Experimental Research on the Structural Behavior of Fractured Coal under Uniaxial Compression

Abstract

:1. Introduction

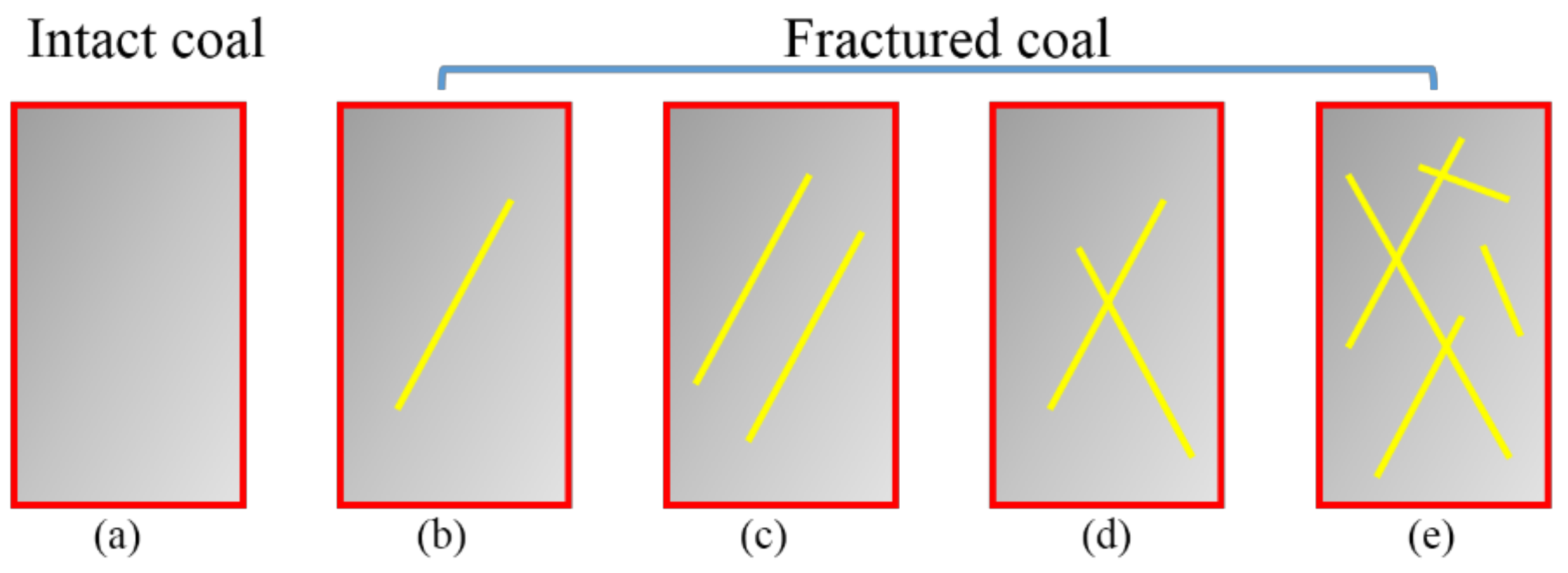

2. Fractured Coal Sample Preparation

2.1. Coal Geology and Sample Classification

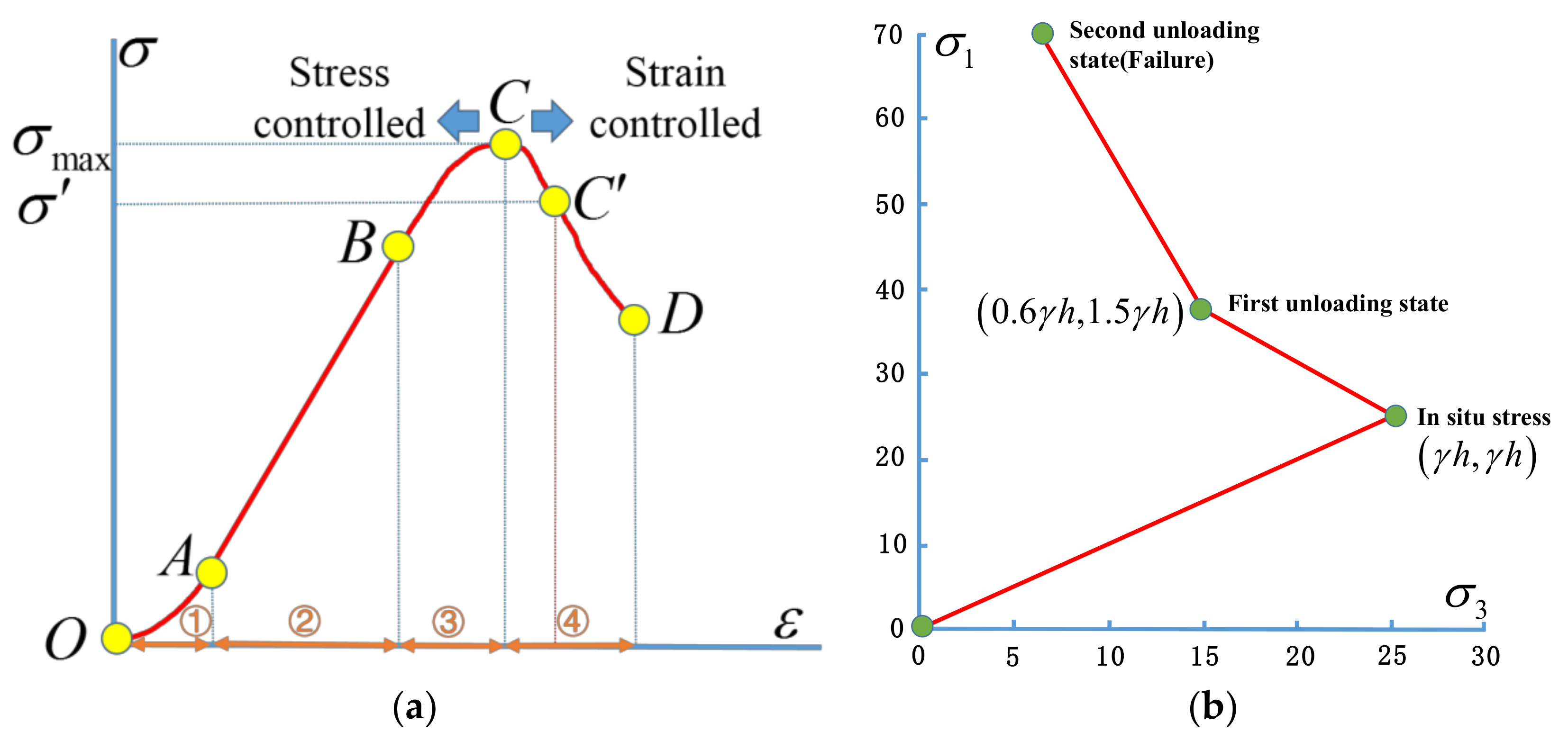

2.2. Sample Preparation under Various Stress Unloading Paths

3. Experimental Results

3.1. Material Behavior of Intact Coal under Uniaxial Compression

3.1.1. Comparison of Physical and Material Parameters

3.1.2. Macro Behavior under Uniaxial Compression

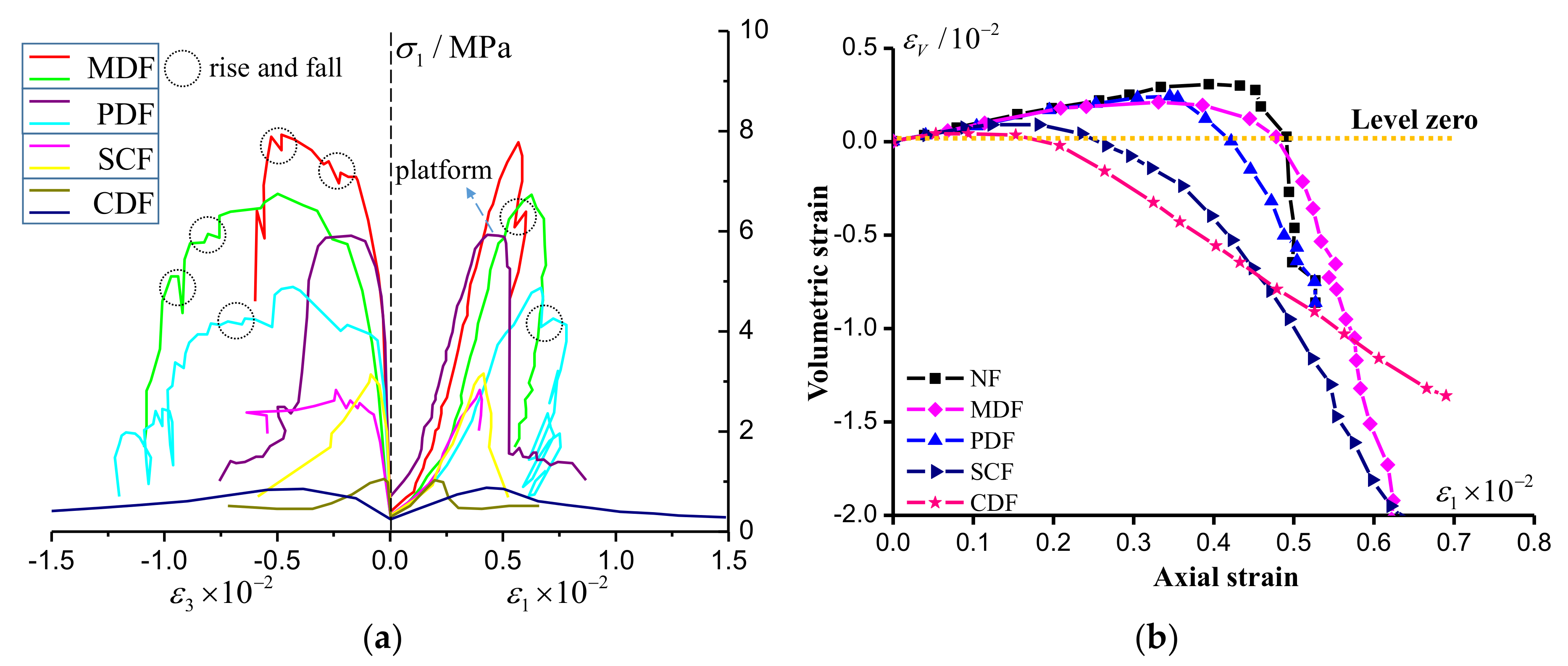

3.2. Structural Behavior of Fractured Coals under Uniaxial Compression

3.2.1. Differences of Structural Deformation

3.2.2. Distribution of Peak Strength

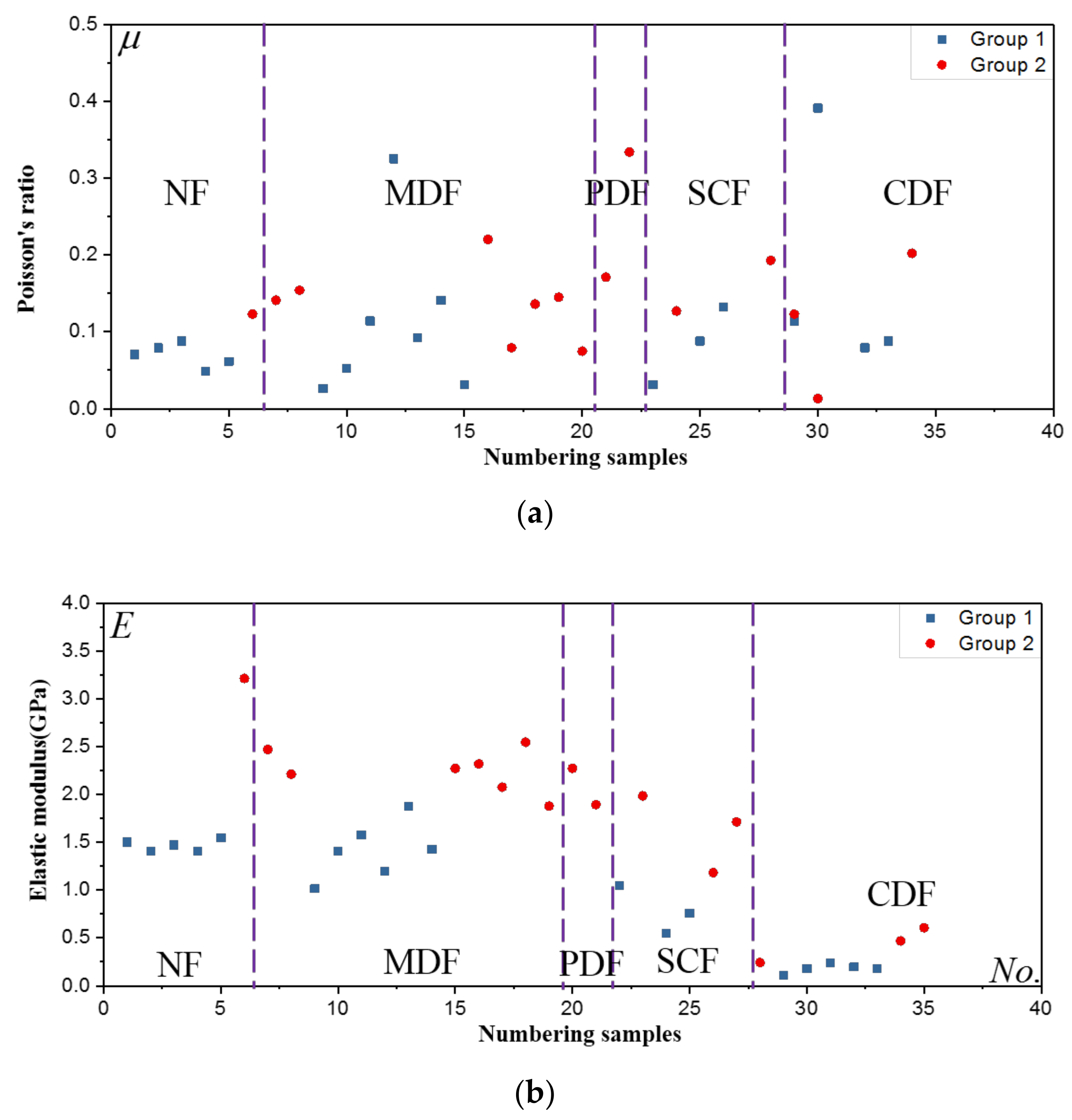

3.2.3. Distribution of Elastic Parameters

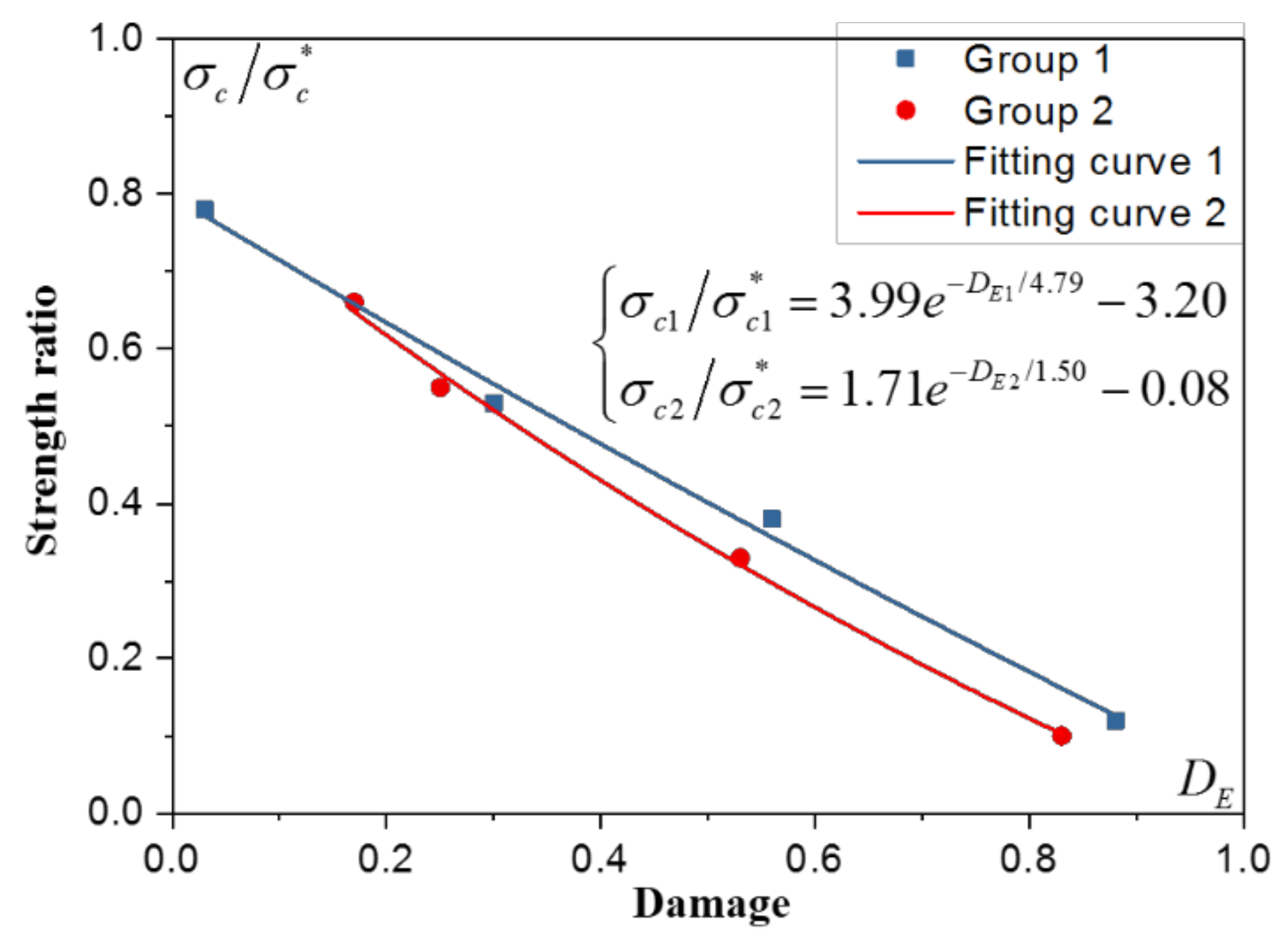

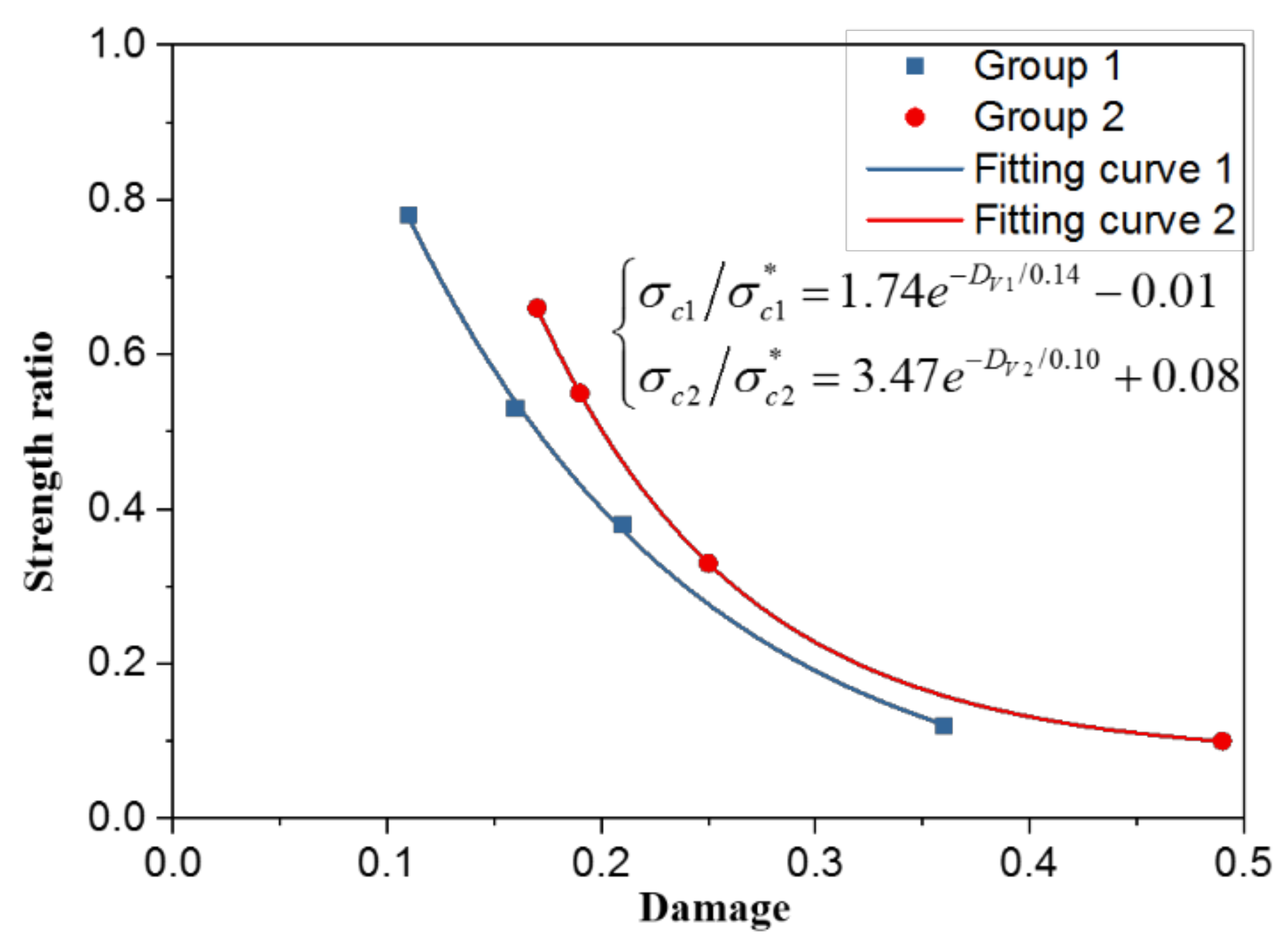

3.3. Relationship between Strength and Physical Parameters of Fractured Coal

