Improved Boiler-Turbine Coordinated Control of CHP Units with Heat Accumulators by Introducing Heat Source Regulation

Abstract

:1. Introduction

2. Model Description

2.1. Plant Description

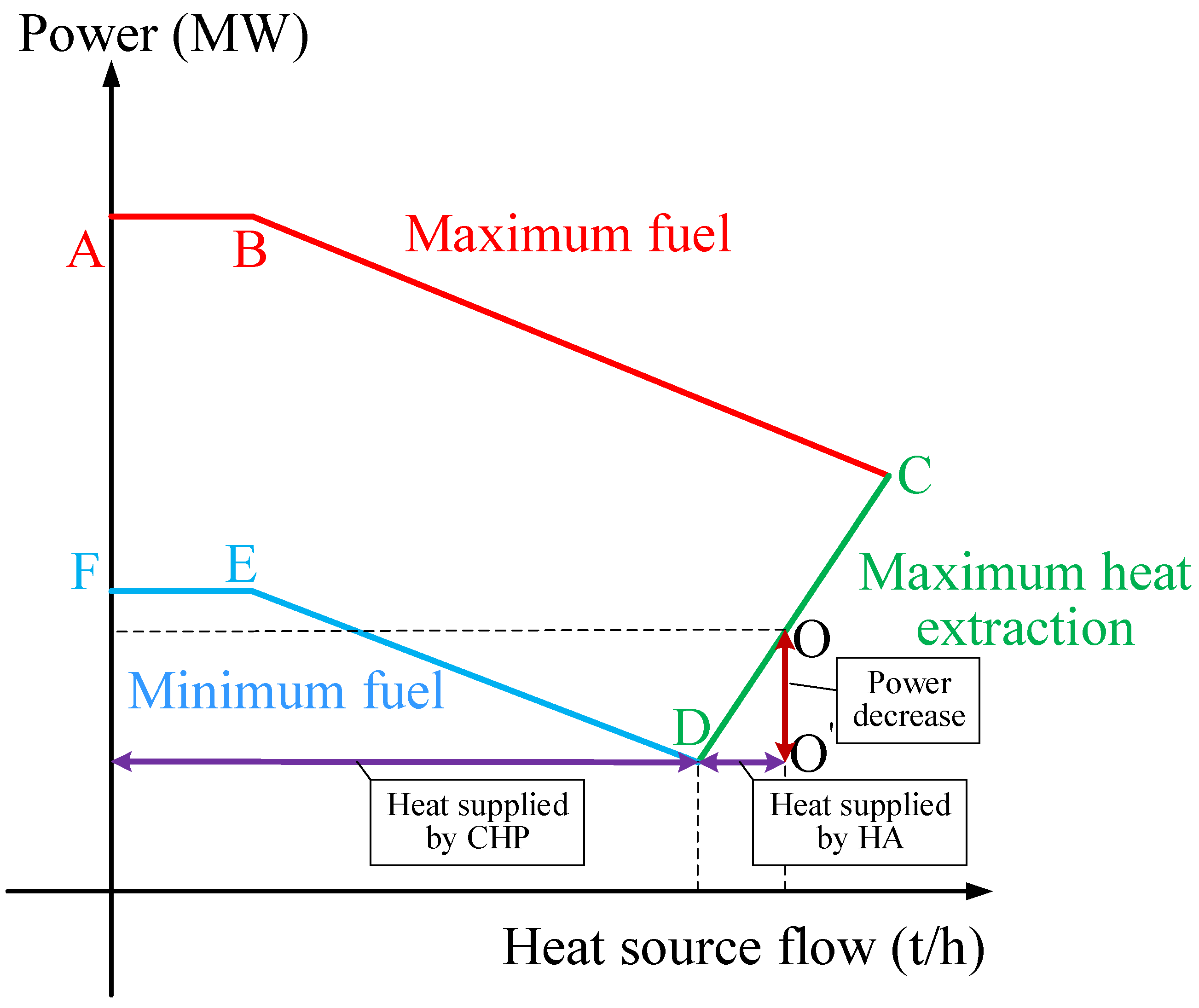

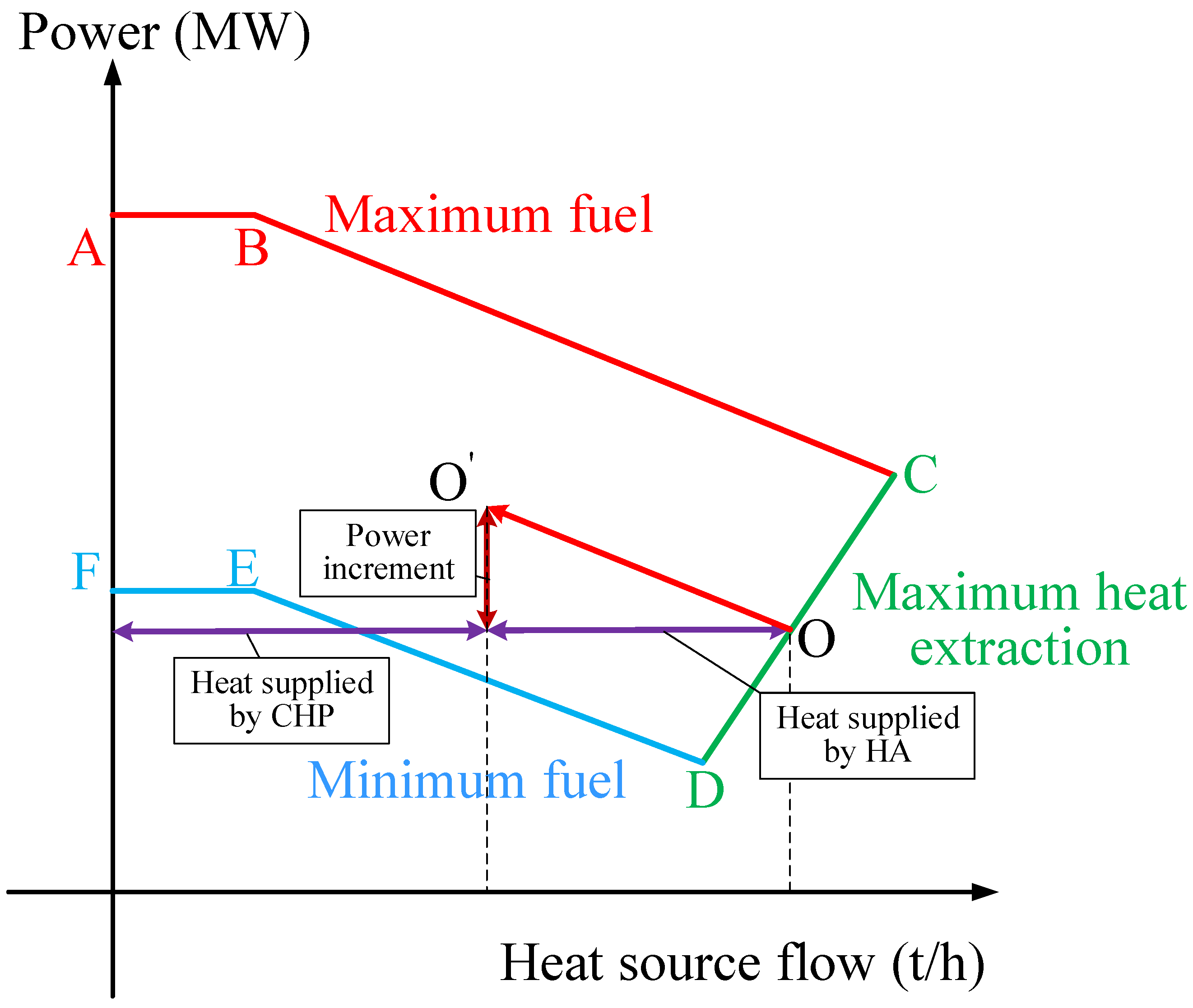

2.2. Heat-Power Conversion Model

2.3. Compensation Characteristics of HA

3. Optimized Control Strategy Design

- (1)

- Heat source extraction regulation should play a major role in the initial control period, and finally heat source extraction flow should recover to its former value.

- (2)

- Fuel flow should follow the power demand and support the total power change at the end of control.

- (3)

- The set point of HA hot water flow should be given so as to control HA.

