Optimization Strategy for Economic Power Dispatch Utilizing Retired EV Batteries as Flexible Loads

Abstract

:1. Introduction

- (i)

- A stochastic day-ahead economic power dispatch model with wind farms and SLBFLs at MW levels is developed. This model utilizes batteries retired from EVs as flexible loads for balancing power and also for minimizing the operating cost and environmental emissions.

- (ii)

- The charging and discharging characteristics of SLBs at different temperatures and currents are obtained and analyzed based on actual NASA battery data.

- (iii)

- The opportunity cost is calculated to compare between the reuse and the disposal of SLBs; an economic analysis is carried out to compare the utilization of SLBs and EV first-life batteries as flexible loads; the thermal power generating cost and the peak-valley difference of loads are also compared with the system involving SLBs in the power dispatch.

- (iv)

- This work has proved that SLBs are more economical to be utilized in large quantity for power dispatch. This will have significant economic implications and environmental benefits for both automotive industry and power industry.

2. Second Life Batteries Characteristics Analysis

2.1. Battery Power Output under Different Operating Temperatures and Charging/Discharging Currents

2.2. SLBFLs in Power Dispatch

3. Economic Power Dispatch Model with Wind Farms and SLBFLs

- is the balance constraint;

- is the unequal constraint;

- is the minimum value of the unequal constraint;

- is the maximum value of the unequal constraint.

