Analysis of the Scavenging Process of a Two-Stroke Free-Piston Engine Based on the Selection of Scavenging Ports or Valves

Abstract

:1. Introduction

2. Fundamental Analysis

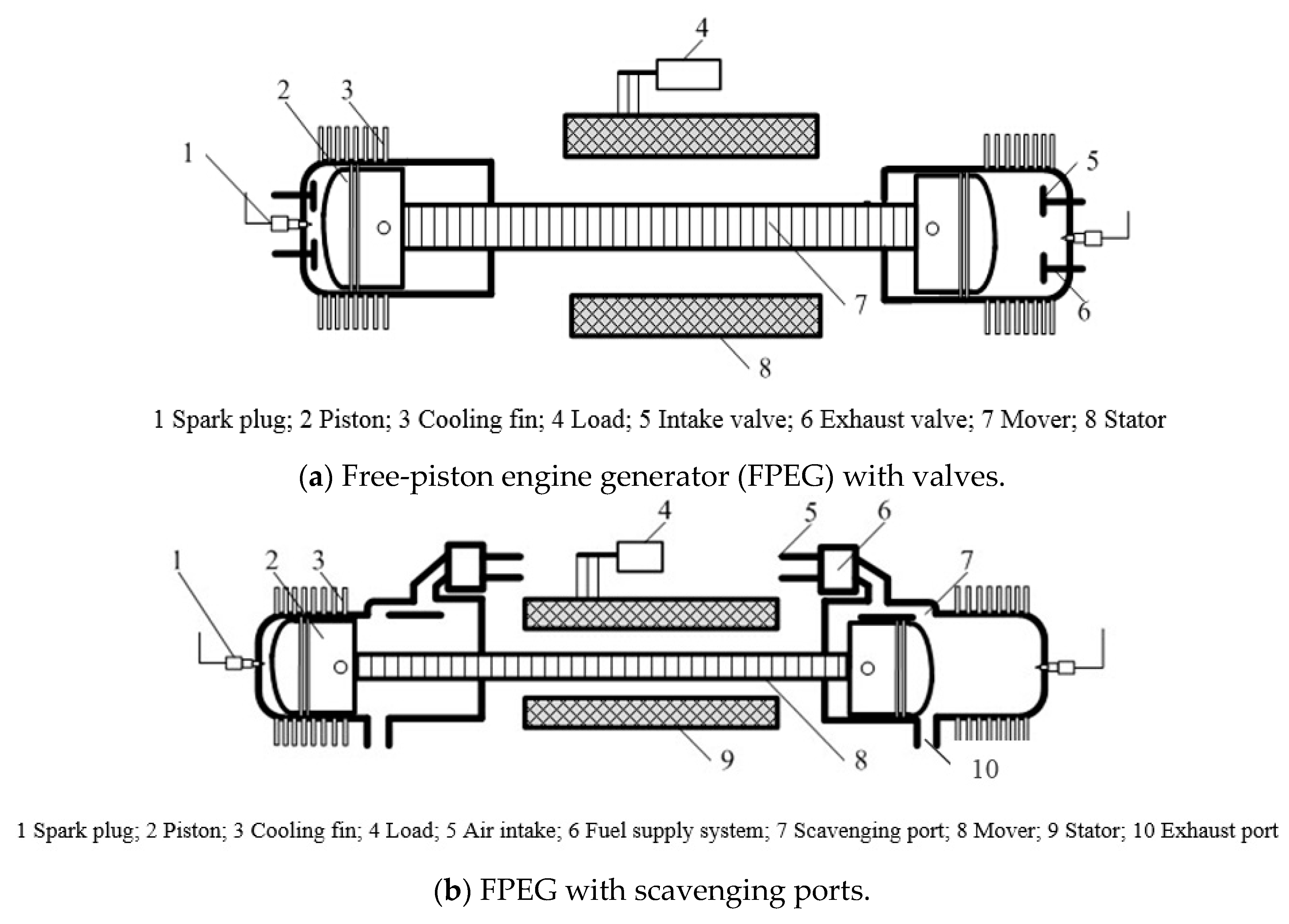

2.1. FPEG Configuration

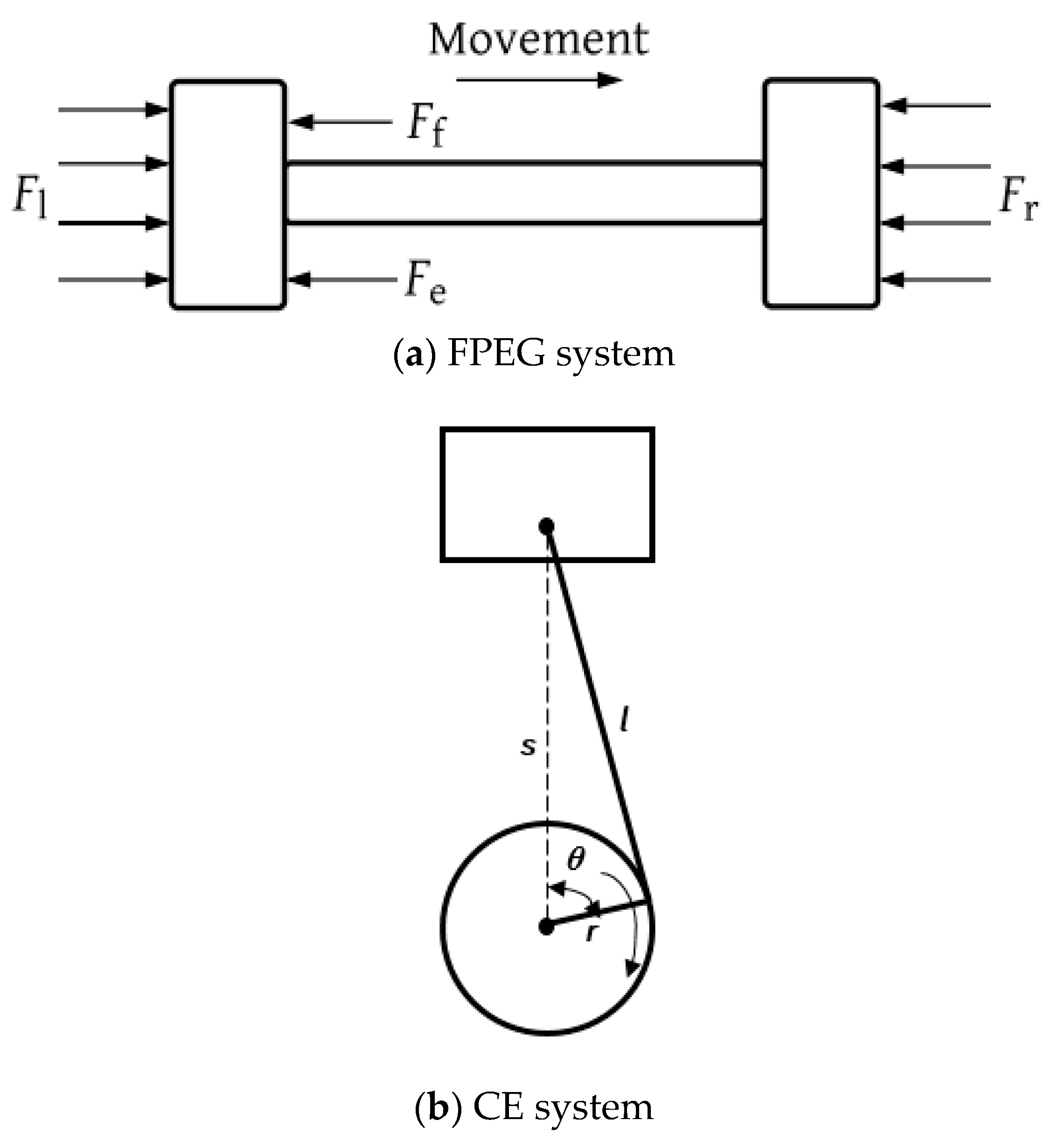

