetically Resonant Wireless Charging System. IEEE Trans. Ind. Electron. 2014, 61, 6758–6768. [Google Scholar] [CrossRef]

- Qu, X.; Han, H.; Wong, S.C.; Tse, C.K.; Chen, W. Hybrid IPT Topologies with Constant Current or Constant Voltage Output for Battery Charging Applications. IEEE Trans. Power Electron. 2015, 30, 6329–6337. [Google Scholar] [CrossRef]

- Zhang, W.; Wong, S.C.; Tse, C.K.; Chen, Q. Load-independent current output of inductive power transfer converters with optimized efficiency. In Proceedings of the 2014 International Power Electronics Conference (IPEC-Hiroshima 2014-ECCE-ASIA), Hiroshima, Japan, 18–21 May 2014; pp. 1425–1429. [Google Scholar]

- Hou, J.; Chen, Q.; Wong, S.C.; Tse, C.K.; Ruan, X. Analysis and Control of Series/Series-Parallel Compensated Resonant Converter for Contactless Power Transfer. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 124–136. [Google Scholar]

- Mude, K.N.; Bertoluzzo, M.; Buja, G.; Pinto, R. Design and experimentation of two-coil coupling for electric city-car WPT charging. J. Electromagn. Waves Appl. 2016, 30, 70–88. [Google Scholar] [CrossRef]

- Aditya, K.; Sood, V.K.; Williamson, S.S. Investigating the magnetic characteristics of unsymmetrical coil pair employing archimedean spiral for EV battery charging. In Proceedings of the IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), Knoxville, TN, USA, 4–6 October 2016; pp. 11–14. [Google Scholar]

- Tan, L.; Li, J.; Chen, C.; Yan, C.; Guo, J.; Huang, X. Analysis and Performance Improvement of WPT Systems in the Environment of Single Non-Ferromagnetic Metal Plates. Energies 2016, 9, 576. [Google Scholar] [CrossRef]

- Elliott, G.A.J.; Raabe, S.; Covic, G.A.; Boys, J.T. Multiphase Pickups for Large Lateral Tolerance Contactless Power-Transfer Systems. IEEE Trans. Ind. Electron. 2010, 57, 1590–1598. [Google Scholar] [CrossRef]

- Lee, S.; Huh, J.; Park, C.; Choi, N.S.; Cho, G.H.; Rim, C.T. On-Line Electric Vehicle using inductive power transfer system. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 1598–1601. [Google Scholar]

- Hasanzadeh, S.; Vaez-Zadeh, S.; Isfahani, A.H. Optimization of a Contactless Power Transfer System for Electric Vehicles. IEEE Trans. Veh. Technol. 2012, 61, 566–3573. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, X.; Wang, C.; He, Y. Comparative Analysis of Two-Coil and Three-Coil Structures for Wireless Power Transfer. IEEE Trans. Power Electron. 2017, 32, 341–352. [Google Scholar] [CrossRef]

- Moon, S.; Moon, G.W. Wireless Power Transfer System with an Asymmetric Four-Coil Resonator for Electric Vehicle Battery Chargers. IEEE Trans. Power Electron. 2016, 31, 6844–6854. [Google Scholar]

- Zhu, Q.; Guo, Y.; Wang, L.; Liao, C.; Li, F. Improving the Misalignment Tolerance of Wireless Charging System by Optimizing the Compensate Capacitor. IEEE Trans. Ind. Electron. 2015, 62, 4832–4836. [Google Scholar] [CrossRef]

- Sullivan, C.R.; Zhang, R.Y. Simplified design method for litz wire. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition—APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; pp. 2667–2674. [Google Scholar]

- Wang, S.; Dorrell, D.G. Copper Loss Analysis of EV Charging Coupler. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Wang, S.; Dorrell, D.G. Loss Analysis of Circular Wireless EV Charging Coupler. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Zheng, C.; Lai, J.S.; Chen, R.; Faraci, W.E.; Zahid, Z.U.; Gu, B.; Zhang, L.; Lisi, G.; Anderson, D. High-Efficiency Contactless Power Transfer System for Electric Vehicle Battery Charging Application. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 65–74. [Google Scholar] [CrossRef]

- Zahid, Z.U.; Dalala, Z.M.; Zheng, C.; Chen, R.; Faraci, W.E.; Lai, J.S.; Lisi, G.; Anderson, D. Modeling and Control of Series–Series Compensated Inductive Power Transfer System. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 111–123. [Google Scholar] [CrossRef]

- Aditya, K.; Williamson, S. Linearization and Control of Series-Series Compensated Inductive Power Transfer System Based on Extended Describing Function Concept. Energies 2016, 9, 962. [Google Scholar] [CrossRef]

- Esteban, B.; Sid-Ahmed, M.; Kar, N.C. A Comparative Study of Power Supply Architectures in Wireless EV Charging Systems. IEEE Trans. Power Electron. 2015, 30, 6408–6422. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, X.; Dai, H. Design and Control of a 3 kW Wireless Power Transfer System for Electric Vehicles. Energies 2016, 9, 10. [Google Scholar] [CrossRef]

- Samanta, S.; Rathore, A.K. Wireless power transfer technology using full-bridge current-fed topology for medium power applications. IET Power Electron. 2016, 9, 1903–1913. [Google Scholar] [CrossRef]

