Lightning Impulse Withstand of Natural Ester Liquid

Abstract

:1. Introduction

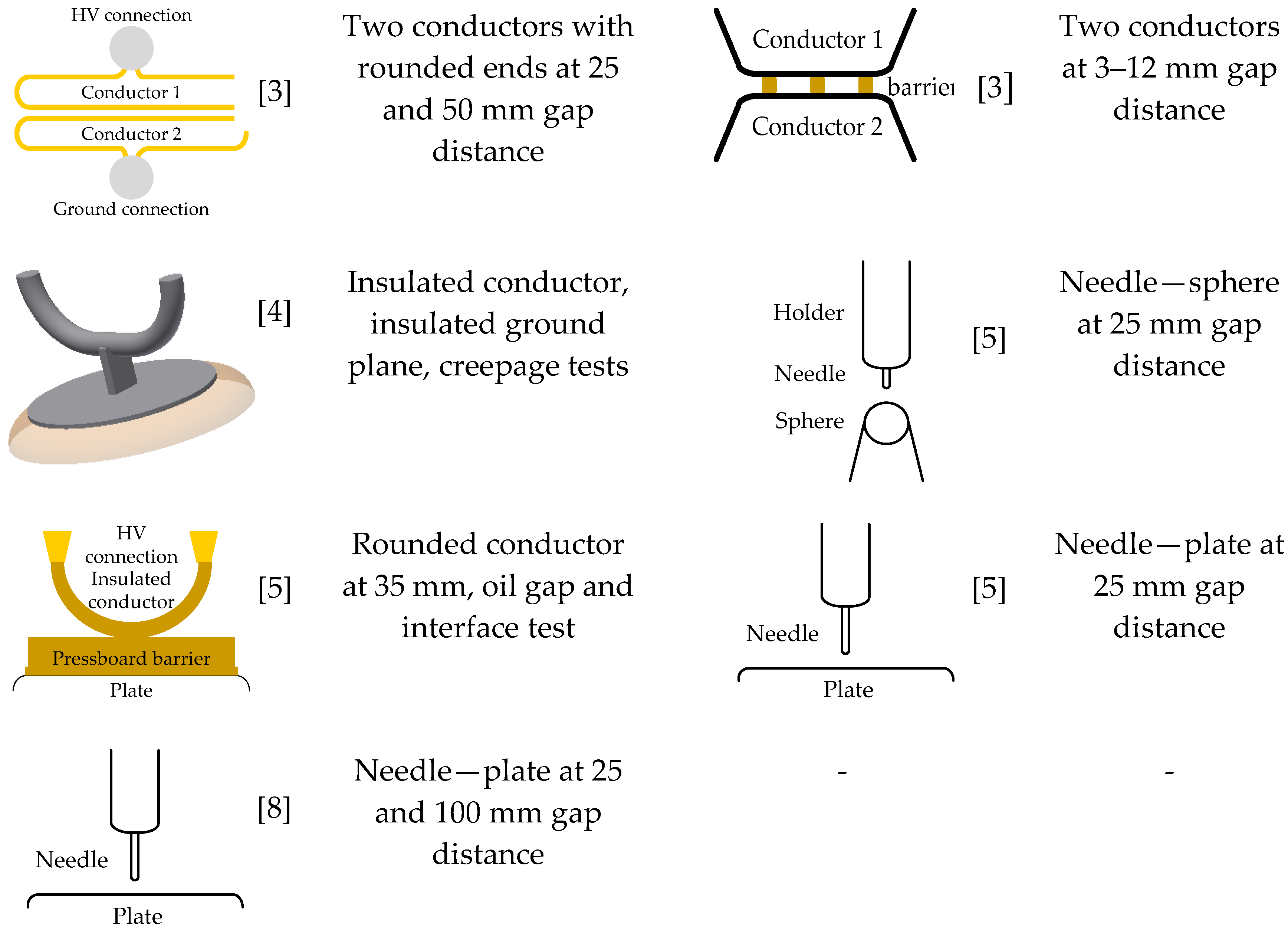

2. Measurement of Breakdown in Insulating Liquid

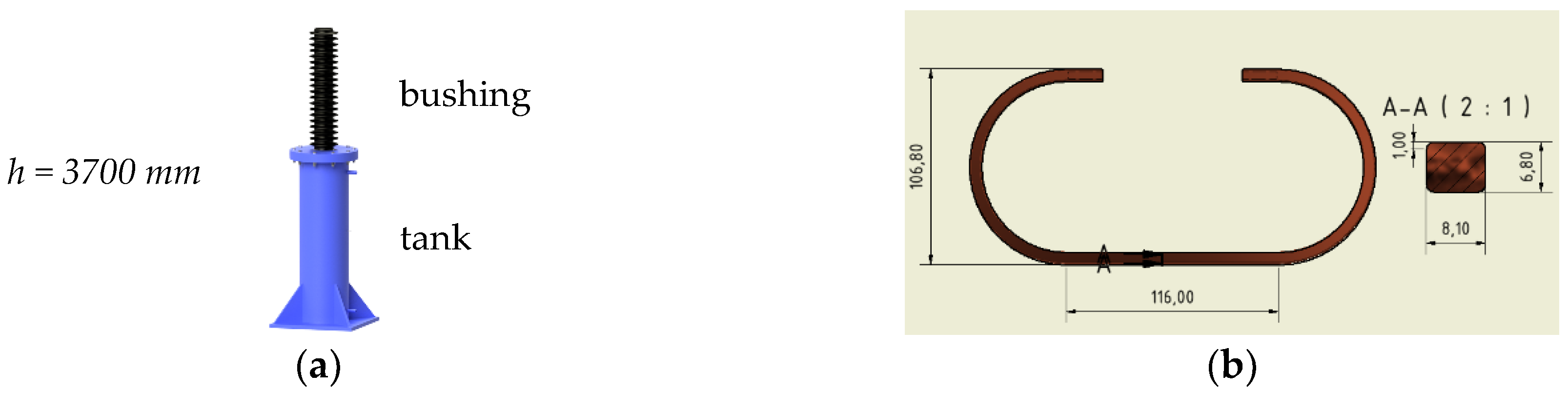

2.1. Lightning Impulse Generating and Measurement Setup

2.2. Procedure

2.3. Electrode Conditioning

2.4. Calculation of Inhomogeneity Degrees

3. Measurement Results

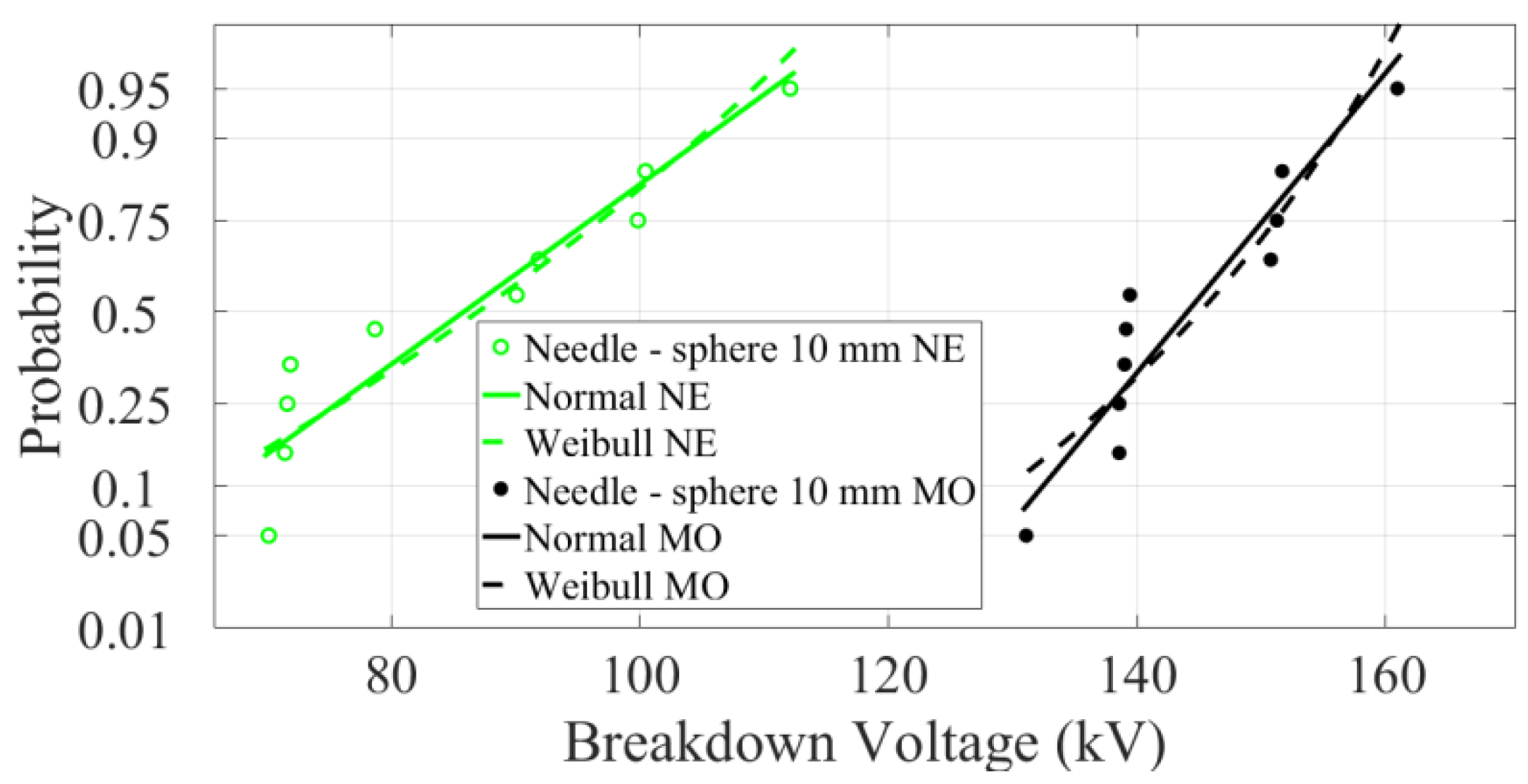

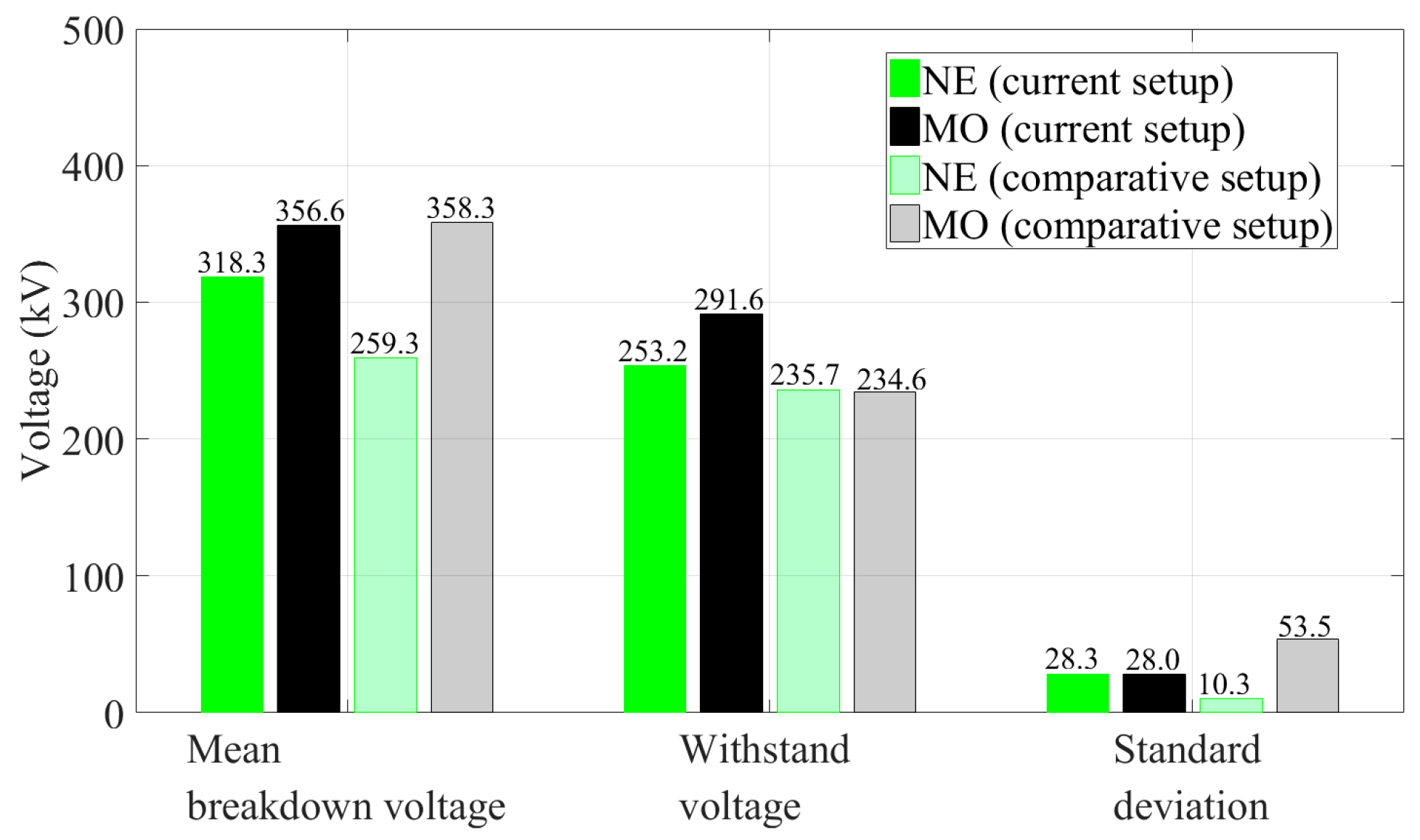

3.1. Mean Breakdown Field Strength, Mean Breakdown Voltage and Withstand Voltage

3.2. Homogeneity Factor and Breakdown Voltage—Differences between Mineral Oil and Natural Ester Liquid

3.3. Conductor Breakdown Test

3.4. Comparison of Different Setups and Explanation of Their Breakdown Results

3.4.1. Needle Arrangement Group (i)

