Best Practices for Recovering Rural Abandoned Towers through the Installation of Small-Scale Biogas Plants

Abstract

:1. Introduction

2. The Energy Rural Silo (ERS)

2.1. Methodology

- Survey of the defined rural area in order to identify the annexes to be recovered and classification to classify them by type;

- Definition of the most adequate energy technology for RES production which could be applied to the previously selected rural buildings;

- Construction of a virtual model of the proposed solution in order to evaluate the plant functional scheme and visual impact of the proposal;

- Analysis of the proposal’s sustainability by evaluating its economic and environmental impacts.

2.2. The Concept of Energy Rural Silo

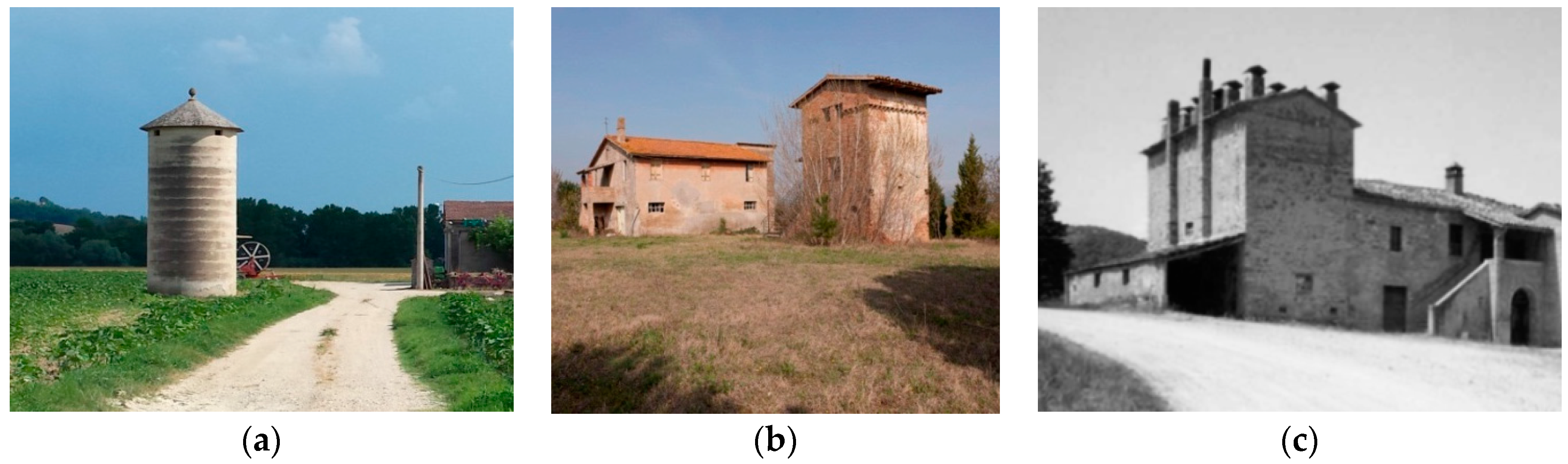

2.3. Rural Buildings in Umbria

2.4. Mini Biogas in Umbria

3. Description of the Case Study

3.1. Building Survey and Modeling

3.2. Biogas and Plant Design

- Loading system, a tank that can store up to 12 m3 of different biomasses, and a specific submerged pump can stir them and make the mixture homogeneous; a regulation valve can dose the quantity of biomass to be loaded to the reactor;

- Anaerobic digester, the biomass based mixture remains in the digester for 15 days by getting warmer through a coil;

- Gasometer, while the digestion process is underway, the resulting biogas is stored in the floating bell with a volume up to 13.5 m3 that corresponds to a maximum height increment of 2 m;

- Biogas cogeneration engine, the engine is fueled by the biogas stored in the upper part of the digester; the electric power can range from 10 to 30 kW, with a corresponding biogas flow rate of respectively 7 and 9 m3/h (at least 65% methane content in biogas) and a thermal power which ranges from 50 to 70 kW;

- Digested matter storage tank, a part of produced heat is transferred towards this tank to ensure drying the digested matter is dried.

