A Case Study of Presplitting Blasting Parameters of Hard and Massive Roof Based on the Interaction between Support and Overlying Strata

Abstract

:1. Introduction

2. Interactions of HMR and Support

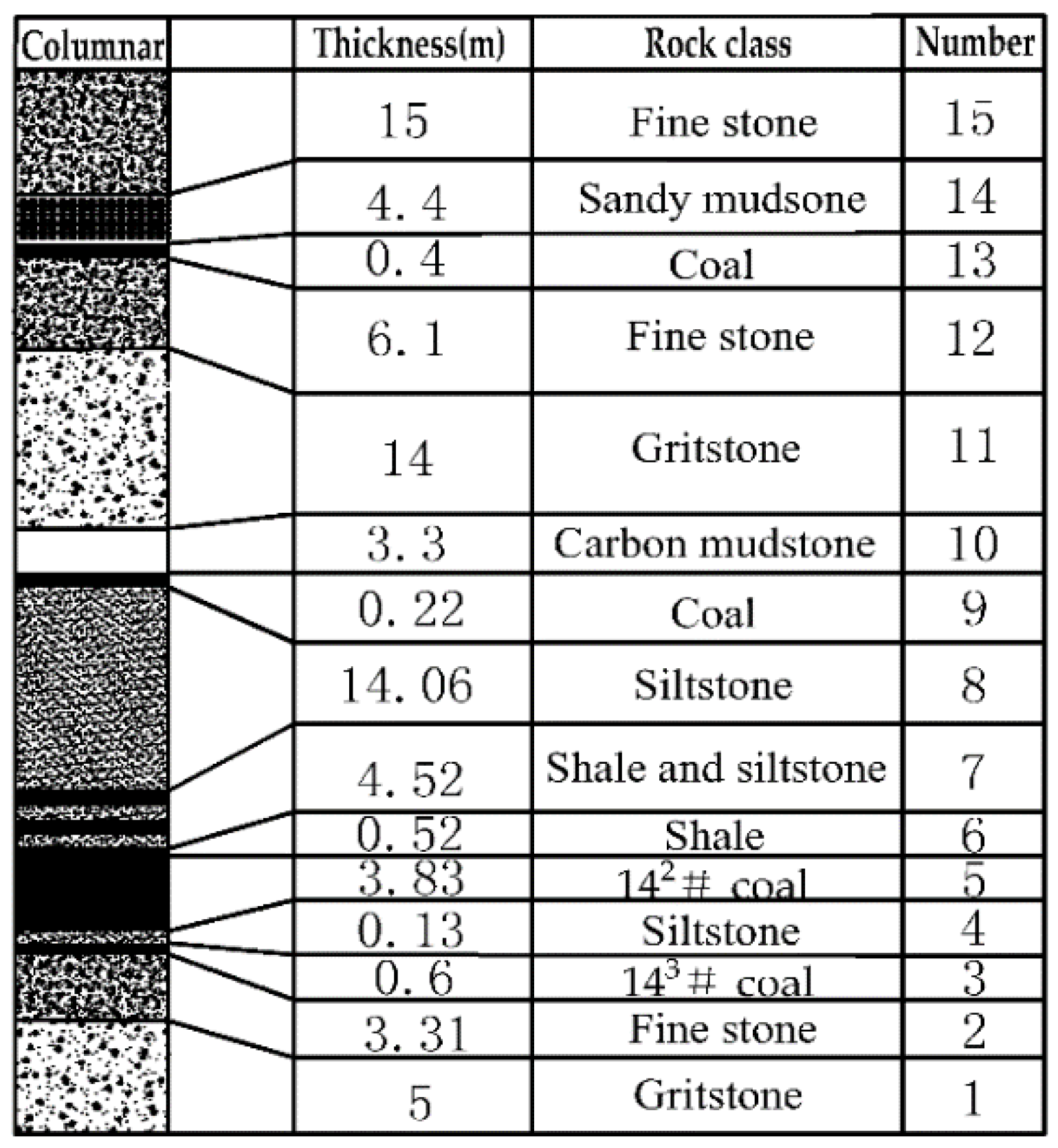

2.1. Geological Conditions

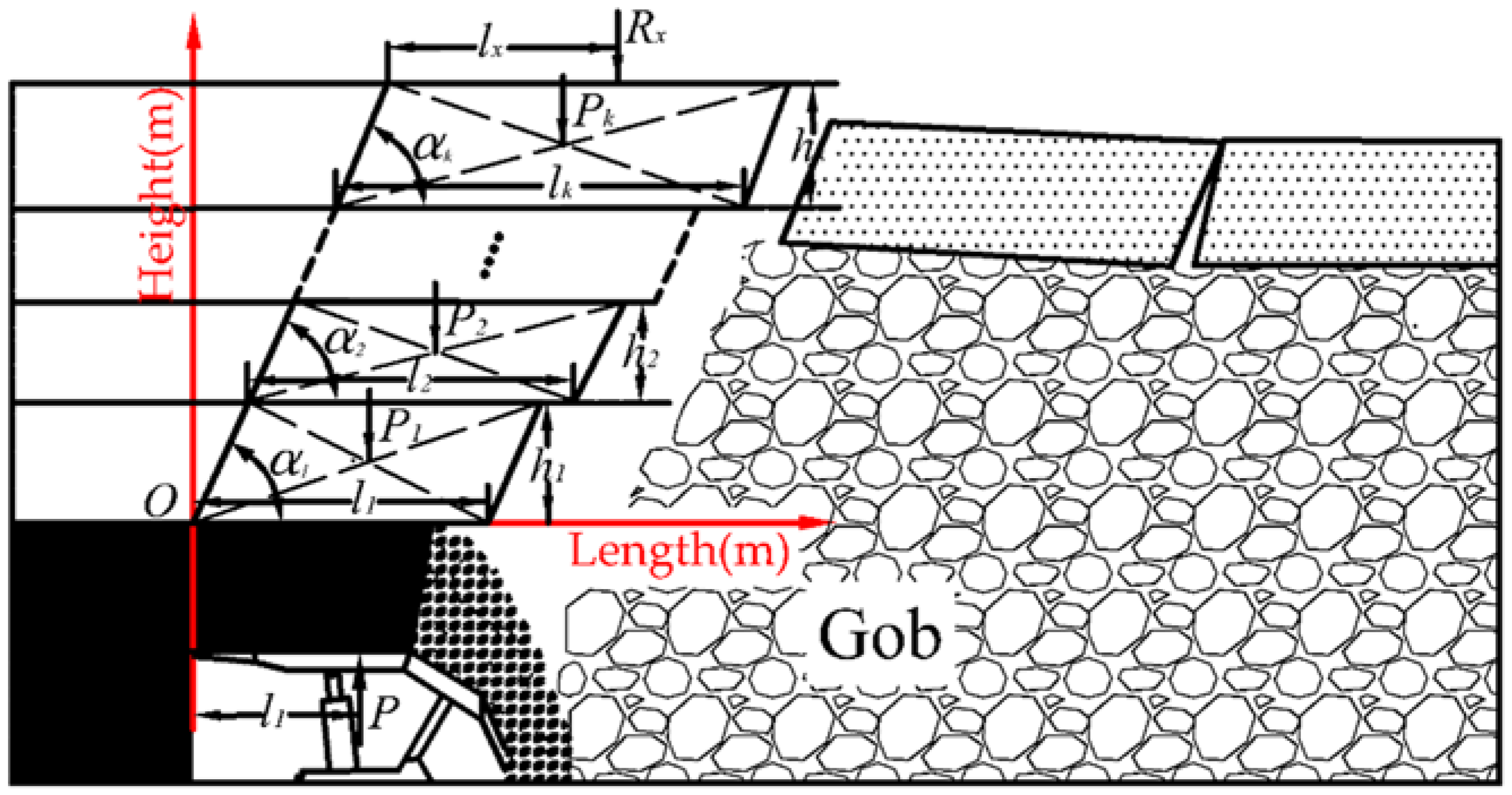

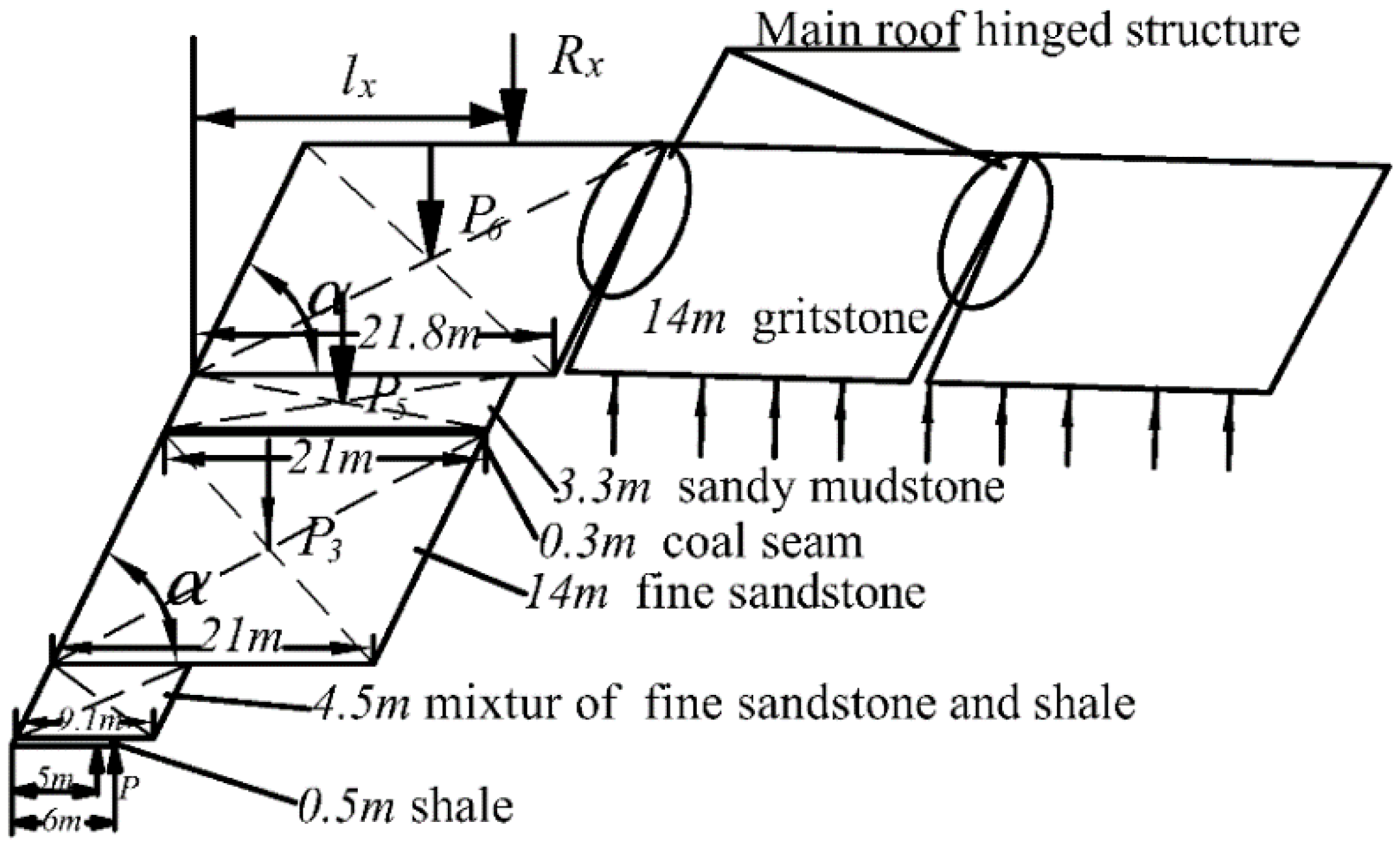

2.2. Mechanical Model of the HMR

2.3. Thickness of Cantilever Group

2.4. Strata Fracture Step