3.3.1. Bulk Density Distribution

3.3.2. Longitudinal Wave Velocity

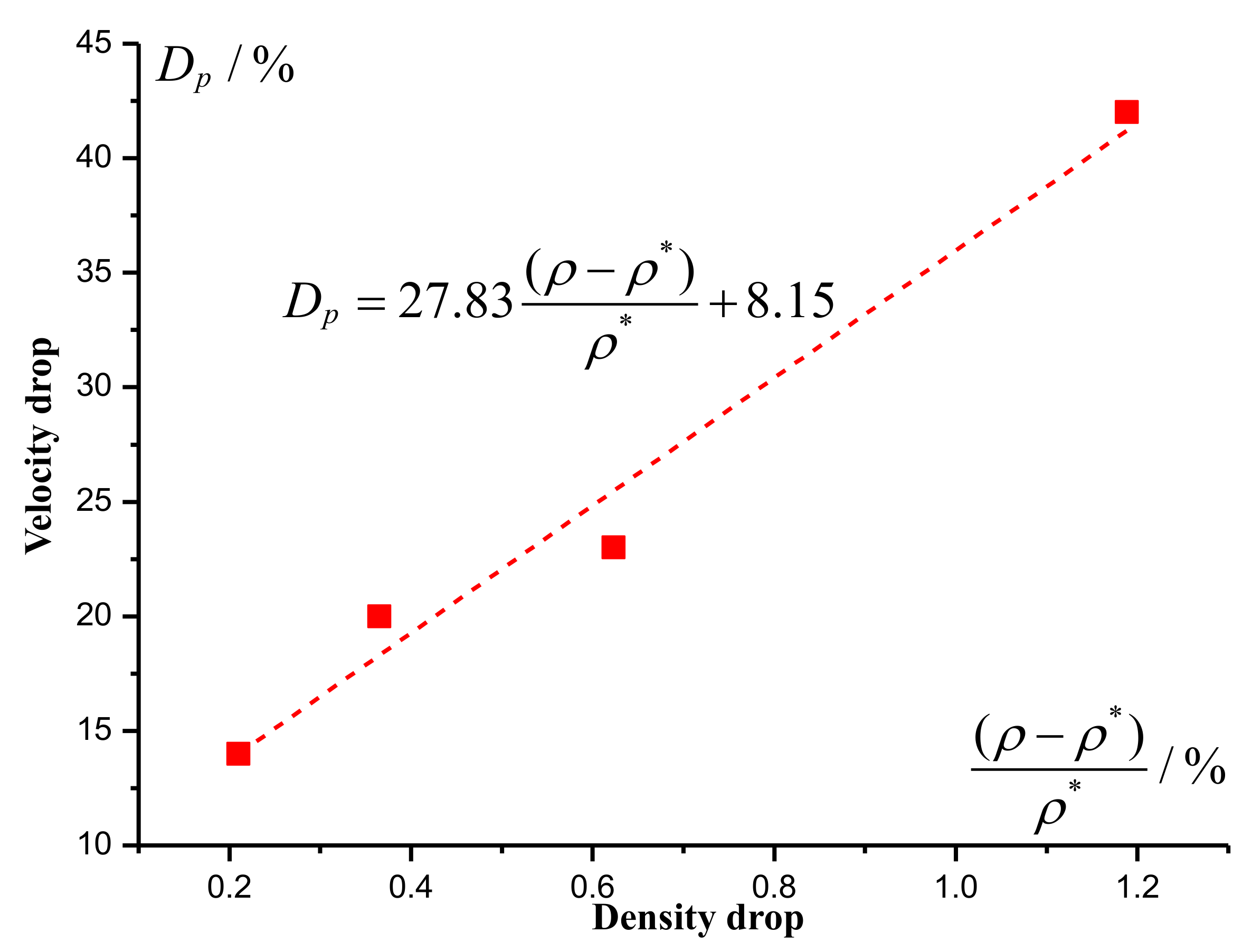

3.3.3. Density Drop and Velocity Drop

4. Discussion on Structural Failure Mechanism

4.1. Structural Failure Characteristics

4.2. Structural Modulus Degradation

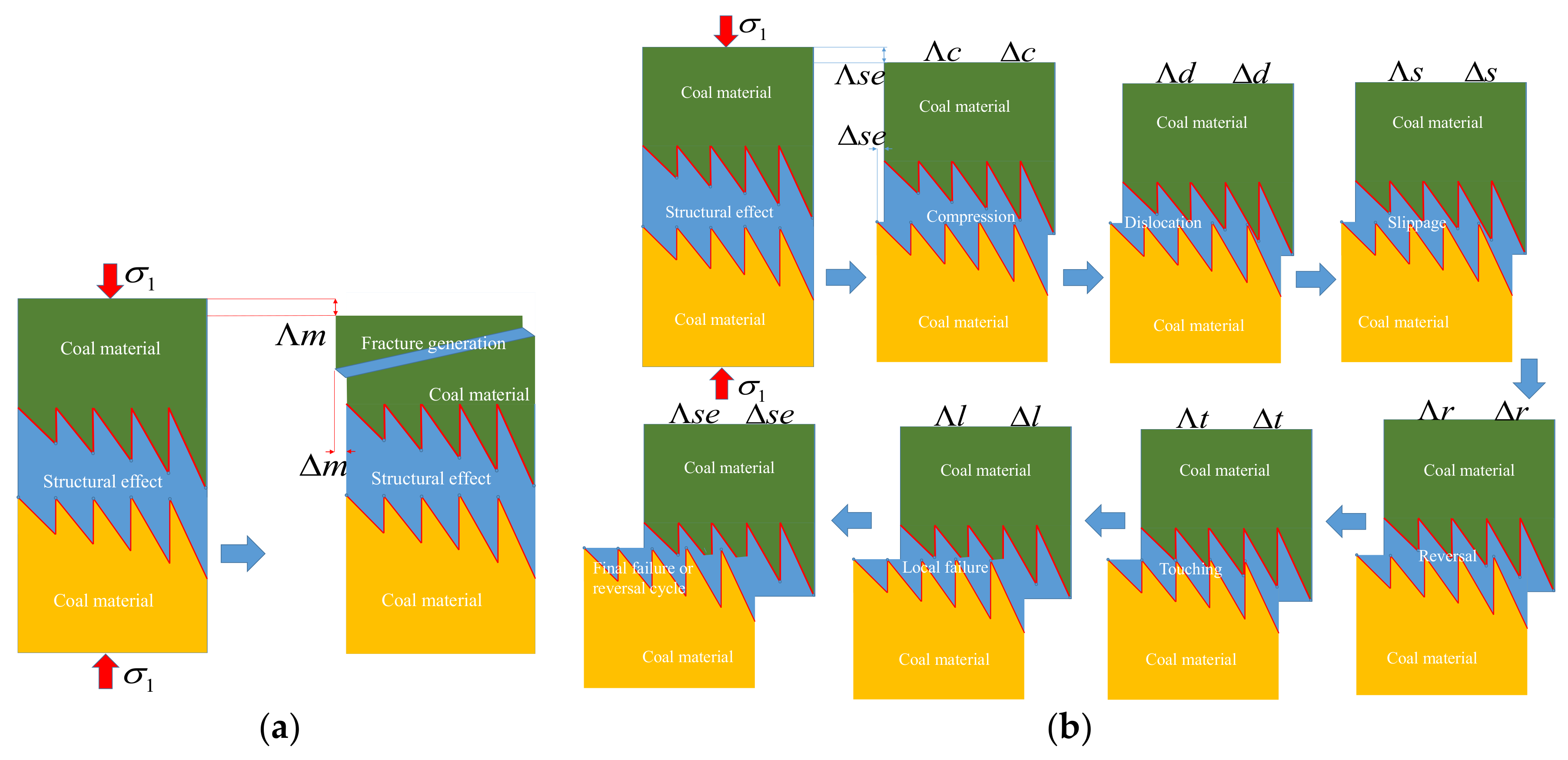

4.3. Mechanisms of the Structural Deformation

4.4. Mechanism on Structural Strength Evolution

5. Conclusions

- (1)

- The structural behavior of fractured coal with the stress drop fluctuation is different from the material behavior. It is a structural rebalance rather than the ductile mechanism that leads to the stress plateau. Describing the complexity of fractures based on the macroscopic damage is still valid.

- (2)

- The backbone fractures significantly impact the strength as verified by different material and structural parameters. Based on the damage of elastic modulus and longitudinal wave velocity, the strength ratio shows an exponential decrease. The application of Poisson’s