1. Introduction

Phase-change materials (PCMs) have been extensively utilized in thermal energy storage (TES) and electronic thermal management (TM) devices in recent years because of their good properties, such as a large amount of latent heat, suitable phase-change temperature and good chemical stabilities [

1,

2]. However, PCMs always suffered from an inherent disadvantage of low thermal conductivity, resulting in poor thermal performance and restricting their further utilization in the field of energy storage and thermal management [

3]. For examples, the thermal conductivity of paraffin is less than 0.4 W/(m·K). Such low thermal conductivity of pure paraffin will lead to small heat transfer rate, resulting in slow heat charging and discharging in TES devices as well as inability to maintain constant temperature in TM systems [

4]. Different methods have been put forward to enhance the thermal conductivity of PCMs, for example, inserting highly conductive materials including metal fins [

5,

6], expanded graphite [

7,

8], and nanoparticles [

9].

Due to their high thermal conductivity and high ratios of heat transfer surface to volume, metal foams are excellent candidates for the enhancement of the thermal conductivity of PCM. Kopanidis et al. [

10] analyzed the relationship between the surface thermal conductivity of copper foam and the fluid pressure drop using numerical methods; the results indicated that the copper foam could achieve good thermal conductivity with a small fluid pressure drop. Xiao et al. [

11] made composite of copper foam/paraffin to improve the thermal conductivity, and found its equivalent thermal conductivity was nearly 15 times larger than that of pure paraffin. Li et al. [

12] also investigated the effect of the foam morphology parameters such as porosity, pore size on the wall temperature of the phase-change energy storage system. The results showed that the influence of pore size was less obvious than that of porosity. Sundarram et al. [

13] used numerical method to analyze metal foam/PCM composite thermal management system, and the results presented that at a fixed porosity, a smaller pore size of the metal foam led to a longer time period, that the temperature of the heat source remained nearly constant. Zhou et al. [

14] compared composite of copper foam/paraffin and expanded graphite/paraffin through experimental method, and found that the former had better heat-transfer performance. Tian et al. [

15] numerically investigated metal foam/paraffin composite based on the two-equation non-equilibrium heat-transfer model; the results showed that heat conduction rate was increased significantly using metal foam, and that natural convection was suppressed owing to the large flow resistance in metal foam. Furthermore, Qu et al. [

16] experimentally investigated the melting processing of metal foam infiltrated with PCM; the results indicated that temperature increased more linearly for the metal foam/PCM composite than for the case of pure paraffin since the enhancement in thermal conduction caused by metal foam exceeded the level of its suppression to natural convection of melted paraffin.

