Analysis of Energy Saving Potential in High-Performance Building Technologies under Korean Climatic Conditions

Abstract

1. Introduction

1.1. Background and Purpose

1.2. Literature Review

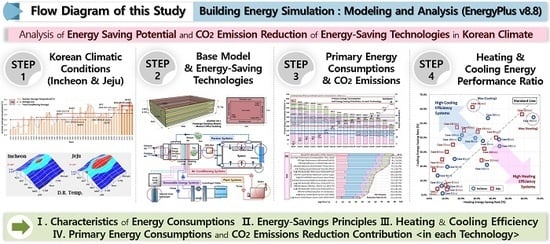

1.3. Method and Process

2. Climate Changes and Conditions in Korea

2.1. Incheon’s Area Average Annual Temperature Changes and Extreme Weather Events

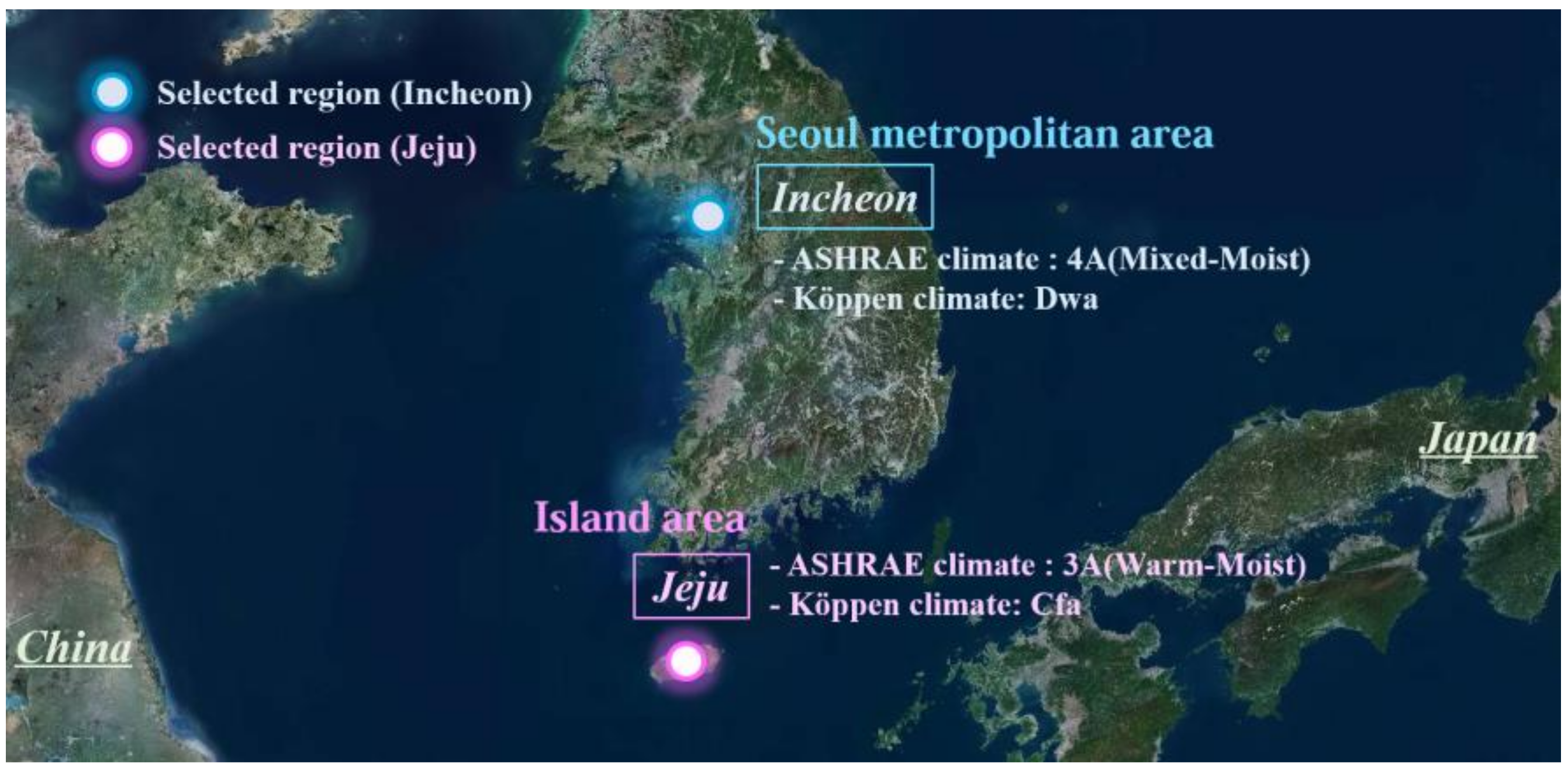

2.2. Comparison of Incheon’s and Jeju’s Climate Conditions

3. Theoretical Framework

3.1. Definition of High-Performance Buildings

3.2. Primary Energy Consumptions and CO2 Emissions

3.2.1. Primary Energy Consumptions and Primary Energy Conversion Factors

3.2.2. CO2 Emissions and CO2 Emission Factors

4. Selection of Simulation Analysis Model and Energy-Saving Technologies

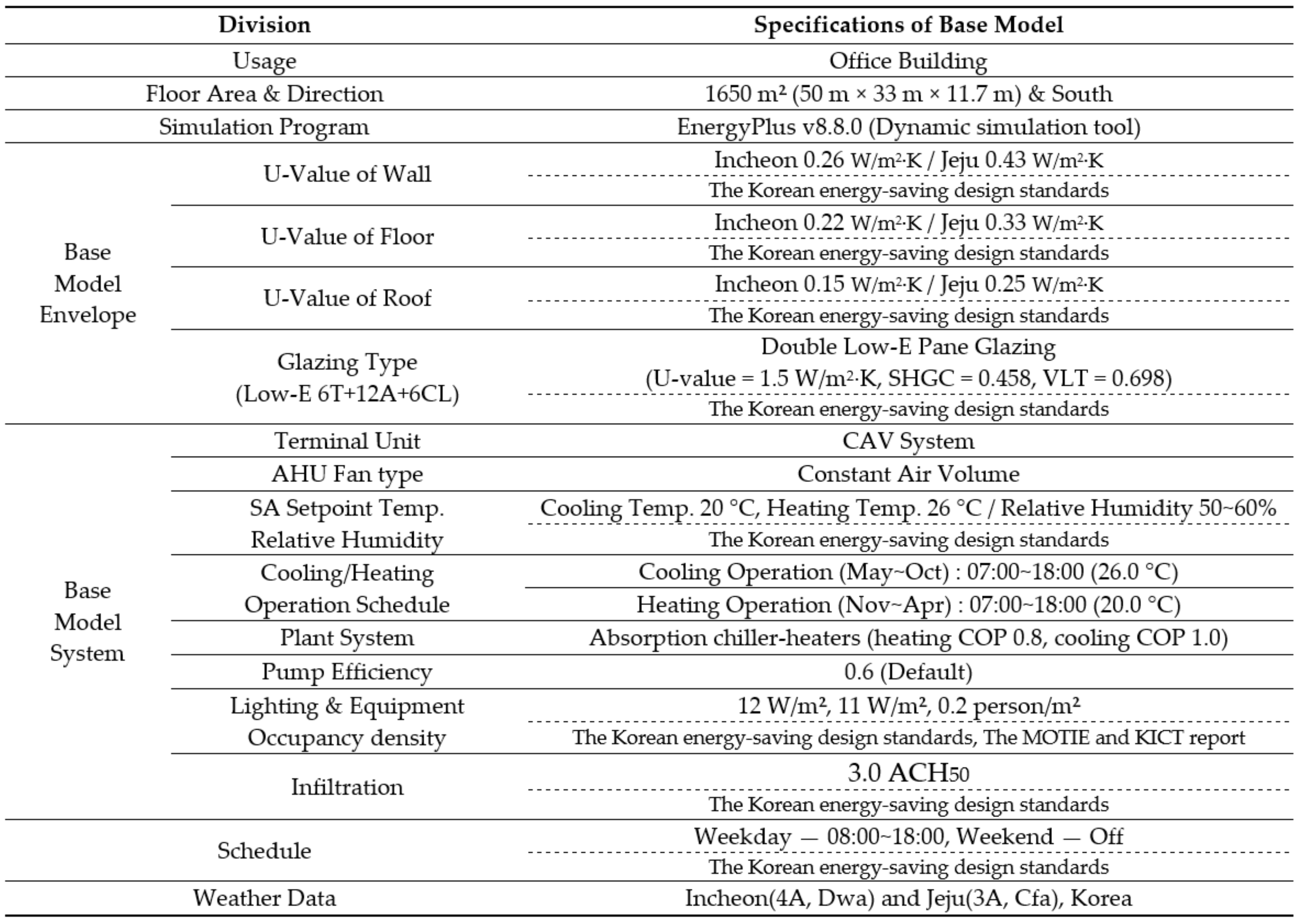

4.1. EnergyPlus Simulation Analysis Model and Input Conditions