3.1. Objective Functions

3.2. Constraint Functions

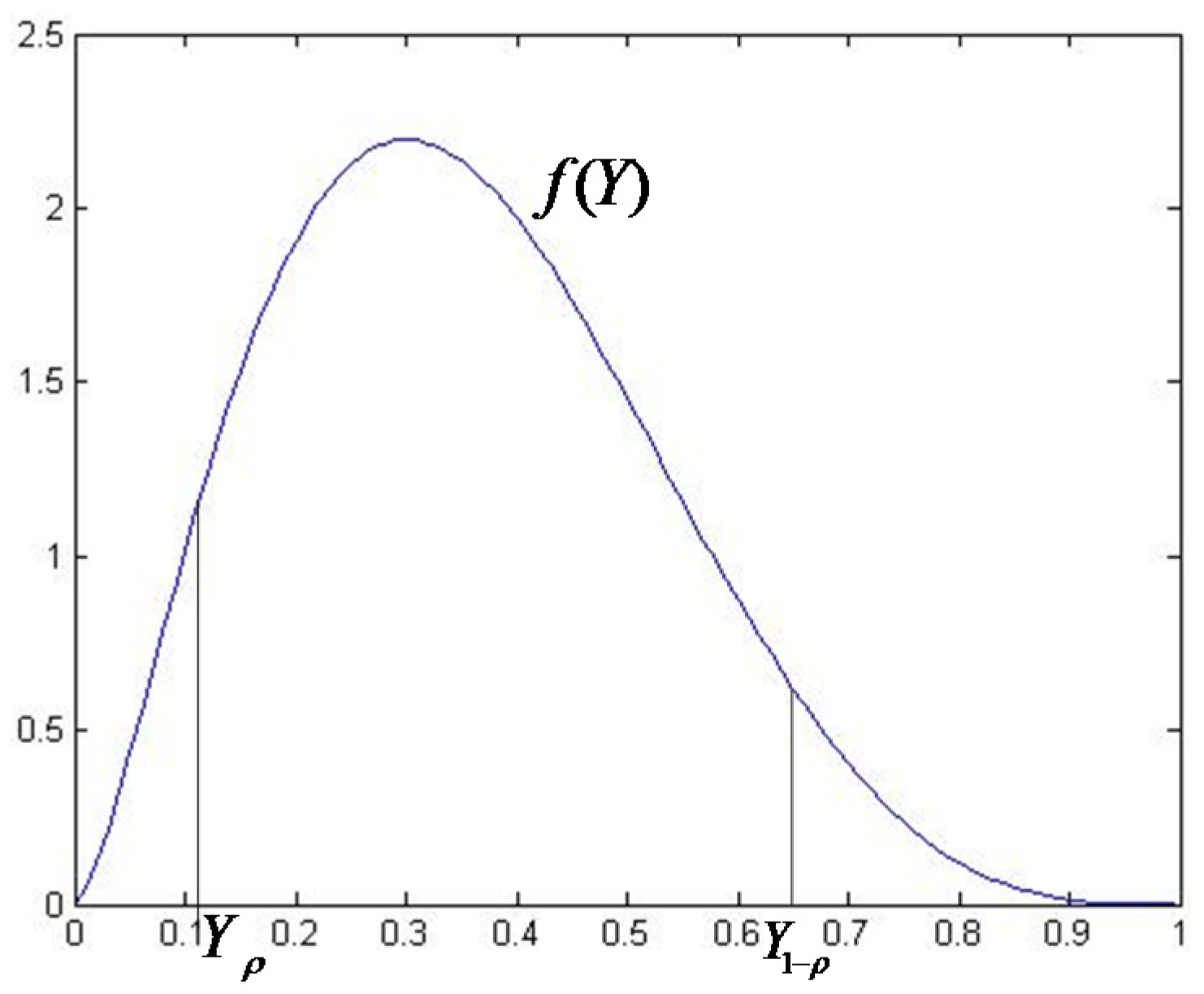

3.3. Stochastic Variables

4. Case Study

- Case 1: the power dispatch with wind farms and without SLBFLs. The spinning reserve confidence degree is 0.9.

- Case 2: the power dispatch with wind farms and SLBFLs at wind power reserve confidence degree of 0.9, 0.95 and 0.98.

- Case 3: the power dispatch with SLBs on supply side and the spinning reserve confidence degree is 0.9.