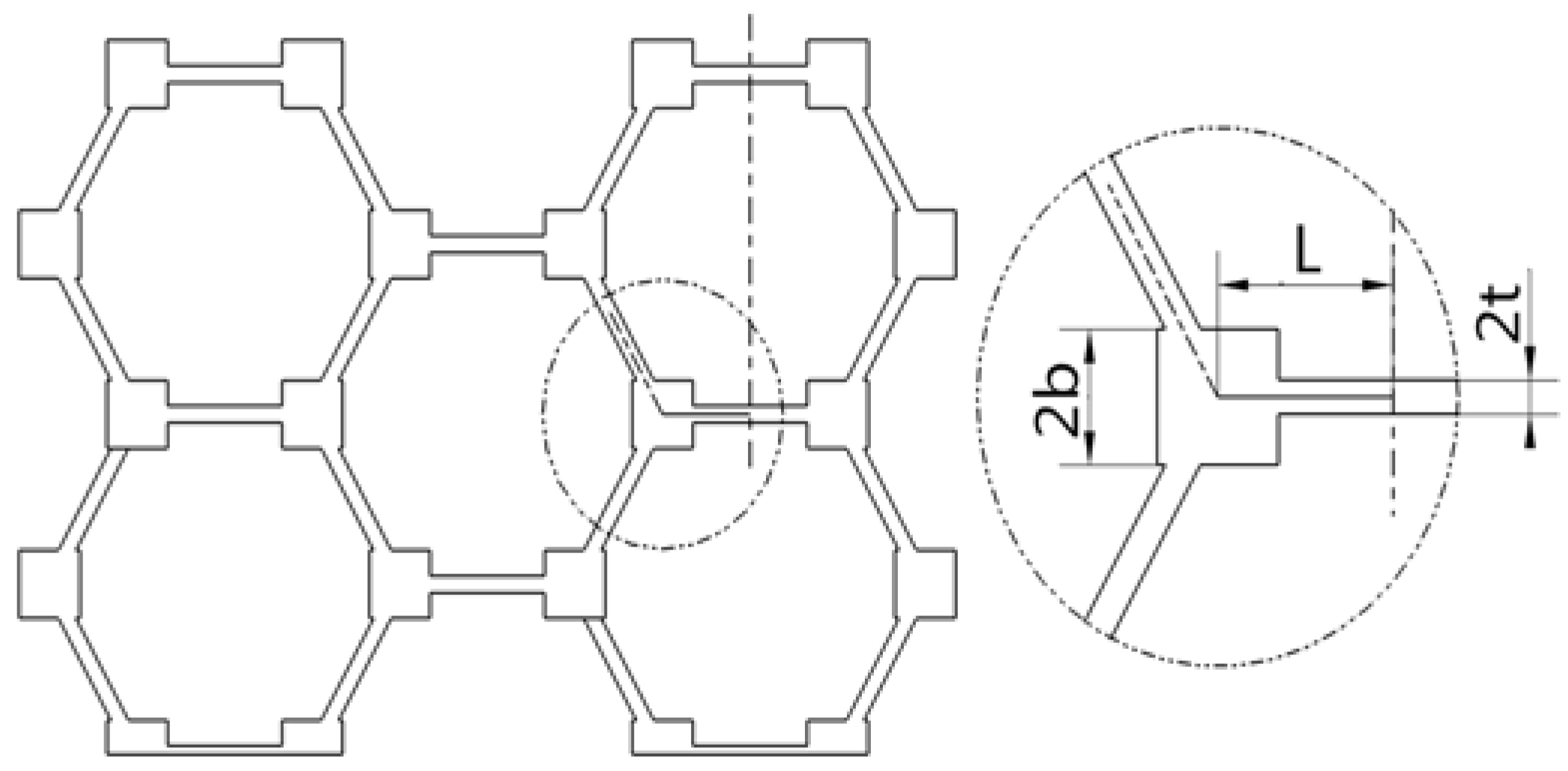

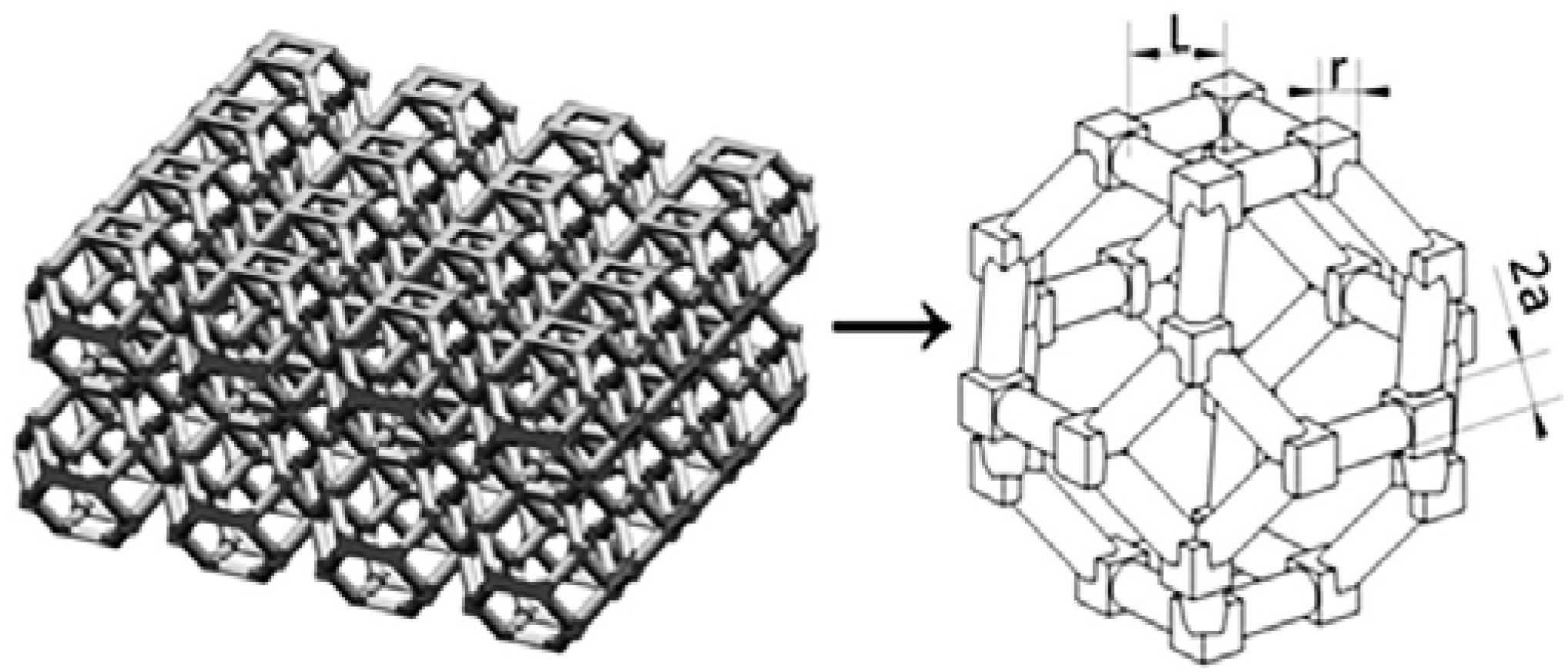

Due to the non-uniformity and randomness of pores in the metal foams, many thermal conductivity models of metal foams had a large error compared with experimental results [

17,

18], but two-dimensional (2D) Calmidi-Mahajan (C-M) model [

19] and three-dimensional (3D) Boomsma-Poulikakos (B-P) model [

20] got high accuracy when used to deduce thermal conduction properties of porous media. However, few papers employed these models to simulate heat transfer performance of metal foam/PCM composite. In this paper, the pore-scale numerical works on the effective thermal conductivity and melting process of copper foam filled with paraffin were conducted by using the improved 2D C-M model and 3D B-P model. The unidirectional heat transfer experimental setup was also established to investigate the effective thermal conductivity of the composite. The relationship between porosity of copper foam and the effective thermal conductivity of the composite was discussed. Finally, the solid–liquid interface development, completely melted time and temperature field distribution of paraffin in the pore of copper foam were also discussed.

3. Experiment

In order to measure the effective thermal conductivity of the composite, which consists of more than a single phase (such as the metal foam/PCM composite), the steady-state method was chosen because it is simpler and less sensitive than transient methods. As shown in

Figure 3, the steady-state experimental setup was designed and established to investigate the relationship between the effective thermal conductivity of the composite and the porosity of copper foam. The experimental setup consisted of thermostatic water-bath, electric heater, plexiglass cavity, composite sample, data acquisition system and DC voltage power supply. A 2 mm thick copper plate was arranged at the bottom and top of the sample to minimize the contact thermal resistance with heat source and cold source. A constant heat flux of 560 W/m

2 was supplied by the heater to the bottom of the sample, while the top of the sample was set as 22 °C through cooling block of the thermostatic water-bath. In order to realize that heat transferred only from bottom surface to top surface of the sample, insulation of the side walls was very important. Thus, a 1 cm thick thermal insulation material (polyurethane foam plate) was used to minimize heat loss from the sides. A total of 18 T-type thermocouples with the accuracy of ±0.1 °C were utilized in the experiment. Five thermocouples were arranged at different heights along the vertical axis of the sample to measure the temperature change. Other thermocouples were arranged on the inner and outer sides of the insulation materials to measure heat loss from side walls, as well as the ambient to observe ambient temperature.