4.2. Selection of Energy-Saving Technologies for High-Performance Building

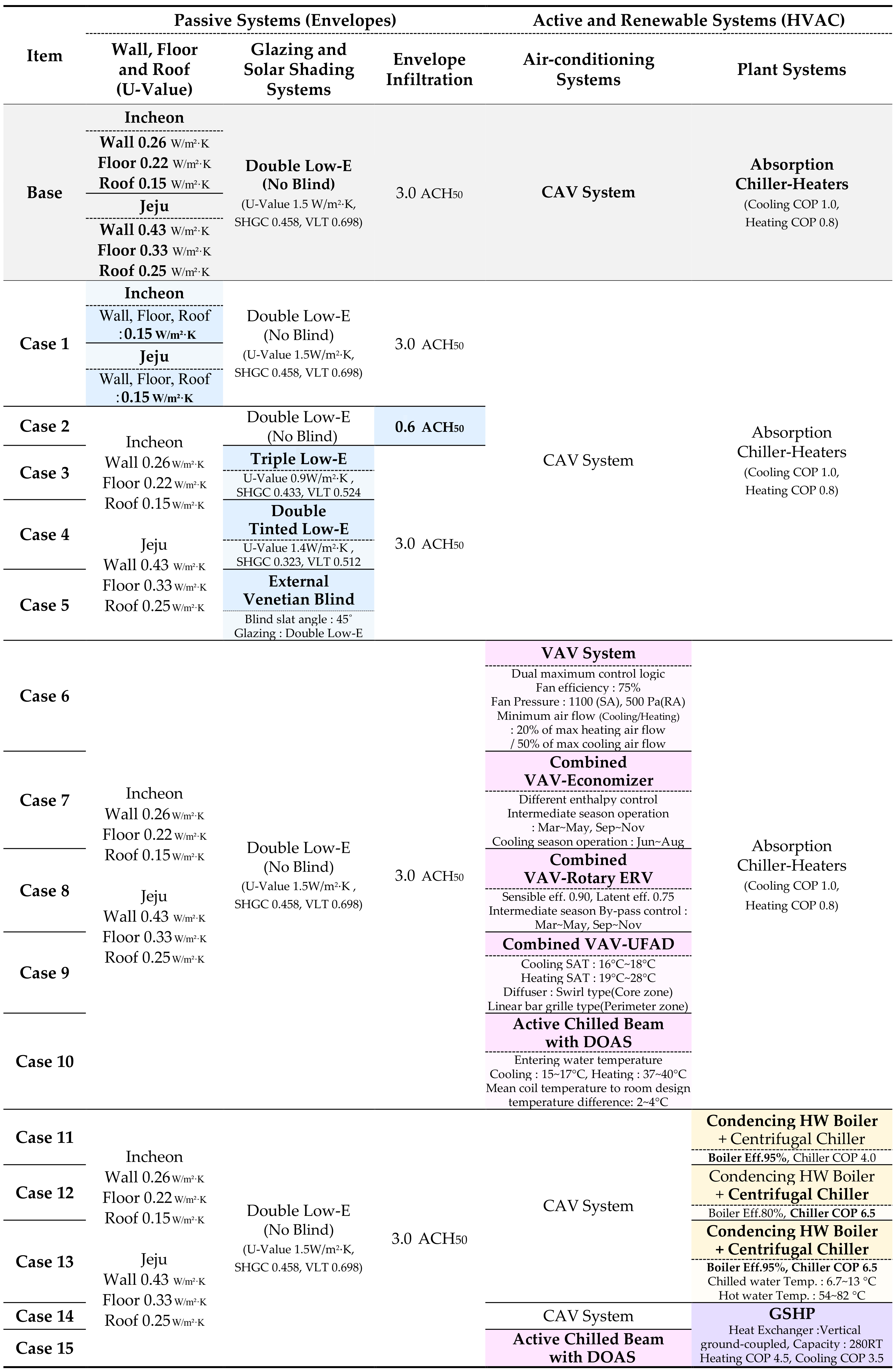

4.2.1. Selection of Passive Systems (Cases 1–5)

4.2.2. Selection of Active Systems (Cases 6–13)

4.2.3. Selection of Renewable Energy Systems (Cases 14–15)

5. EnergyPlus Simulation Results

5.1. Analysis of the Primary Energy Consumptions in Passive Systems

5.1.1. Simulation Results for Case 1 and Case 2 (High-Performance Envelopes and Infiltration)

5.1.2. Simulation Results for Case 3, Case 4, and Case 5 (High-Efficiency Glazings and Shading Systems)

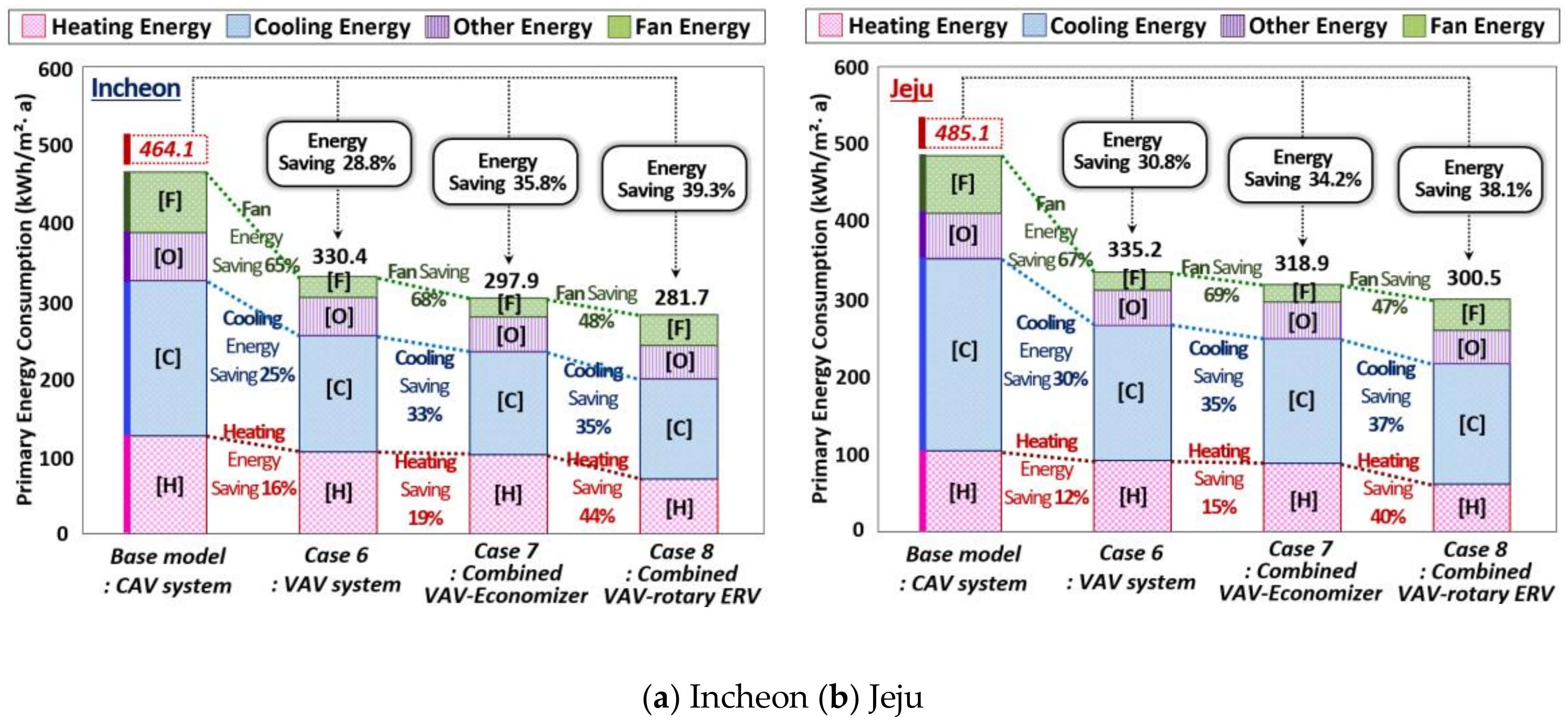

5.2. Analysis of the Primary Energy Consumptions in Active Systems

5.2.1. Simulation Result for Case 6 (VAV System with Dual Maximum Control Logic)

5.2.2. Simulation Results for Case 7 (Economizer Enthalpy Control) and Case 8 (Rotary ERV with VAV System)

5.2.3. Simulation Results for Case 9 (UFAD with VAV System) and Case 10 (Active Chilled Beam with DOAS)

5.2.4. Simulation Results for Cases 11–13 (High Efficiency Condensing HW Boiler And Centrifugal Chiller)

5.3. Analysis of the Primary Energy Consumptions in Renewable Energy Systems

Simulation Result for Case 14 (CAV+GSHP) and Case 15 (Active Chilled Beam with DOAS+GSHP)

5.4. Comprehensive Analysis of the Simulations (Primary Energy Consumptions and CO2 Emissions)

5.4.1. Overall Primary Energy Consumption and Comparisons with Benchmark Values

5.4.2. Each System’s CO2 Emissions and Reduction Rate Analysis

5.4.3. Analysis of the Correlation between the Primary Energy Consumptions and CO2 Emissions

5.4.4. Analysis of Heating and Cooling Energy Performance Ratio of Each System

6. Discussion

7. Summary and Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ACH | Air Change per Hour |

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| CAV | Constant Air Volume |