4. Simulations and Analysis

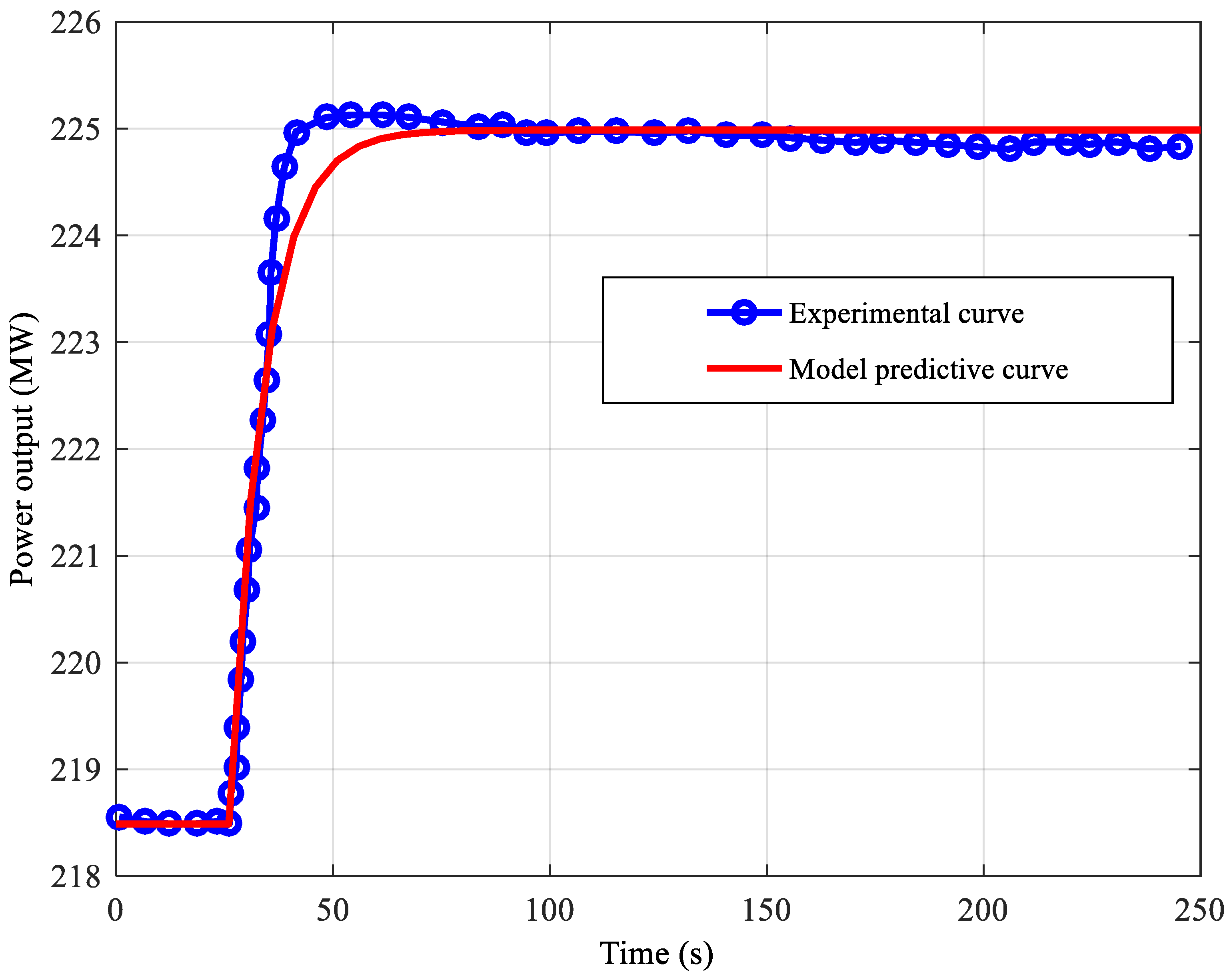

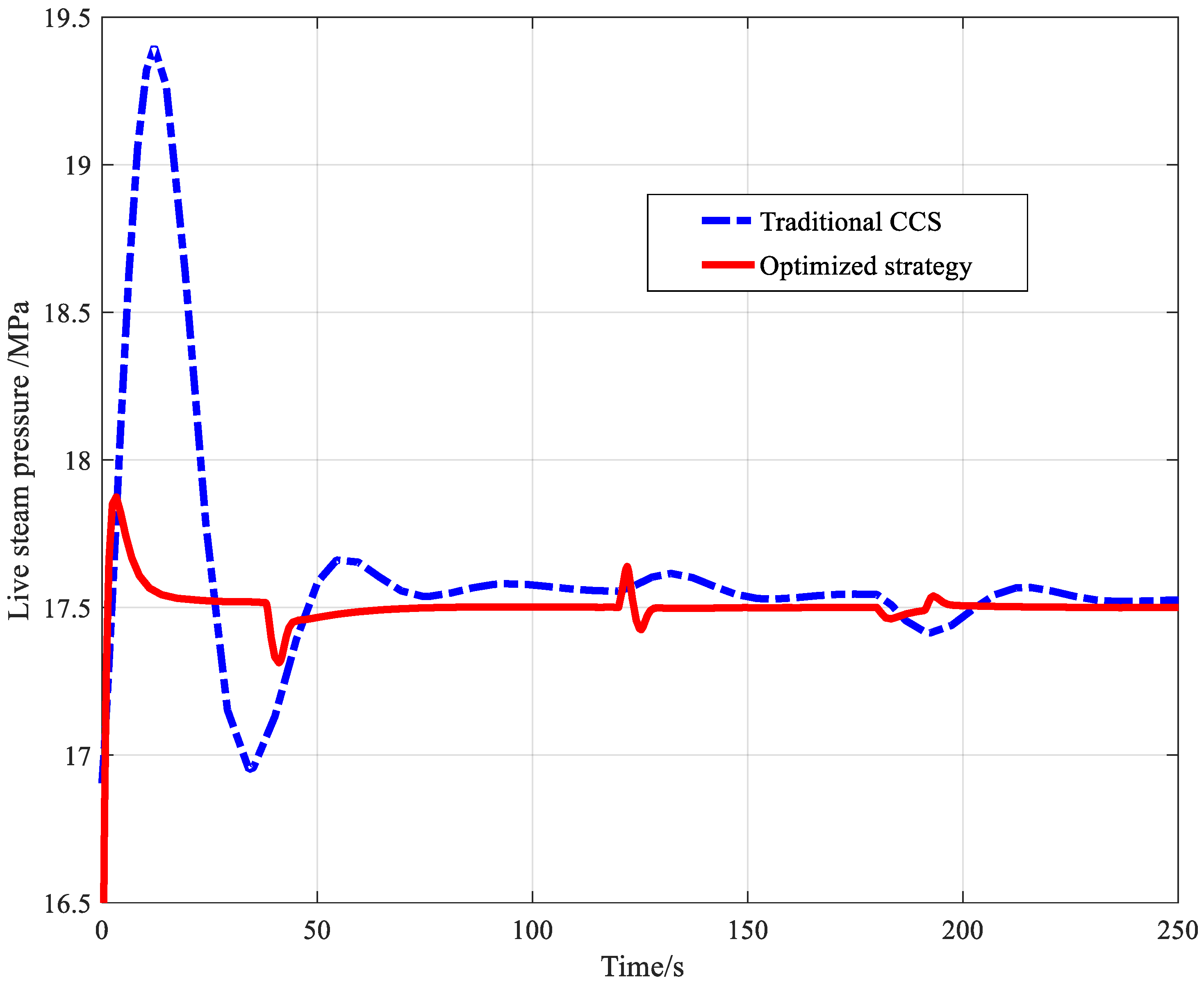

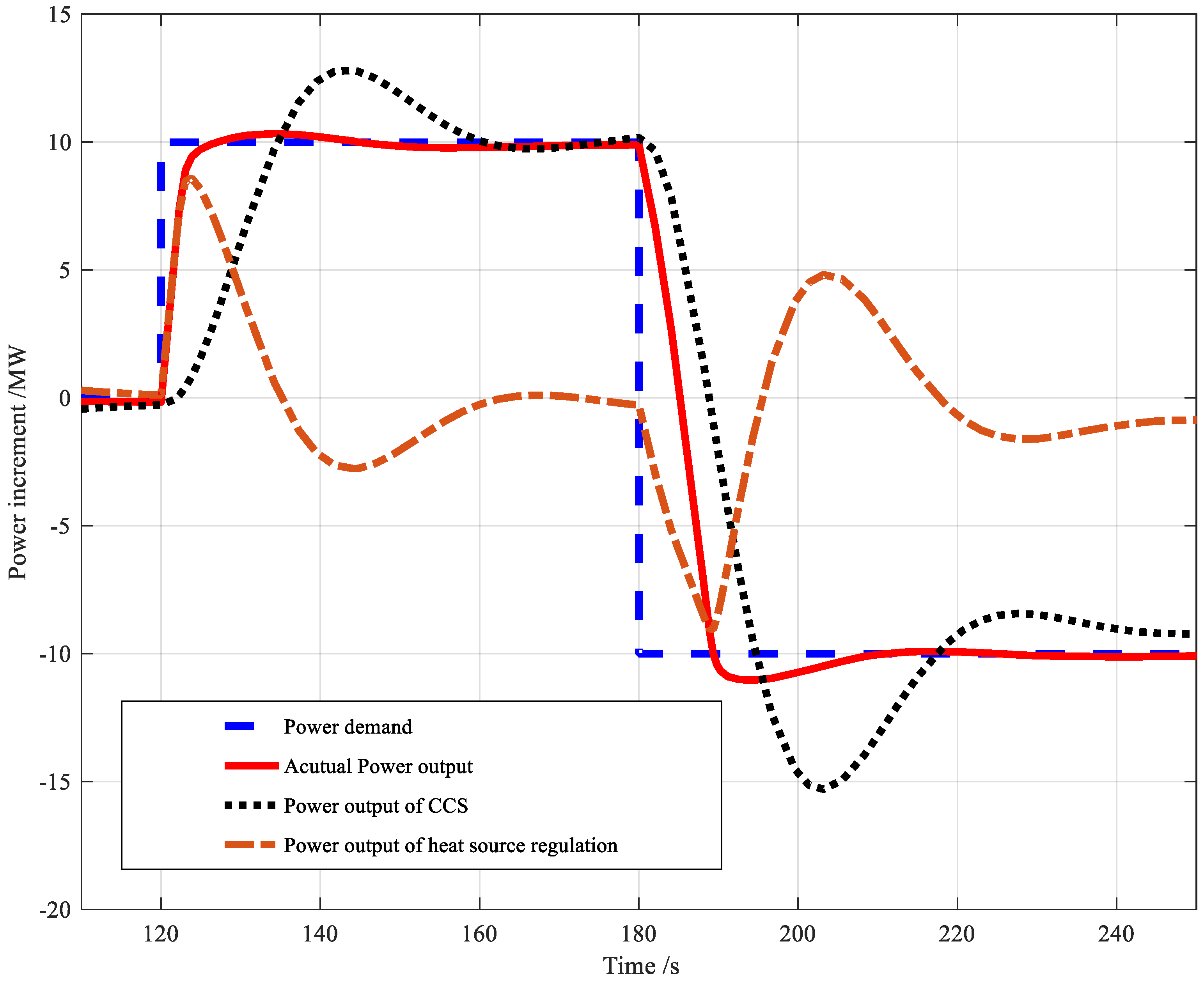

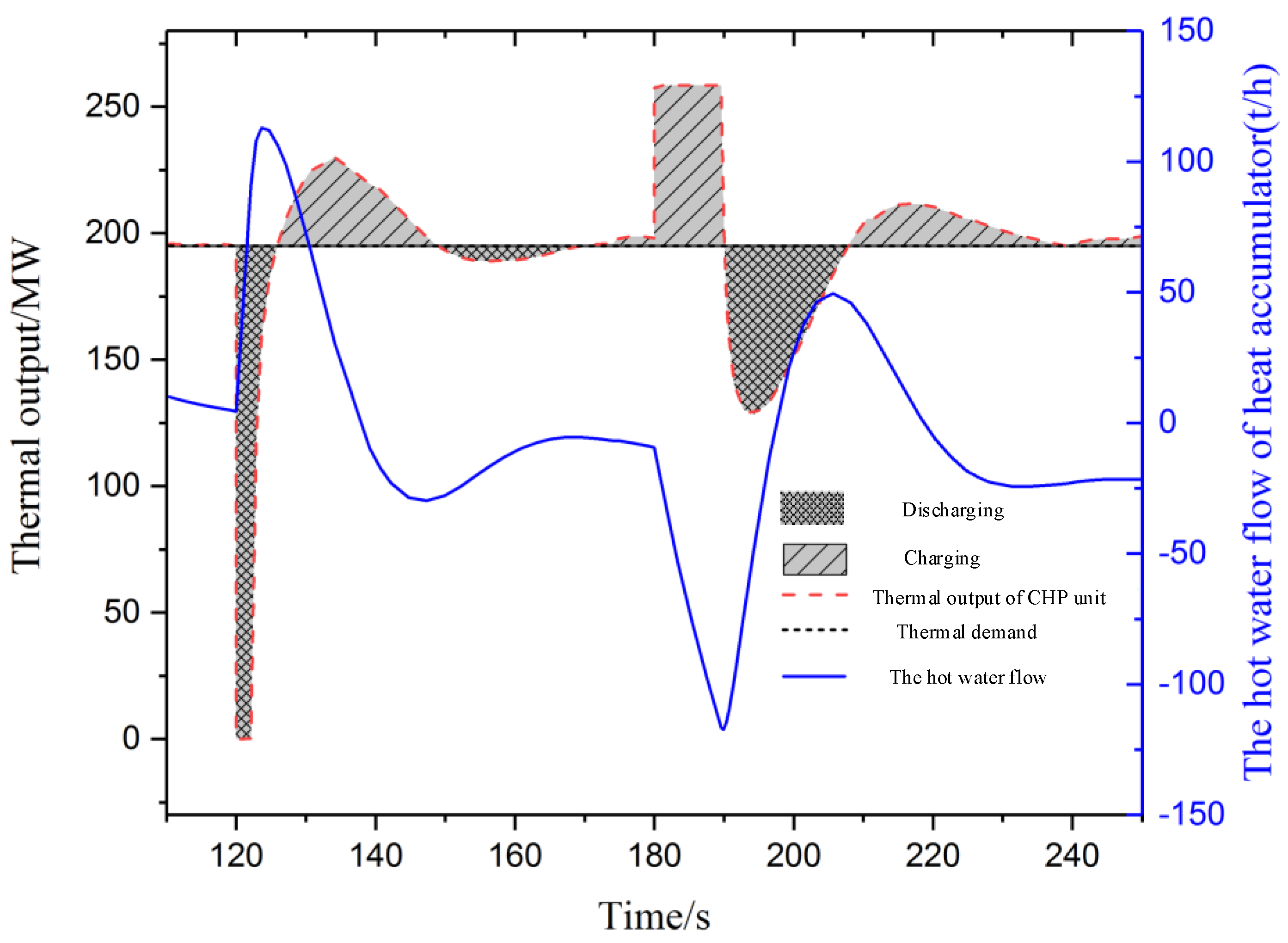

4.1. Power Step Test

4.2. Power Ramp Test

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| P | Active power |

| K | Gain coefficient |

| T | Time constant |

| mfw | Feed water mass flow |

| A | System characteristic matrix |

| h0 | Live steam enthalpy |

| σ | Reheater enthalpy rise |

| hc | Exhausted steam enthalpy |

| mHA | Water mass flow of HA |

| μHA | Valve opening of HA |

| pt | Live steam pressure |

| G(s) | Transfer function |

| μB | Boiler fuel flow |

| IAE | Integrated absolute error |

| K1 | Regulating rate factor |

| K3 | Responding rate |

| mh | Heat source mass flow |

| τ | Column vector of feed water enthalpy rise |

