Experimental Investigation into the Effect of Oil Injection on the Performance of a Variable Speed Twin-Screw Compressor

Abstract

:1. Introduction

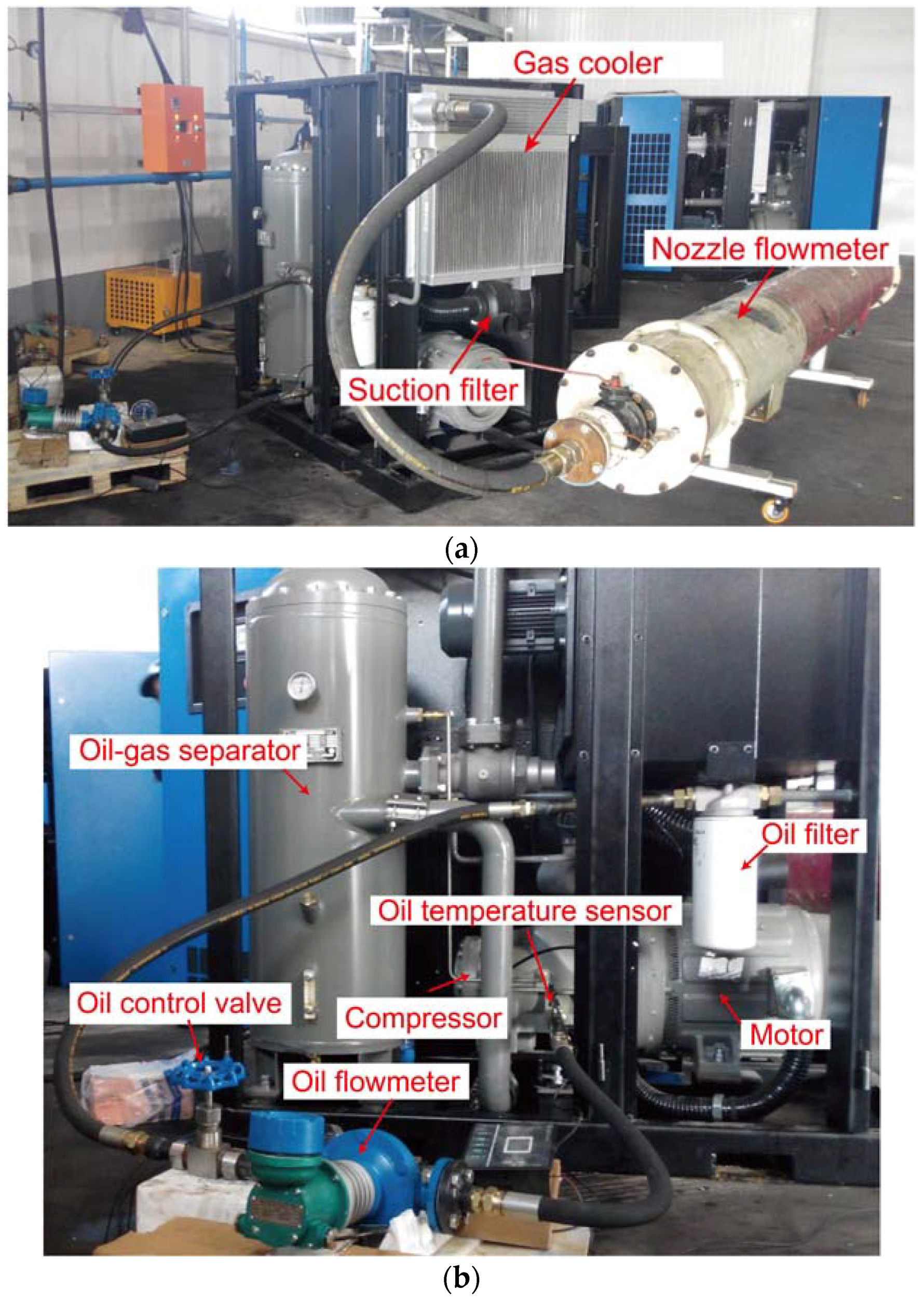

2. Experimental Setup

2.1. Compressor Test System

2.2. Experimental Conditions and Data Reduction

2.3. Error Analysis

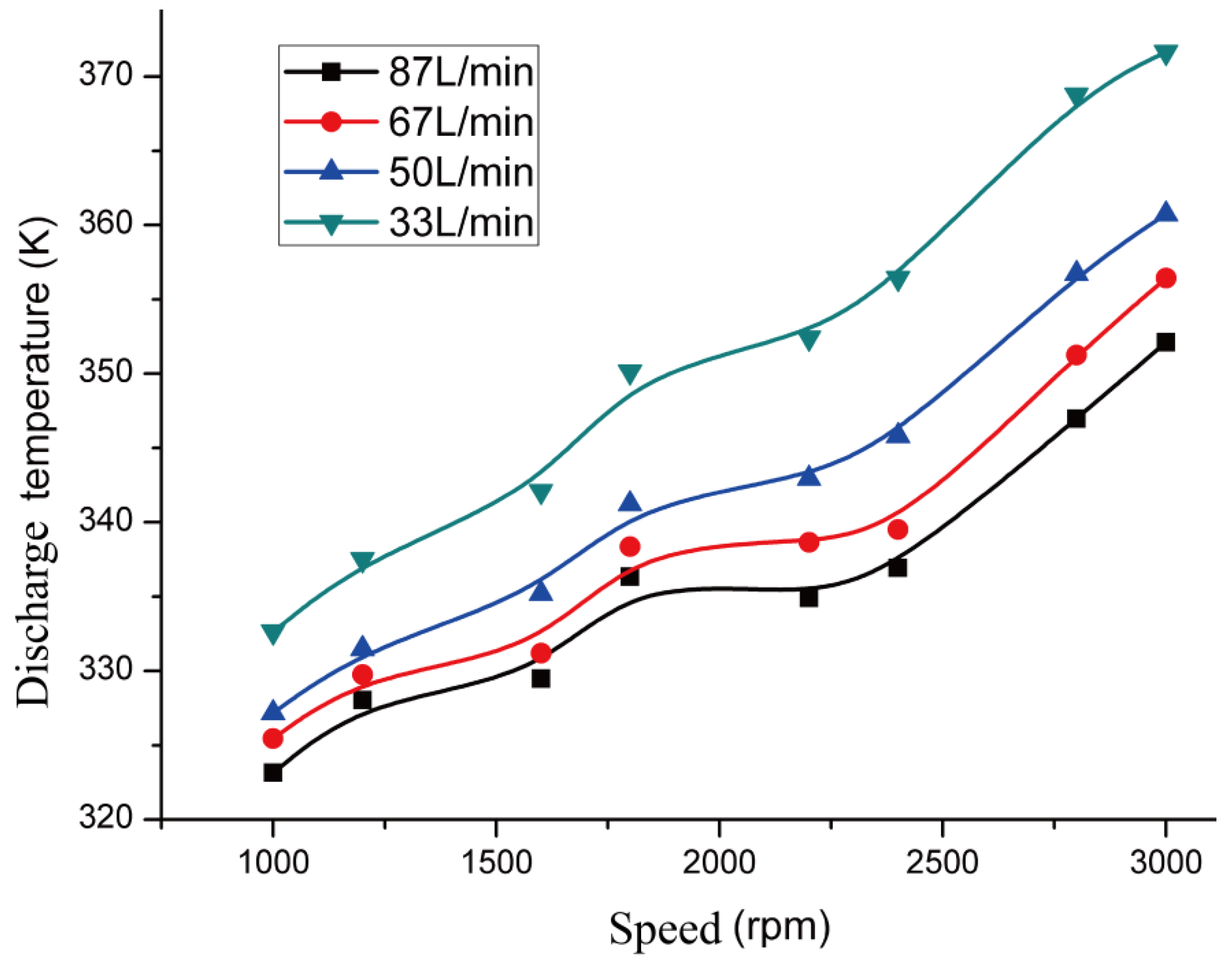

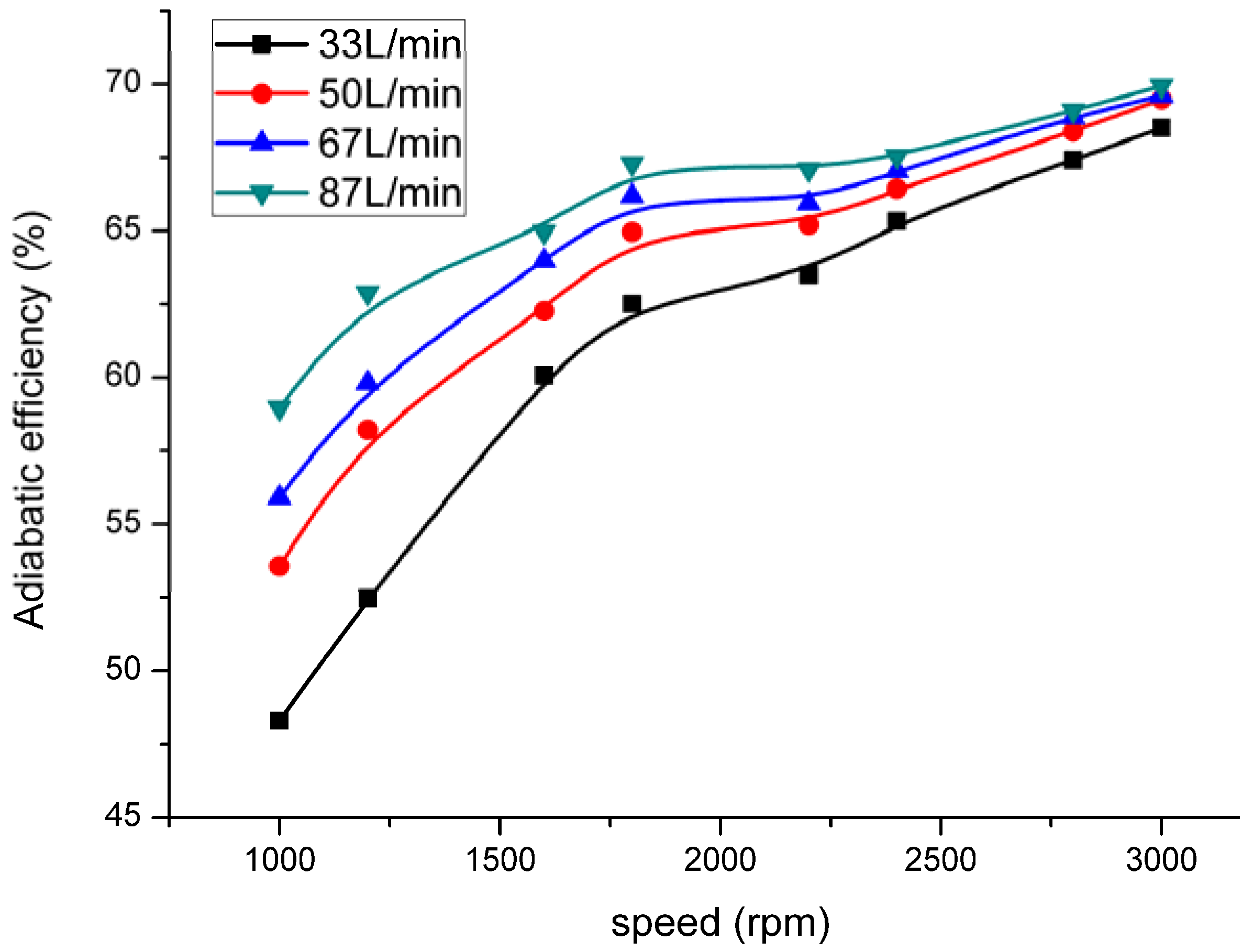

3. Results and Discussion