| CBECS | Commercial Buildings Energy Consumption Survey |

| CDD | Cooling Degree Days |

| COP | Coefficient of Performance |

| DB | Data Base |

| DOAS | Dedicated Outdoor Air System |

| DOE | U.S. Department of Energy |

| ECM | Energy Conservation measures |

| EIA | Energy Information Administration |

| ERV | Energy Recovery Ventilation |

| EPBD | Energy Performance of Buildings Directive |

| EPW | EnergyPlus Weather File |

| GSHP | Ground Source Heat Pump |

| HDD | Heating Degree Days |

| HVAC | Heating, Ventilation and Air Conditioning |

| HW Boiler | Hot Water Condensing Boiler |

| IEA | International Energy Agency |

| LCBP | Low Carbon Buildings Program |

| NEDO | New Energy and Industrial Technology Development Organization |

| nZEBs | Nearly Zero Energy Buildings |

| PTZ | Éco-Prêt à Taux Zéro |

| REHVA | Federation of European Heating, Ventilation and Air Conditioning Associations |

| SHCG | Solar Heat Gain Coefficient |

| UFAD | Underfloor Air Distribution |

| VAV | Variable Air Volume |

| VLT | Visible Light Transmittance |

| WMO | World Meteorological Organization |

References

- Edenhofer, O.R.; Pichs-Madruga, Y.; Sokona, E.; Farahani, S.; Kadner, K.; Seyboth, A.; Adler, I.; Baum, S.; Brunner, P.; Eickemeier, B.; et al. Climate Change 2014 Mitigation of Climate Change; Working Group III Contribution to the Fifth Assessment Report of IPCC; UNEP: Geneva, Switzerland, 2015; ISBN 978-92-9169-142-5. [Google Scholar]

- The Core Writing Team of IPCC; Pachauri, R.K.; Meyer, L. Synthesis Report IPCC Climate Change 2014 Synthesis Report; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2015; ISBN 978-92-9169-143-2. [Google Scholar]

- Shen, Y.; Wei, R.; Xu, L. Energy consumption prediction of a greenhouse and optimization of daily average temperature. Energies 2018, 11, 65. [Google Scholar] [CrossRef]

- Oleson, K.W.; Anderson, G.B.; Jones, B.; McGinnis, S.A.; Sanderson, B. Avoided climate impacts of urban and rural heat and cold waves over the US using large climate model ensembles for RCP 8.5 and RCP 4.5. Clim. Chang. 2015, 1–16. [Google Scholar] [CrossRef]

- Lhotka, O.; Kyselý, J.; Farda, A. Climate change scenarios of heat waves in Central Europe and their uncertainties. Theor. Appl. Climatol. 2017, 1–12. [Google Scholar] [CrossRef]

- Mann, M.E.; Rahmstorf, S.; Kornhuber, K.; Steinman, B.A.; Miller, S.K.; Coumou, D. Influence of anthropogenic climate change on planetary wave resonance and extreme weather events. Sci. Rep. 2017, 7, 45242. [Google Scholar] [CrossRef] [PubMed]

- Ceccherini, G.; Russo, S.; Ameztoy, I.; Romero, C.P.; Carmona-Moreno, C. Magnitude and frequency of heat and cold waves in recent decades: The case of South America. Nat. Hazards Earth Syst. Sci. 2016, 16, 821–831. [Google Scholar] [CrossRef]

- Fan, S.; Yang, X. Arctic and East Asia winter climate variations associated with the eastern Atlantic pattern. J. Clim. 2017, 30, 573–583. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, Y. The linkage between upper-level jet streams over East Asia and East Asian winter monsoon variability. J. Clim. 2015, 28, 9013–9028. [Google Scholar] [CrossRef]

- Briner, G.; Prag, A. Establishing and Understanding Post-2020 Climate Change Mitigation Commitments; OECD: Paris, France, 2013. [Google Scholar]

- Tavoni, M.; Kriegler, E.; Riahi, K.; Van Vuuren, D.P.; Aboumahboub, T.; Bowen, A.; Campiglio, E.; Kober, T.; Jewell, J.; Luderer, G.; et al. Post-2020 climate agreements in the major economies assessed in the light of global models. Nat. Clim. Chang. 2015, 5, 119. [Google Scholar] [CrossRef]

- Höhne, N.; Fekete, H.; den Elzen, M.G.; Hof, A.F.; Kuramochi, T. Assessing the ambition of post-2020 climate targets: A comprehensive framework. Clim. Policy 2017, 1–16. [Google Scholar] [CrossRef]

- Thornton, B.A.; Rosenberg, M.A.; Richman, E.E.; Wang, W.; Xie, Y.; Zhang, J.; Cho, H.; Mendon, V.V.; Athalye, R.A.; Liu, B. Achieving the 30% Goal: Energy and Cost Savings Analysis of ASHRAE Standard 90.1-2010; U.S. Department of Energy: Washington, DC, USA, 2011.

- New Building Institute (NBI). Getting to Zero 2012 Status Update: A First Look at the Costs and Features of Zero Energy Commercial Buildings; NBI: Portland, OR, USA, 2012. [Google Scholar]

- Dall’O, G.; Belli, V.; Brolis, M.; Mozzi, I.; Fasano, M. Nearly zero-energy buildings of the Lombardy region (Italy), a case study of high-energy performance buildings. Energies 2013, 6, 3506–3527. [Google Scholar] [CrossRef]

- Li, C.; Hong, T.; Yan, D. An insight into actual energy use and its drivers in high-performance buildings. Appl. Energy 2014, 131, 394–410. [Google Scholar] [CrossRef]

- D’Agostino, D.; Zangheri, P.; Castellazzi, L. Towards nearly zero energy buildings in Europe: A focus on retrofit in non-residential buildings. Energies 2017, 10, 117. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Zhao, H.X.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- The International Energy Agency (IEA). Modernising Building Energy Codes to Secure Our Global Energy Future; IEA: Paris, France, 2013. [Google Scholar]

- Krarti, M.; Deneuville, A. Comparative evaluation of optimal energy efficiency designs for French and US office buildings. Energy Build. 2015, 93, 332–344. [Google Scholar] [CrossRef]

- Boyano, A.; Hernandez, P.; Wolf, O. Energy demands and potential savings in European office buildings: Case studies based on EnergyPlus simulations. Energy Build. 2015, 65, 19–28. [Google Scholar] [CrossRef]

- Jiang, B.; Mao, P.; Tan, Y.; Yao, X. A study of climate-responsive building technologies in different climate regions of China. In Proceedings of the 20th International Symposium on Advancement of Construction Management and Real Estate, Singapore, 9 June 2016; Springer: Singapore, 2016; pp. 1111–1121. [Google Scholar] [CrossRef]