| m | Column vector of extraction steam flow |

| Ah | Characteristic column vector of heat source extraction |

| hh,w | Drainage water enthalpy from heating station |

| hw,i | Outlet water enthalpy of the ith preheater |

| τi | Feed water enthalpy rise of the ith preheater |

| mt | Mass flow of extraction steam for feed water pump turbine |

| Cp | Specific heat of circulating water |

| Tout | Outlet water temperature of heating station |

| Tin | Inlet water temperature of heating station |

| mcir | Mass flow of circulating water in heat network |

| μT | Live steam valve opening |

| ITAE | Integrated time absolute error |

| K2 | Regulating AC-curacy factor |

| KP | Overall index |

References

- Jovanovic, N.; García-González, J.; Cerisola, S.; Barquin, J. Impact of risk aversion on the operation of hydroelectric reservoirs in the presence of renewable energy sources. Energies 2018, 11, 1389. [Google Scholar] [CrossRef]

- Rikos, E.; Caerts, C.; Cabiati, M.; Syed, M.; Burt, G. Adaptive fuzzy control for power-frequency characteristic regulation in high-res power systems. Energies 2017, 10, 982. [Google Scholar] [CrossRef]

- Waite, M.; Modi, V. Modeling wind power curtailment with increased capacity in a regional electricity grid supplying a dense urban demand. Appl. Energy 2016, 183, 299–317. [Google Scholar] [CrossRef] [Green Version]

- Dong, C.; Qi, Y.; Dong, W.; Lu, X.; Liu, T.; Qian, S. Decomposing driving factors for wind curtailment under economic new normal in China. Appl. Energy 2018, 217, 178–188. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A.; Mirandola, A. Dynamic behaviour analysis of a three pressure level heat recovery steam generator during transient operation. Energy 2015, 90, 1595–1605. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Liu, M.; Chong, D.; Yan, J. Improving operational flexibility by regulating extraction steam of high-pressure heaters on a 660 MW supercritical coal-fired power plant: A dynamic simulation. Appl. Energy 2018, 212, 1295–1309. [Google Scholar] [CrossRef]

- Tian, Z.; Yuan, J.; Xu, L.; Zhang, X.; Wang, J. Model-based adaptive sliding mode control of the subcritical boiler-turbine system with uncertainties. ISA Trans. 2018, 79, 161–171. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Li, D.; Lee, K.Y.; Xue, Y. Control-oriented modeling and analysis of direct energy balance in coal-fired boiler-turbine unit. Control Eng. Pract. 2016, 55, 38–55. [Google Scholar] [CrossRef]

- Sondhi, S.; Hote, Y.V. Fractional order PID controller for load frequency control. Energy Convers. Manag. 2014, 85, 343–353. [Google Scholar] [CrossRef]

