Current Signature and Vibration Analyses to Diagnose an In-Service Wind Turbine Drive Train

Abstract

:1. Introduction

2. Fault Diagnosis Techniques for Drive Trains and Induction Generators

3. Methods

3.1. Current Signature Analysis

3.2. Vibration Analysis

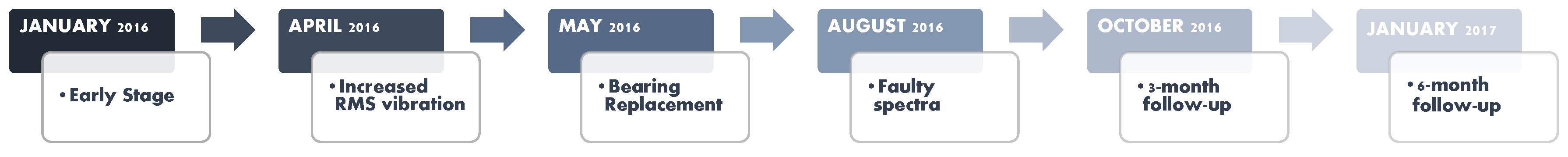

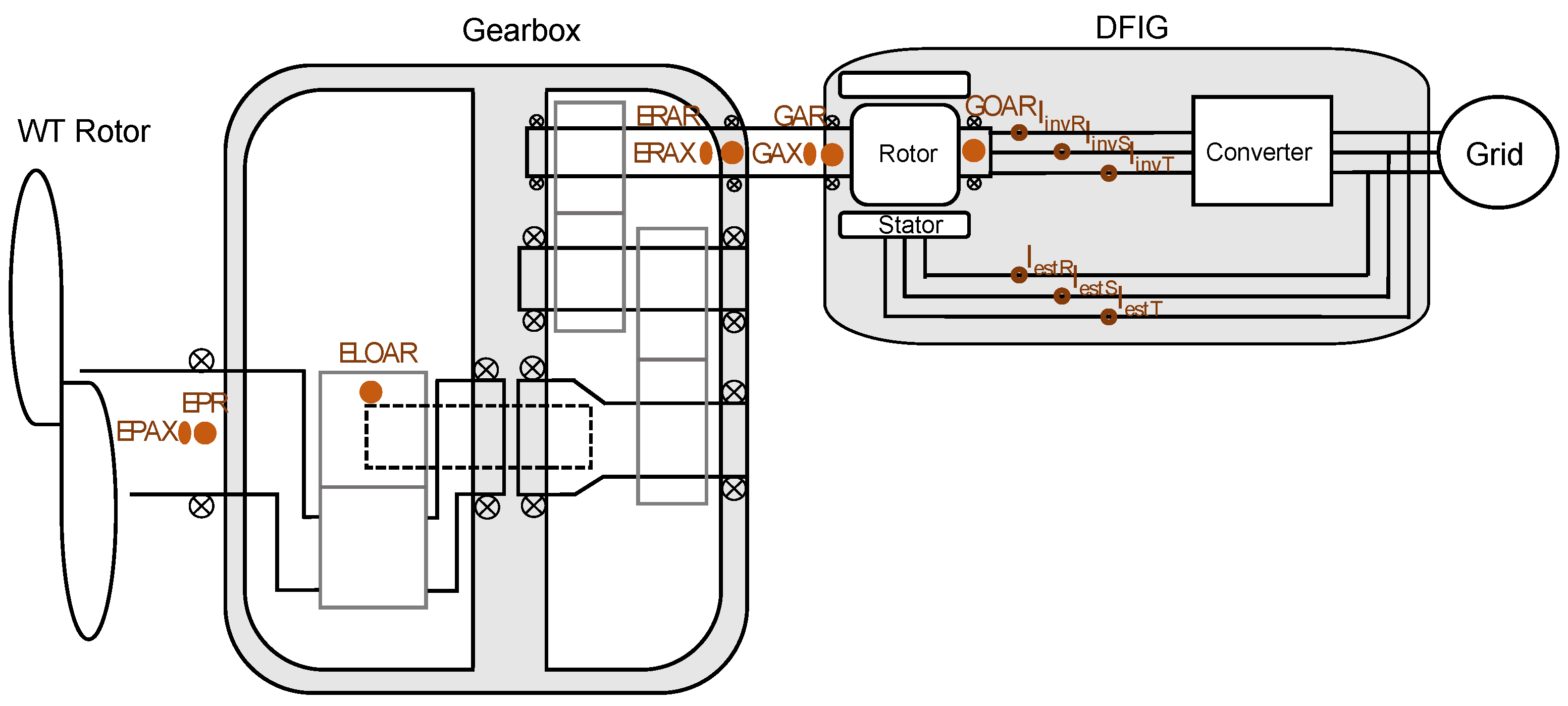

4. Data Base Description of In-Service Wind Turbine

5. Spectral Analysis through Currents and Vibrations

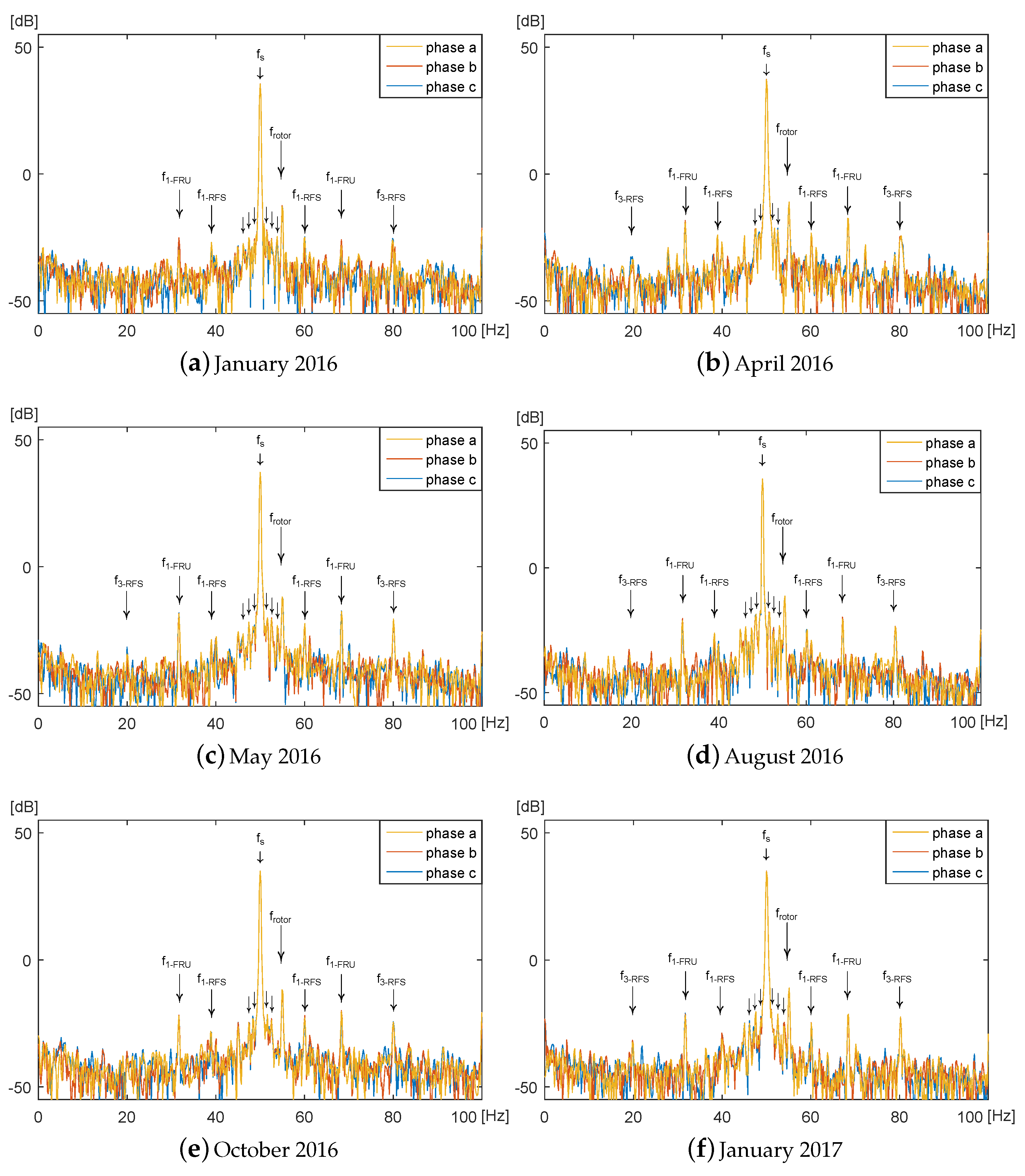

5.1. Current Signature Analysis

5.1.1. Loading Condition A

- Certain harmonics that might be related to damaged teeth, scoring or debris (, Equation (3)), appear around the supply frequency. These seem to increase until August 2016, both in number of harmonic pairs found as well as in their amplitude levels, which then improve (the number of harmonic pairs decreases) but not completely in September and October 2016, increasing again up to January 2017. Gearbox lubrication during scheduled maintenance would explain this.

- With regards to rotor electrical unbalance (, Equation (2)), only the first pair can be identified in the spectrum. Since no more harmonics () can be identified, as previously explained, rotor electrical unbalance cannot be diagnosed.

- For rotor mechanical asymmetries (, Equation (1)) more than one (the first) pair is present in the spectra. In January 2016, apart from the first harmonic pair (), the right side of the third harmonic pair () can be seen in the spectra. Later, from April 2016 to August 2016, the full third pair is seen ( and ). In September and October 2016, again only the right side of the third harmonic pair () is found besides the first pair (). Later, in January 2017, again and harmonics are identified. According to the literature [21,55], the presence of this third harmonic pair confirms rotor unbalance of mechanical nature.