- Hurtado, L.A.; Rhodes, J.D.; Nguyen, P.H.; Kamphuis, I.G.; Webber, M.E. Quantifying demand flexibility based on structural thermal storage and comfort management of non-residential buildings: A comparison between hot and cold climate zones. Appl. Energy 2017, 195, 1047–1054. [Google Scholar] [CrossRef]

- Engelmann, P.; Kalz, D.; Salvalai, G. Cooling concepts for non-residential buildings: A comparison of cooling concepts in different climate zones. Energy Build. 2014, 82, 447–456. [Google Scholar] [CrossRef]

- Salvalai, G.; Pfafferott, J.; Sesana, M.M. Assessing energy and thermal comfort of different low-energy cooling concepts for non-residential buildings. Energy Convers. Manag. 2013, 76, 332–341. [Google Scholar] [CrossRef]

- Pfafferott, J. Enhancing the Design and the Operation of Passive Cooling Concepts: Monitoring and Data Analysis in Four Low-energy Office Buildings with Night Ventilation; Fraunhofer-IRB-Verlag: Munich, Germany, 2004; ISBN 3816766269. [Google Scholar]

- Lam, J.C.; Wan, K.K.; Tsang, C.L.; Yang, L. Building energy efficiency in different climates. Energy Convers. Manag. 2008, 49, 2354–2366. [Google Scholar] [CrossRef]

- Singh, R.; Sartor, D.; Ghatikar, G. Best Practices Guide for High-Performance Indian Office Buildings; Lawrence Berkeley National Laboratory (LBNL): Berkeley, CA, USA, 2013. [Google Scholar]

- Im, P.; Haberl, J.S. A survey of high performance schools. In Proceedings of the Fifteenth Symposium on Improving Building Systems in Hot and Humid Climates, Orlando, FL, USA, 24–26 July 2006; Energy Systems Laboratory: Orlando, FL, USA, 26 July 2006. Available online: http://esl.tamu.edu (accessed on 2 April 2018).

- Rodriguez-Ubinas, E.; Montero, C.; Porteros, M.; Vega, S.; Navarro, I.; Castillo-Cagigal, M.; Matallanas, E.; Gutiérrez, A. Passive design strategies and performance of Net EnergyPlus Houses. Energy Build. 2014, 83, 10–22. [Google Scholar] [CrossRef]

- Polly, B.; Gestwick, M.; Bianchi, M.; Anderson, R.; Horowitz, S.; Christensen, C.; Judkoff, R. A Method for Determining Optimal Residential Energy Efficiency Retrofit Packages; U.S. Department of Energy: Washington, DC, USA, 2011.

- International Energy Agency (IEA). World Energy Balances 2017 Edition; IEA: Paris, France, 2017; ISBN 978-92-64-27809-7. [Google Scholar]

- National Renewable Energy Laboratory (NREL). Realizing High-Performance Buildings—How to Maintain Energy-Efficient Design Intent during Building Operation; NREL: Denver, CO, USA, 2015. [Google Scholar]

- Day, J.K.; Gunderson, D.E. Understanding high performance buildings: The link between occupant knowledge of passive design systems, corresponding behaviors, occupant comfort and environmental satisfaction. Build. Environ. 2015, 84, 114–124. [Google Scholar] [CrossRef]

- Deru, M.; Field, K.; Studer, D.; Benne, K.; Griffith, B.; Torcellini, P.; Liu, B.; Halverson, M.; Winiarski, D.; Rosenberg, M.; et al. U.S. Department of Energy Commercial Reference Building Models of the National Building Stock; National Renewable Energy Laboratory (NREL): Denver, CO, USA, 2011. [Google Scholar]

- U.S. Department of Energy (DOE). DOE Reference Commercial Buildings Report; Prototype Building Model Package. Available online: https://www.energycodes.gov/development/commercial/prototype_models (accessed on 14 March 2018).

- U.S. Department of Energy (DOE). EnergyPlus Engineering Reference (Version 8.8.0 Documentation; Building Technologies Program); U.S. Department of Energy: Washington, DC, USA, 2017.

- Energy Information Administration (EIA). Commercial Buildings Energy Consumption Survey (CBECS). 2012. Available online: https://www.eia.gov/consumption/commercial/ (accessed on 14 March 2018).

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). Energy Standard for Buildings Except Low-Rise Residential Buildings; ANSI/ASHRAE/IESNA Standard 90.1-2004; ASHRAE: Atlanta, GA, USA, 2004. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). Energy Standard for Buildings Except Low-Rise Residential Buildings; ANSI/ASHRAE/IESNA Standard 90.1-2010; ASHRAE: Atlanta, GA, USA, 2012. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. Building Energy Efficiency Certification System of Korea. 2017. Available online: http://www.molit.go.kr/USR/I0204/m_45/dtl.jsp?idx=14790 (accessed on 14 March 2018).

- Korea Meteorological Administration (KMA). 2017 Abnormal Climate Report; KMA: Seoul, Korea, 2017; ISBN 11-1360000-000705-01. Available online: http://www.climate.go.kr/home/bbs/list.php?code=93&bname=abnormal (accessed on 14 March 2018).

- Korea Meteorological Administration (KMA). National Climate Data Center, Weather Data Release Portal. Available online: https://data.kma.go.kr/cmmn/main.do (accessed on 14 March 2018).

- World Meteorological Organization (WMO). WMO Statement on the State of the Global Climate in 2016; WMO: Geneva, Switzerland, 2016; ISBN 978-92-63-11189-0. [Google Scholar]

- Korea Meteorological Administration (KMA). Climate Change Outlook Report on the Korean Peninsula; KMA: Seoul, Korea, 2017; ISBN 11-1360000-000861-01. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ASHRAE 90.1-2010 International Climate Zone Definitions; ASHRAE: Atlanta, GA, USA, 2012; Available online: http://www.built-environments.com/International_Climate_Zones.pdf (accessed on 2 April 2018).

- EnergyPlus. EnergyPlus Weather Data. Available online: https://energyplus.net/weather/ (accessed on 14 March 2018).