2.4.1. Load of Overlying Strata

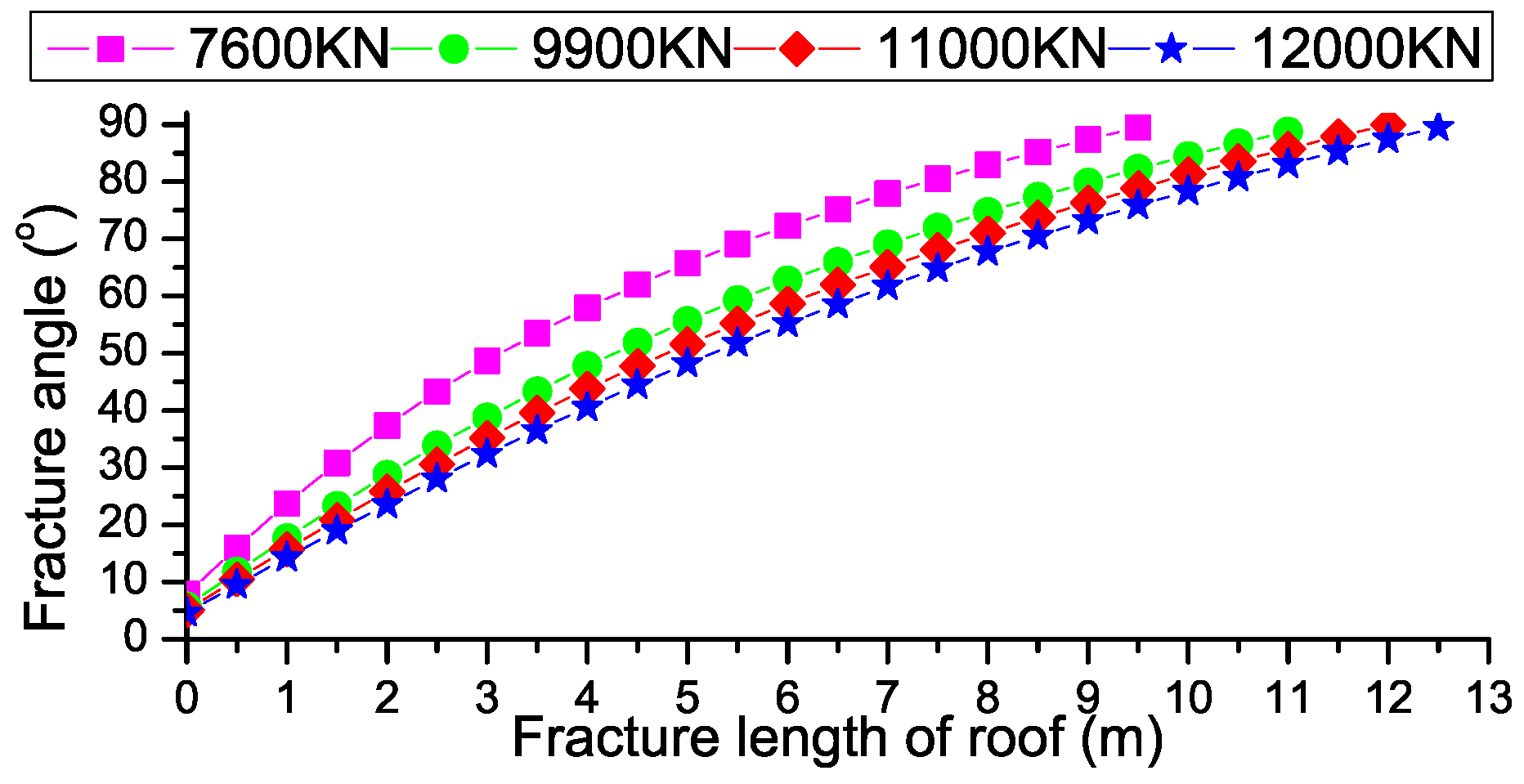

2.4.2. Naturally Fracture Step and the Working Resistance of Supports

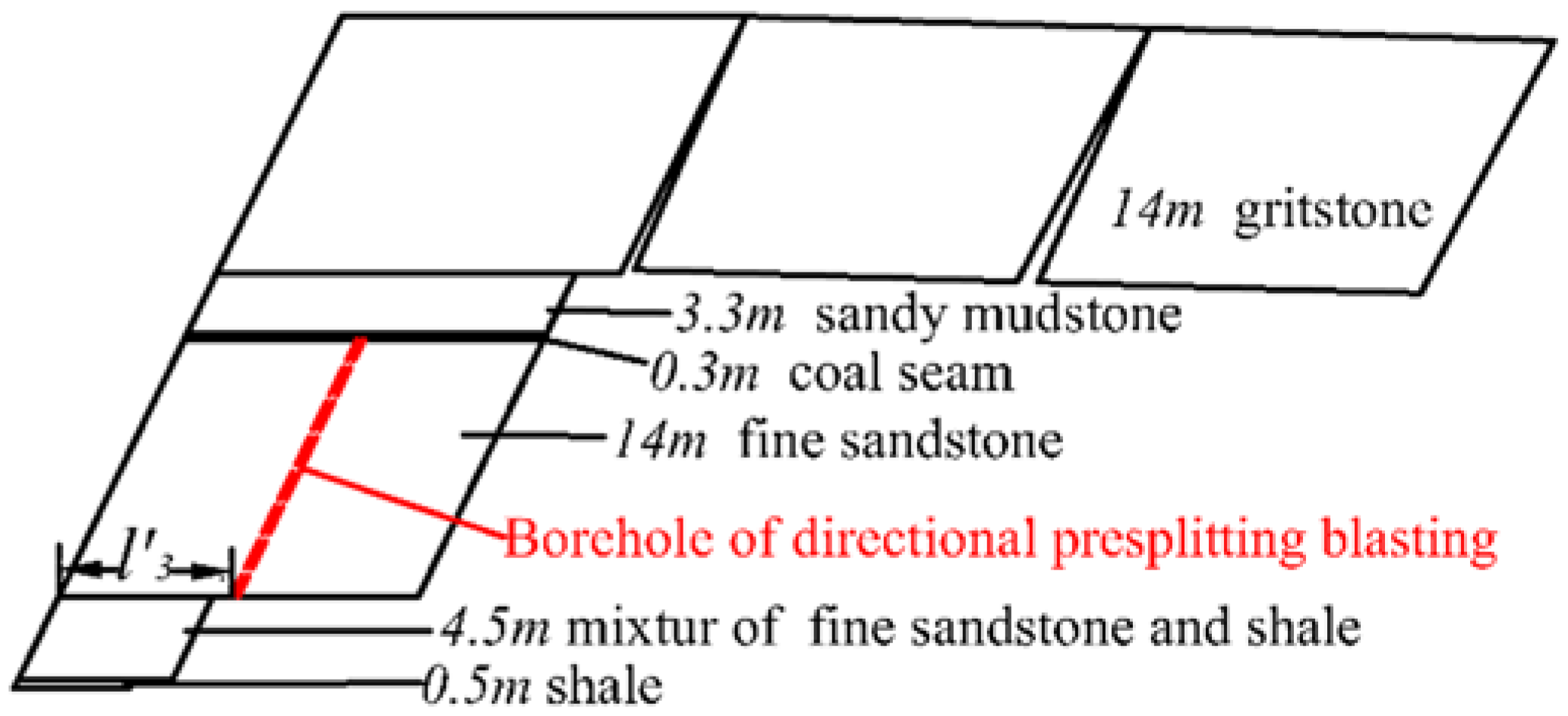

3. Blasting Parameters for Fracture of HMR