- Yu, D.; Xu, J. Nonlinear coordinated control of drum boiler power unit based on feedback linearization. IEEE Trans. Energy Convers. 2005, 20, 204–210. [Google Scholar] [CrossRef]

- Moradi, H.; Bakhtiari-Nejad, F.; Saffar-Avval, M. Robust control of an industrial boiler system; a comparison between two approaches: Sliding mode control & technique. Energy Convers. Manag. 2009, 50, 1401–1410. [Google Scholar] [CrossRef]

- Yu, T.; Chan, K.W.; Tong, J.P.; Zhou, B.; Li, D.H. Coordinated robust nonlinear boiler-turbine-generator control systems via approximate dynamic feedback linearization. J. Process. Control 2010, 20, 365–374. [Google Scholar] [CrossRef]

- Liu, X.; Cui, J. Economic model predictive control of boiler-turbine system. J. Process. Control 2018, 66, 59–67. [Google Scholar] [CrossRef]

- Kong, X.; Liu, X.; Lee, K.Y. Nonlinear multivariable hierarchical model predictive control for boiler-turbine system. Energy 2015, 93, 309–322. [Google Scholar] [CrossRef]

- Wu, X.; Shen, J.; Li, Y.; Lee, K.Y. Data-driven modeling and predictive control for boiler-turbine unit using fuzzy clustering and subspace methods. ISA Trans. 2014, 53, 699–708. [Google Scholar] [CrossRef] [PubMed]

- Lausterer, G.K. Improved maneuverability of power plants for better grid stability. Control Eng. Pract. 1998, 6, 1549–1557. [Google Scholar] [CrossRef]

- Hu, Y.; Zeng, D.L.; Liu, J.Z.; Zhao, Z.; Li, Y.Z. Dynamic model for controller design of condensate throttling systems. ISA Trans. 2015, 58, 622–628. [Google Scholar] [CrossRef] [PubMed]

- Umezawa, S. Output increase of conventional thermal power plants by the method of feed water bypassing feed water heaters. Mech. Engi. J. 2014, 1, TEP0043. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Shahidehpour, M.; Wang, J.; Zhang, B. Combined heat and power dispatch considering pipeline energy storage of district heating network. IEEE Trans. Sustain. Energy 2016. [Google Scholar] [CrossRef]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Liu, C.; Sun, R.; Wang, W.; Li, H. Increasing the flexibility of combined heat and power for wind power integration in china: Modeling and implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, Z.; Zhao, J.; Wang, J. Integrated heat and power dispatch truly utilizing thermal inertia of district heating network for wind power integration. Appl. Energy 2018, 211, 865–874. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Lv, Q.; Li, W. Combined heat and power dispatch considering heat storage of both buildings and pipelines in district heating system for wind power integration. Energies 2017, 10, 893. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, K.; Long, H.; Gao, J.; Yan, X.; Kato, T.; Suzuoki, Y. Integrated electricity and heating demand-side management for wind power integration in China. Energy 2014, 78, 235–246. [Google Scholar] [CrossRef]

- Gu, W.; Wang, J.; Lu, S.; Luo, Z.; Wu, C. Optimal operation for integrated energy system considering thermal inertia of district heating network and buildings. Appl Energy 2017, 199, 234–246. [Google Scholar] [CrossRef]

- Korpela, T.; Kaivosoja, J.; Majanne, Y.; Laakkonen, L.; Nurmoranta, M.; Vilkko, M. Utilization of district heating networks to provide flexibility in CHP production. Energy Procedia 2017, 116, 310–319. [Google Scholar] [CrossRef]

- Streckienė, G.; Martinaitis, V.; Andersen, A.N.; Katz, J. Feasibility of CHP-plants with thermal stores in the German spot market. Appl. Energy 2009, 86, 2308–2316. [Google Scholar] [CrossRef]

- Željko, B.; Kopjar, D. Improvement of the cogeneration plant economy by using heat accumulator. Energy 2006, 31, 2285–2292. [Google Scholar] [CrossRef]

- Zhao, H.; Holst, J.; Arvastson, L. Optimal operation of coproduction with storage. Energy 1998, 23, 859–866. [Google Scholar] [CrossRef]

- Nuytten, T.; Claessens, B.; Paredis, K.; Van Bael, J.; Six, D. Flexibility of a combined heat and power system with thermal energy storage for district heating. Appl. Energy 2013, 104, 583–591. [Google Scholar] [CrossRef]

- Diangelakis, N.A.; Panos, C.; Pistikopoulos, E.N. Design optimization of an internal combustion engine powered CHP system for residential scale application. Comput. Manag. Sci. 2014, 11, 237–266. [Google Scholar] [CrossRef]