ratio for fractured coal is not effective due to the discontinuous effect. The greater the density drop, the lower the strength ratio. There is a linear relationship between drops of wave velocity and density.

- (3)

- There is a transition of failure mode from material failure to structural failure, i.e., continuous to discontinuous failure. It is observed that the post-peak unloading is a coupling of the structural unloading and the material unloading. The post-peak unloading includes the elastic strain recovery and resilience strain recovery. The structural damage defined based on the structural modulus can effectively illustrate the evolution of strength.

- (4)

- A new model is proposed to illustrate coupling material and structural effects. The structural deformation includes compression, dislocation, slippage, touching, local failure, and final failure or reversal cycle. Based on the internal friction angle, a new mechanism on structural strength evolution is suggested to improve the understanding of the falling stress cycles effectively.

Author Contributions

Funding

Conflicts of Interest

References

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. Sci. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Dia, A.; Gruau, G.; Olivié-Lauquet, G.; Riou, C.; Molénat, J.; Curmi, P. The distribution of rare earth elements in groundwaters: Assessing the role of source-rock composition, redox changes and colloidal particles. Geochim. Cosmochim. Ac. 2000, 64, 4131–4151. [Google Scholar] [CrossRef]

- Goodman, R.E.; Taylor, R.L.; Brekke, T.L. A model for the mechanics of jointed rock. J. Soil Mech. Found. Div. 1968, 94, 637–665. [Google Scholar]

- Einstein, H.H.; Hirschfeld, R.C. Model studies on mechanics of jointed rock. J. Soil Mech. Found. Div. 1973, 99, 229–248. [Google Scholar]

- Barton, N.; Bandis, S. Effects of block size on the shear behavior of jointed rock. In Proceedings of the 23rd US Symposium on Rock Mechanics (USRMS), Berkeley, CA, USA, 25–27 August 1982. [Google Scholar]