In the present experiment, four composite samples having an approximate dimension of 100 × 100 × 30 mm were prepared through inserting paraffin into copper foam. Four different copper foams with the porosity of 93%, 95%, 96% and 98% respectively, were used in the experiment, and the pore size of the copper foams was 10PPI.

When all the thermocouples collected ambient temperature, the heat flux began to be applied to the composite. The temperature of the composite gradually increased until it reached the steady state and all the thermocouples in the composite recorded the temperature. The experiment was considered as completed after collecting an unchanged temperature distribution in the composite for at least 10 min. After obtaining the temperature distribution, the effective thermal conductivity of the composite can be evaluated by using Fourier’s law. To ensure repeatability and accuracy of the experimental data, the experiment was conducted three times for each composite sample. The experimental data was showed in the next section and compared to the numerical results.

The uncertainty of the experiment was also analyzed in the paper. The overall uncertainty was mainly due to the inaccuracies of measurement for power input, temperature, thickness, porosity and heat loss. The deviation of power input by DC voltage power supply was 0.42%. With δT being ±0.1 °C (±0.4%) for the thermocouples, δH being ±0.2 mm (±0.66%) for the thickness of the composite, δε being ±0.5%. q

loss was estimated at 0.192 W according to the thermocouples arranged on the inner and outer sides of the insulation materials and the thermal conductivity of insulation materials, and q being 5.6 W (560 W/m

2). The overall uncertainty of the experiment was calculated at 3.58% by the following equation:

where P, T, H, ε and q

loss were the power input, temperature, thickness of the composite, porosity and heat loss, respectively.

4. Results and Discussion

According to the simulation method explained in

Section 2.2, several thermal conduction simulations were conducted for the composite at different porosity of copper foam. The temperature distribution in the composite was presented in

Figure 4 for the porosity of 95%.

The temperature of hot side can be integrated based on the obtained temperature field. Knowing the heat flux through the composite and the temperature difference, the effective thermal conductivity of the composite can be calculated by utilizing Fourier’s law. The simulated results of the effective thermal conductivity of the composite were shown in

Table 2 and

Table 3 based on the 2D C-M and 3D B-P models, respectively.