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- United States Government Printing Office (GPO). Energy Policy Act of 2005, Public Law 109–58, Section 914. Building Standards; 109th Congress; GPO: Washington, DC, USA, 2011. [Google Scholar]

- United States Government Printing Office (GPO). Energy Independence and Security Act of 2007, Public Law 110–140, Title IV-Energy Savings in Buildings and Industry, Section 401. Definitions; 110th Congress; GPO: Washington, DC, USA, 2011. [Google Scholar]

- International Energy Agency (IEA); Energy in Buildings and Communities Programme (EBC). Total Energy Use in Buildings: Analysis and Evaluation Methods (Annex 53); AECOM: Croydon, UK, 2016. [Google Scholar]

- Schicktanz, M.D.; Wapler, J.; Henning, H.M. Primary energy and economic analysis of combined heating, cooling and power systems. Energy 2011, 36, 575–585. [Google Scholar] [CrossRef]

- Gustafsson, M.; Thygesen, R.; Karlsson, B.; Ödlund, L. Rev-Changes in Primary Energy Use and CO2 Emissions—An Impact Assessment for a Building with Focus on the Swedish Proposal for Nearly Zero Energy Buildings. Energies 2017, 10, 978. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). CO2 Emissions from Fuel Combustion Highlights (2017 Edition); IEA: Paris, France, 2017; ISBN 978-92-64-27818-9. [Google Scholar]

- Korea Energy Agency (KEA). Carbon Neutral Program Guideline; KEA: Gyeonggi-Do, Korea, 2017. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories Volume 2 Energy; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Ministry of Land, Infrastructure and Transport (MOLIT); Korea Energy Agency (KEA). Building Energy Saving Design Standards of Korea; KEA: Gyeonggi-Do, Korea, 2017. [Google Scholar]

- Ministry of Trade, Industry and Energy (MOTIE); Korea Institute of Civil Engineering and Building Technology (KICT). The Study of the Development of Energy Performance Assessment Method and Policy in Buildings; KICT: Gyeonggi-Do, Korea, 2017. [Google Scholar]

- Korea Energy Agency (KEA); Korea Institute of Civil Engineering and Building Technology (KICT). Establishing Data Base of Building Energy Design Situation and Developing High Efficiency Building Design Guideline; KEA: Gyeonggi-Do, Korea, 2017. [Google Scholar]

- Korea Energy Agency (KEA); Korea Appraisal Board (KAB). Development of Building Energy Integrated Support System for the Spread of Low-Energy Building Workshop; Korea Energy Agency and Korea Appraisal Board DB: Gyeonggi-Do, Korea, 2016. [Google Scholar]

- Passive House Institute (PHI). Criteria for the Passive House, ener PHit and PHI Low Energy Building Standard; PHI: Darmstadt, Germany, 2016. [Google Scholar]

- Korean Institute of Architectural Sustainable Environment and Building Systems (KIAEBS). Building Airtightness Criteria. 2013. Available online: http://www.kiaebs.org/html/sub08_1.jsp?ncode=a001&num=104 (accessed on 14 March 2018).

- Kim, C.H.; Kim, K.S. Evaluation of thermal and visual environment for the glazing and shading device in an office building with installed of venetian blind. Korea Inst. Ecol. Archit. Environ. 2015, 15, 101–109. [Google Scholar] [CrossRef]

- Taylor, S.T.; Stein, J.; Paliaga, G.; Cheng, H. Dual Maximum VAV Box Control Logic. ASHRAE J. 2012, 54, 16. [Google Scholar]

- Pang, X.; Piette, M.A.; Zhou, N. Characterizing variations in variable air volume system controls. Energy Build. 2017, 135, 166–175. [Google Scholar] [CrossRef]

- Son, J.E.; Lee, K.H. Cooling energy performance analysis depending on the economizercycle control methods in an office building. Energy Build. 2016, 120, 45–57. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, L. Energy analysis on VAV system with different air-side economizers in China. Energy Build. 2010, 42, 1220–1230. [Google Scholar] [CrossRef]

- Air-Conditioning, Heating, and Refrigeration Institute (AHRI). AHRI Guideline V, Calculating the Efficiency of Energy Recovery Ventilation and Its Effect on Efficiency and Sizing of Building HVAC Systems; AHRI: Arlington, TX, USA, 2011. [Google Scholar]

- Ministry of Trade, Industry and Energy (MOTIE). Regulation on Promoting the Supply of High-Efficiency energy Equipment; MOTIE: Sejong-si, Korea, 2017. [Google Scholar]

- Zhang, J.; Fung, A.S.; Jhingan, S. Analysis and feasibility study of residential integrated heat and energy recovery ventilator with built-in economizer using an excel spreadsheet program. Energy Build. 2014, 75, 430–438. [Google Scholar] [CrossRef]

- Kim, C.H.; Lee, S.E.; Kim, K.S. Evaluation of energy conservation rate in a energy recovery ventilator according to by-pass control. In Proceedings of the KIAEBS 2015 Fall Annual Conference, Busan, Korea, 13 November 2015; Korean Institute of Architectural Sustainable Environment and Building Systems (KIAEBS): Seoul, Korea, 2015. [Google Scholar]

- Pasut, W.; Bauman, F.; De Carli, M. The use of ducts to improve the control of supply air temperature rise in UFAD systems: CFD and lab study. Appl. Energy 2014, 134, 490–498. [Google Scholar] [CrossRef]

- Yu, K.H. A Study of Optimal Design in Underfloor Air Distribution System with Plenum Chamber. Ph.D. Dissertation, Hanyang University, Seoul, Korea, 2016. [Google Scholar]

- Yu, K.H.; Yoon, S.H.; Jung, H.K.; Kim, K.H.; Song, K.D. Influence of lighting loads upon thermal comfort under CBAD and UFAD systems. Energies 2015, 8, 6079–6097. [Google Scholar] [CrossRef]

- Korea Hanmi Publishing Company. Monthly Journal of Equipment Technology; Korea Hanmi Publishing Company: Seoul, Korea, 2013; ISSN 1739-5836. [Google Scholar]

- Virta, M.; Butler, D.; Graslund, J.; Hogeling, J.; Kristiansen, E.L.; Reinikainen, M.; Svensson, G. Chilled Beam Application Guidebook; Federation of European Heating, Ventilation and Air-conditioning Associations (REHVA): Brussels, Belgium, 2006; ISBN 978-2960046830. [Google Scholar]

- Rhee, K.N.; Shin, M.S.; Choi, S.H. Thermal uniformity in an open plan room with an active chilled beam system and conventional air distribution systems. Energy Build. 2015, 93, 236–248. [Google Scholar] [CrossRef]