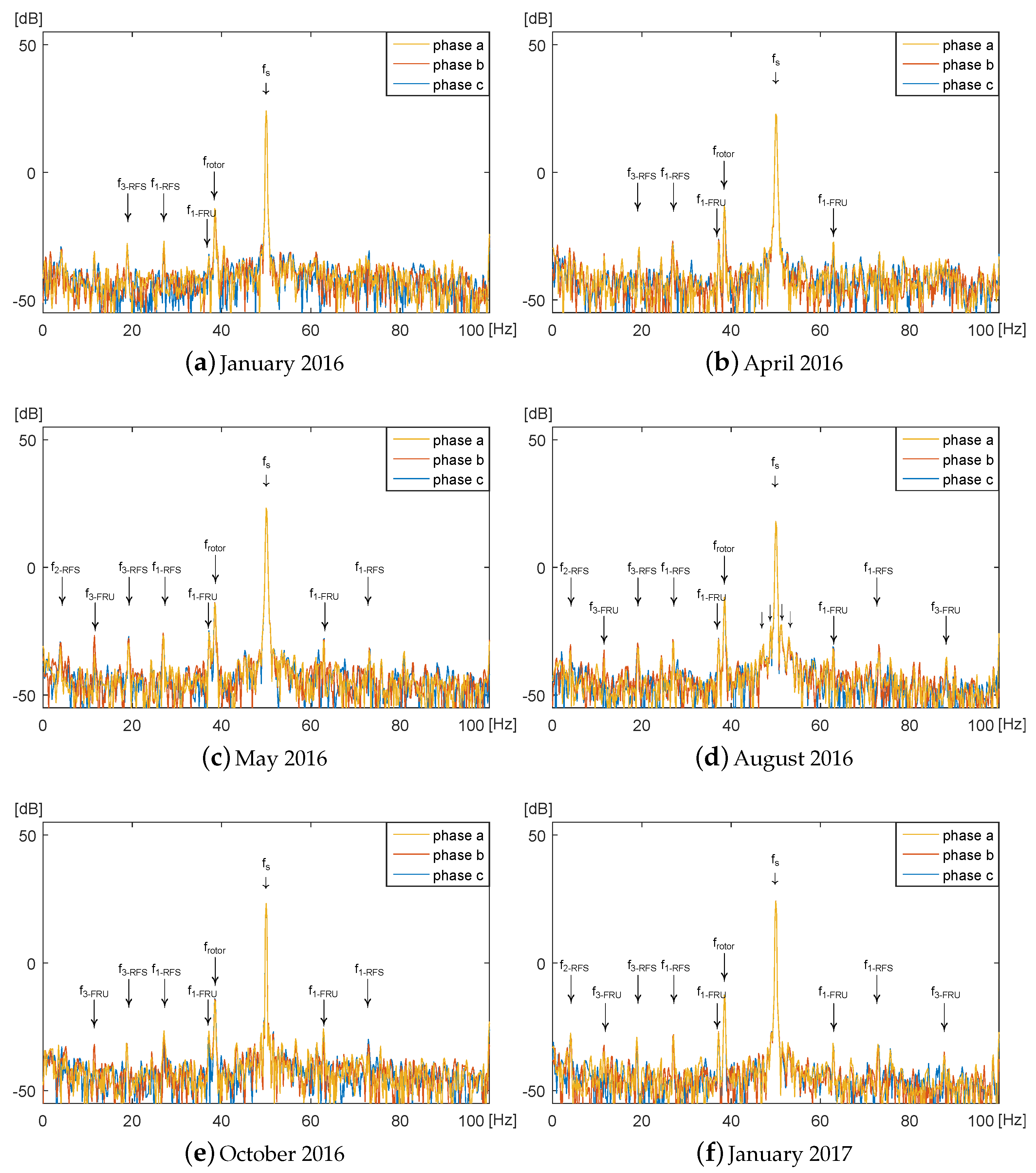

5.1.2. Loading Condition B

- Around the supply frequency, only two harmonic pairs are found for in August 2016. This month is therefore the most affected according to both loading conditions.

- The presence of rotor electrical unbalance components () is also different. In this case, more than the first pair is seen from May 2016 onwards. However, this further pair (, or the left side of this pair in some cases) does not appear in each of the three current phases, being present in only one or two of them. This is explained by the fact that mechanical unbalances induce differences in the magnetic field, and hence also in the electrical currents through each phase, but not evenly, with these being more evident at lower loads [22,46]. Therefore, rotor electrical unbalance cannot be determined.

- With regards to rotor mechanical asymmetries (), although the pairs found, apart from the first one (), differ from those found at full load, their evolution is alike: they seem to evolve until August 2016, then improve (less harmonic pairs found) immediately afterwards, and then worsen (again more harmonics) until January 2017.