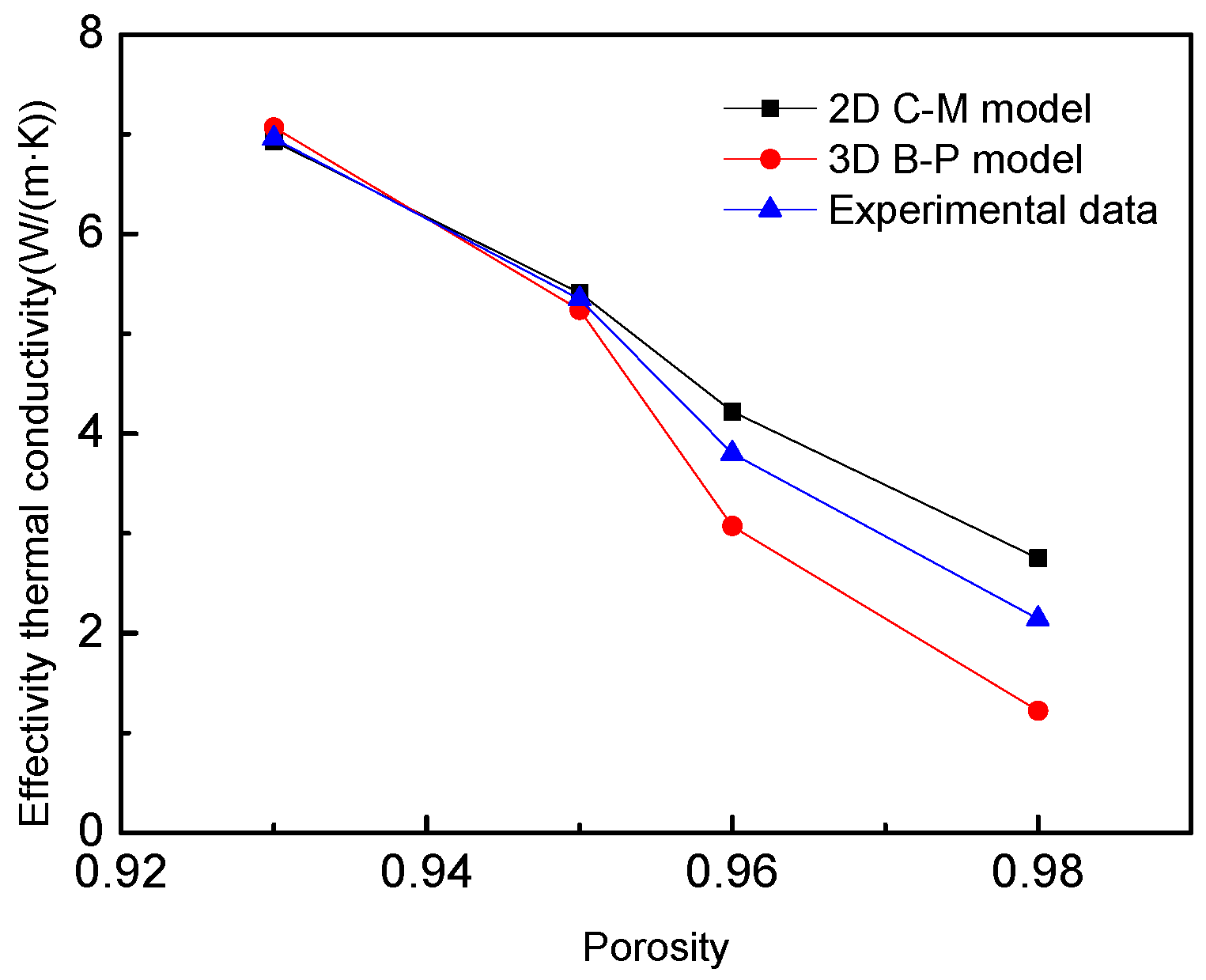

In 2D C-M model, the effective thermal conductivities were 6.93, 5.41, 4.22 and 2.75 W/(m·K), for porosity of 93%, 95%, 96% and 98% respectively, which were 26.7, 20.8, 16.2 and 10.6 times larger than that of pure paraffin. In 3D B–P model, the effective thermal conductivities were 7.07, 5.24, 3.07 and 1.22 W/(m·K), for porosity of 93%, 95%, 96% and 98% respectively, which were 27.2, 20.2, 11.8 and 4.7 times larger than that of pure paraffin. Based on these results, it was obvious that the copper foam can enhance the thermal conductivity of paraffin, i.e., the smaller the porosity of copper foam, the higher the effective thermal conductivity of the composite. Although the addition of copper foam can improve the energy storage efficiency of PCM, utilizing copper foam reduces the capacity of the PCM in condition of the same container when compared to the case of pure PCM, i.e., the smaller the porosity of copper foam, the less the energy storage. Therefore, in order to establish a better energy storage system, both the porosity of the copper foam and the capacity of PCM need to be considered.