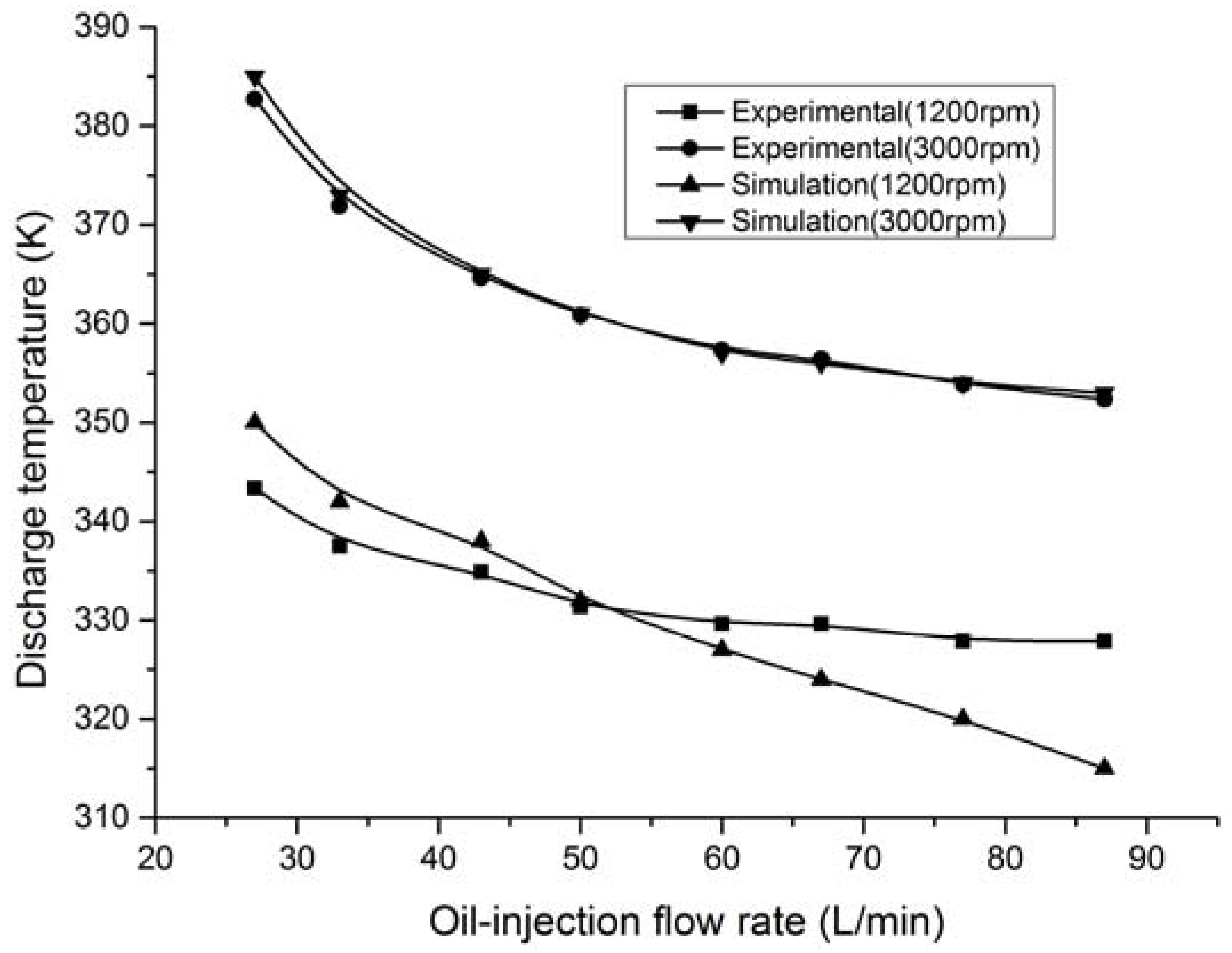

3.1. Effect of Oil Injection on Thermodynamic Performance

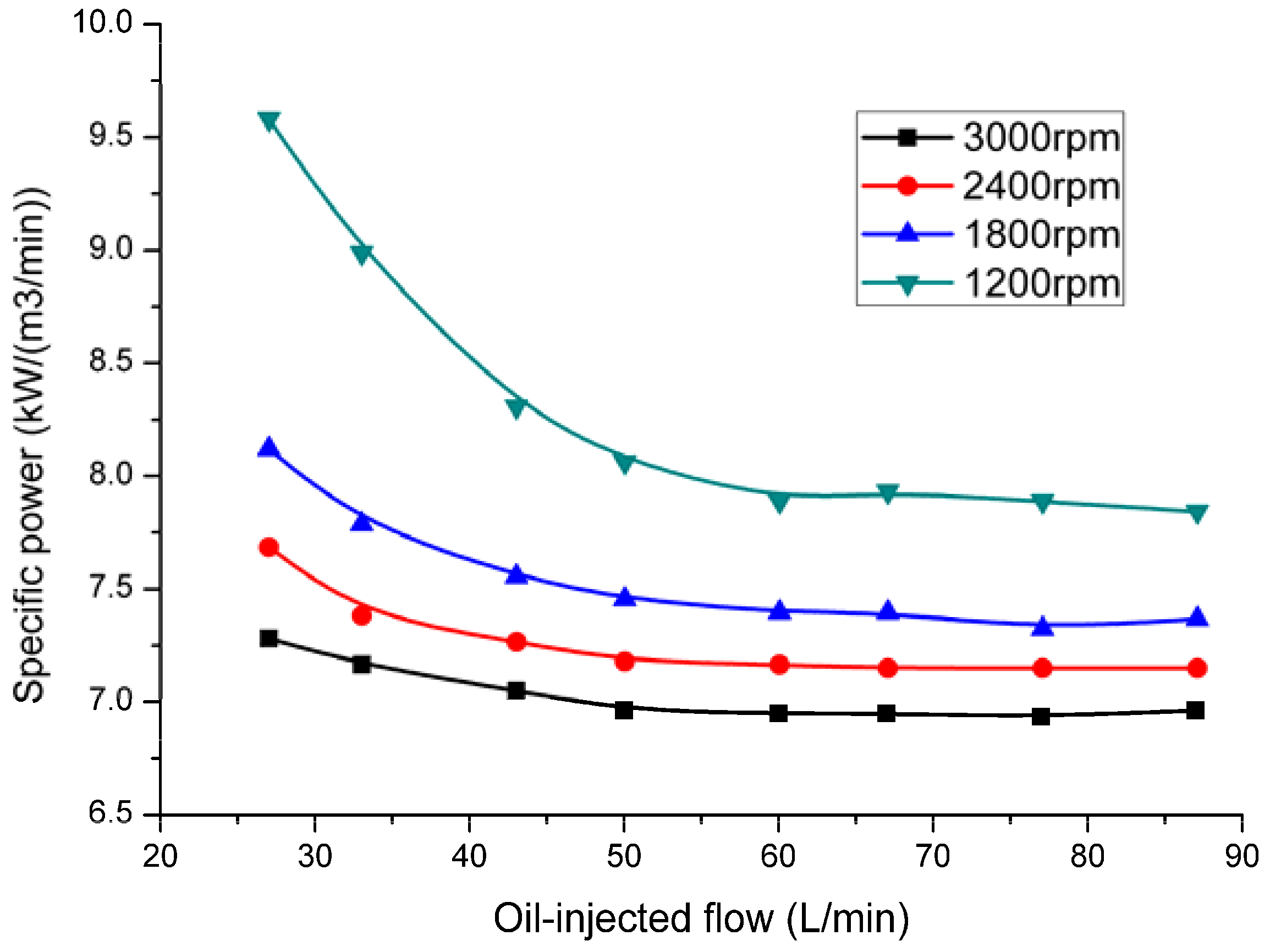

3.2. Optimization of the Oil Injection Flow Rate

3.3. The Heat Transfer Model in Compression Chamber

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fleming, J.S.; Tang, Y.; Cook, G. The twin helical screw compressor, part 2: A mathematical model of the working