4. On-Site Application and Effect Analysis

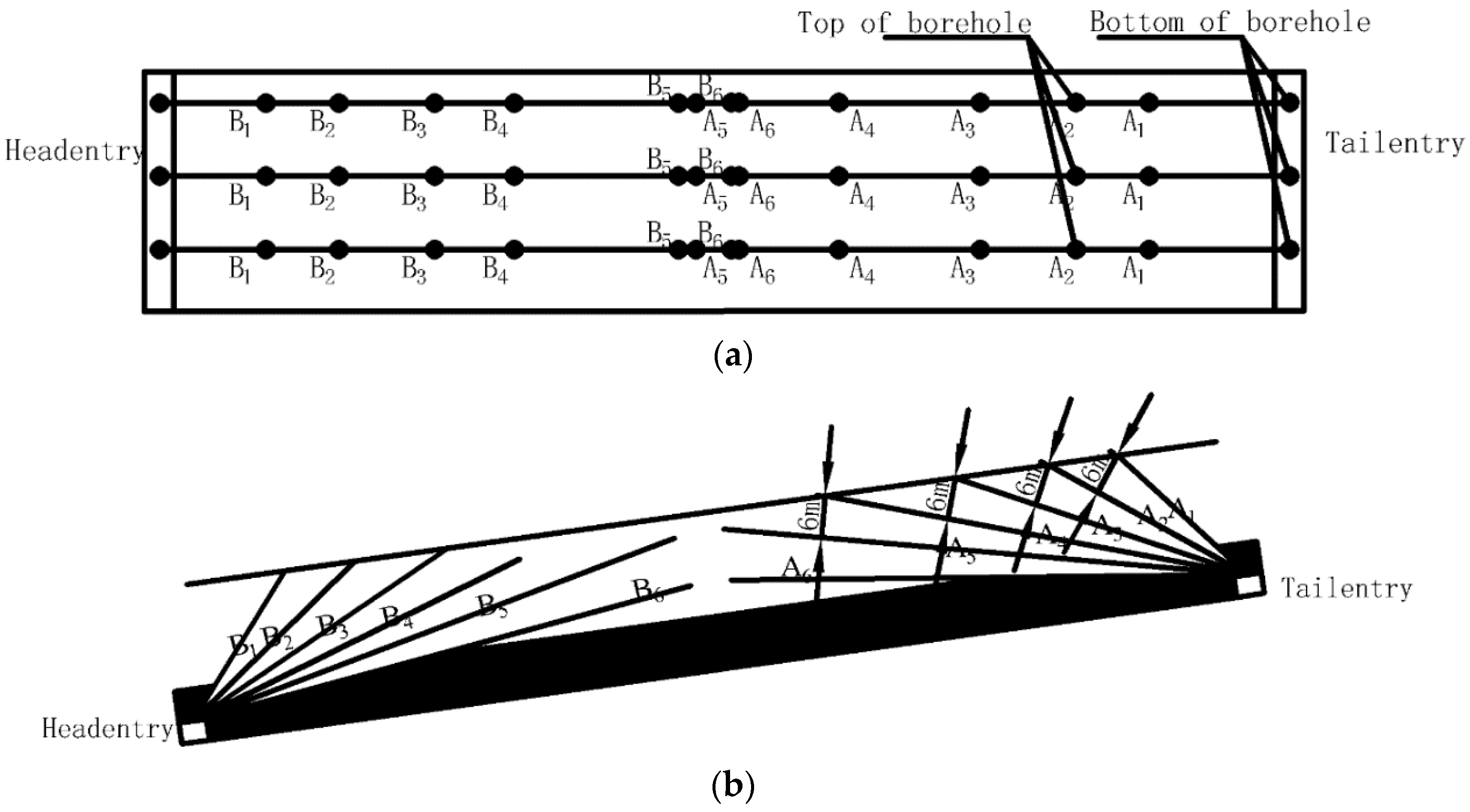

4.1. On-Site Blasting Parameters at Working Face

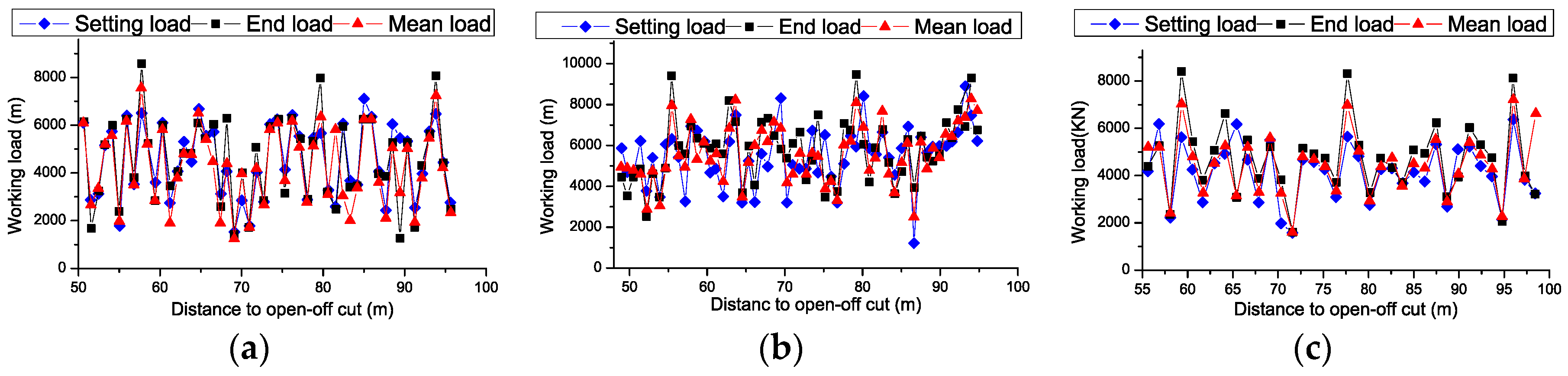

4.2. Blasting Affect

5. Conclusions

- (1)

- The mechanical model for the hinge balanced cantilever beam structure of the HMR was established. Then, the stability conditions and the influencing factors of the cantilever beams were determined.