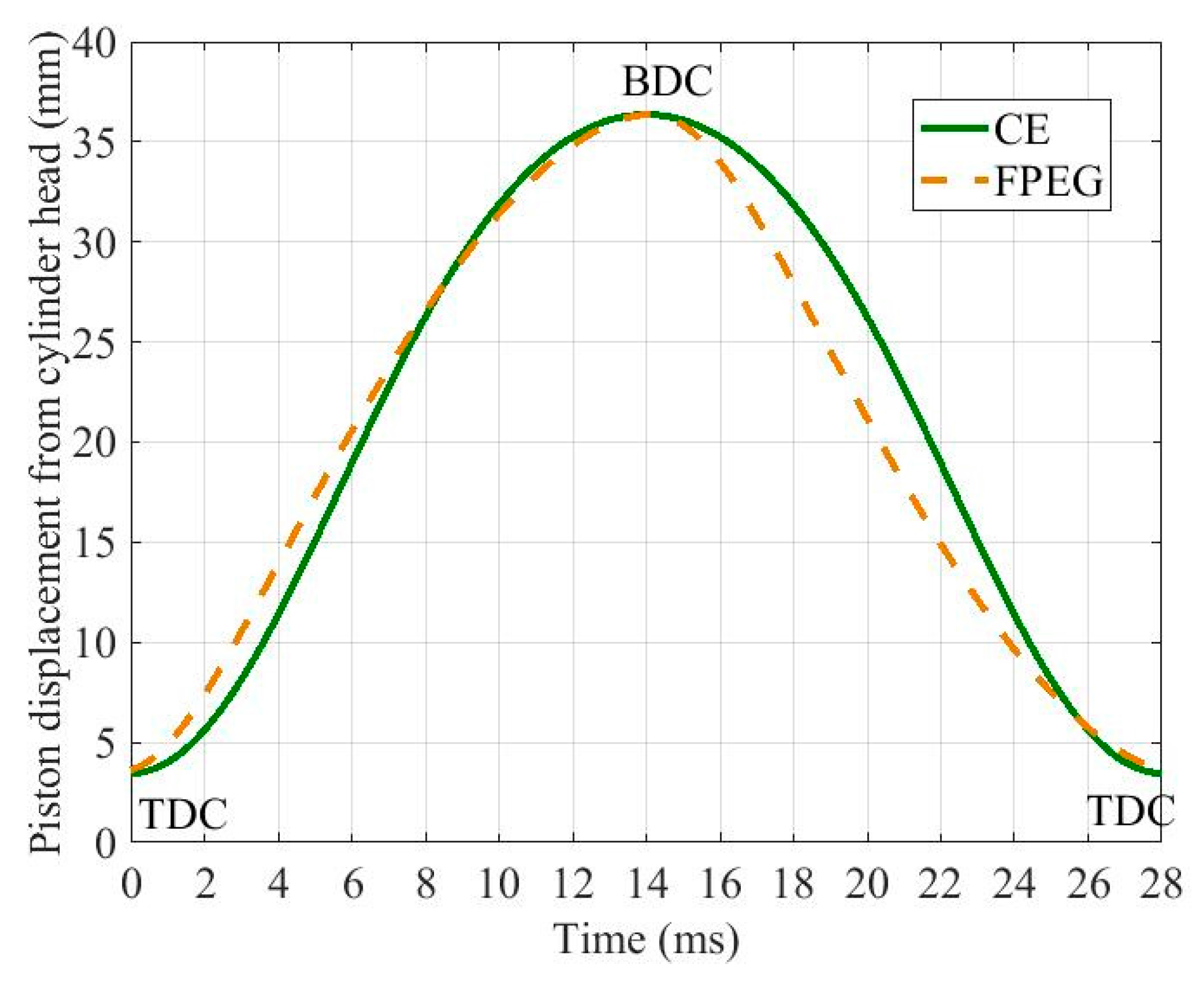

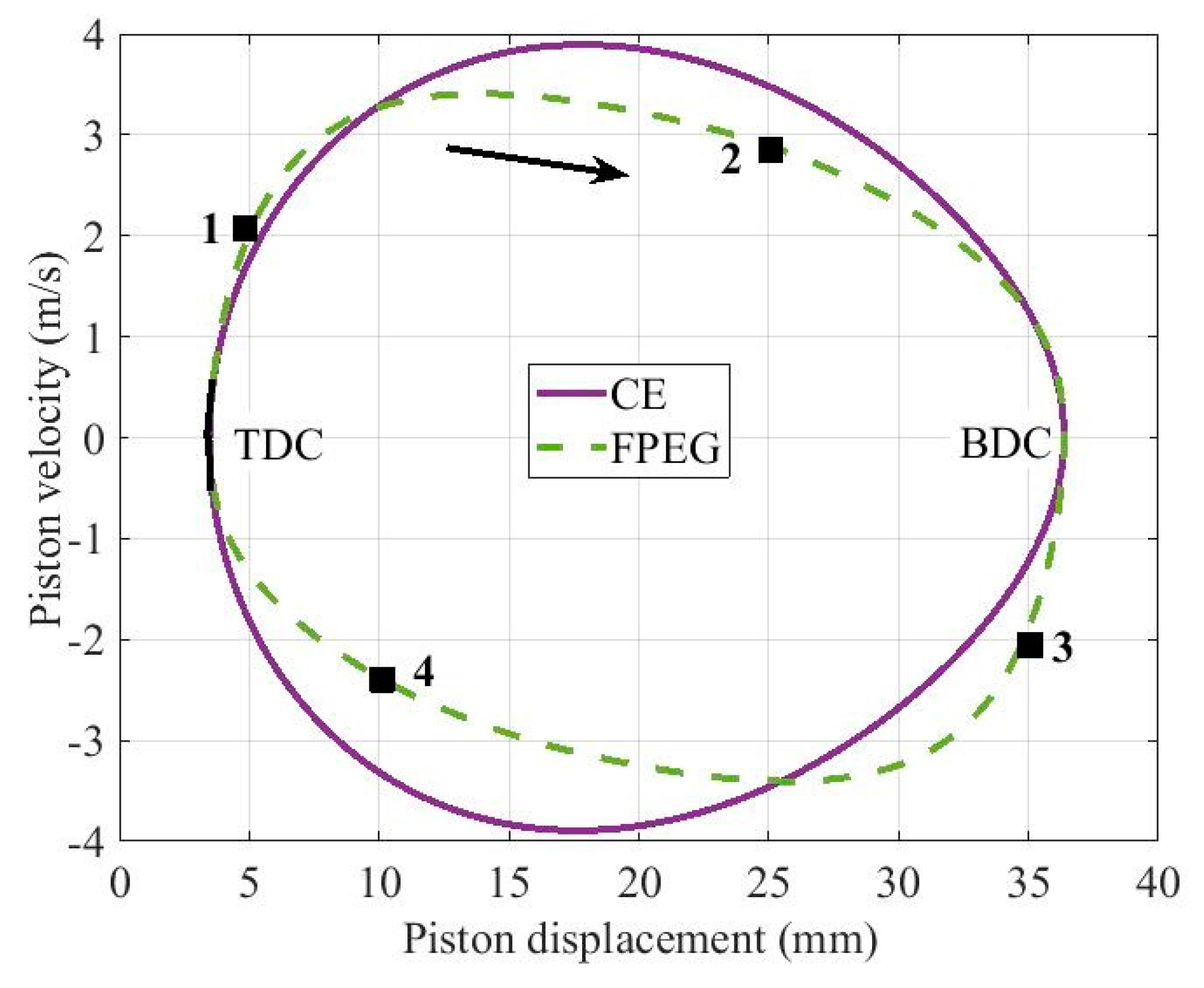

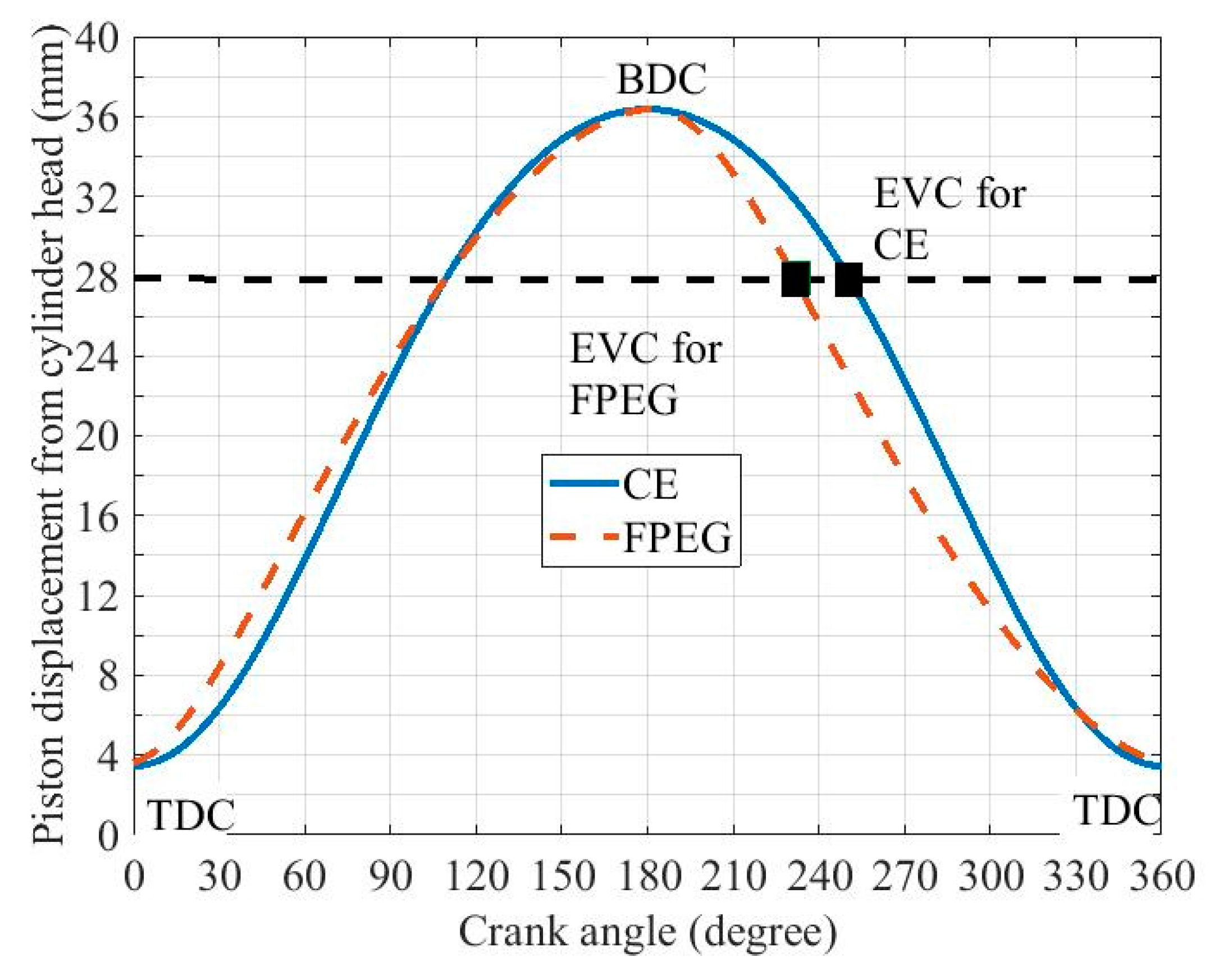

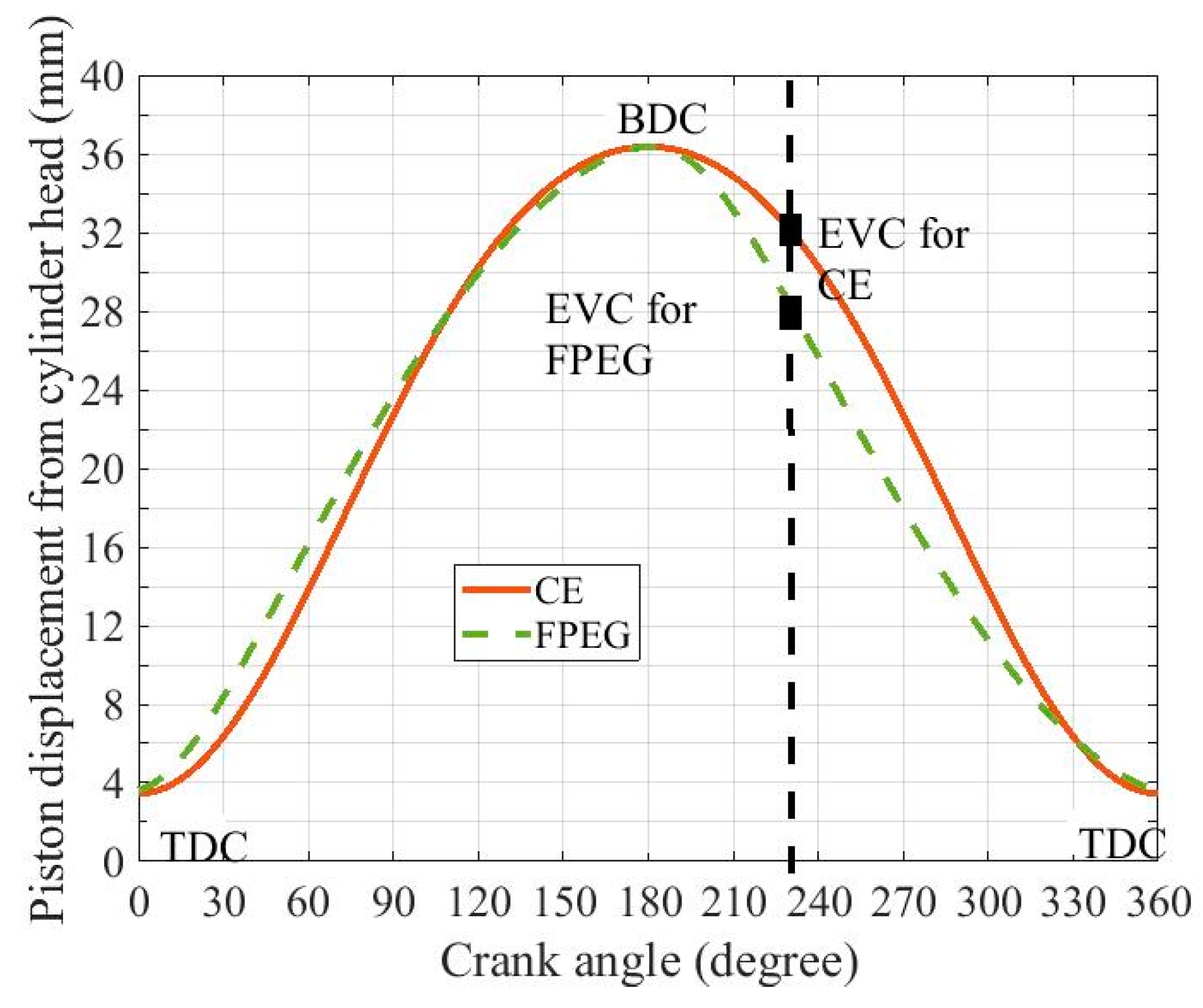

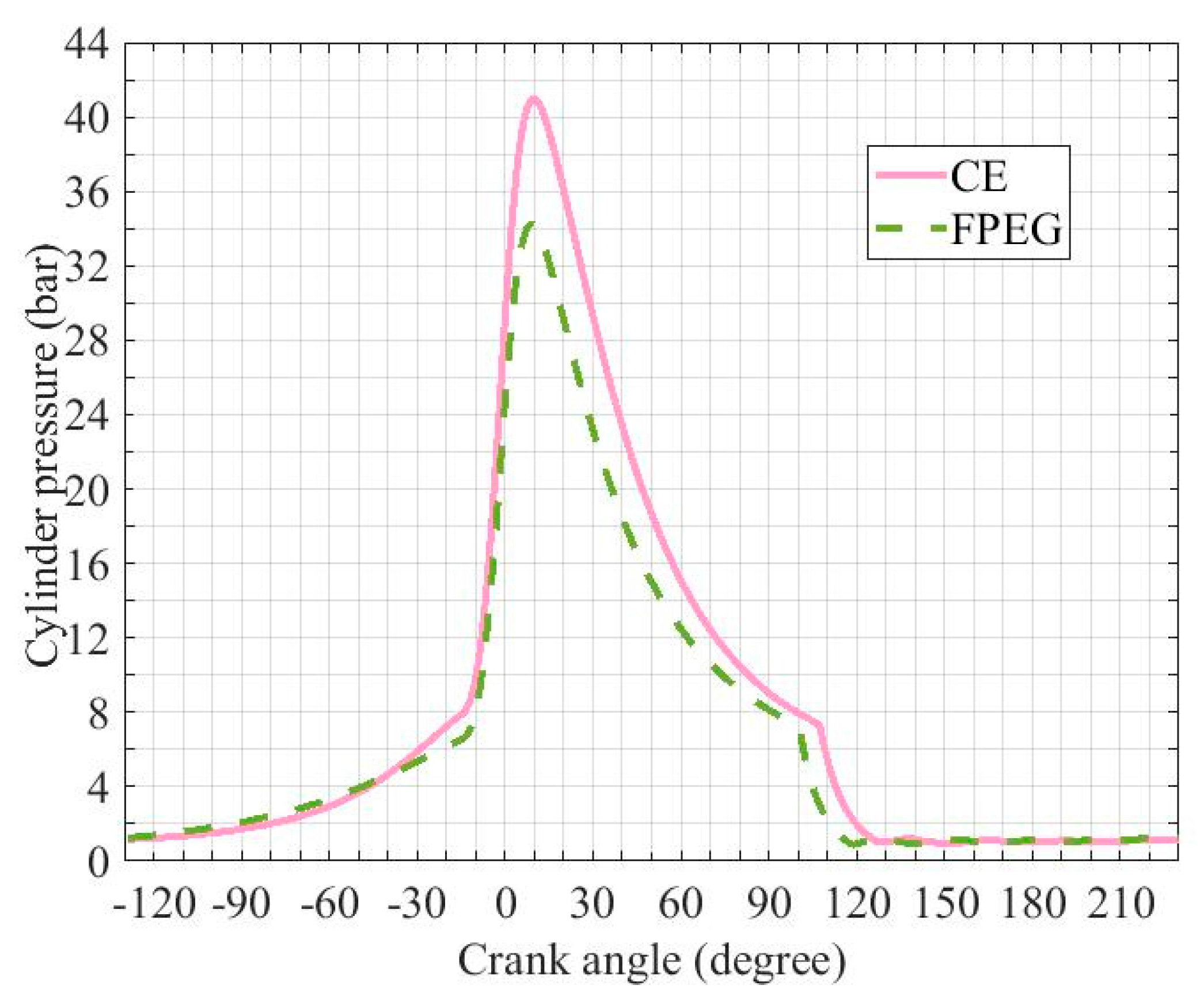

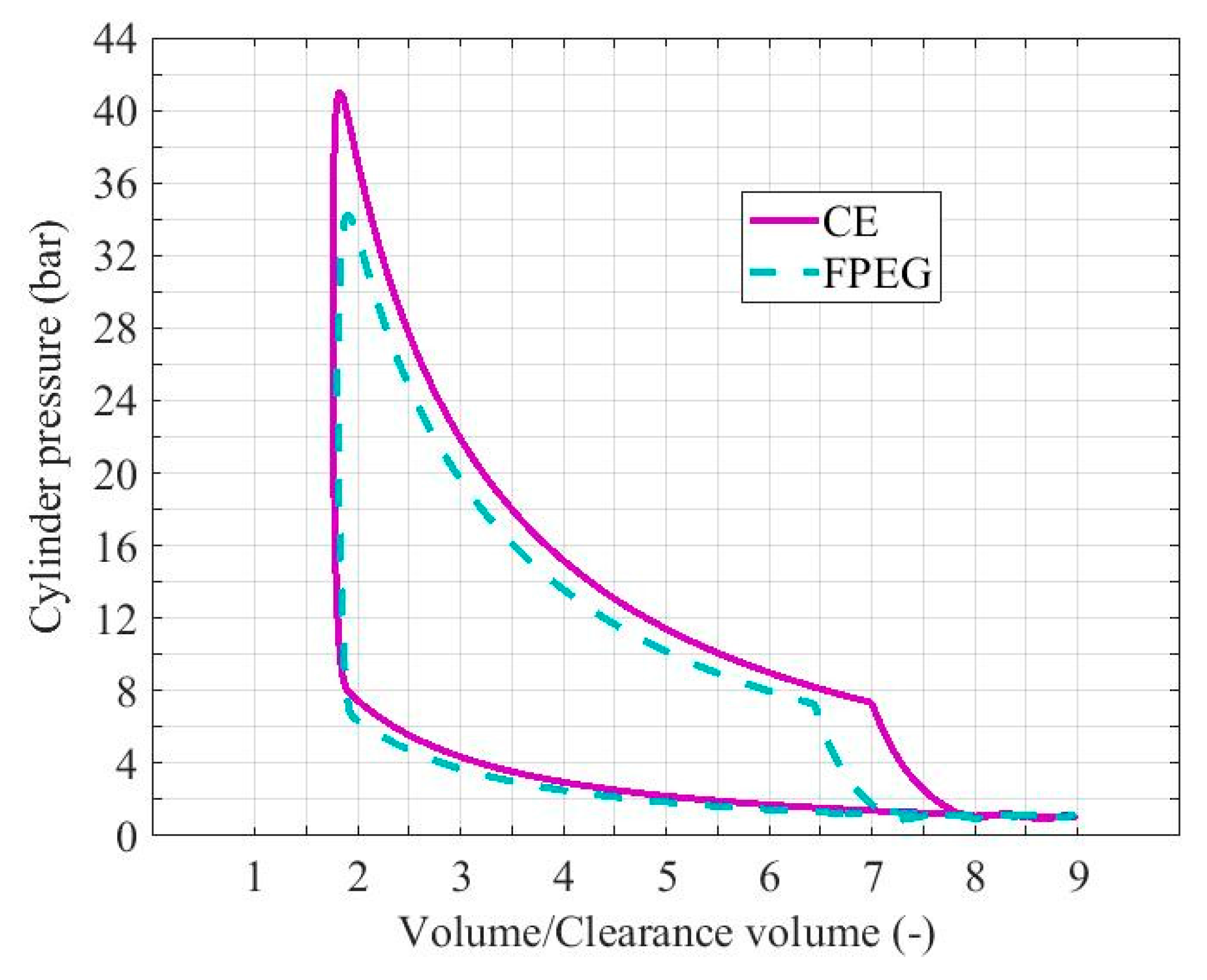

2.2. Comparison of FPEG with a Conventional Engine (CE)

2.3. Valve Opening Timing

2.4. Simulation Methodology

- (a)

- If an engine with scavenging ports is adopted for the FPEG prototype, information on the performance of the scavenging process, the difference compared to that of the CE with the same cylinder, and the methods to improve the system scavenging process are collected.

- (b)

- If an engine with valves is adopted for the FPEG prototype, information on how the valve timing will affect its scavenging process, the difference compared to that of the CE with the same cylinder, and the optimised valve timing are collected.