- Oda, M. An equivalent continuum model for coupled stress and fluid flow analysis in jointed rock masses. Water Resur. Res. 1986, 22, 1845–1856. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. The geomechanics classification in rock engineering applications. In Proceedings of the 4th International Society for Rock Mechanics (ISRM) Congress, Montreux, Switzerland, 2–8 September 1979. [Google Scholar]

- Bjureland, W.; Spross, J.; Johansson, F.; Prästings, A.; Larsson, S. Challenges in Applying Fixed Partial Factors to Rock Engineering Design. Geo-Risk 2017, 384–393. [Google Scholar] [CrossRef]

- Price, N.J. Fault and Joint Development: In Brittle and Semi-Brittle Rock; Elsevier: London, UK, 2016; pp. 73–79. [Google Scholar]

- Hosseini, N.; Oraee, K.; Shahriar, K.; Goshtasbi, K. Studying the stress redistribution around the longwall mining panel using passive seismic velocity tomography and geostatistical estimation. Arab. J. Geosci. 2013, 6, 1407–1416. [Google Scholar] [CrossRef]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- Mughieda, O.; Omar, M.T. Stress analysis for rock mass failure with offset joints. Geotech. Geol. Eng. 2008, 26, 543–552. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Bhattacharjee, R.; Tiwari, S.; Kushwaha, A.; Roy, L.B. Evaluation of stability of underground workings for exploitation of an inclined coal seam by the ubiquitous joint model. Int. J. Rock Mech. Min. Sci. 2017, 93, 101–114. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Bhattacherjee, R.; Tewari, S.; Kushwaha, A. Effect of Fault on the Stability of Workings Underground Extraction of Coal. NexGen Technologies for Mining and Fuel Industries (Volume I and II); CSIR-Central Institute of Mining and Fuel Research: Dhanb, India, 2017; pp. 155–165. [Google Scholar]

- Medhurst, T.P.; Brown, E.T. A study of the mechanical behaviour of coal for pillar design. Int. J. Rock Mech. Min. Sci. 1998, 35, 1087–1105. [Google Scholar] [CrossRef]