- (2)

- Combined with the actual production background of the Silaogou coal mine working face in the Datong mining area, the thickness of the roof in a cantilevered state in the mining process was analyzed. The breaking form, order, and step of each roof were determined. The reasonable working resistance was calculated under the natural breaking condition of the roofs, and the result being a safe working resisitance could not be achieved. Hence, the presplitting blasting method was presented for treating the key strata of the HMR, and the reasonable breaking step and working resistance of the support were obtained through calculation. The blasting parameters in the field of working face were also determined.

- (3)

- The field test shows that the roof presplitting blasting successfully controlled the breaking step distance of the critical layer of the roof, effectively slowed down the mining pressure, and provided the basis for the mining of similar conditions. In future, high efficiency blasting techniques will be researched to effectively enhance the control of the HMR, increasing the safety of workers and the efficiency of mining operations at the working face.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhao, T.; Liu, C.Y.; Yetilmezsoy, K.; Zhang, B.S.; Zhang, S. Fractural structure of thick hard roof stratum using long beam theory and numerical modeling. Environ. Earth Sci. 2017, 76, 751. [Google Scholar] [CrossRef]

- Zhang, J.X.; Li, B.Y.; Zhou, N.; Zhang, Q. Application of solid backfilling to reduce hard-roof caving and longwall coal face burst potential. Int. J. Rock Mech. Min. Sci. 2016, 88, 197–205. [Google Scholar] [CrossRef]

- Liu, C.; Li, H.M.; Mitri, H.; Jiang, D.J.; Li, H.G.; Feng, J.F. Voussoir beam model for lower strong roof strata movement in longwall mining—Case study. J. Rock Mech. Geotech. Eng. 2017, 9, 1171–1176. [Google Scholar] [CrossRef]

- Galvin, J.; Hebblewhite, B. Geomechanics developments in mining coal under strong roof and weak floor conditions. In Proceedings of the Ninth International Congress on Rock Mechanics, Paris, France, 25–28 August 1999; pp. 277–281. [Google Scholar]

- Ning, J.G.; Wang, J.; Jiang, L.S.; Jiang, N.; Liu, X.S.; Jiang, J.Q. Fracture analysis of double-layer hard and thick roof and the controlling effect on strata behavior: A case study. Eng. Fail. Anal. 2017, 81, 117–134. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Analytical approaches for studying the stability of laminated roof strata. Int. J. Rock Mech. Min. Sci. 2015, 79, 99–108. [Google Scholar] [CrossRef]

- Li, M.; Zhou, N.; Zhang, J.X.; Liu, Z.C. Numerical modelling of mechanical behavior of coal mining hard roofs in different backfill ratios: A case study. Energies 2017, 10, 1005. [Google Scholar]

- Guo, W.J.; Li, Y.Y.; Yin, D.W.; Zhang, S.C.; Sun, X.Z. Mechanisms of rock burst in hard and thick upper strata and rock-burst controlling technology. Arab. J. Geosci. 2016, 9, 561. [Google Scholar] [CrossRef]

- Zubelewicz, A.; Mroz, Z. Numerical-simulation of rock burst processes treated as problems of dynamic instability. Rock Mech. Rock Eng. 1983, 16, 253–274. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, N.; Xue, J.H.; Zhang, L. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Shik, V.M. Value of the longwall length as a regulator of the intensity of geomechanical processes on beds with strong roof rocks. J. Min. Sci. 1992, 28, 1–5. [Google Scholar] [CrossRef]

- Chernov, O.I. Hydrodynamic stratification of petrologically uniform strong rocks as a means of controlling intransigent roofs. Sov. Min. 1982, 18, 102–107. [Google Scholar] [CrossRef]

- Zhang, N.B.; Liu, C.Y. Radiation characteristics of natural gamma-ray from coal and gangue for recognition in top coal caving. Sci. Rep. UK 2018, 8, 190. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.B.; Liu, C.Y.; Yang, P.J. Flow of top coal and roof rock and loss of top coal in fully mechanized top coal caving mining of extra thick coal seams. Arab. J. Geosci. 2016, 9, 465. [Google Scholar] [CrossRef]

- Guo, W.B.; Wang, H.S.; Dong, G.W.; Li, L.; Huang, Y.G. A case study of effective support working resistance and roof support technology in thick seam fully-mechanized face mining with hard roof conditions. Sustainability 2017, 9, 935. [Google Scholar] [CrossRef]

- Yang, J.X.; Liu, C.Y.; Yu, B. Application of confined blasting in water-filled deep holes to control strong rock pressure in hard rock mines. Energies 2017, 10, 1874. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Zhang, N.; Shimada, H.; Sasaoka, T.; Wahyudi, S. Optimization of hard roof structure over retained goaf-side gateroad by pre-split blasting technology. Int. J. Rock Mech. Min. Sci. 2017, 100, 330–337. [Google Scholar] [CrossRef]

- Shimada, H.; Matsui, K.; Anwar, H. Control of hard-to-collapse massive roofs in longwall faces using a hydraulic fracturing technique. In Proceedings of the 17th International Conference on Ground Control in Mining, Wollongong, Australia, 14–17 July 1998; pp. 79–87. [Google Scholar]

- Koehler, M.; Carey, J. Blasting techniques to control roof failure in an underground limestone mine. In Proceedings of the Twenty-Eighth Annual Conference on Explosives and Blasting Technique, Las Vegas, NV, USA, 10–13 February 2002; pp. 91–102. [Google Scholar]