3. Results and Discussion

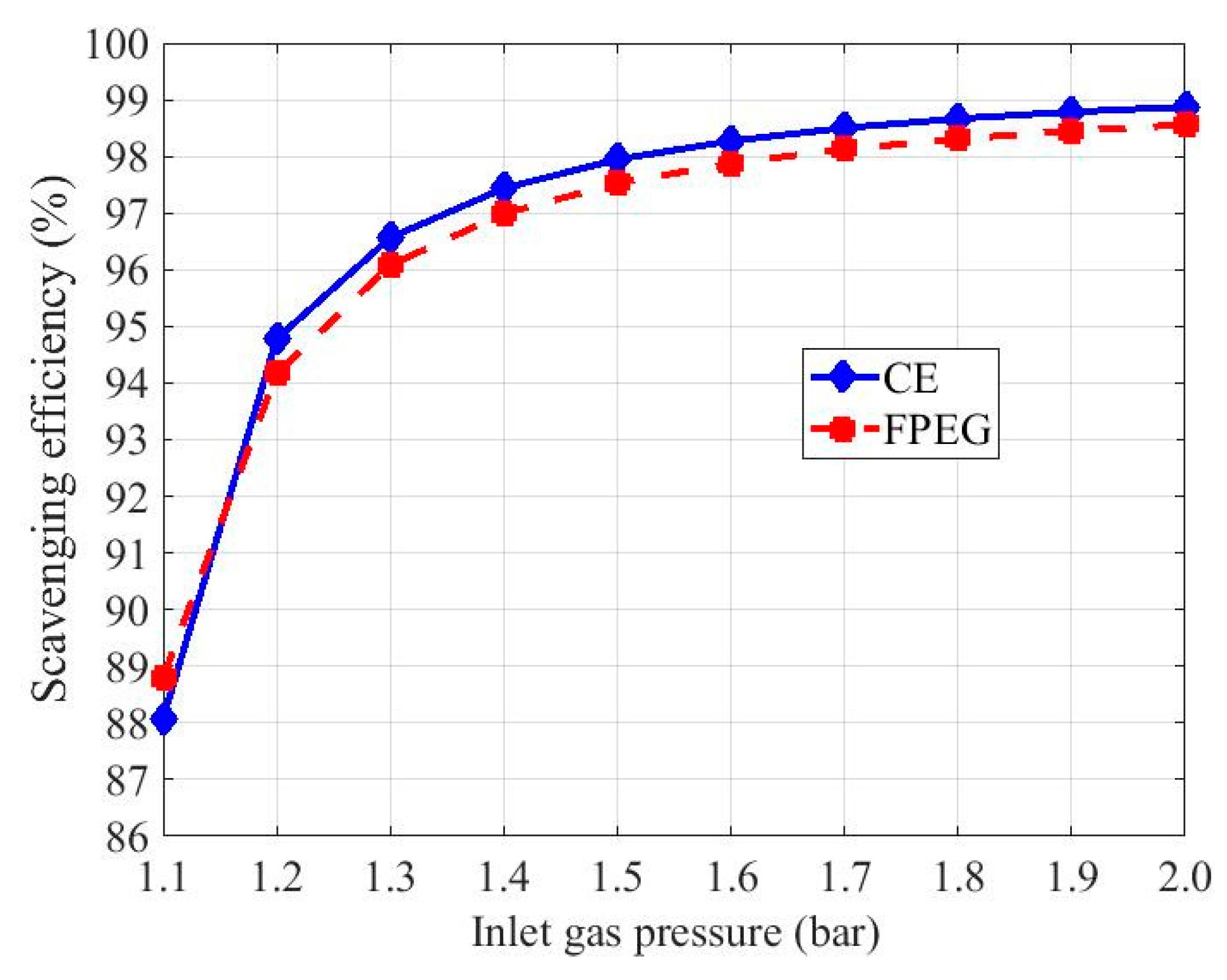

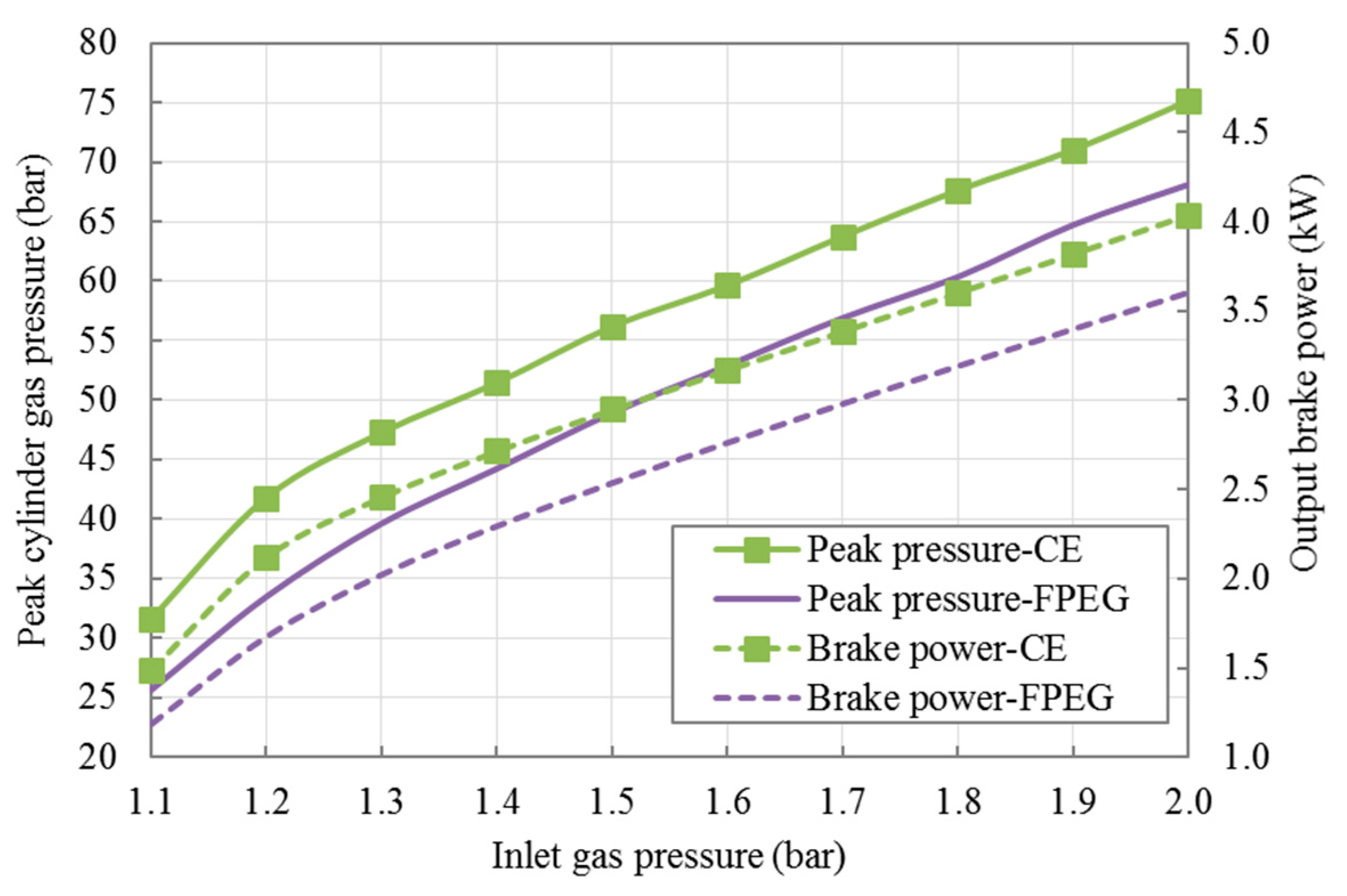

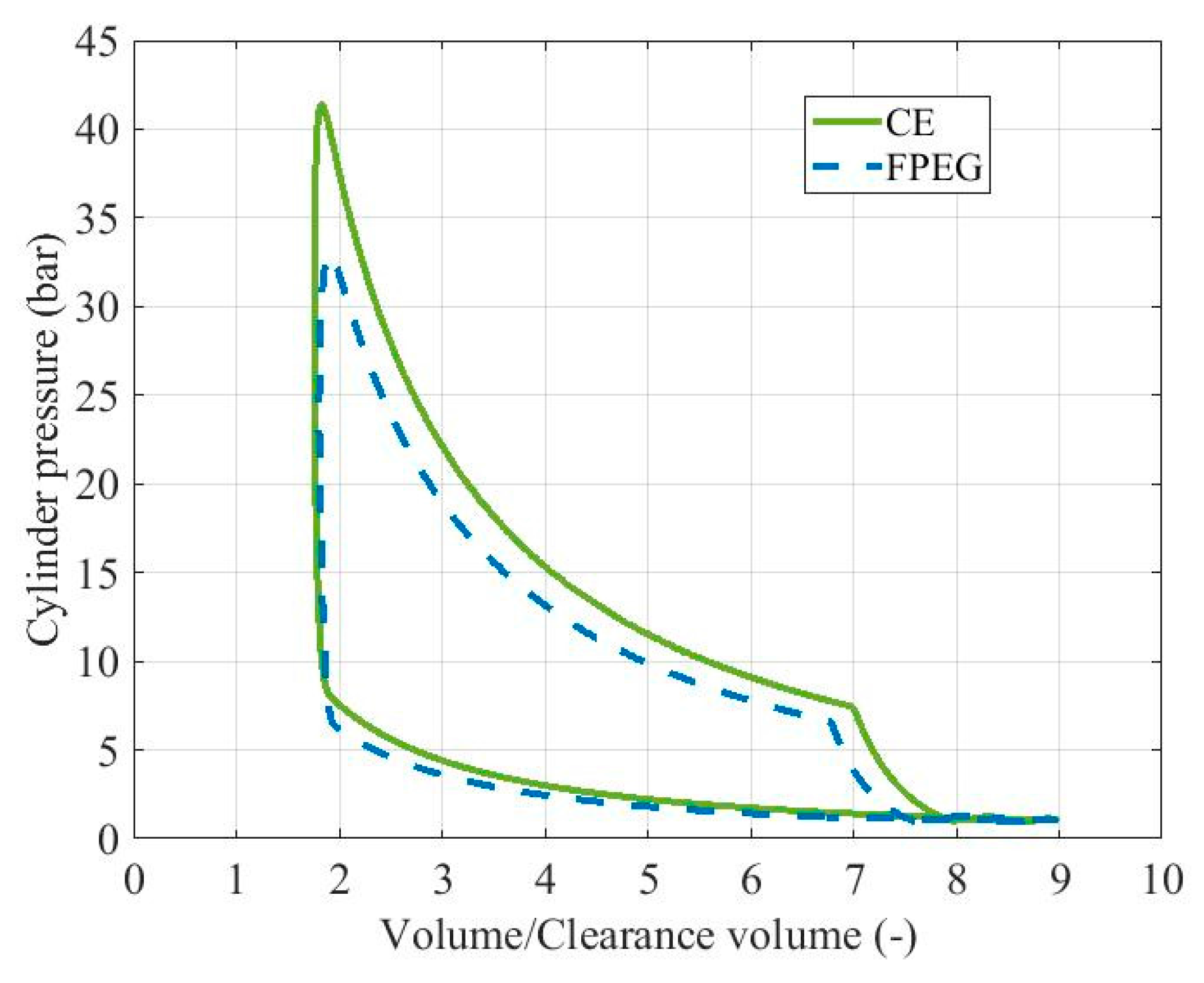

3.1. FPEG with Scavenging Ports

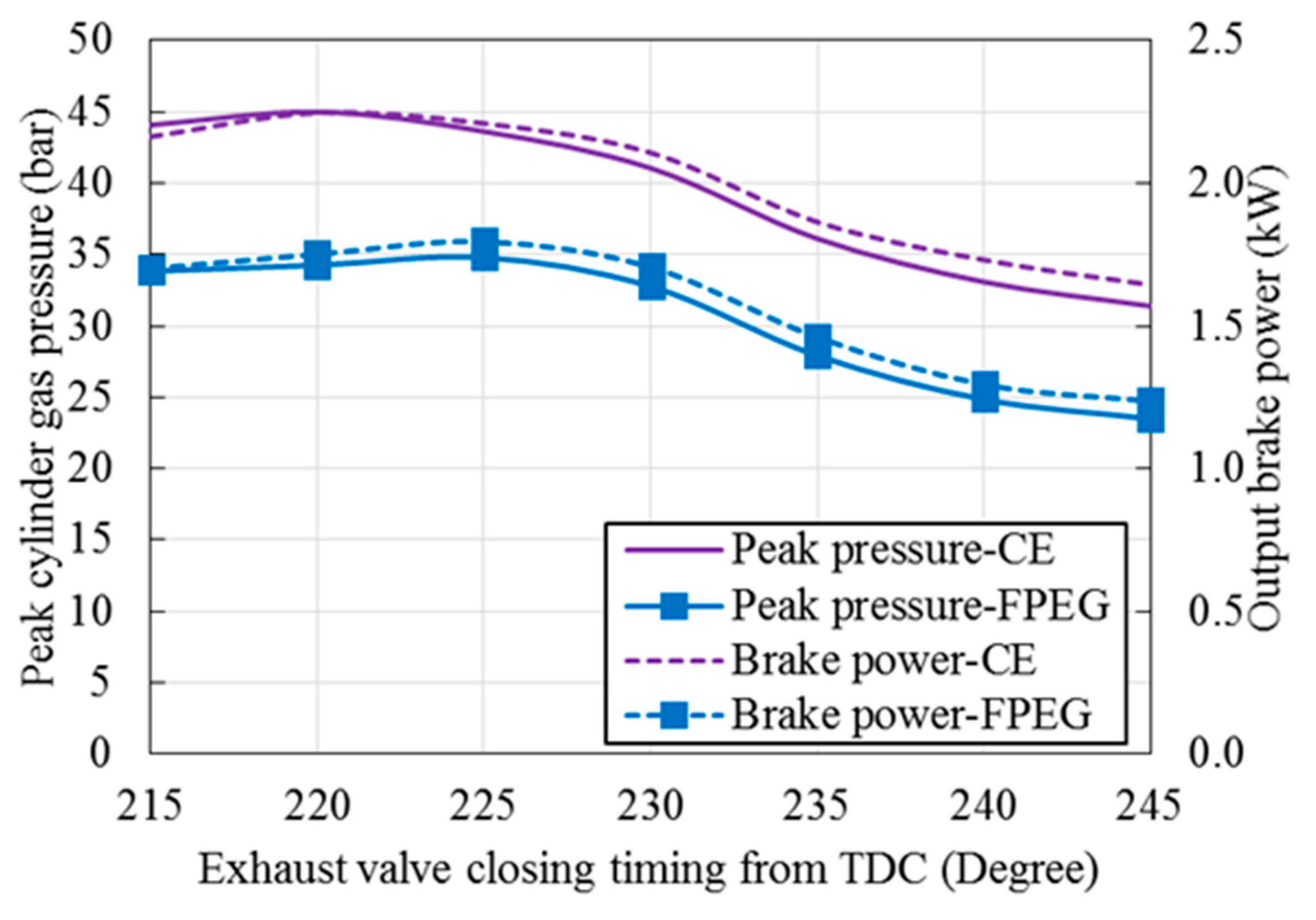

3.2. FPEG with Valves

4. Conclusions

- (1)

- Compared with a CE, the piston of the FPEG moves faster after combustion takes place, as it is not restricted by the crankshaft system, while becomes slower soon after this. The piston velocity of an FPEG will be lower when the piston is approaching its TDC during the compression process, and the peak velocity achieved is also lower than that of a CE.

- (2)

- For the CE and FEPG using scavenging ports with the EVC timing set to be 32 mm from the cylinder head, the peak cylinder pressure, engine power output, and scavenging efficiency of the FEPG are found to be lower than that of a CE with the same size and operation conditions. For an FPEG prototype of this kind, in order to improve its power output to the same level as that of a CE with the same size, the inlet gas pressure is suggested to be improved to above 1.4 bar for a better power output, which is approximately 0.2 bar higher than that used for a CE.

- (3)

- If a CE cylinder with exhaust valves is adopted or referred to during the development of an FPEG prototype, and the exhaust valve is set to close at 50° after BDC, the engine-indicated work of the FPEG are found to be lower