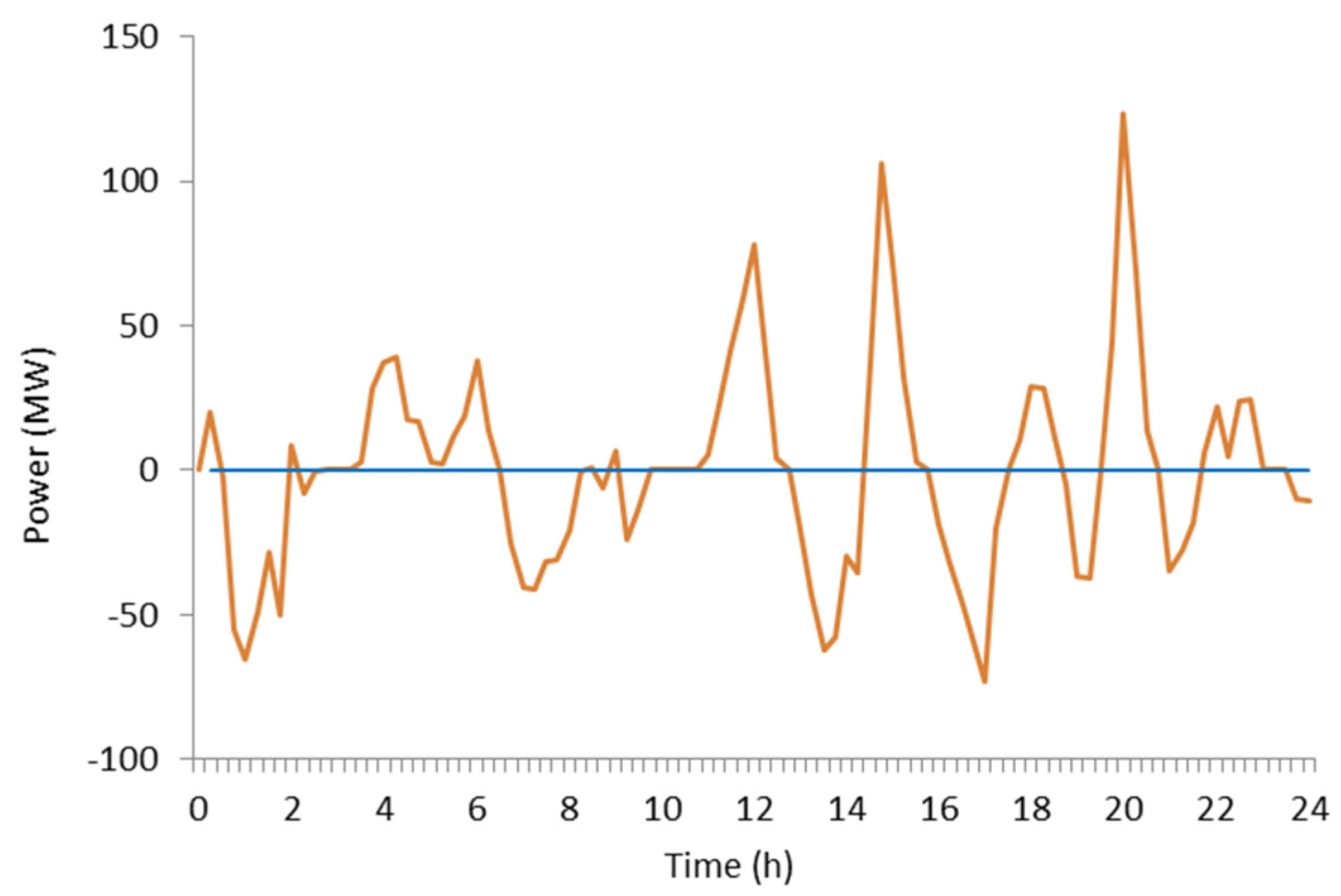

4.1. The Result Comparison of Case 1 and Case 2 with 0.9 Confidence Degree

4.2. The Result Comparison of Case 2 and Case 3

4.3. The Result Comparison of Case 2 with Different Confidence Degrees

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, C.; Muljadi, E.; Chung, C.C. Coordinated Control of Wind Turbine and Energy Storage System for Reducing Wind Power Fluctuation. Energies 2018, 11, 52. [Google Scholar] [CrossRef]

- Liu, J.T.; Feng, S.H.; Wang, K.; Guo, X.R.; Xu, L.Z. Method to determine spinning reserve requirement for a grid with large-scale wind power penetration. J. Eng. 2017, 2017, 1686–1691. [Google Scholar] [CrossRef]

- Qin, B.; Liu, D.; Cao, M.; Zou, J. Formal modeling and verification of flexible load control for power grid CPS based on differential dynamic logic. In Proceedings of the 2017 IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 26–28 November 2017; pp. 1–6. [Google Scholar]

- González, F.D.; Sumper, A.; Bellmunt, O.G.; Robles, R.V. A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 2012, 16, 2154–2171. [Google Scholar] [CrossRef]

- Wang, K.; Yao, J.; Yao, L.; Yang, S.; Yong, T. Survey of research on flexible loads scheduling technologies. Autom. Electr. Power Syst. 2014, 38, 127–135. [Google Scholar]

- Moghaddam, I.N.; Chowdhury, B.H.; Mohajeryami, S. Predictive Operation and Optimal Sizing of Battery Energy Storage With High Wind Energy Penetration. IEEE Trans. Ind. Electron. 2018, 65, 6686–6695. [Google Scholar] [CrossRef]

- Dui, X.; Zhu, G.; Yao, L. Two-Stage Optimization of Battery Energy Storage Capacity to Decrease Wind Power Curtailment in Grid-Connected Wind Farms. IEEE Trans. Power Syst. 2018, 33, 3296–3305. [Google Scholar] [CrossRef]

- Hu, J.; Sarker, M.R.; Wang, J.; Wen, F.; Liu, W. Provision of flexible ramping product by battery energy storage in day-ahead energy and reserve markets. IET Gener. Transm. Distrib. 2018, 12, 2256–2264. [Google Scholar] [CrossRef]

- Cai, H.; Chen, Q.; Guan, Z.; Huang, J. Day-ahead optimal charging/discharging scheduling for electric vehicles in microgrids. Prot. Control Mod. Power Syst. 2018, 73, 9. [Google Scholar] [CrossRef]

- Li, J.L.; Xiu, X.Q.; Liu, D.T.; Hui, D. Research on Second Use of Retired Electric Vehicle Battery Energy Storage System Considering Policy Incentive. High Volt. Eng. 2015, 42, 2562–2568. [Google Scholar]

- Ma, J.; Ma, Q.B. Development status and tendency of electric vehicles in China. Mech. Equip. 2017, 48, 44. [Google Scholar]

- Xia, M.; Lai, Q.; Zhong, Y.; Li, C.; Chiang, H.D. Aggregator-Based Interactive Charging Management System for Electric Vehicle Charging. Energies 2016, 9, 159. [Google Scholar] [CrossRef]