- Duan, C.; Jiang, C.; Taylor, A.; Bai, K. Design of a zero-voltage-switching large-air-gap wireless charger with low electric stress for electric vehicles. IET Power Electron. 2013, 6, 1742–1750. [Google Scholar] [CrossRef]

- Gao, Y.; Farley, K.B.; Tse, Z.T.H. A Uniform Voltage Gain Control for Alignment Robustness in Wireless EV Charging. Energies 2015, 8, 8355–8370. [Google Scholar] [CrossRef]

| Serial Number | Title of the Paper | Year | Authors | Description | Need of Improvement |

|---|---|---|---|---|---|

| 1 | Optimal Design of ICPT Systems Applied to Electrical Vehicle Battery Charge [24]. | 2009 | Jesus Sallan et al. | Described step by step design of core less Inductively coupled CPT for finding optimal parameters with large air gap that delivers high power efficiently. | Magnetic flux density surrounding the vehicle has to be considered in design process to avoid radiation effect on human beings. |

| 2 | Design and Optimization of Circular Magnetic Structures for Lumped Inductive Power Transfer Systems [37] | 2011 | Mickel Budhia et al. | Describes the design of charging pad that includes Aluminium backing plate, Aluminium ring, Ferrites, coil and plastic cover. Optimization of charging pad with respect to various pad parameters is shown with the aim of high efficiency and power transfer. | Optimization of asymmetrical coils can be evaluated with this procedure as they give better misalignment tolerance. |

| 3 | High Misalignment Tolerant Compensation Topology for ICPT Systems [38] | 2012 | Juan L. Villa et al. | SPS compensation topology is proposed to transfer maximum power in the case of misalignment without having burden on the source. By selecting proper ratio between transmitter side capacitors, combined characteristics of SS and PS topologies are obtained. | Soft switching has to be implemented to reduce switching losses of the converter. |

| 4 | Coil Design and Shielding Methods for a Magnetic Resonant Wireless Power Transfer System [21] | 2013 | Jiseong Kim et al. | Describes passive and active shielding. In passive shielding ferromagnetic materials are used to guide the flux or conductive materials to generate reverse magnetic field. In active shielding counter current source is used to suppress the time varying EMF outside the vehicle. Requirement of current source is eliminated by reactive resonant current loop. | Optimal placement of cancel coils with minimum number of turns is the need of reactive resonant current loop. |

| 5 | Design Considerations to Reduce Gap Variation and Misalignment Effects for the Inductive Power Transfer system [39] | 2015 | Cong Zheng et al. | Coupling coefficient of asymmetrical coils with receiver coil outer diameter less than transmitting coil inner diameter is less sensitive to misalignment and gap variation | Coupling coefficient under perfect alignment condition is less. Asymmetrical coils with equal outer diameter on both coils and variation in inner diameter gives better coupling coefficient and less sensitive to misalignment, gap variation |

| 6 | Design and Experimentation of WPT Charger for Electric City Car [40] | 2015 | Giuseppe Buja et al. | Described step by step design of CPT charger that includes sizing of converters, coil coupling and loss assessment in each stage. | Primary side control technique can be implemented to maintain efficiency of the CPT charger at different stages of battery. |

| 7 | Primary-Side Power Flow Control of Wireless Power Transfer for Electric Vehicle Charging [41] | 2015 | John M. Miller et al. | Power flow to the load is controlled from transmitting side with feedback of receiving side information using wireless communication system | Wireless Communication devices can be eliminated in controlling the power flow from transmitting side. |

| 8 | Efficiency Study of Vertical Distance Variations in Wireless Power Transfer for E-Mobility [42] | 2016 | Morteza Ghorbani Eftekhar et al. | Presented the analysis of effect of decreasing the vertical distance on mutual inductance and efficiency. At low vertical distance mutual inductance is high and efficiency is high but vertical distance less than 4 cm, third harmonic interference will come into picture. | At low vertical distance mutual inductance is more sensitive to horizontal misalignment which should be considered. |

| Ref No. with Year | Charging Distance | Efficiency | Power Transferred | Operating Frequency |

|---|---|---|---|---|

| Electric city car (2015) [40] | 10 cm | Overall efficiency from grid side AC to battery (DC) is 77% | 560 W | 85 kHz |

| KANGOO RENAULT (2015) [43] | 10 cm | DC-DC efficiency of 89.15% | 2 kW | 33 kHz |

| 1-kW-class golf-cart (2016) [44] | 15.6 cm | DC-DC efficiency of 96% | 1 kW | 20.15 kHz |

| Type of Compensation | Expression for Primary Capacitor for Zero Reactance Seen from Transmitting Side | Reflected Resistance from Receiving Side | Reflected Reactance from Receiving Side |

|---|---|---|---|

| S-S topology | |||

| S-P topology | |||

| P-P topology | |||

| P-S topology |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaka, R.; Keshri, R.K. Review on Contactless Power Transfer for Electric Vehicle Charging. Energies 2017, 10, 636. https://doi.org/10.3390/en10050636

Vaka R, Keshri RK. Review on Contactless Power Transfer for Electric Vehicle Charging. Energies. 2017; 10(5):636. https://doi.org/10.3390/en10050636

Chicago/Turabian StyleVaka, Ravikiran, and Ritesh Kumar Keshri. 2017. "Review on Contactless Power Transfer for Electric Vehicle Charging" Energies 10, no. 5: 636. https://doi.org/10.3390/en10050636