- Matsui, K.; Shimada, H.; Anzwar, H.Z. Acceleration of massive roof caving in a longwall gob using a hydraulic fracturing. Min. Sci. Technol. 1999, 99, 43–46. [Google Scholar]

- Jiang, J.Q.; Dai, J.; Wang, P.; Zhang, L.L. Overlying hard and thick strata breaking movement and broken-roof control. Rock Soil Mech. 2014, 35, 264–270. [Google Scholar]

- Sawmliana, C.; Roy, P.P. A new blastability index for hard roof management in blasting gallery method. Geotech. Geol. Eng. 2012, 30, 1357–1367. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yang, J.X.; Yu, B. Rock-breaking mechanism and experimental analysis of confined blasting of borehole surrounding rock. Int. J. Min. Sci. Technol. 2017, 27, 795–801. [Google Scholar]

- Huang, B.X.; Chen, S.L.; Zhao, X.L. Hydraulic fracturing stress transfer methods to control the strong strata behaviours in gob-side gateroads of longwall mines. Arab. J. Geosci. 2017, 10, 236. [Google Scholar] [CrossRef]

- Chong, Z.H.; Li, X.H.; Chen, X.Y.; Zhang, J.; Lu, J.Z. Numerical investigation into the effect of natural fracture density on hydraulic fracture network propagation. Energies 2017, 10, 914. [Google Scholar] [CrossRef]

- Zhao, D.; Feng, Z.C.; Zhao, Y.S. Effects and Influences of Water Injection on Coalbed Exploitation in Mining Engineering; Crc Press-Taylor & Francis Group: Boca Raton, FL, USA, 2012; pp. 731–735. [Google Scholar]

- Zhou, N.; Zhang, J.X.; Yan, H.; Li, M. Deformation behavior of hard roofs in solid backfill coal mining using physical models. Energies 2017, 10, 557. [Google Scholar] [CrossRef]

- Verma, H.K.; Samadhiya, N.K.; Singh, M.; Goel, R.K.; Singh, P.K. Blast induced rock mass damage around tunnels. Tunn. Undergr. Space Technol. 2018, 71, 149–158. [Google Scholar] [CrossRef]

- Bendezu, M.; Romanel, C.; Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 2017, 182, 1–13. [Google Scholar] [CrossRef]

- Singh, P.K.; Roy, M.P.; Paswan, R.K.; Sarim, M.; Kumar, S.; Jha, R.R. Rock fragmentation control in opencast blasting. J. Rock Mech. Geotech. Eng. 2016, 8, 225–237. [Google Scholar] [CrossRef]

- Piyush, R.; Hakan, S.; Per-Arne, L.; Uday, K. Measurement-while-drilling technique and its scope in design and prediction of rock blasting. Int. J. Min. Sci. Technol. 2016, 26, 711–719. [Google Scholar]

- Yang, J.X.; Liu, C.Y. Experimental study and engineering practice of pressured water coupling blasting. Shock Vib. 2017, 2017, 5484598. [Google Scholar] [CrossRef]

- Li, T.C.; Liu, H.Q.; Wang, C. Study of millisecond blasting technology of shaft excavation by one-step deep-hole blasting. Rock Soil Mech. 2012, 33, 1742–1746. [Google Scholar]

- Wei, J.P. Numerical simulation of hard roof’s safety control. Prog. Saf. Sci. Tech. 2006, 6, 1792–1795. [Google Scholar]

- Liu, C.Y.; Yang, J.X.; Yu, B.; Wu, F.F. Support resistance determination of fully mechanized top-coal caving face in extra thick seam under multi-layered hard strata. J. Min. Saf. Eng. 2015, 32, 7–13. [Google Scholar]

| Lithology | Sandy Mudstone | Shale | Fine Sandstone | Medium-Coarse Sandstone | Coal |

|---|---|---|---|---|---|

| Expansion coefficient | 1.1 | 1.1 | 1.25 | 1.2 | 1.2 |

| Density/kg/m3 | 2500 | 2500 | 2530 | 2530 | 1400 |

| Layer Number | Lithology | Thickness/m | Density/kg/m3 | Elasticity Modulus/Gpa | Load of Strata/kN/m2 | Tensile Strength/Mpa | Fracture Step/m | Limit Length of Cantilever/m | Weight/kN/m |

|---|---|---|---|---|---|---|---|---|---|

| 10 | Fine sandstone | 15 | 2530 | 25.4 | - | 8.9 | - | - | - |

| 9 | Chiltern | 4.4 | 2500 | 23.43 | - | 4 | - | - | - |

| 8 | Coal seam | 0.4 | 1426 | 2.8 | 2.6 | - | - | - | |

| 7 | Fine sandstone | 6.1 | 2530 | 25.4 | 8.9 | - | - | - | |

| 6 | Medium-coarse sandstone | 14 | 2530 | 21.3 | 550.966 | 8 | 21.8 | 21.8 | 7722 |