- Scholtès, L.; Donzé, F.V.; Khanal, M. Scale effects on strength of geomaterials, case study: Coal. J. Mech. Phys. Solids 2011, 59, 1131–1146. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Sharrock, G.; Hebblewhite, B.K. Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput. Geotech. 2013, 49, 206–225. [Google Scholar] [CrossRef]

- Zdravkov, A.; Bechtel, A.; Sachsenhofer, R.F.; Kortenski, J. Palaeoenvironmental implications of coal formation in Dobrudzha Basin, Bulgaria: Insights from organic petrological and geochemical properties. Int. J. Coal. Geol. 2017, 180, 1–17. [Google Scholar] [CrossRef]

- Bieniawski, Z.T.; Bernede, M.J. Suggested methods for determining the uniaxial compressive strength and deformability of rock materials: Part 1. Suggested method for determining deformability of rock materials in uniaxial compression. Int. J. Rock Mech. Min. Sci. Geo. Abs. 1979, 16, 138–140. [Google Scholar] [CrossRef]

- Tsiambaos, G.; Sabatakakis, N. Considerations on strength of intact sedimentary rocks. Eng. Geol. 2004, 72, 261–273. [Google Scholar] [CrossRef]

- Yu, J.; Tahmasebi, A.; Han, Y.; Yin, F.; Li, X. A review on water in low rank coals: The existence, interaction with coal structure and effects on coal utilization. Fuel. Process. Technol. 2013, 106, 9–20. [Google Scholar] [CrossRef]

- Shi, B.; Zhou, F. Impact of heat and mass transfer during the transport of nitrogen in coal porous media on coal mine fires. Sci. World J. 2014. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Armstrong, R.T.; Ramandi, H.L.; Mostaghimi, P. Coal cleat reconstruction using micro-computed tomography imaging. Fuel 2016, 181, 286–299. [Google Scholar] [CrossRef]

- Schiessel, H.; Metzler, R.; Blumen, A.; Nonnenmacher, T.F. Generalized viscoelastic models: Their fractional equations with solutions. J. Phys. A Math. Gen. 1995, 28, 6567–6584. [Google Scholar] [CrossRef]

- Qin, S.J.; Badgwell, T.A. An overview of nonlinear model predictive control applications. Nonlinear Model Predict. Control 2000, 26, 369–392. [Google Scholar]

- Cai, Y.; Liu, D.; Mathews, J.P.; Pan, Z.; Elsworth, D.; Yao, Y.; Guo, X. Permeability evolution in fractured coal—Combining triaxial confinement with X-ray computed tomography, acoustic emission and ultrasonic techniques. Int. J. Coal. Geol. 2014, 122, 91–104. [Google Scholar] [CrossRef]

- Krajcinovic, D.; Fonseka, G.U. The continuous damage theory of brittle materials, part 1: General theory. Int. J. Appl. Mech. 1981, 48, 809–815. [Google Scholar] [CrossRef]

- Krajcinovic, D.; Silva, M.A.G. Statistical aspects of the continuous damage theory. Int. J. Solids. Struct. 1982, 18, 551–562. [Google Scholar] [CrossRef]

- Den Outer, A.; Kaashoek, J.F.; Hack, H.R. Difficulties with using continuous fractal theory for discontinuity surfaces. Int. J. Rock Mech. Min. Sci. Geo. Abs. 1995, 32, 3. [Google Scholar] [CrossRef]

- Zoback, M.D.; Hickman, S. In situ study of the physical mechanisms controlling induced seismicity at Monticello Reservoir, South Carolina. J. Geophys. Res. 1982, 87, 6959–6974. [Google Scholar] [CrossRef] [Green Version]

- Fardin, N.; Feng, Q.; Stephansson, O. Application of a new in situ 3D laser scanner to study the scale effect on the rock joint surface roughness. Int. J. Rock Mech. Min. Sci. 2004, 2, 329–335. [Google Scholar] [CrossRef]

- Yang, X.X.; Jing, H.W.; Tang, C.A.; Yang, S.Q. Effect of parallel joint interaction on mechanical behavior of jointed rock mass models. Int. J. Rock Mech. Min. Sci. 2017, 92, 40–53. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, R.; Xie, H.; Gao, M.; Xie, J. Mining-induced coal permeability change under different mining layouts. Rock. Mech. Rock. Eng. 2016, 49, 3753–3768. [Google Scholar] [CrossRef]

- Wawersik, W.R.; Fairhurst, C. A study of brittle rock fracture in laboratory compression experiments. Int. J. Rock Mech. Min. Sci. Geo. Abs. 1970, 7, 561–575. [Google Scholar] [CrossRef]

- Lemaitre, J. How to use damage mechanics. Nucl. Eng. Des. 1984, 80, 233–245. [Google Scholar] [CrossRef]

- Corbin, S.F.; Wilkinson, D.S. Influence of matrix strength and damage accumulation on the mechanical response of a particulate metal matrix composite. Acta Metall. Mater. 1994, 42, 1329–1335. [Google Scholar] [CrossRef]

- Smith, P.A.; Wood, J.R. Poisson’s ratio as a damage parameter in the static tensile loading of simple crossply laminates. Compos. Sci. Technol. 1990, 38, 85–93. [Google Scholar] [CrossRef]

- Gercek, H. Poisson’s ratio values for rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 1–13. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Engineering classification of jointed rock masses. Civ. Eng. South Afr. 1973, 15, 335–343. [Google Scholar]

- Lawn, B.R.; Evans, A.G.; Marshall, D.B. Elastic/plastic indentation damage in ceramics: The median/radial crack system. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Choi, H.Y.; Wu, H.Y.T.; Chang, F.K. A new approach toward understanding damage mechanisms and mechanics of laminated composites due to low-velocity impact: Part II—Analysis. J. Compos. Mater. 1991, 25, 1012–1038. [Google Scholar] [CrossRef]