- Rhee, K.N.; Choi, S.H.; Kim, C.H. Comparative evaluation of the thermal uniformity in a space with active chilled beam and conventional air conditioning systems. J. Archit. Inst. Korea Plan. Des. 2014, 30, 199–206. [Google Scholar] [CrossRef]

- Kim, C.H.; Lee, S.E.; Yu, K.H.; Kim, K.S. An analysis of the energy performance and thermal comfort in an office building with active chilled beam system. In Proceedings of the SAREK 2016 Summer Annual Conference, Pyeongchang, Korea, 22–24 June 2016; The Society of Air-Conditioning and Refrigerating Engineers of Korea (SAREK): Seoul, Korea, 2016. [Google Scholar]

- Weiss, M.; Dittmar, L.; Junginger, M.; Patel, M.K.; Blok, K. Market diffusion, technological learning, and cost-benefit dynamics of condensing gas boilers in the Netherlands. Energy Policy 2009, 37, 2962–2976. [Google Scholar] [CrossRef]

- Satyavada, H.; Baldi, S. Monitoring energy efficiency of condensing boilers via hybrid first-principle modelling and estimation. Energy 2018, 142, 121–129. [Google Scholar] [CrossRef]

- Tran, D.A.T.; Chen, Y.; Chau, M.Q.; Ning, B. A robust online fault detection and diagnosis strategy of centrifugal chiller systems for building energy efficiency. Energy Build. 2015, 108, 441–453. [Google Scholar] [CrossRef]

- Wang, H. Empirical model for evaluating power consumption of centrifugal chillers. Energy Build. 2017, 140, 359–370. [Google Scholar] [CrossRef]

- Korea Energy Agency (KEA). Energy GHG Technology Information Platform Service, Saving Technology DB. Available online: http://tips.energy.or.kr/main/main.aspx (accessed on 14 March 2018).

- The Society of Air-Conditioning and Refrigerating Engineers of Korea (SAREK). Planning Technology Roadmap for Refrigeration Sector Final Report; SAREK: Seoul, Korea, 2008. [Google Scholar]

- Ministry of Trade, Industry and Energy (MOTIE). Act on the Development, Utilization and Promotion of New Renewable Energy; MOTIE: Sejong-si, Korea, 2017. [Google Scholar]

- Korean Standards Association (KSA). KS B ISO 13256-2 Part 2 Water-to-Water and Brine-to-Water Heat Pumps; KSA: Seoul, Korea, 2014. [Google Scholar]

- Gschwend, A.; Menzi, T.; Caskey, S.; Groll, E.A.; Bertsch, S.S. Energy consumption of cold climate heat pumps in different climates–Comparison of single-stage and two-stage systems. Int. J. Refrigeration 2016, 62, 193–206. [Google Scholar] [CrossRef]

- Miara, M.; Cunther, D.; Langner, R.; Helmling, S. Efficiency of Heat Pumps in Real Operating Conditions–Results of three Monitoring Campaigns in Germany; Federation of European Heating, Ventilation and Air-conditioning Associations (REHVA) Journal: Brussels, Belgium, 2014. [Google Scholar]

- Walter, T.; Sohn, M.D. A regression-based approach to estimating retrofit savings using the Building Performance Database. Appl. Energy 2016, 179, 996–1005. [Google Scholar] [CrossRef]

- Sandberg, N.H.; Sartori, I.; Heidrich, O.; Dawson, R.; Dascalaki, E.; Dimitriou, S.; Vimm-r, T.; Filippidou, F.; Stegnar, G.; Šijanec Zavrl, M.; et al. Dynamic building stock modelling: Application to 11 European countries to support the energy efficiency and retrofit ambitions of the EU. Energy Build. 2016, 132, 26–38. [Google Scholar] [CrossRef]

- Asadi, E.; Da Silva, M.G.; Antunes, C.H.; Dias, L. Multi-objective optimization for building retrofit strategies: A model and an application. Energy Build. 2012, 44, 81–87. [Google Scholar] [CrossRef]

- Morofsky, E.; Cane, D. Low-energy building design, economics and the role of energy storage. In Proceedings of the 9th International Conference on Thermal Storage, Warsaw, Poland, 1–4 September 2003; Warsaw University of Technology, Institute of Heat Engineering: Warsaw, Poland, 2013. [Google Scholar]

- Ferrara, M.; Fabrizio, E.; Virgone, J.; Filippi, M. A simulation-based optimization method for cost-optimal analysis of nearly Zero Energy Buildings. Energy Build. 2014, 84, 442–457. [Google Scholar] [CrossRef]

- Kneifel, J. Life-cycle carbon and cost analysis of energy efficiency measures in new commercial buildings. Energy Build. 2010, 42, 333–340. [Google Scholar] [CrossRef]

- Cho, J.K.; Shin, S.H.; Kim, J.H.; Hong, H.K. Development of an energy evaluation methodology to make multiple predictions of the HVAC&R system energy demand for office buildings. Energy Build. 2014, 80, 169–183. [Google Scholar] [CrossRef]

- National Assembly Research Service (NARS). Status of Zero Energy Buildings and Improvement Tasks; NARS: Seoul, Korea, 2017. [Google Scholar]

- Ministry of Land, Infrastructure and Transport (MOLIT); Korea Institute of Civil Engineering and Building Technology (KICT). A Study on the Improvement and Supporting System for the Activation of Zero Energy Building; KICT: Sejong-si, Korea, 2017. [Google Scholar]

- Hamdy, M.; Hasan, A.; Siren, K. A multi-stage optimization method for cost-optimal and nearly-zero-energy building solutions in line with the EPBD-recast 2010. Energy Build. 2013, 56, 189–203. [Google Scholar] [CrossRef]

- Kurnitski, J.; Saari, A.; Kalamees, T.; Vuolle, M.; Niemelä, J.; Tark, T. Cost optimal and nearly zero (nZEB) energy performance calculations for residential buildings with REHVA definition for nZEB national implementation. Energy Build. 2011, 43, 3279–3288. [Google Scholar] [CrossRef]

- Congedo, P.M.; D’Agostino, D.; Baglivo, C.; Tornese, G.; Zacà, I. Efficient solutions and cost-optimal analysis for existing school buildings. Energies 2016, 9, 851. [Google Scholar] [CrossRef]

- Congedo, P.M.; Baglivo, C.; D’Agostino, D.; Zacà, I. Cost-optimal design for nearly zero energy office buildings located in warm climates. Energy 2015, 91, 967–982. [Google Scholar] [CrossRef]

- Sanchez, M.C.; Brown, R.E.; Webber, C.; Homan, G.K. Savings estimates for the United States Environmental Protection Agency’s ENERGY STAR voluntary product labeling program. Energy Policy 2008, 36, 2098–2108. [Google Scholar] [CrossRef]

- Residential Energy Services Network (RESNET). Available online: http://www.hersindex.com/ (accessed on 25 March 2018).