- Sun, H.; Shen, Z.H.; Zhou, W.; Hu, S.B.; Ma, Q.; Chen, X.D.; Li, C.P.; Yang, W.Q. Congestion Dispatch Research of Active Distribution Network With Electric Vehicle Group Response. Proc. CSEE 2017, 19, 5549–5559. [Google Scholar]

- Godina, R.; Paterakis, N.G.; Erdinç, O.; Rodrigues, E.M.G.; Catalão, J.P.S. Electric vehicles home charging impact on a distribution transformer in a Portuguese Island. In Proceedings of the International Symposium on Smart Electric Distribution Systems and Technologies, Vienna, Austria, 8–11 September 2015; pp. 74–79. [Google Scholar]

- Viswanathan, V.V.; Kintner-Meyer, M. Second use of transportation batteries: Maximizing the value of batteries for transportation and grid services. IEEE Trans. Veh. Technol. 2011, 60, 2963–2970. [Google Scholar] [CrossRef]

- Development Status and Tendency of EV Battery Recycling and Utilization. Available online: http://shupeidian.bjx.com.cn/news/20180112/873651.shtml (accessed on 12 January 2018).

- Joseph, A.; Shahidehpour, M. Battery storage systems in electric power systems. In Proceedings of the Power Engineering Society General Meeting, Montreal, QC, Canada, 18–22 June 2006; p. 8. [Google Scholar]

- Viswanathan, V.V.; Kintner-Meyer, M. Energy efficiency evaluation of a stationary lithium-ion battery container storage system via electro-thermal modeling and detailed component analysis. Appl. Energy 2018, 210, 211–229. [Google Scholar]

- Ciobotaru, C.K.; Saez-De-Ibarra, A.; Laserna, E.M.; Stroe, D.I.; Swierczynski, M.; Rodriguez, P. Second Life Battery Energy Storage System for Enhancing Renewable Energy Grid Integration. In Proceedings of the Energy Conversion Congress & Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 78–84. [Google Scholar]

- Kazakos, S.S.; Daniel, S.; Buckley, S. Distributed energy storage using second-life electric vehicle batteries. In Proceedings of the Power in Unity: A Whole System Approach, London, UK, 16–17 October 2014; pp. 1–6. [Google Scholar]

- Gladwin, D.T.; Gould, C.R.; Stone, D.A.; Foster, M.P. Viability of ‘second-life’ use of electric and hybrid-electric vehicle battery packs. In Proceedings of the Industrial Electronics Society, IECON 2013—39th Annual Conference, Vienna, Austria, 10–13 November 2014; pp. 1922–1927. [Google Scholar]

- Martinez-Laserna, E.; Sarasketa-Zabala, E.; Villarreal, I.; Stroe, D.I.; Swierczynski, M.; Warnecke, A.; Jean-Marc, T.; Goutam, S.; Omar, N.; Rodriguez, P. Technical viability of battery second life: A study from the ageing perspective. IEEE Trans. Ind. Appl. 2018, 54, 2703–2713. [Google Scholar] [CrossRef]

- Debnath, U.K.; Ahmad, I.; Habibi, D. Gridable vehicles and second life batteries for generation side asset management in the Smart Grid. Electr. Power Energy Syst. 2016, 82, 114–123. [Google Scholar] [CrossRef]

- Hernández, J.C.; Sanchez-Sutil, F.; Vidal, P.G.; Rus-Casas, C. Primary frequency control and dynamic grid support for vehicle-to-grid in transmission systems. Int. J. Electr. Power Energy Syst. 2018, 100, 152–166. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, C. Configuration and operation combined optimization for ev battery swapping station considering PV consumption bundling. Prot. Control Mod. Power Syst. 2017, 2, 26. [Google Scholar] [CrossRef]

- Gerssen-Gondelach, S.J.; Faaij, A.P.C. Performance of batteries for electric vehicles on short and longer term. J. Power Sources 2012, 212, 111–129. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.; Xiong, R.; He, H.; Mu, H.; Wang, C. A novel method on estimating the degradation and state of charge of lithium-ion batteries used for electrical vehicles. Appl. Energy 2017, 207, 336–345. [Google Scholar] [CrossRef]

- Abdel-Monem, M.; Hegazy, O.; Omar, N.; Trad, K.; Bossche, P.V.D.; Mierlo, J.V. Lithium-ion batteries: Comprehensive technical analysis of second-life batteries for smart grid applications. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; pp. 1–16. [Google Scholar]