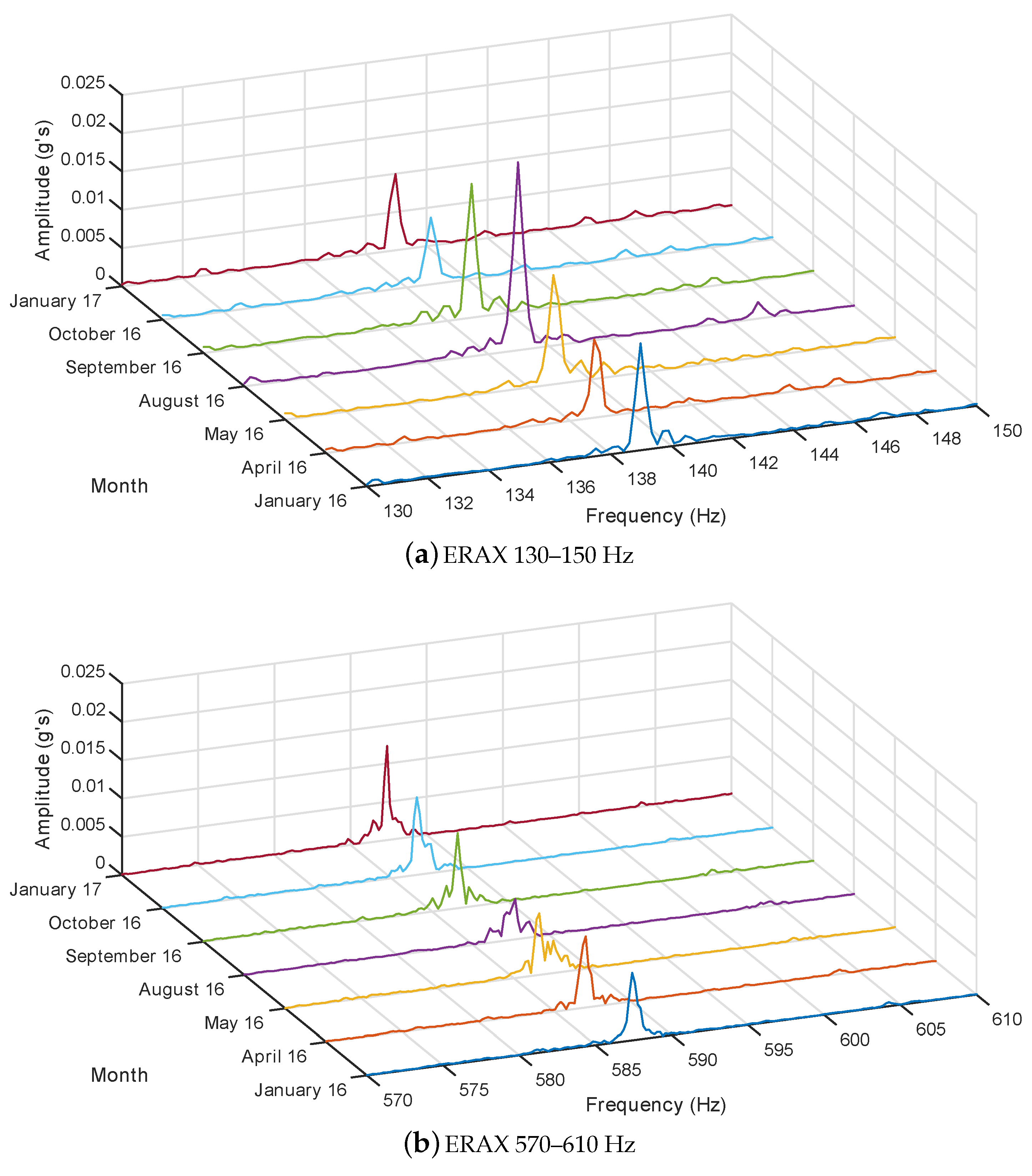

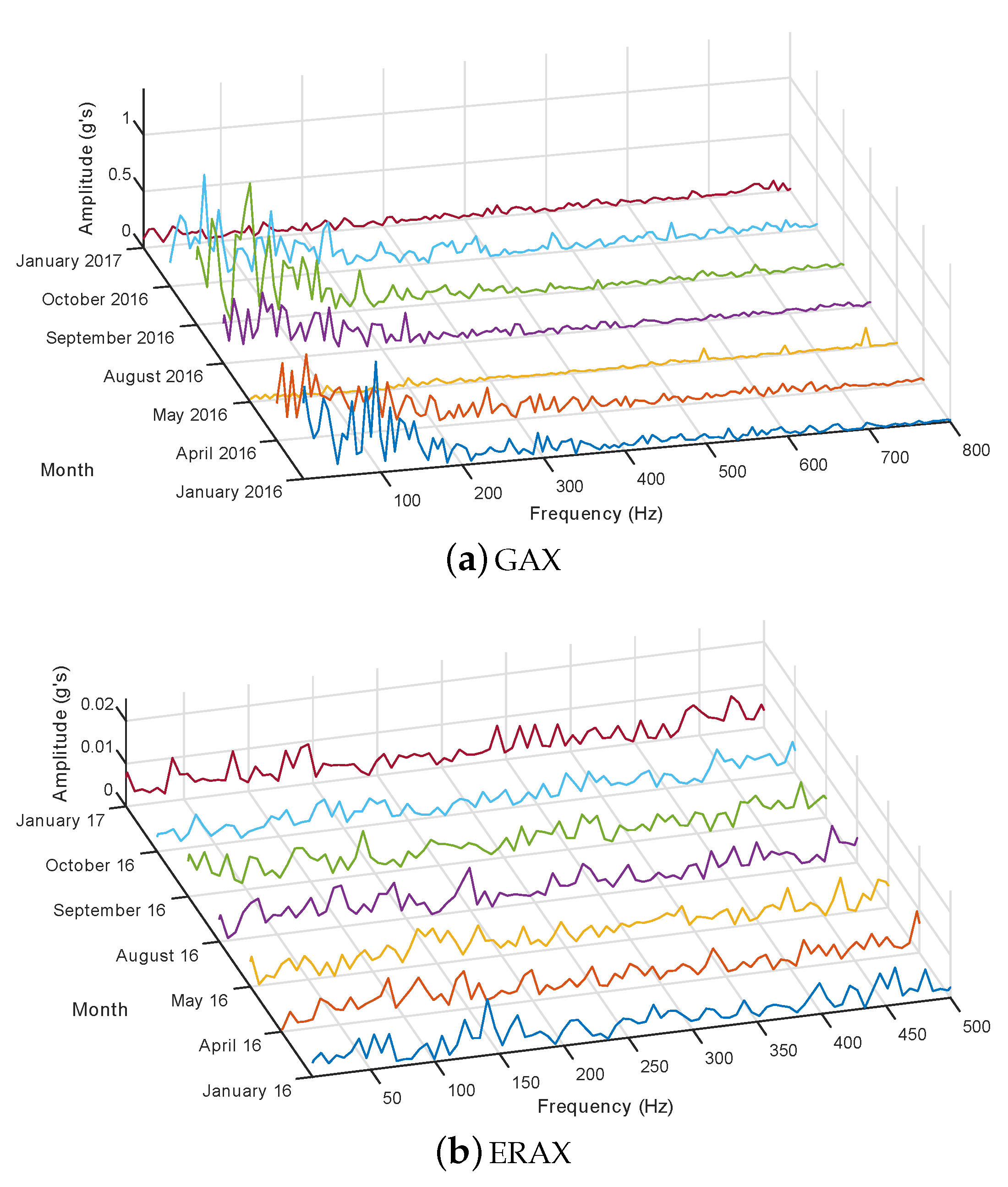

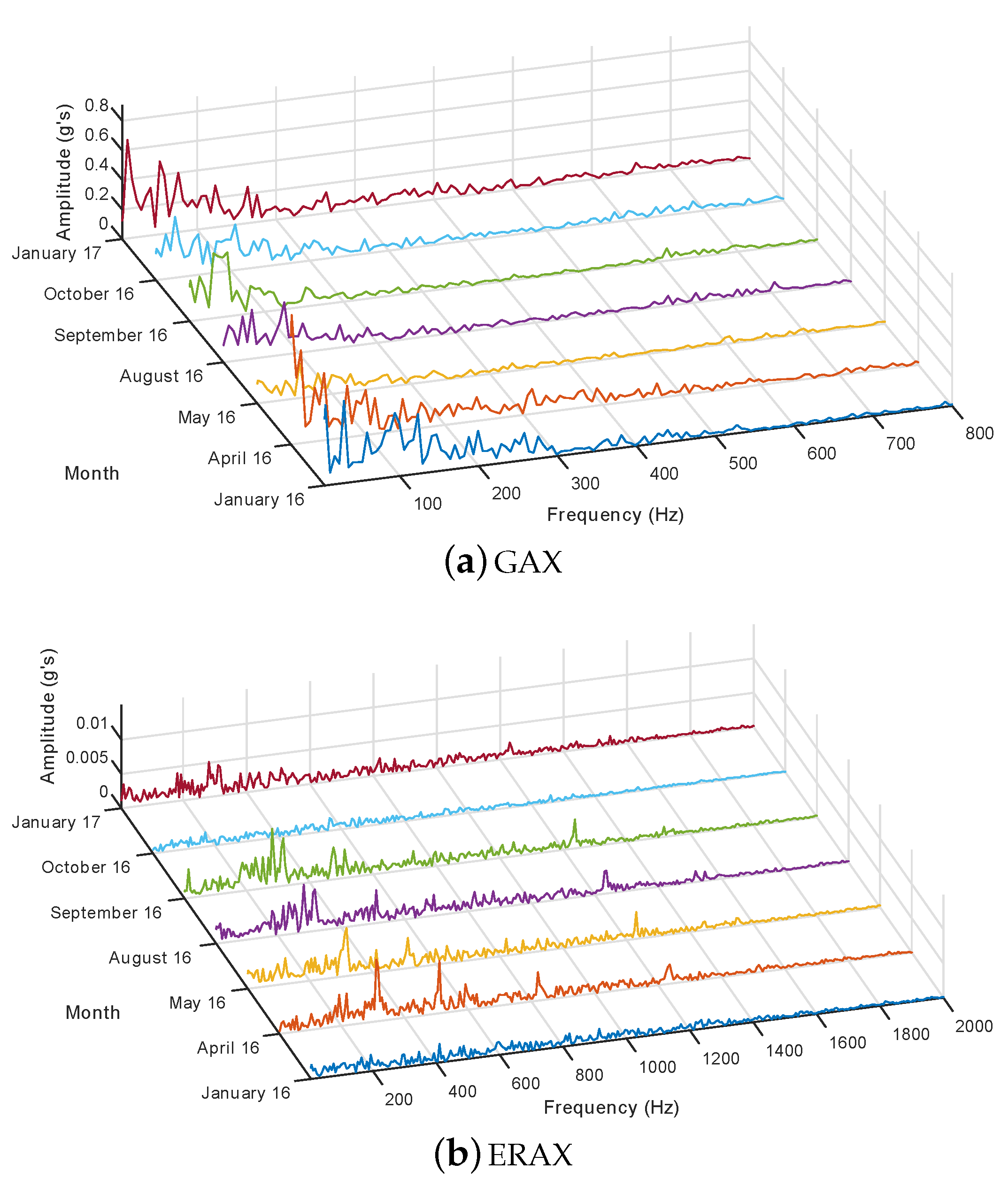

5.2. Vibration Analysis

5.2.1. Loading Condition A

5.2.2. Loading Condition B

5.3. Results and Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| Bearing ball contact angle | |

| B | Bearing ball diameter |

| Bearing fault frequency | |

| Outer-ball passing frequency | |

| Bearing ball spin frequency | |

| Gearbox mesh j fault frequency | |

| Rotor electrical unbalance fault frequency | |

| Gearbox shaft i fault frequency | |

| Fundamental train frequency | |

| Gearbox fault frequency | |

| Bearing inner-race fault frequency | |

| Gearbox mesh j rotating frequency | |

| Bearing outer-race fault frequency | |

| Rotor mechanical asymmetry fault frequency | |

| Gearbox shaft i rotating frequency | |

| Supply frequency | |

| Gearbox ratio | |

| Inner-ball passing frequency | |

| Number of bearing balls | |

| Number of teeth in mesh j | |

| P | Bearing ball pitch diameter |

| p | Number of pole pairs |

| s | Slip |

References

- Honrubia-Escribano, A.; Gomez-Lazaro, E.; Fortmann, J.; Sorensen, P.; Martin-Martinez, S. Generic dynamic wind turbine models for power system stability analysis: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 81, 1939–1952. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Sinha, Y.; Steel, J. A progressive study into offshore wind farm maintenance optimisation using risk based failure analysis. Renew. Sustain. Energy Rev. 2015, 42, 735–742. [Google Scholar] [CrossRef]

- Kabir, M.J.; Oo, A.M.; Rabbani, N. A brief review on offshore wind turbine fault detection and recent development in condition monitoring based maintenance system. In Proceedings of the IEEE Power Engineering Conference AUPEC, Wollongong, Australia, 27–30 September 2015; pp. 1–7. [Google Scholar]