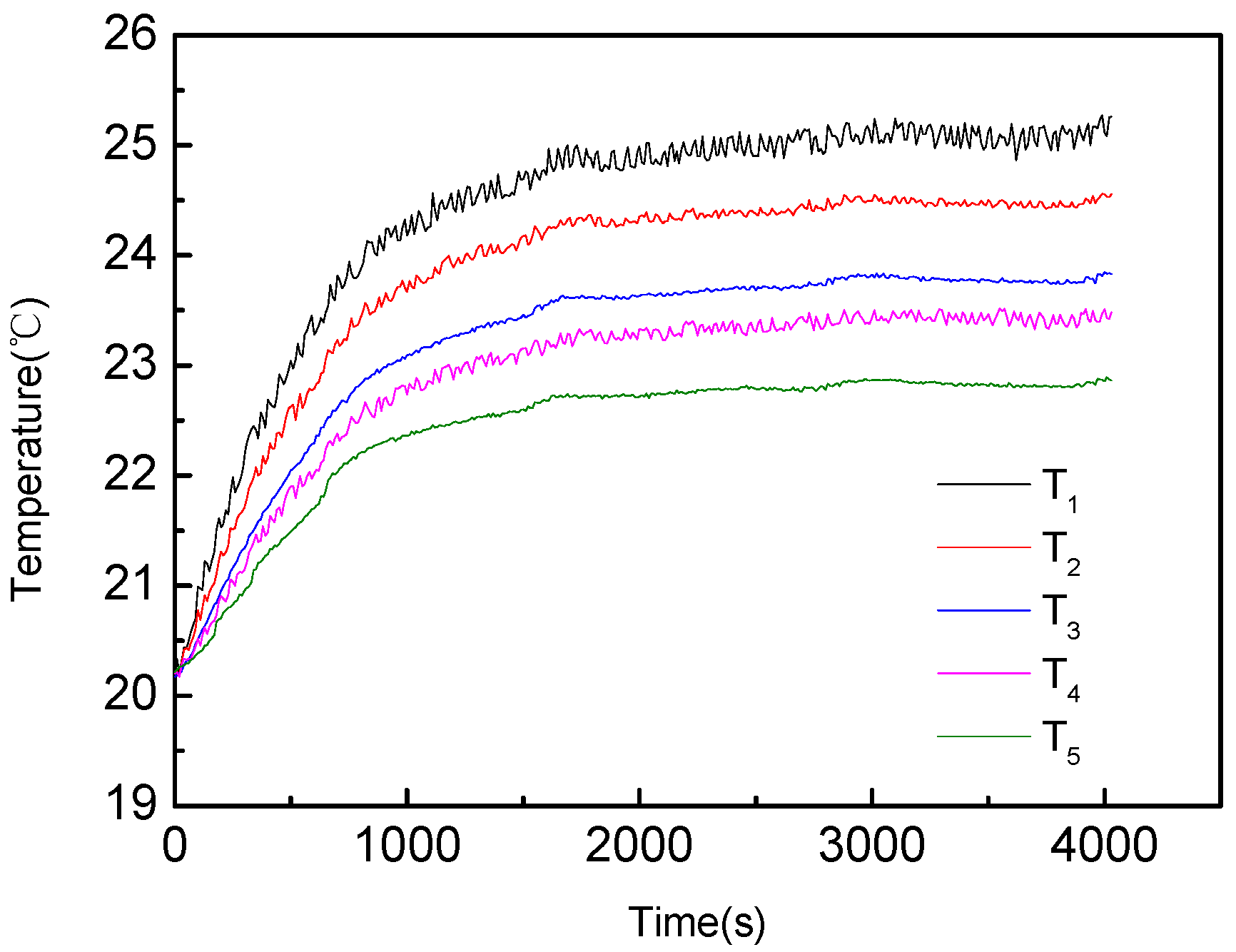

Based on the experimental method mentioned in

Section 3, the temperature variation of the composite was measured. The temperature of the composite for the porosity of 95% during the experiment was presented in

Figure 5. After applying the heat flux to the bottom side of the composite, the temperature of each point in the composite increased with time until thermocouple recordings did not change.