than that of the CE as the compression stroke of the FPEG is reduced. For an FPEG prototype with valves, the exhaust valve is suggested to be closed earlier to improve its power output (but no earlier than 225°), and a higher intake pressure is also suggested if its output power is expected to be the same or higher than that of a CE. Meanwhile, the EVC timing is not considered useful to control power output for the FPEG as the improvement is very low, while boosting the intake pressure is overwhelmingly better than changing the EVC timing.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mikalsen, R.; Roskilly, A.P. A review of free-piston engine history and applications. Appl. Therm. Eng. 2007, 27, 2339–2352. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, F.; Huang, Y.; Zhao, C. Determination of TDC in a hydraulic free-piston engine by a novel approach. Appl. Therm. Eng. 2014, 70, 524–530. [Google Scholar] [CrossRef]

- Jia, B.; Smallbone, A.; Zuo, Z.; Feng, H.; Roskilly, A.P. Design and simulation of a two-or four-stroke free-piston engine generator for range extender applications. Energy Convers. Manag. 2016, 111, 289–298. [Google Scholar] [CrossRef]

- Goto, S.; Moriya, K.; Kosaka, H.; Akita, T.; Hotta, Y.; Umeno, T.; Nakakita, K. Development of Free Piston Engine Linear Generator System Part 2—Investigation of Control System for Generator; SAE Technical Paper; SAE International: Detroit, MI, USA, 2014. [Google Scholar]