- Pérez, J.M.P.; Márquez, F.P.G.; Tobias, A.; Papaelias, M. Wind turbine reliability analysis. Renew. Sustain. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Warner, E. Global Wind Report. Annual Market Update; Technical Report; Global Wind Energy Council: Brussels, Belgium, 2015. [Google Scholar]

- Pozo, F.; Vidal, Y. Wind turbine fault detection through principal component analysis and statistical hypothesis testing. Energies 2016, 9, 3. [Google Scholar] [CrossRef] [Green Version]

- Pozo, F.; Vidal, Y.; Serrahima, J.M. On real-time fault detection in wind turbines: Sensor selection algorithm and detection time reduction analysis. Energies 2016, 9, 520. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, X. Simultaneous fault detection and sensor selection for condition monitoring of wind turbines. Energies 2016, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Rubert, T.; McMillan, D.; Niewczas, P. A decision support tool to assist with lifetime extension of wind turbines. Renew. Energy 2017, 120, 423–433. [Google Scholar] [CrossRef]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2017, 82, 1261–1271. [Google Scholar] [CrossRef]

- Tautz-Weinert, J.; Watson, S.J. Using SCADA data for wind turbine condition monitoring—A review. IET Renew. Power Gener. 2016, 11, 382–394. [Google Scholar] [CrossRef]

- Pozo, F.; Vidal, Y.; Salgado, O. Wind Turbine Condition Monitoring Strategy through Multiway PCA and Multivariate Inference. Energies 2018, 11, 749. [Google Scholar] [CrossRef]

- Pei, Y.; Qian, Z.; Jing, B.; Kang, D.; Zhang, L. Data-Driven Method for Wind Turbine Yaw Angle Sensor Zero-Point Shifting Fault Detection. Energies 2018, 11, 553. [Google Scholar] [CrossRef]