| 5 | Sandy mudstone | 3.3 | 2500 | 23.43 | 82.4 | 4 | 6.7 | 21 | 1741 |

| 4 | Coal seam | 0.3 | 1400 | 2.8 | - | 2.6 | - | 21 | 89 |

| 3 | Fine sandstone | 14 | 2530 | 25.4 | 435.637 | 8.9 | 21.1 | 21 | 7474 |

| 2 | Shale and siltstone | 4.5 | 2530 | 20.0 | 112.5 | 6.9 | 9.1 | 9 | 1024 |

| 1 | Shale | 0.5 | 2500 | - | 12.5 | 5.4 | - | 7 | 75 |

| Program | Units | Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | B1 | A2 | B2 | A3 | B3 | A4 | B4 | A5 | B5 | A6 | B6 | ||

| Perf length | m | 25.4 | 32.8 | 44.4 | 52.6 | 74 | 74.2 | ||||||

| Perf horizontal angle | 90 | 90 | 90 | 90 | 90 | 90 | |||||||

| Perf vertical angle | 50 | 37 | 26 | 18 | 13 | 7 | |||||||

| No. | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| Drill diameter | mm | 60 | 60 | 60 | 60 | 60 | 60 | ||||||

| Explosive density | kg/m3 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 | ||||||

| Detonating velocity | m/s | 5540 | 5540 | 5540 | 5540 | 5540 | 5540 | ||||||

| Explosive payload per meter | kg/m | 3.29 | 3.29 | 3.29 | 3.29 | 3.29 | 3.29 | ||||||

| Loaded length | m | 16.9 | 21.9 | 29.6 | 35.1 | 49.3 | 49.5 | ||||||

| Loaded weight | kg | 10 | 12.7 | 17.2 | 20.1 | 24 | 24.2 | ||||||

| Filling length | m | 8.5 | 10.9 | 14.8 | 17.5 | 24.6 | 24.7 | ||||||

| Detonating fuse length | m | 27.4 | 34.8 | 46.4 | 54.6 | 76 | 76.2 | ||||||

| No. of detonators | 2 | 2 | 2 | 2 | 2 | 2 | |||||||

| No. of segments of detonators | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | |

| Explosive type | Emulsion explosive | ||||||||||||

| Pressure Property | Location | Pressure Procedure | Dynamic Load km | ||||

|---|---|---|---|---|---|---|---|

| Function Time | Effecting Scope/m | Pressure Step/m | |||||

| Cycle | Days | ||||||

| Setting load of the upper roof | 1 | tip middle tail | 3 3 2 | 0.4 0.7 0.3 | 2 2.6 1.7 | 58.9 55.5 58.9 | 1.38 1.42 1.38 |

| average | 3.3 | 0.5 | 2.1 | 57.8 | 1.39 | ||

| Cyclic load of the upper roof | 1 | tip middle tail | 3 5 6 | 1 0.4 1 | 2.6 4.4 5.2 | 12.6 10.5 11.2 | 1.27 1.36 1.36 |

| average | 4.7 | 0.8 | 4.1 | 11.4 | 1.33 | ||

| 2 | tip middle tail | 5 7 3 | 3.2 2 0.2 | 4.3 6.1 2.6 | 11.9 9.6 10.8 | 1.35 1.37 1.32 | |

| average | 5 | 1.8 | 3.3 | 10.8 | 1.35 | ||

| Program | Testing Line | Supporting Resistance/kN | Supporting Resistance/kN·m−2 | |||||

|---|---|---|---|---|---|---|---|---|

| Average | Mean Square Error | Maximum | Average | Maximum | Ratio | No. of Cycles | ||

| Setting load | Tip | 5647.6 | 1535.4 | 7129 | 52 | |||

| Middle | 3944.6 | 1415.6 | 8918.5 | |||||

| Tail | 6240 | 1562.7 | 7273.4 | |||||

| Average | 6260 | 1504.6 | 7773.6 | 559.3 | 886.6 | 0.63 | ||

| Final resistance | Tip | 5926 | 1605.3 | 6782.6 | ||||

| Middle | 8797.5 | 1290.5 | 9871 | |||||

| Tail | 7544.1 | 1671 | 8168 | |||||

| Average | 7436 | 1522.3 | 8273.9 | 473.6 | 836.5 | 0.57 | ||

| Time weighted resistance | Tip | 5456.3 | 4391.4 | 6678.3 | ||||

| Middle | 7312 | 1282 | 8220 | |||||

| Tail | 6835 | 1380.4 | 7811 | |||||

| Average | 6553 | 2351.3 | 7869.8 | |||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Liu, C.; Chen, B. A Case Study of Presplitting Blasting Parameters of Hard and Massive Roof Based on the Interaction between Support and Overlying Strata. Energies 2018, 11, 1363. https://doi.org/10.3390/en11061363

Zhang N, Liu C, Chen B. A Case Study of Presplitting Blasting Parameters of Hard and Massive Roof Based on the Interaction between Support and Overlying Strata. Energies. 2018; 11(6):1363. https://doi.org/10.3390/en11061363

Chicago/Turabian StyleZhang, Ningbo, Changyou Liu, and Baobao Chen. 2018. "A Case Study of Presplitting Blasting Parameters of Hard and Massive Roof Based on the Interaction between Support and Overlying Strata" Energies 11, no. 6: 1363. https://doi.org/10.3390/en11061363