- Tikkanen, S.; Vilenius, M. On the dynamic characteristics of the hydraulic free piston engine. In Proceedings of the ICMA’98: International Conference on Machine Automation, Tampere, Finland, 15–18 September 1998. [Google Scholar]

- Achten, P.A.; van den Oever, J.P.; Potma, J.; Vael, G.E. Horsepower with Brains: The Design of the Chiron Free Piston Engine; SAE Technical Paper; SAE International: Milwaukee, WI, USA, 2000. [Google Scholar]

- Van Blarigan, P.; Paradiso, N.; Goldsborough, S. Homogeneous Charge Compression Ignition with a Free Piston: A New Approach to Ideal Otto Cycle Performance; SAE Technical Paper; SAE International: San Francisco, CA, USA, 1998. [Google Scholar]

- Jia, B.; Mikalsen, R.; Smallbone, A.; Zuo, Z.; Feng, H.; Roskilly, A.P. Piston motion control of a free-piston engine generator: A new approach using cascade control. Appl. Energy 2016, 179, 1166–1175. [Google Scholar] [CrossRef]

- Max, E. FPEC, Free piston energy converter. In Proceedings of the 21st Electric Vehicle Symposium & Exhibition, EVS, Monaco, France, 2–6 April 2005. [Google Scholar]

- Haag, J.; Kock, F.; Chiodi, M.; Mack, O.; Bargende, M.; Naumann, C.; Slavinskaya, N.; Heron, A.; Riedel, U.; Ferrari, C. Development Approach for the Investigation of Homogeneous Charge Compression Ignition in a Free-Piston Engine. Available online: https://doi.org/10.4271/2013-24-0047 (accessed on 25 January 2018).