- Baumann, M.; Rohr, S.; Lienkamp, M. Cloud-connected battery management for decision making on second-life of electric vehicle batteries. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 April 2018; pp. 1–6. [Google Scholar]

- Graber, G.; Galdi, V.; Calderaro, V.; Mancarella, P. A stochastic approach to size EV charging stations with support of second life battery storage systems. In Proceedings of the 2017 IEEE Manchester PowerTech, Manchester, UK, 18–22 June 2017; pp. 1–6. [Google Scholar]

- Li, R. Research on Evaluation and Estimation Methods for State of Health of Power Lithium Iron Battery. Ph.D. Thesis, Harbin University of Science and Technology, Harbin, China, June 2016. [Google Scholar]

- Zhang, H. Energy Storage Optimization Planning Considering Second-Use Batteries. Master’s Thesis, North China Electric Power University, Beijing, China, March 2017. [Google Scholar]

- Tong, S.; Fung, T.; Park, J.W. Reusing Electric Vehicle Battery for Demand Side Management integrating Dynamic Pricing. In Proceedings of the IEEE International Conference on Smart Grid Communications, Miami, FL, USA, 2–5 November 2015; pp. 325–330. [Google Scholar]

- Castano, S.; Jimenez, D.S.; Sanz, J. BMS influence on Li-ion packs characterization and modeling. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; pp. 1–6. [Google Scholar]

- Saha, B.; Goebel, K.; Battery Data Set. NASA Ames Prognostics Data Repository. 2007. Available online: http://ti.arc.nasa.gov/project/prognostic-data-repository (accessed on 16 November 2017).

- Chen, L.; Ji, B.; Cao, W.P.; Pan, H.H.; Tian, B.B.; Lin, W.L. Grey system theory-based capacity estimation method for Li-ion batteries. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014; pp. 1–5. [Google Scholar]

- Li, Y.Z. Discussion of “adaptive robust optimization for the security constrained unit commitment problem”. IEEE Trans. Power Syst. 2014, 29, 996. [Google Scholar] [CrossRef]

- Zhou, W.; Peng, Y.; Sun, H.; Wei, Q.H. Dynamic economic dispatch in wind power integrated system. Proc. CSEE 2009, 29, 13–18. [Google Scholar]

- Rebours, Y.; Kirschen, D.; Trotignon, M. Fundamental design issues in markets for ancillary services. Electr. J. 2007, 20, 26–34. [Google Scholar] [CrossRef]

- Liu, J.C.; Li, D.F. Corrections to “TOPSIS-Based Nonlinear-Programming Methodology for Multi-attribute Decision Making With Interval-Valued Intuitionistic Fuzzy Sets. IEEE Trans. Fuzzy Syst. 2018, 26, 391. [Google Scholar] [CrossRef]

- Liu, X. Impact of beta-distributed wind power on economic load dispatch. Electr. Power Compon. Syst. 2011, 39, 768–779. [Google Scholar] [CrossRef]

- Zhang, H.F.; Gao, F.; Wu, J.; Liu, K. A Dynamic Economic Dispatching Model for Power Grid Containing Wind Power Generation System. Power Syst. Technol. 2013, 37, 1298–1303. [Google Scholar]

- Shen, Z.; Xie, S.Q.; Pan, C.Y. Probability and Statistics; High Education Press: Beijing, China, June 2008; pp. 139–143, 161–163. [Google Scholar]

- Attaviriyanupap, P.; Kita, H.; Tanaka, E.; Hasegawa, J. A hybrid EP and SQP for dynamic economic dispatch with nonsmooth fuel cost function. IEEE Trans. Power Syst. 2002, 17, 411–416. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhao, J.Q.; Chen, X.Y. Multi-objective Unit Commitment Fuzzy Modeling and Optimization for Energy-saving and Emission Reduction. Proc. CSEE 2010, 30, 71–76. [Google Scholar]

- Wang, X.; Gaustad, G.; Babbitt, C.W.; Richa, K. Economies of scale for future lithium-ion battery recycling infrastructure. Resour. Conserv. Recycl. 2014, 83, 53–62. [Google Scholar] [CrossRef]