- Carroll, J.; McDonald, A.; McMillan, D. Failure rate, repair time and unscheduled O&M cost analysis of offshore wind turbines. Wind Energy 2015, 19, 1107–1119. [Google Scholar] [Green Version]

- Márquez, F.P.G.; Pérez, J.M.P.; Marugán, A.P.; Papaelias, M. Identification of critical components of wind turbines using FTA over the time. Renew. Energy 2016, 87, 869–883. [Google Scholar] [CrossRef]

- Kia, S.H.; Henao, H.; Capolino, G.A. Survey of real-time fault diagnosis techniques for electromechanical systems. In Proceedings of the IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Nottingham, UK, 20–21 April 2017; pp. 290–297. [Google Scholar]

- Romero-Troncoso, R.J.; Saucedo-Gallaga, R.; Cabal-Yepez, E.; Garcia-Perez, A.; Osornio-Rios, R.A.; Alvarez-Salas, R.; Miranda-Vidales, H.; Huber, N. FPGA-based online detection of multiple combined faults in induction motors through information entropy and fuzzy inference. IEEE Trans. Ind. Electron. 2011, 58, 5263–5270. [Google Scholar] [CrossRef]

- Cheng, F.; Qu, L.; Qiao, W. Fault Prognosis and Remaining Useful Life Prediction of Wind Turbine Gearboxes Using Current Signal Analysis. IEEE Trans. Sustain. Energy 2017, 9. [Google Scholar] [CrossRef]

- Kia, S.H.; Henao, H.; Capolino, G.A. Gear tooth surface damage fault detection using induction machine electrical signature analysis. In Proceedings of the 9th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Valencia, Spain, 27–30 August 2013; pp. 358–364. [Google Scholar]

- Kia, S.H.; Henao, H.; Capolino, G.A. Fault index statistical study for gear fault detection using stator current space vector analysis. IEEE Trans. Ind. Appl. 2016, 52, 4781–4788. [Google Scholar] [CrossRef]