process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1998, 212, 369–380. [Google Scholar] [CrossRef]

- Hanjalic, K.; Stošić, N. Development and optimization of screw machines with a simulation model-Part II: Thermodynamic performance simulation and design optimization. Trans. ASME J. Fluids Eng. 1997, 119, 664–670. [Google Scholar] [CrossRef]

- Peng, X.; Xing, Z.; Cui, T.; Li, L. Analysis of the working process in an oil-flooded screw compressor by means of an indicator diagram. Proc. Inst. Mech. Eng. Part A J. Power Energy 2002, 216, 465–470. [Google Scholar] [CrossRef]

- Stošic, N.; Milutinović, L.; Hanjalić, K.; Kovačević, A. Investigation of the influence of oil injection upon the compressor working process. Int. J. Refrig. 1992, 15, 206–220. [Google Scholar] [CrossRef]

- Stošić, N.; Smith, I.K.; Kovačević, A. Optimization of screw compressors. Appl. Therm. Eng. 2003, 23, 1177–1195. [Google Scholar] [CrossRef]

- Wu, H.; Li, J.; Xing, Z. Theoretical and experimental research on the working process of screw refrigeration compressor under superfeed condition. Int. J. Refrig. 2017, 30, 1329–1335. [Google Scholar] [CrossRef]

- Wu, H.; Xing, Z.; Shu, P. Theoretical and experimental study on indicator diagram of twin-screw refrigeration compressor. Int. J. Refrig. 2004, 27, 331–338. [Google Scholar]