- Kozłowski, M.; Bedon, C.; Honfi, D. Numerical Analysis and 1D/2D Sensitivity Study for Monolithic and Laminated Structural Glass Elements under Thermal Exposure. Materials 2018, 11, 1447. [Google Scholar] [CrossRef] [PubMed]

| Samples | Peak Strength | Poisson’s Ratio | Elastic Modulus | Density | Longitudinal Wave Velocity | |||

|---|---|---|---|---|---|---|---|---|

| σc/MPa | µ50 | µ100 | E50/GPa | E100/GPa | ρ/g⋅cm−3 | Vp/m⋅s−1 | ||

| Group 1 Weakened Coal | 1 | 5.96 | 0.07 | 0.44 | 1.5 | 1.28 | 1.33 | - |

| 2 | 5.18 | 0.08 | 0.31 | 1.39 | 1.16 | 1.36 | 836.03 | |

| 3 | 6.71 | 0.09 | 0.78 | 1.48 | 1.18 | 1.32 | 694.94 | |

| 4 | 6.14 | 0.05 | 0.49 | 1.42 | 0.8 | 1.36 | - | |

| 5 | 5.97 | 0.06 | 0.17 | 1.54 | 1.31 | 1.39 | 916.7 | |

| Means | 5.99 | 0.07 | 0.44 | 1.47 | 1.15 | 1.35 | 815.89 | |

| SD | 0.49 | 0.02 | 0.20 | 0.05 | 0.18 | 0.02 | - | |

| Group 2 Strong Coal | 1 | 18.8 | 0.12 | 0.42 | 3.2 | 2.14 | 1.54 | 1652.8 |

| 2 | 15.5 | 0.14 | 1.53 | 2.46 | 1.99 | 1.52 | 1548 | |

| 3 | 13.16 | 0.15 | 1.28 | 2.2 | 1.49 | 1.46 | - | |

| Means | 15.82 | 0.14 | 1.08 | 2.62 | 1.87 | 1.51 | 1600.4 | |

| SD | 2.31 | 0.02 | 0.48 | 0.42 | 0.28 | 0.03 | - | |

| Times(II/I) | 2.64 | 2.0 | 2.45 | 1.78 | 1.63 | 1.12 | 1.96 | |

| Fracture Pttern | Mean Strength | Strength Ratio | |||

|---|---|---|---|---|---|

| Group 1 | Group 2 | Group 1 | Group 2 | Mean | |

| NF | 5.99 | 15.82 | 1.00 | 1.00 | 1.00 |

| MDF | 4.67 | 10.42 | 0.78 | 0.66 | 0.72 |

| 3.18 | 8.72 | 0.53 | 0.55 | 0.54 | |

| SCF | 2.28 | 5.29 | 0.38 | 0.33 | 0.36 |

| CDF | 0.74 | 1.62 | 0.12 | 0.10 | 0.11 |

| Fracture Pattern | Elastic Modulus | Modulus Ratio | |||

|---|---|---|---|---|---|

| Group 1 | Group 2 | Group 1 | Group 2 | Mean | |

| NF | 1.47 | 2.62 | 1.00 | 1.00 | 1.00 |

| MDF | 1.42 | 2.17 | 0.97 | 0.83 | 0.90 |

| 1.03 | 1.97 | 0.70 | 0.75 | 0.73 | |

| SCF | 0.65 | 1.23 | 0.44 | 0.47 | 0.46 |

| CDF | 0.18 | 0.44 | 0.12 | 0.17 | 0.15 |

| Fracture Pattern | Density Drop | Velocity Ratio | ||||

|---|---|---|---|---|---|---|

| Group 1 | Group 2 | Mean | Group 1 | Group 2 | Mean | |

| MDF | 0.33 | 0.09 | 0.21 | 0.89 | 0.83 | 0.86 |

| 0.47 | 0.26 | 0.365 | 0.84 | 0.81 | 0.80 | |

| SCF | 0.647 | 0.599 | 0.623 | 0.79 | 0.75 | 0.77 |

| CDF | 1.829 | 1.939 | 1.884 | 0.64 | 0.51 | 0.58 |

| Fracture Pattern | Compressive Strength | Failure Conversion | ||

|---|---|---|---|---|

| Trend | Failure Mechanism | Structural Failure | ||

| NF | 1.00 |  | Tension and shear failures |  |

| MDF | 0.72 | Tension material failure; Slippage structural failure | ||

| 0.54 | Material and structural failures co-influence | |||

| SCF | 0.36 | Tension material failure, slippage, tension structural failure | ||

| CDF | 0.11 | Slippage, expansion structural failure, rarely in material failure | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, D.; Zhou, H.; Liu, J.; Zhou, J.; Liu, Y.; Zhao, Y.; Zhang, L. Experimental Research on the Structural Behavior of Fractured Coal under Uniaxial Compression. Energies 2018, 11, 2538. https://doi.org/10.3390/en11102538

Xue D, Zhou H, Liu J, Zhou J, Liu Y, Zhao Y, Zhang L. Experimental Research on the Structural Behavior of Fractured Coal under Uniaxial Compression. Energies. 2018; 11(10):2538. https://doi.org/10.3390/en11102538

Chicago/Turabian StyleXue, Dongjie, Hongwei Zhou, Jianfeng Liu, Jie Zhou, Yintong Liu, Yongwei Zhao, and Liao Zhang. 2018. "Experimental Research on the Structural Behavior of Fractured Coal under Uniaxial Compression" Energies 11, no. 10: 2538. https://doi.org/10.3390/en11102538

APA StyleXue, D., Zhou, H., Liu, J., Zhou, J., Liu, Y., Zhao, Y., & Zhang, L. (2018). Experimental Research on the Structural Behavior of Fractured Coal under Uniaxial Compression. Energies, 11(10), 2538. https://doi.org/10.3390/en11102538