- Solar America Cities Program. Available online: http://www.solarknoxville.org/program/ (accessed on 25 March 2018).

- Federal Ministry for Economic Affairs and Energy. Available online: https://www.bmwi.de/Redaktion/EN/Artikel/Energy/nape-neuerungen-im-ueberblick-01-03.html (accessed on 25 March 2018).

- Department of Energy & Climate Change. Evaluation of the Low Carbon Buildings Programme, Undertaken by Ipsos MORI and CAG consultants for the Department of Energy and Climate Change; Department of Energy & Climate Change: London, UK, 2011. [Google Scholar]

- Ministère de la Transition Écologique et Solidaire. Available online: https://www.ecologique-solidaire.gouv.fr/eco-pret-taux-zero-eco-ptz (accessed on 25 March 2018).

- Ayoub, N.; Yuji, N. Governmental intervention approaches to promote renewable energies—Special emphasis on Japanese feed-in tariff. Energy Policy 2012, 43, 191–201. [Google Scholar] [CrossRef]

- Korea Energy Economics Institute. Examples of Policy and Implications of Building Energy in Major Countries, Energy Focus; Korea Energy Economics Institute: Seoul, Korea, 2013. [Google Scholar]

- Ministry of Land, Infrastructure and Transport (MOLIT); Korea Institute of Civil Engineering and Building Technology (KICT). Study on Greenhouse Gas Reduction Plan for Climate Change Response Buildings; KICT: Gyeonggi-Do, Korea, 2009. [Google Scholar]

| Regions | ASHRAE Climate | Köppen Climate | Latitude N (°) Longitude E (°) | Outdoor Air Temperature (Monthly Average) Min/Avg/Max (°C) | Relative Humidity (Monthly Average) Min/Avg/Max (%) | HDD (18 °C) | CDD (10 °C) |

|---|---|---|---|---|---|---|---|

| Incheon | 4A (Mixed-Moist) | Dwa | 37.45/126.70 | −2.2/12.7/27.5 | 46.5/68.8/87.6 | 2749 | 2327 |

| Jeju | 3A (Warm-Moist) | Cfa | 33.49/126.46 | 4.1/18.6/31.4 | 53.1/73.5/92.1 | 1621 | 2632 |

| Level | Primary Energy Consumption Per Unit Area (kWh/m²·a) | Level | Primary Energy Consumption Per Unit Area (kWh/m²·a) |

|---|---|---|---|

| 1+++ | E < 80 | 3 | 320 ≤ E < 380 |

| 1++ | 80 ≤ E < 140 | 4 | 380 ≤ E < 450 |

| 1+ | 140 ≤ E < 200 | 5 | 450 ≤ E < 520 |

| 1 | 200 ≤ E < 260 | 6 | 520 ≤ E < 610 |

| 2 | 260 ≤ E < 320 | 7 | 610 ≤ E < 700 |

| Energy Supply Sector | Primary Energy Factors in Korea |

|---|---|

| Fuel (coal, oil, gas) | 1.1 |

| Electric power | 2.75 |

| District heating | 0.728 |

| District cooling | 0.937 |

| World | 1990 | 1995 | 2000 | 2005 | 2010 | 2014 | 2015 | Growth Rate 1990–2015 |

|---|---|---|---|---|---|---|---|---|

| Korea | 231.7 | 357.1 | 431.7 | 457.5 | 550.7 | 567.8 | 586.0 | 152.9% |

| OECD Asia Oceania | 1588.0 | 1821.2 | 1991.5 | 2099.6 | 2150.6 | 2218.0 | 2201.9 | 38.7% |

| OECD Europe | 3924.1 | 3833.2 | 3899.4 | 4037.2 | 3801.6 | 3397.8 | 3447.6 | −12.1% |

| OECD Americas | 5508.3 | 5850.4 | 6567.0 | 6710.2 | 6384.4 | 6232.4 | 6060.7 | 10.2% |

| Energy Supply Sector | CO2 Emission Factors (kgCO2/TJ) | CO2 Emission Factors (kgCO2/kWh) |

|---|---|---|

| Electric power | 129,631 | 0.4663 |

| LNG(Natural gas) | 56,467 | 0.2031 |

| Gas/Diesel oil | 72,600 | 0.2612 |

| Primary Energy Consumptions in Incheon and Jeju (kWh/m2a) | |||

|---|---|---|---|

| Incheon | Jeju | ||

| Heating energy | 126.5 | Heating energy | 104.6 |

| Cooling energy | 198.7 | Cooling energy | 247.9 |

| Fan & Other energy | 76.8, 62.0 | Fan & Other energy | 74.0, 58.5 |

| Total energy | 464.1 (Level 5) | Total energy | 485.1 (Level 5) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.-H.; Lee, S.-E.; Kim, K.-S. Analysis of Energy Saving Potential in High-Performance Building Technologies under Korean Climatic Conditions. Energies 2018, 11, 884. https://doi.org/10.3390/en11040884

Kim C-H, Lee S-E, Kim K-S. Analysis of Energy Saving Potential in High-Performance Building Technologies under Korean Climatic Conditions. Energies. 2018; 11(4):884. https://doi.org/10.3390/en11040884

Chicago/Turabian StyleKim, Chul-Ho, Seung-Eon Lee, and Kang-Soo Kim. 2018. "Analysis of Energy Saving Potential in High-Performance Building Technologies under Korean Climatic Conditions" Energies 11, no. 4: 884. https://doi.org/10.3390/en11040884

APA StyleKim, C.-H., Lee, S.-E., & Kim, K.-S. (2018). Analysis of Energy Saving Potential in High-Performance Building Technologies under Korean Climatic Conditions. Energies, 11(4), 884. https://doi.org/10.3390/en11040884