- Chen, W.; Xing, Z.; Tang, H.; Wu, H. Theoretical and experimental investigation on the performance of screw refrigeration compressor under part-load conditions. Int. J. Refrig. 2011, 34, 1141–1150. [Google Scholar] [CrossRef]

- He, Z.; Xing, Z.; Chen, W.; Wang, X. Thermal and hydraulic analysis on the flow around the motor in semi-hermetic twin-screw refrigeration compressors. Appl. Therm. Eng. 2013, 58, 114–124. [Google Scholar] [CrossRef]

- Fujiwara, M.; Osada, Y. Performance analysis of an oil-injected screw compressor and its application. Int. J. Refrig. 1995, 18, 220–227. [Google Scholar] [CrossRef]

- Paepe, M.D.; Bogaert, W.; Mertens, D. Cooling of oil injected screw compressors by oil atomization. Appl. Therm. Eng. 2005, 25, 2764–2779. [Google Scholar] [CrossRef]

- Seshaiah, N.; Ghosh, S.K.; Sahoo, R.K.; Sarangi, S.K. Mathematical modeling of the work cycle of oil injected rotary twin screw compressor. Appl. Therm. Eng. 2007, 27, 145–155. [Google Scholar] [CrossRef]

- Seshaiah, N.; Sahoo, R.K.; Sarrangi, S.K. Theoretical and experimental studies on oil injected twin-screw air compressor when compressing different light and heavy gases. Appl. Therm. Eng. 2010, 30, 327–339. [Google Scholar] [CrossRef]

- Hsieh, S.H.; Shih, Y.C.; Hsieh, W.H.; Lin, F.Y.; Tsai, M.J. Calculation of temperature distributions in the rotors of oil-injected screw compressors. Int. J. Therm. Sci. 2011, 50, 1271–1284. [Google Scholar] [CrossRef]

- Wu, X.; Xing, Z.; He, Z.; Wang, X.; Chen, W. Effects of lubricating oil on the performance of a semi-hermetic twin-screw compressor. Appl. Therm. Eng. 2017, 112, 340–351. [Google Scholar] [CrossRef]

- Cuevas, C.; Lebrun, J. Testing and modeling of a variable speed scroll compressor. Appl. Therm. Eng. 2009, 29, 469–478. [Google Scholar] [CrossRef]

- Liang, H.B.; Li, X.H. Application of Frequency Conversion Technology in Air-compressor Units Control System. Procedia Eng. 2011, 15, 944–948. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Liu, K.; Yu, H.; Cheng, K. Design of high-performance water-in-glass evacuated tube solar water heaters by a high-throughput screening based on machine learning: A combined modeling and experimental study. Sol. Energy 2017, 142, 61–67. [Google Scholar] [CrossRef]

- Li, G.; Wu, Y.; Zhang, Y.; Zhi, R.; Wang, J.; Ma, C. Performance study on a single-screw expander for a small-scale pressure recovery system. Energies 2016, 10, 6. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, D.; Yu, H.; Ma, W.; Gin, G. Field measurement and numerical simulation of combined solar heating operation modes for domestic buildings based on the Qinghai-Tibetan plateau case. Energy Build. 2018, 167, 312–321. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, W.; Zhai, X.; Qian, C.; Chen, X. Feasibility and performance study of the hybrid ground-source heat pump system for one office building in Chinese heating dominated areas. Renew. Energy 2017, 101, 1131–1140. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, K.; Li, H.; Cao, G.; Wu, D.; Shi, Y. Exploring the potential relationship between indoor air quality and the concentration of airborne culturable fungi: A combined experimental and neural network modeling study. Environ. Sci. Pollut. Res. 2018, 25, 3510–3517. [Google Scholar] [CrossRef] [PubMed]

- Bevington, P.R.; Robinson, D.K. Data Reduction and Error Analysis for the Physical Sciences, 3rd ed.; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Byeon, S.S.; Lee, J.Y.; Kim, Y.J. Performance characteristics of a 4 × 6 oil-free twin-screw compressor. Energies 2017, 10, 945. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, H.; Song, S.; Zhang, J.; Wu, Y.; Zhang, Y.; Wang, H.; Chang, Y.; Bei, C. Performance analysis of the vehicle diesel engine-orc combined system based on a screw expander. Energies 2014, 7, 3400–3419. [Google Scholar] [CrossRef]