- Kosaka, H.; Akita, T.; Moriya, K.; Goto, S.; Hotta, Y.; Umeno, T.; Nakakita, K. Development of Free Piston Engine Linear Generator System Part 1-Investigation of Fundamental Characteristics. Available online: https://doi.org/10.4271/2014-01-1203 (accessed on 25 January 2018).

- Kock, F.; Haag, J.; Friedrich, H.E. The Free Piston Linear Generator-Development of an Innovative, Compact, Highly Efficient Range-Extender Module. Available online: https://doi.org/10.4271/2013-01-1727 (accessed on 25 January 2018).

- Nandkumar, S. Two-Stroke Linear Engine; West Virginia University: Morgantown, WV, USA, 1998. [Google Scholar]

- Houdyschell, D. A Diesel Two-Stroke Linear Engine; West Virginia University: Morgantown, WV, USA, 2000. [Google Scholar]

- Hansson, J. Analysis and Control of a Hybrid Vehicle Powered by Free-Piston Energy Converter. Ph.D. Thesis, Kungliga Tekniska Hogskolan, Stockholm, Sweden, 2006. [Google Scholar]

- Johnson, T.A.; Leick, M.T. Experimental Evaluation of the Free Piston Engine—Linear Alternator (FPLA); Sandia National Laboratories: Albuquerque, NM, USA, 2015. [Google Scholar]

- Vysoký, O. Linear Combustion Engine as Main Energy Unit for Hybrid Vehicles; Proceedings of Transtec Prague; Czech Technical University: Prague, Czech Republic, 2007; pp. 236–244. [Google Scholar]

- Feng, H.; Guo, C.; Jia, B.; Zuo, Z.; Guo, Y.; Roskilly, T. Research on the intermediate process of a free-piston linear generator from cold start-up to stable operation: Numerical model and experimental results. Energy Convers. Manag. 2016, 122, 153–164. [Google Scholar] [CrossRef]

- Miao, Y.; Zuo, Z.; Feng, H.; Guo, C.; Song, Y.; Jia, B.; Guo, Y. Research on the Combustion Characteristics of a Free-Piston Gasoline Engine Linear Generator during the Stable Generating Process. Energies 2016, 9, 655. [Google Scholar] [CrossRef]

- Li, Q.; Xiao, J.; Huang, Z. Simulation of a two-stroke free-piston engine for electrical power generation. Energy Fuels 2008, 22, 3443–3449. [Google Scholar] [CrossRef]

- Hanipah, M.R. Development of a Spark Ignition Free-Piston Engine Generator. Ph.D. Thesis, Newcastle University, Newcastle upon Tyne, UK, 2015. [Google Scholar]

- Jia, B.; Zuo, Z.; Tian, G.; Feng, H.; Roskilly, A.P. Development and validation of a free-piston engine generator numerical model. Energy Convers. Manag. 2015, 91, 333–341. [Google Scholar] [CrossRef]

- Mao, J.; Zuo, Z.; Feng, H. Parameters coupling designation of diesel free-piston linear alternator. Appl. Energy 2011, 88, 4577–4589. [Google Scholar] [CrossRef]

- Mao, J.; Feng, H.; Zuo, Z. Dimensionless Parametric Analysis of Spark Ignited Free-Piston Linear Alternator. Available online: https://www.intechopen.com/books/thermodynamics-interaction-studies-solids-liquids-and-gases/dimensionless-parametric-analysis-of-spark-ignited-free-piston-linear-alternator (accessed on 25 January 2018).

- Mao, J.; Zuo, Z.; Li, W.; Feng, H. Multi-dimensional scavenging analysis of a free-piston linear alternator based on numerical simulation. Appl. Energy 2011, 88, 1140–1152. [Google Scholar] [CrossRef]

- Goldsborough, S.S.; van Blarigan, P. Optimizing the Scavenging System for a Two-Stroke Cycle, Free Piston Engine for High Efficiency and Low Emissions: A Computational Approach. Available online: https://doi.org/10.4271/2003-01-0001 (accessed on 25 January 2018).

- Aichlmayr, H.T. Design Considerations, Modeling, and Analysis of Micro-Homogeneous Charge Compression Ignition Combustion Free-Piston Engines. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2002. [Google Scholar]

- Jia, B.; Smallbone, A.; Feng, H.; Tian, G.; Zuo, Z.; Roskilly, A.P. A fast response free-piston engine generator numerical model for control applications. Appl. Energy 2016, 162, 321–329. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; Mcgraw-hill New York: New York, NY, USA, 1988; Volume 930. [Google Scholar]

| Parameters (Unit) | FPEG | CE |

|---|---|---|

| Piston diameter (mm) | 50.0 | 50.0 |

| Stroke (mm) | 33.0 | 33.0 |

| Compression ratio (-) | 10.5 | 10.5 |

| Connecting rod length (mm) | - | 49.5 |

| Crank radius (mm) | - | 16.5 |

| Parameters (Unit) | Value |

|---|---|

| Engine speed (rpm) | 2143 |

| Number of valves (-) | 2 |

| Intake valve diameter (mm) | 18.0 |

| Exhaust valve diameter (mm) | 18.0 |

| Valve lift (mm) | 4.2 |

| Fuel type (-) | Octane |

| Fuel lower heating valve (J/kg) | 4.4 × 107 |

| Air fuel ratio (-) | 14.7 |

| Intake air pressure (bar) | 1.0–2.0 |

| Intake air temperature (K) | 300.0 |

| Ignition timing (°) | 15 bTDC |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, B.; Wang, Y.; Smallbone, A.; Roskilly, A.P. Analysis of the Scavenging Process of a Two-Stroke Free-Piston Engine Based on the Selection of Scavenging Ports or Valves. Energies 2018, 11, 324. https://doi.org/10.3390/en11020324

Jia B, Wang Y, Smallbone A, Roskilly AP. Analysis of the Scavenging Process of a Two-Stroke Free-Piston Engine Based on the Selection of Scavenging Ports or Valves. Energies. 2018; 11(2):324. https://doi.org/10.3390/en11020324

Chicago/Turabian StyleJia, Boru, Yaodong Wang, Andrew Smallbone, and Anthony Paul Roskilly. 2018. "Analysis of the Scavenging Process of a Two-Stroke Free-Piston Engine Based on the Selection of Scavenging Ports or Valves" Energies 11, no. 2: 324. https://doi.org/10.3390/en11020324