3.2.1. Plant Technology

3.2.2. Insulation Layer’s Properties

3.2.3. Coil Heat Exchanger

3.2.4. Biogas Cogeneration Engine

3.3. Biomass Pathway and Biogas Production

3.4. Economical and Environmental Sustainability

3.5. Application of Solid Oxide Fuel Cells (SOFC) Stack

4. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| RES | Renewable Energy Sources |

| GSE | Manager of Public Energy |

| ERS | Energy Rural Silo |

| ICE | Internal Combustion Engine |

| CHP | Combined Heat and Power |

| OPEX | Operating Expenditure |

| CAPEX | Capital Expenditure |

| SOFC | Solid Oxide Fuel Cells |

References

- European Union. Directive 2010/31/EU on the Energy Performance of Buildings (Recast)—19 May 2010; European Union: Brussels, Belgium, 2010. [Google Scholar]

- Edenhofer, O.; Madruga, R.P.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schlömer, S.; et al. Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Marrakech Action Proclamation for Our Climate and Sustainable Development; UNFCCC: Marrakech, Morocco, 2016. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Report of the Conference of the Parties on Its Twenty-Second Session; UNFCCC: Marrakech, Morocco, 2016. [Google Scholar]

- Lovins Amory, B. Renewable Energy’s ‘Footprint’ Myth. Electr. J. 2011, 24, 40–47. [Google Scholar] [CrossRef]

- Lewandowska-Bernat, A.; Desideri, U. Opportunities of Power-to-Gas technology. Energy Procedia 2017, 105, 4569–4574. [Google Scholar] [CrossRef]

- Papurello, D.; Lanzini, A.; Tognana, L.; Silvestri, S.; Santarelli, M. Waste to energy: Exploitation of biogas from organic waste in a 500 Wel solid oxide fuel cell (SOFC) stack. Energy 2015, 85, 145–158. [Google Scholar] [CrossRef]

- Agostini, S. Architettura Rurale: La via del Recupero. Alternative di Intervento Sull’esistente; Franco Angeli Editore: Rome, Italy, 1999. [Google Scholar]

- Cotana, F.; Belardi, P.; Tamagnini, C.; Materazzi, A.L.; Fornaciari, M.; Petrozzi, A.; Pisello, A.L.; Cavalaglio, G.; Coccia, V.; Pagnotta, G.; et al. TIAR: Renewable energy production, storage and distribution; a new multidisciplinary approach for the design of rural facility. Energy Procedia 2014, 45, 323–332. [Google Scholar] [CrossRef]

- Pisello, A.L.; Petrozzi, A.; Castaldo, V.L.; Cotana, F. On an innovative integrated technique for energy refurbishment of historical buildings: Thermal-energy, economic and environmental analysis of a case study. Appl. Energy 2014, 162, 1313–1322. [Google Scholar] [CrossRef]

- IEC-International Electrotechnical Commission. Grid Integration of Large-Capacity Renewable Energy Source and Use of Large-Capacity Electrical Energy Storage; White Papers; International Electrotechnical Commission (IEC) Market Strategy Board: Rome, Italy, 2001. [Google Scholar]

- Mosannenzadeh, F.; Bisello, A.; Vaccaro, R.; D’Alonzo, V.; Hunter, G.W.; Vettorato, D. Smart energy city development: A story told by urban planners. Cities 2017, 64, 54–65. [Google Scholar] [CrossRef]

- Rossi, F.; Nicolini, A. A cylindrical small size molten carbonate fuel cell: Experimental investigation on materials and improving performance solutions. Fuel Cells 2009, 9, 170–177. [Google Scholar] [CrossRef]

- Rossi, F.; Nicolini, A. Experimental investigation on a novel electrolyte configuration for cylindrical molten carbonate fuel cells. J. Fuel Cell Sci. Technol. 2011, 8, 051012. [Google Scholar] [CrossRef]

- Cotana, F.; Rossi, F.; Nicolini, A. A new geometry high performance small power MCFC. J. Fuel Cell Sci. Technol. 2004, 1, 25–29. [Google Scholar] [CrossRef]

- Bonamente, E.; Pelliccia, L.; Merico, M.C.; Rinaldi, S.; Petrozzi, A. The multifunctional environmental energy tower: Carbon footprint and land use analysis of an integrated renewable energy plant. Sustainability 2015, 7, 13564–13584. [Google Scholar] [CrossRef]

- King, E.A.; Bourdeau, E.P.; Zheng, X.Y.K.; Pilla, F. A combined assessment of air and noise pollution on the High Line, New York City. Transp. Res. Part D Transp. Environ. 2016, 42, 91–103. [Google Scholar] [CrossRef]

- Maritime Museum in Helsingør, Denmark. Available online: http://mfs.dk/en/ (accessed on 12 February 2017).