- Jin, Q.H. Recycling Modes of Power Batteries of Electric Vehicles Based on Product Life Cycle. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, April 2016. [Google Scholar]

- USGS. Mineral Commodity Summaries 2012. U.S. Geological Survey, 2012. Available online: https://minerals.usgs.gov/minerals/pubs/mcs/2012/mcs2012.pdf (accessed on 20 April 2018).

| Wind Farm | Installation Capacity (MW) | SLBFL | Installation Capacity (MW) |

|---|---|---|---|

| 1 | 60 | 1 | 200 |

| 2 | 120 | 2 | 150 |

| 3 | 180 | 3 | 150 |

| 4 | 240 | ||

| Total Capacity | 600 | Total Capacity | 500 |

| Unit | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Pmax (MW) | 470 | 460 | 340 | 300 | 243 | 160 | 130 | 120 | 80 | 55 |

| Pmin (MW) | 150 | 135 | 73 | 60 | 73 | 57 | 20 | 47 | 20 | 55 |

| a ($/MW2h) | 0.00043 | 0.00063 | 0.00039 | 0.00070 | 0.00079 | 0.00056 | 0.00211 | 0.00480 | 0.10908 | 0.00951 |

| b ($/MWh) | 21.60 | 21.05 | 20.81 | 23.90 | 21.62 | 17.87 | 16.51 | 23.23 | 19.58 | 22.54 |

| c ($/h) | 958.20 | 1313.6 | 604.97 | 471.60 | 480.29 | 601.75 | 502.70 | 639.40 | 455.60 | 692.40 |

| e ($/h) | 450 | 600 | 320 | 260 | 280 | 310 | 300 | 340 | 270 | 380 |

| F (rad/MW) | 0.041 | 0.036 | 0.028 | 0.052 | 0.063 | 0.048 | 0.086 | 0.082 | 0.098 | 0.094 |

| α (kg/MW2h) | 0.022 | 0.020 | 0.044 | 0.058 | 0.065 | 0.080 | 0.075 | 0.082 | 0.090 | 0.084 |

| β (kg/MWh) | −2.86 | −2.72 | −2.94 | −2.35 | −2.36 | −2.28 | −2.36 | −1.29 | −1.14 | −2.14 |

| γ (kg/h) | 130 | 132 | 137 | 130 | 125 | 110 | 135 | 157 | 160 | 137.7 |

| UR | 120 | 120 | 120 | 100 | 100 | 100 | 50 | 50 | 50 | 50 |

| DR | 120 | 120 | 120 | 100 | 100 | 100 | 50 | 50 | 50 | 50 |

| CoeURi ($/MWh) | 14.7 | 15.5 | 15.2 | 17.8 | 19.3 | 19.8 | 18.7 | 21.7 | 23.4 | 25.2 |

| CoeDRi ($/MWh) | 15.2 | 14.8 | 15.1 | 18.6 | 21.2 | 19.5 | 19 | 22 | 23.1 | 25.6 |

| Coeramp−upi ($/MWh) | 3.13 | 3.08 | 3.75 | 4.17 | 5.88 | 9.71 | 9.09 | 13.7 | 16.67 | 28.57 |

| Coeramp−downi ($/MWh) | 3.13 | 3.08 | 3.75 | 4.17 | 5.88 | 9.71 | 9.09 | 13.7 | 16.67 | 28.57 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Sun, H.; Peng, F.; Zhou, W.; Cao, W.; Su, A.; Chen, X.; Sun, M. Optimization Strategy for Economic Power Dispatch Utilizing Retired EV Batteries as Flexible Loads. Energies 2018, 11, 1657. https://doi.org/10.3390/en11071657

Hu S, Sun H, Peng F, Zhou W, Cao W, Su A, Chen X, Sun M. Optimization Strategy for Economic Power Dispatch Utilizing Retired EV Batteries as Flexible Loads. Energies. 2018; 11(7):1657. https://doi.org/10.3390/en11071657

Chicago/Turabian StyleHu, Shubo, Hui Sun, Feixiang Peng, Wei Zhou, Wenping Cao, Anlong Su, Xiaodong Chen, and Mingze Sun. 2018. "Optimization Strategy for Economic Power Dispatch Utilizing Retired EV Batteries as Flexible Loads" Energies 11, no. 7: 1657. https://doi.org/10.3390/en11071657