After obtaining the temperature distribution of the composite for different porosity via experimental method, the effective thermal conductivity of the composite can also be extracted by using Fourier’s law. The effective thermal conductivity of composite based on the simulation was validated against the experimental results (

Figure 6). When the porosities of the copper foam were 93% and 95%, the simulation results were well consistent with the experimental results, which indicated that two models can be used to accurately simulate the effective thermal conductivity of the copper foam/paraffin composite in condition of low porosity copper foam. However, when the porosity was 96%, the error between numerical and experimental result was larger, especially in B-P model. When the porosity further increased to 98%, the relative error increased to 43%. It can also be seen from

Figure 6 that when the porosity of copper foam was larger than 95%, the simulation result obtained through 2D C-M model was larger than the experimental results, while the results obtained through 3D B-P model was smaller than the experimental results. The deviation was reasonable because thermal conductivity of the composite mainly depended on the metal fiber conduction, and as the porosity of copper foam increased, the metal fiber became smaller, resulting in the decrease in the contact area between the metal fiber and paraffin. However, the contact area in 2D C-M model was reduced less than that in actual copper foam, while that in the 3D B-P model was decreased more than that in actual copper foam. So 2D C-M model overestimated, and 3D B-P model underestimated the experimental results when the porosity was larger than 95%.