- Savola, T.; Fogelholm, C.J. MINLP optimisation model for increased power production in small-scale CHP plants. Appl. Therm. Eng. 2007, 27, 89–99. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Y.; Zeng, D.; Wang, W. Optimization of an air-cooling system and its application to grid stability. Appl. Therm. Eng. 2013, 61, 206–212. [Google Scholar] [CrossRef]

- Lissner, M.; Tissot, J.; Leducq, D.; Azzouz, K.; Fournaison, L. Performance study of latent heat accumulators: Numerical and experimental study. Appl. Therm. Eng. 2016, 102, 604–614. [Google Scholar] [CrossRef]

- Tan, W.; Liu, J.; Fang, F.; Chen, Y. Tuning of PID controllers for boiler-turbine units. ISA Trans. 2004, 43, 571–583. [Google Scholar] [CrossRef]

- Wang, W.; Liu, J.; Zeng, D.; Niu, Y.; Cui, C. An improved coordinated control strategy for boiler-turbine units supplemented by cold source flow adjustment. Energy 2015, 88, 927–934. [Google Scholar] [CrossRef]

- Long, D.; Wang, W.; Yao, C.; Liu, J. An experiment-based model of condensate throttling and its utilization in load control of 1000 MW power units. Energy 2017, 133, 941–954. [Google Scholar] [CrossRef]

| Main Steam Flow (t/h) | Heat Source Flow (t/h) | Rated Power Output (MW) | K with Rated Data | Predicted K | Predicted Power Output (MW) | Relative Error |

|---|---|---|---|---|---|---|

| 1137 | 0 | 348.481 | - | - | 348.569 | 0.02% |

| 1137 | 500 | 280.443 | −0.1361 | −0.1388 | 279.177 | 0.45% |

| 1137 | 600 | 266.889 | −0.1360 | −0.1388 | 265.298 | 0.59% |

| Unit Type | Heating Drainage Water Direction | Main Steam Flow (t/h) | Heat Source Flow (t/h) | Predicted K | Predicted Power Output (MW) |

|---|---|---|---|---|---|

| 310 MW | Deaerator | 985 | 0 | -- | 302.9555 |

| 985 | 100 | −0.1159 | 291.3618 | ||

| 985 | 200 | −0.1158 | 279.7680 | ||

| 1038 | 0 | -- | 280.6682 | ||

| 1038 | 150 | −0.0887 | 267.3590 | ||

| 1038 | 300 | −0.0887 | 254.0498 | ||

| 600 MW | 6# LP preheater | 1533 | 0 | -- | 503.3288 |

| 1533 | 200 | 0.1899 | 465.3421 | ||

| 1533 | 400 | 0.1899 | 427.3553 | ||

| 1856 | 450 | -- | 497.2991 | ||

| 1856 | 500 | −0.1740 | 488.5960 | ||

| 1856 | 550 | −0.1741 | 479.8929 | ||

| 850 MW | 5# LP preheater | 1913 | 0 | -- | 690.1195 |

| 1913 | 200 | −0.1420 | 661.7166 | ||

| 1913 | 400 | −0.1419 | 633.3137 | ||

| 2469 | 0 | -- | 855.0893 | ||

| 2469 | 250 | −0.1267 | 823.4086 | ||

| 2469 | 500 | −0.1267 | 791.7279 |

| Performance Index | Traditional CCS | Optimized Strategy |

|---|---|---|

| IAE index | 77.4 | 14.5 |

| ITAE index | 14,097 | 2725 |

| AGC index: K1 | 0.9 | 1.49 |

| AGC index: K2 | 1.226 | 1.855 |

| AGC index: K3 | 1.73 | 2.00 |

| AGC index: KP | 1.908 | 5.527 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Sun, Y.; Jing, S.; Zhang, W.; Cui, C. Improved Boiler-Turbine Coordinated Control of CHP Units with Heat Accumulators by Introducing Heat Source Regulation. Energies 2018, 11, 2815. https://doi.org/10.3390/en11102815

Wang W, Sun Y, Jing S, Zhang W, Cui C. Improved Boiler-Turbine Coordinated Control of CHP Units with Heat Accumulators by Introducing Heat Source Regulation. Energies. 2018; 11(10):2815. https://doi.org/10.3390/en11102815

Chicago/Turabian StyleWang, Wei, Yang Sun, Sitong Jing, Wenguang Zhang, and Can Cui. 2018. "Improved Boiler-Turbine Coordinated Control of CHP Units with Heat Accumulators by Introducing Heat Source Regulation" Energies 11, no. 10: 2815. https://doi.org/10.3390/en11102815