- Kondo, S.; Takahashi, Y. The analysis of leakage in a twin-screw compressor and its application to performance improvement. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1995, 209, 125–136. [Google Scholar]

- Tian, Y.; Shen, J.; Wang, C.; Xing, Z.; Wang, X. Modeling and performance study of a water-injected twin-screw water vapor compressor. Int. J. Refrig. 2017, 83, 75–87. [Google Scholar] [CrossRef]

- Tian, Y.; Xing, Z.; He, Z.; Wu, H. Modeling and performance analysis of twin-screw steam expander under fluctuating operating conditions in steam pipeline pressure energy recovery applications. Energy 2017, 141, 692–701. [Google Scholar] [CrossRef]

| Operating Parameters | |||||

| Nominal speed | Volume ratio | Nominal volumetric flow rate | Nominal discharge pressure | Nominal power | Nominal frequency |

| 3000 rpm | 4.4 | 13.5 m3/min | 0.8 MPa | 75 kW | 150 Hz |

| Compressor structure parameters | |||||

| Parameter | Male rotor | Female rotor | |||

| Number of teeth | 4 | 6 | |||

| Diameter of rotor D/mm | 178.5 | 169.1 | |||

| Length of rotor L/mm | 275 | 275 | |||

| Torsion angle Ψ/° | 300° | 200° | |||

| Diameter of the injection port d/mm | 18 | ||||

| Designed internal volume ratio, vi | 4.4 | ||||

| Theoretical displacement volume Qv/cm3 | 4185.5 | ||||

| Rotational Speed/r·min−1 | Oil injection Flow Rate Qoil/L·min−1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| High speed (rpm) | 3000 | 27 | 33 | 43 | 50 | 60 | 67 | 77 | 87 |

| 2800 | |||||||||

| Medium speed (rpm) | 2200 | 27 | 33 | 43 | 50 | 60 | 67 | 77 | 87 |

| 1800 | |||||||||

| Low speed (rpm) | 1200 | 27 | 33 | 43 | 50 | 60 | 67 | 77 | 87 |

| 1000 | |||||||||

| Compressor operating parameter | Suction temperature (K) | Suction pressure (MPa) | Discharge pressure (MPa) | Oil temperature (K) | |||||

| Value | 290 | 0.1 | 0.8 | 303 | |||||

| Rotational Speed | Oil injection Flow Rate under Different Performance Parameter | Trade-off among Parameters | |||

|---|---|---|---|---|---|

| Discharge Temperature | Specific Power | Volumetric Efficiency | Adiabatic Efficiency | ||

| 3000 rpm | >43 | >43 | >50 | >43 | 50 |

| 2800 rpm | >33 | >50 | >50 | >50 | 50 |

| 2400 rpm | >33 | >50 | >50 | >50 | 50 |

| 2200 rpm | >33 | >50 | >50 | >50 | 50 |

| 1800 rpm | >33 | >50 | >50 | >50 | 50 |

| 1600 rpm | <50 | >50 | >50 | >50 | 50 |

| 1200 rpm | <43 | >50 | >50 | >50 | 43 |

| 1000 rpm | <33 | >50 | >50 | >50 | 33 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Wang, T.; Wang, X.; Peng, X.; Xing, Z. Experimental Investigation into the Effect of Oil Injection on the Performance of a Variable Speed Twin-Screw Compressor. Energies 2018, 11, 1342. https://doi.org/10.3390/en11061342

He Z, Wang T, Wang X, Peng X, Xing Z. Experimental Investigation into the Effect of Oil Injection on the Performance of a Variable Speed Twin-Screw Compressor. Energies. 2018; 11(6):1342. https://doi.org/10.3390/en11061342

Chicago/Turabian StyleHe, Zhilong, Tao Wang, Xiaolin Wang, Xueyuan Peng, and Ziwen Xing. 2018. "Experimental Investigation into the Effect of Oil Injection on the Performance of a Variable Speed Twin-Screw Compressor" Energies 11, no. 6: 1342. https://doi.org/10.3390/en11061342

APA StyleHe, Z., Wang, T., Wang, X., Peng, X., & Xing, Z. (2018). Experimental Investigation into the Effect of Oil Injection on the Performance of a Variable Speed Twin-Screw Compressor. Energies, 11(6), 1342. https://doi.org/10.3390/en11061342