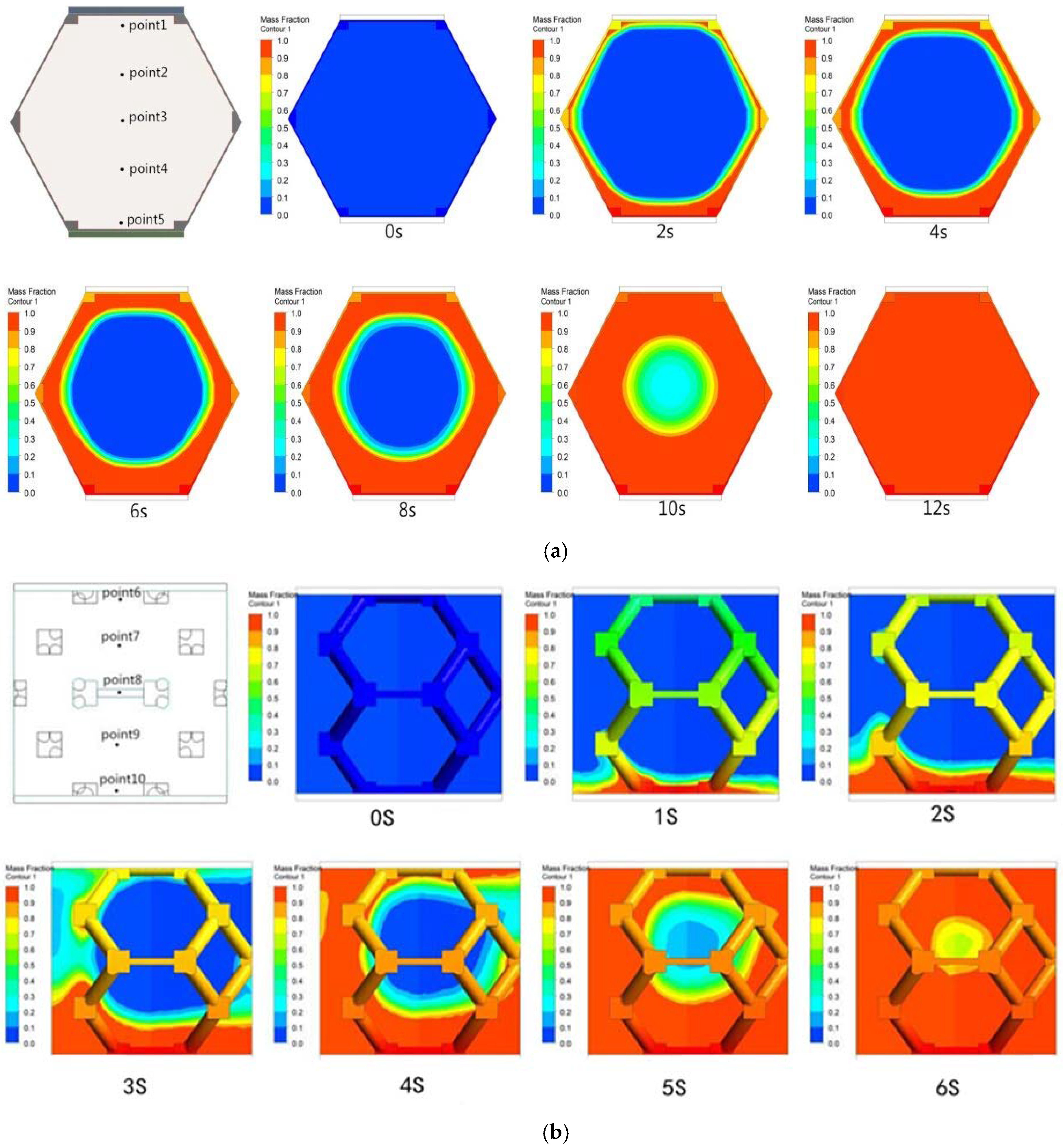

Based on the numerical method mentioned above, the melting processes of the composite by using 2D C-M and 3D B-P models were presented in

Figure 7. The composite can be divided into three different regions in the melting process, namely solid-phase region, liquid-phase region and mushy region. The blue color represented solid-phase region, red color was liquid-phase region and other color indicated mushy region. During the melting process, solid-phase zone decreased, the mushy region thickened and liquid-phase region increased gradually. The melting processes of paraffin in the two models were similar. At the beginning of the melting process, the heat was transferred from the heat source to the bottom of the composite quickly, so the paraffin at the bottom melted first. Then the heat was spread to all the structure including the top part due to the high thermal conductivity of copper foam, leading to the melting of the paraffin contacting with the copper fiber. Then the inner part of the paraffin was also gradually heated and melted. The solid–liquid interface of paraffin developed from the boundary to the inner of the composite, resulting in that the solid paraffin was surrounded by the melted paraffin. The melting processes of the paraffin in the two models were well consistent with the obtained experimental phenomena, which presented that in pore scale, the paraffin near metal fiber melted first and the melting front was parallel to the structure of metal fiber, and with the increase of melting time, the melting front moved to the center of pore structure [

22]. The completely melted time of the whole process took 12 s in 2D C-M model, and 7 s in 3D B-P model. This big difference between the two models was obviously not caused by the effective thermal conductivity difference (5.41 W/(m·K) and 5.24 W/(m·K), respectively), but by the distribution of copper fibers in the composite. Although the porosities for both models were 95%, the copper fiber in 2D C-M model distributed around the structure, the contact area was very small, while that in 3D B–P model was distributed in the inner part, thus the completely melted time was larger in 2D C-M model.

Temperature variation as a function of time during the melting process was presented in

Figure 8. It was obvious that temperature growth rate in 2D C-M model was similar to that in 3D B-P model. It was found out that at the beginning of heating, the temperature of the composite increased rapidly because the paraffin absorbed little heat in solid-phase sensible heat storage stage and the heat transfer performance of paraffin was improved by copper foam. When the temperature rose to the phase transition temperature, the paraffin began to melt and absorbed a lot of heat, so the growth rate of the temperature was slowed down, and when the paraffin was completely melted, growth rate of the temperature was increased again. It can also be seen from

Figure 8 that the bottom of both models almost reached the temperature of the heat source within 1 s, and the temperature of the paraffin near copper fiber also increased quickly because of the high thermal conductivity of copper fiber. The temperature growth speed in the centre of the composite was the slowest due to the low thermal conductivity of the paraffin, leading to the small heating speed. The increasing order of the temperature in the composite was in agreement with the melting process shown in

Figure 7, which presented the paraffin at the bottom and near the metal fiber melted first and the paraffin in the centre of the pore finally melted. Additionally, the simulated results were also consistent well with our previous experimental data [

23] in which the PCM was filled within the copper foam, thus it further verified the effectiveness of the two models utilized in simulating the melting process of metal foam/PCM composite.