- Gasometer in Wien. Available online: http://www.gasometer.at/de/ (accessed on 25 June 2017).

- European Commission (COM614). Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Bruxelles, Belgium, 2013. [Google Scholar]

- Agenzia nazionale per le nuove tecnologie, l'energia e lo sviluppo economico sostenibile (ENEA). Architettura Bioclimatica; De Luca Editore: Rome, Italy, 1983. [Google Scholar]

- Martelli, R. I Materiali e gli Elementi Costruttivi Nella Casa Rurale; Olschki Ed.: Florence, Italy, 1969. [Google Scholar]

- Pagnotta, G. Umbria Architettura Tradizione. Rilievo e Catalogazione Dell’architettura rurale in Umbria. Ph.D. Thesis, University of Perugia, Perugia, Italy.

- Bonasera, F.; Desplanques, H.; Fondi, M.; Poeta, A. La Casa Rurale Nell'umbria. C.N.R., Ricerche Sulle Dimore Rurali in Italia; Olschki Ed.: Florence, Italy, 1955. [Google Scholar]

- Ministero delle Politiche Agricole, Alimentari e Forestali (MIPAAF). Piano Strategico per l’innovazione e la Ricerca nel Settore Agricolo Alimentare e Forestale (2014–2020); MIPAAF: Rome, Italy, 2014. [Google Scholar]

- Gestore dei Servizi Energetici (GSE). Statistic Report on Energy from Renewable Sources; GSE: Rome, Italy, 2014. [Google Scholar]

- California Integrated Waste Management Board. Current Anaerobic Digestion Technologies Used for Treatment of Municipal Organic Solid Waste; Public Affairs Office; Publications Clearinghouse: Sacramento, CA, USA, 2008.

- Administrative Appeals Tribunal (AAT). Abwasser- und Abfalltechnik GmbH Technology for Biogas. Available online: http://www.aat-biogas.at/it/esibizioni-profilo/sistemi-di-digestori/ (accessed on 25 February 2017).

- Costruire un impianto di biogas: Dal Nord Italia all’Abruzzo. In Proceedings of the Administrative Appeals Tribunal (AAT) Conference, Pescara, Italy, 23 February 2010.

- Sarikaya, E.; Demirer, G.N. Biogas production from broiler manure, wastewater treatment plant sludge, and greenhouse waste by anaerobic co-digestion. J. Renew. Sustain. Energy 2013, 5. [Google Scholar] [CrossRef]

- Insulating Materials. Available online: https://tirichiamo.it/page/Ristrutturazioni/Isolamento-Termico/Insufflaggio-Intercapedine-Prezzi-Costi-e-Consigli.aspx (accessed on 14 August 2017).

- Italian Standards, UNI EN ISO 13370. Heat Transfer toward the Ground; UNI—Ente Nazionale Italiano di Unificazione: Milan, Italy, 2001. [Google Scholar]

- Beretta Caldaie. Prontuario Tecnico; Hoepli Editore: Lecco, Italy, 2014. [Google Scholar]

- Tedom Biogas Engine. Available online: http://en.tedomengines.com/ (accessed on 10 March 2017).

- Novamont Mater-Bi. Available online: http://www.novamont.com/mater-bi (accessed on 10 March 2017).