- Choi, S.; Akin, B.; Rahimian, M.M.; Toliyat, H.A. Implementation of a fault-diagnosis algorithm for induction machines based on advanced digital-signal-processing techniques. IEEE Trans. Ind. Electron. 2011, 58, 937–948. [Google Scholar] [CrossRef]

- Choi, S.; Akin, B.; Rahimian, M.M.; Toliyat, H.A. Performance-oriented electric motors diagnostics in modern energy conversion systems. IEEE Trans. Ind. Electron. 2012, 59, 1266–1277. [Google Scholar] [CrossRef]

- Neti, P.; Zhang, P.; Shah, M.; Younsi, K. Electrical signature analysis based online monitoring of drive-trains for doubly-fed wind generators. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society (IECON), Montreal, QC, Canada, 25–28 October 2012. [Google Scholar]

- Zhang, P.; Neti, P. Detection of gearbox bearing defects using electrical signature analysis for Doubly-fed wind generators. In Proceedings of the Energy Conversion Congress and Exposition (ECCE), Denver, CO, USA, 15–19 September 2013; pp. 4438–4444. [Google Scholar]

- Sheng, S. Wind Turbine Gearbox Condition Monitoring Round Robin Study-Vibration Analysis; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2012.

- Siegel, D.; Zhao, W.; Lapira, E.; AbuAli, M.; Lee, J. A comparative study on vibration-based condition monitoring algorithms for wind turbine drive trains. Wind Energy 2014, 17, 695–714. [Google Scholar] [CrossRef]

- Randall, R. Cepstrum analysis and gearbox fault-diagnosis. Maint. Manag. Int. 1982, 3, 183–208. [Google Scholar]

- Bechhoefer, E.; Kingsley, M. A review of time synchronous average algorithms. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September 2009; pp. 24–33. [Google Scholar]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics:a tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Xu, B.; Sun, L.; Xu, L.; Xu, G. Improvement of the Hilbert method via ESPRIT for detecting rotor fault in induction motors at low slip. IEEE Trans. Energy Convers. 2013, 28, 225–233. [Google Scholar] [CrossRef]

- Dahiya, R.; Himani. Condition monitoring of wind turbine for rotor fault detection under non stationary conditions. Ain Shams Eng. J. 2017. [Google Scholar] [CrossRef]

- Sapena-Baño, A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Martinez-Roman, J.; Matic, D. Fault diagnosis of rotating electrical machines in transient regime using a single stator current’s FFT. IEEE Trans. Instrum. Meas. 2015, 64, 3137–3146. [Google Scholar] [CrossRef]

- Lu, D.; Qiao, W.; Gong, X. Current-Based Gear Fault Detection for Wind Turbine Gearboxes. IEEE Trans. Sustain. Energy 2017. [Google Scholar] [CrossRef]

- Shahriar, M.R.; Borghesani, P.; Ledwich, G.; Tan, A.C. Performance analysis of electrical signature analysis-based diagnostics using an electromechanical model of wind turbine. Renew. Energy 2018, 116, 15–41. [Google Scholar] [CrossRef]

- Artigao, E.; Honrubia-Escribano, A.; Gomez-Lazaro, E. Current signature analysis to monitor DFIG wind turbine generators: A case study. Renew. Energy 2018, 116, 5–14. [Google Scholar] [CrossRef]

- Gritli, Y.; Stefani, A.; Rossi, C.; Filippetti, F.; Chatti, A. Experimental validation of doubly fed induction machine electrical faults diagnosis under time-varying conditions. Elect. Power Syst. Res. 2011, 81, 751–766. [Google Scholar] [CrossRef]

- Gritli, Y.; Zarri, L.; Rossi, C.; Filippetti, F.; Capolino, G.A.; Casadei, D. Advanced diagnosis of electrical faults in wound-rotor induction machines. IEEE Trans. Ind. Electron. 2013, 60, 4012–4024. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Tassoni, C.; Capolino, G.A. Advances in diagnostic techniques for induction machines. IEEE Trans. Ind. Electron. 2008, 12, 4109–4126. [Google Scholar] [CrossRef]

- Williamson, S.; Djurovic, S. Origins of Stator Current Spectra in DFIGs with Winding Faults and Excitation Asymmetries. In Proceedings of the IEEE International Electric Machines and Drives Conference, IEMDC’09, Miami, FL, USA, 3–6 May 2009; Volume 9, pp. 563–570. [Google Scholar]

- Crabtree, C.J.; Djurovic, S.; Tavner, P.J.; Smith, A. Condition monitoring of a wind turbine DFIG by current or power analysis. In Proceedings of the 5th IET International Conference on Power Electronics, Machines and Drives (PEMD), Brighton, UK, 19–21 April 2010; pp. 1–6. [Google Scholar]

- Crabtree, C.; Djurovic, S.; Tavner, P.; Smith, A. Fault frequency tracking during transient operation of wind turbine generators. In Proceedings of the 2010 XIX International Conference on IEEE Electrical Machines (ICEM), Rome, Italy, 6–8 September 2010; pp. 1–5. [Google Scholar]

- Djurovic, S.; Crabtree, C.J.; Tavner, P.J.; Smith, A. Condition monitoring of wind turbine induction generators with rotor electrical asymmetry. IET Renew. Power Gener. 2012, 6, 207–216. [Google Scholar] [CrossRef]

- Mohanty, A.; Kar, C. Fault detection in a multistage gearbox by demodulation of motor current waveform. IEEE Trans. Ind. Electron. 2006, 53, 1285–1297. [Google Scholar] [CrossRef]

- Rajagopalan, S.; Habetler, T.G.; Harley, R.G.; Sebastian, T.; Lequesne, B. Current/voltage-based detection of faults in gears coupled to electric motors. IEEE Trans. Ind. Appl. 2006, 42, 1412–1420. [Google Scholar] [CrossRef]

- Kia, S.H.; Henao, H.; Capolino, G.A. Gearbox monitoring using induction machine stator current analysis. In Proceedings of the IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Cracow, Poland, 6–8 September 2007; pp. 149–154. [Google Scholar]

- Kar, C.; Mohanty, A.R. Monitoring gear vibrations through motor current signature analysis and wavelet transform. Mech. Syst. Signal Process. 2006, 20, 158–187. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H. A review of induction motors signature analysis as a medium for faults detection. IEEE Trans. Ind. Electron. 2000, 47, 984–993. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H.; Kliman, G.B. What stator current processing-based technique to use for induction motor rotor faults diagnosis? IEEE Trans. Energy Convers. 2003, 18, 238–244. [Google Scholar] [CrossRef]

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor faults. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar] [CrossRef]

- McFadden, P. Detecting fatigue cracks in gears by amplitude and phase demodulation of the meshing vibration. J. Vib. Acoust. Stress Reliab. Des. 1986, 108, 165–170. [Google Scholar] [CrossRef]

- Sudhakar, G.; Sekhar, A. Coupling misalignment in rotating machines: modelling, effects and monitoring. Noise Vib. Worldw. 2009, 40, 17–39. [Google Scholar] [CrossRef]

- Casadei, D.; Filippetti, F.; Rossi, C.; Stefani, A.; Yazidi, A.; Capolino, G.A. Diagnostic Technique based on Rotor Modulating Signals Signature Analysis for Doubly Fed Induction Machines in Wind Generator Systems. IEEE Ind. Appl. 2006, 44, 1525–1532. [Google Scholar]

| Label | Sensor Location | Sensor Type | Sampling Parameters |

|---|---|---|---|

| ELOAR | gearbox planetary stage radial | ||

| EPAX | main shaft axial | Accelerometers | |

| EPR | main shaft radial | IEPE | 1.5 kHz |

| ERAR | gearbox high speed shaft drive end radial | 5.4 s | |

| ERAX | gearbox high speed shaft non drive end axial | ±50 g | |

| GAR | generator drive end radial | 0.5 Hz–10 kHz | 48 kHz |

| GAX | generator drive end axial | 0.17 s | |

| GOAR | generator non drive end radial | ||

| IestR | stator current phase a | Current | |

| IestS | stator current phase b | Transducers | |

| IestT | stator current phase c | 1.5 kHz | |

| IinvR | rotor-side converter current phase a | HOP 2000-SB/SP1 | 5.4 s |

| IinvS | rotor-side converter current phase b | ±3000 A | |

| IinvT | rotor-side converter current phase c |

| Loading Condition A | ||||||

|---|---|---|---|---|---|---|

| January 2016 | April 2016 | May 2016 | August 2016 | October 2016 | January 2017 | |

| Power (kW) | 1061 | 1326 | 1300 | 1066 | 1012 | 1046 |

| Speed shaft (rpm) | 1098 | 1102 | 1098 | 1102 | 1098 | 1098 |

| Slip | ||||||

| Loading Condition B | ||||||

| January 2016 | April 2016 | May 2016 | August 2016 | October 2016 | January 2017 | |

| Power (kW) | 280 | 278 | 276 | 148 | 259 | 294 |

| Speed shaft (rpm) | 769 | 769 | 769 | 769 | 769 | 769 |

| Slip | ||||||

| Month | January 2016 | April 2016 | May 2016 | August 2016 | October 2016 | January 17 |

|---|---|---|---|---|---|---|

| Month | January 2016 | April 2016 | May 2016 | August 2016 | October 2016 | January 2017 |

|---|---|---|---|---|---|---|

| - | - | - | - | - | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Artigao, E.; Koukoura, S.; Honrubia-Escribano, A.; Carroll, J.; McDonald, A.; Gómez-Lázaro, E. Current Signature and Vibration Analyses to Diagnose an In-Service Wind Turbine Drive Train. Energies 2018, 11, 960. https://doi.org/10.3390/en11040960

Artigao E, Koukoura S, Honrubia-Escribano A, Carroll J, McDonald A, Gómez-Lázaro E. Current Signature and Vibration Analyses to Diagnose an In-Service Wind Turbine Drive Train. Energies. 2018; 11(4):960. https://doi.org/10.3390/en11040960

Chicago/Turabian StyleArtigao, Estefania, Sofia Koukoura, Andrés Honrubia-Escribano, James Carroll, Alasdair McDonald, and Emilio Gómez-Lázaro. 2018. "Current Signature and Vibration Analyses to Diagnose an In-Service Wind Turbine Drive Train" Energies 11, no. 4: 960. https://doi.org/10.3390/en11040960