- Cavalaglio, G.; Petrozzi, A.; Coccia, V.; D’Antonio, S.; Cotana, S. Mass and energy flows of cardoon oil in a prototype system for seeds milling and vegetable oil treatment and cogeneration. Energy Procedia 2015, 82, 681–685. [Google Scholar]

- Castelli, S.; Negri, M. La Digestione Anaerobica: Processo e Parametri di Controllo. Biomasse ed Energia. Produzione, Gestione e Processi di Trasformazione; Maggioli Editore: Rimini, Italy, 2011; pp. 163–181. [Google Scholar]

- Adani, F.; Schievano, A.; D’Imporzano, G. I fattori che rendono ottimale la razione per il digestore. L'Informatore Agrario 2008, 40, 19–22. [Google Scholar]

- Petrozzi, A.; Cavalaglio, G.; Coccia, V.; Nicolini, A.; Barbanera, M.; Cotana, F. Energy Enhancement of the Residues from the Cardoon Seeds Milling: Preliminary Experimentation in a Small Size Biogas Plant. Energy Procedia 2016, 101, 440–447. [Google Scholar] [CrossRef]

- Ministero dello Sviluppo Economico, Ministero dell’Ambiente. Decreto del 23 Giugno 2016: Incentivazione dell’energia elettrica prodotta da fonti rinnovabili diverse dal fotovoltaico; Gazzetta Ufficiale: Rome, Italy, 2016.

- Bruno, I. La Valutazione Delle Emissioni Evitate; Unità Studi GSE: Rome, Italy, 2013. [Google Scholar]

- Papurello, D.; Soukoulis, C.; Schuhfried, E.; Cappellin, L.; Gasperi, F.; Silvestri, S.; Santarelli, M.; Biasioli, F. Monitoring of volatile compound emissions during dry anaerobic digestion of the Organic Fraction of Municipal Solid Waste by Proton Transfer Reaction Time-of-Flight Mass Spectrometry. Bioresour. Technol. 2012, 126, 254–265. [Google Scholar] [CrossRef] [PubMed]

- Papurello, D.; Tomasi, L.; Silvestri, S.; Santarelli, M. Evaluation of the Wheeler-Jonas parameters for biogas trace compounds removal with activated carbons. Fuel Process. Technol. 2016, 152, 93–101. [Google Scholar] [CrossRef]

| Components and Their Properties | Value |

|---|---|

| Façade|Stone Wool | |

| Thermal conductivity, λ (W/mK) | 0.044 |

| Thickness, s (m) | 0.440 |

| Thermal flow, Φ (W) | 137.90 |

| Basement|Cellular Glass | |

| Thermal conductivity, λ (W/mK) | 0.004 |

| Thickness, s (m) | 0.100 |

| Thermal flow, Φ (W) | 115.40 |

| Floating Gas-Holder|Steel Bell | |

| Thermal conductivity, λ (W/mK) | 0.120 |

| Thickness, s (m) | 0.002 |

| Thermal flow, Φ (W) | 8733.16 |

| Total Thermal Flow, Φtot (W) | 8986.46 |

| Parameter | Value |

|---|---|

| Electric nominal power (kW) | 21 |

| Maximum thermal power (kW) | 46.5 |

| Primary power (kW) | 73.5 |

| Electric yield (%) | 28.6 |

| Thermal yield (%) | 63.2 |

| Global yield (%) | 92.9 |

| Biogas consumption—75% of power (Nm3/h) | 9.1 |

| Component/Work Description | Amount |

|---|---|

| Cogenerator engine | 25,000 € |

| Steel digester | 7000 € |

| Heat exchanger | 4000 € |

| Biomass and digestated matter tanks | 5000 € |

| Piping, pumps, mixing system | 3000 € |

| PLC- automation | 2000 € |

| Roofing, insulation, silo restoration | 10,000 € |

| Total costs | 56,000 € |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manni, M.; Coccia, V.; Cavalaglio, G.; Nicolini, A.; Petrozzi, A. Best Practices for Recovering Rural Abandoned Towers through the Installation of Small-Scale Biogas Plants. Energies 2017, 10, 1224. https://doi.org/10.3390/en10081224

Manni M, Coccia V, Cavalaglio G, Nicolini A, Petrozzi A. Best Practices for Recovering Rural Abandoned Towers through the Installation of Small-Scale Biogas Plants. Energies. 2017; 10(8):1224. https://doi.org/10.3390/en10081224

Chicago/Turabian StyleManni, Mattia, Valentina Coccia, Gianluca Cavalaglio, Andrea Nicolini, and Alessandro Petrozzi. 2017. "Best Practices for Recovering Rural Abandoned Towers through the Installation of Small-Scale Biogas Plants" Energies 10, no. 8: 1224. https://doi.org/10.3390/en10081224