3.4.2. Conductor Arrangement Group (ii)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pompili, M.; Calcara, L.; Sturchio, A.; Catanzaro, F. Natural esters distribution transformers: A solution for environmental and fire risk prevention. In Proceedings of the AEIT, Capri, Italy, 5–7 October 2016. [Google Scholar] [CrossRef]

- Vukovic, D.; Jovalekic, M.; Tenbohlen, S. Comparative Experimental Study of Dielectric Strength of Oil-cellulose Insulation for Mineral and Vegetable-based Oils. In Proceedings of the IEEE ISEI, San Juan, PR, USA, 10–13 June 2012; pp. 424–428. [Google Scholar] [CrossRef]

- Sbravati, A.; Rapp, K.J. Challenges for the application of Natural Ester fluids in extra high voltage transformers. In Proceedings of the CIGRE-AORC Technical Meeting 2016, New Delhi, India, 24–26 February 2016. [Google Scholar]

- Prevost, T. Dielectric properties of natural esters and their influence on transformer insulation system design and performance. In Proceedings of the IEEE PES T&D, Dallas, TX, USA, 21–24 May 2006. [Google Scholar] [CrossRef]

- Liu, R.; Törnkvist, C.; Chandramouli, V.; Girlanda, O.; Pettersson, L. Geometry impact on streamer propagation in transformer insulation liquids. In Proceedings of the Annual Report CEIDP, West Lafayette, IN, USA, 17–20 October 2010. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Z.D. Streamer characteristic and breakdown in synthetic and natural ester transformer liquids with pressboard interface under lightning impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1908–1917. [Google Scholar] [CrossRef]

- Denat, A.; Lesaint, O.; McCluskey, F. Breakdown of liquids in long gaps: Influence of distance, impulse shape, liquid nature, and interpretation of measurements. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2581–2591. [Google Scholar] [CrossRef]

- Liu, R.; Törnkvist, C.; Chandramouli, V.; Girlanda, O.; Pettersson, L. Ester fluids as alternative for mineral oil: The difference in streamer velocity and LI breakdown voltage. In Proceedings of the Annual Report CEIDP, Virginia Beach, VA, USA, 18–21 October 2009; pp. 543–548. [Google Scholar] [CrossRef]

- Hwang, J.G.; Zahn, M.; Pettersson, L. Mechanisms behind positive streamers and their distinct propagation modes in transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 162–174. [Google Scholar] [CrossRef]

- Lesaint, O. Prebreakdown phenomena in liquids: Propagation “modes” and basic physical properties. J. Phys. D Appl. Phys. 2016. [Google Scholar] [CrossRef]

- Lesaint, O.; Top, T.V. Streamer initiation in mineral oil. Part I: Electrode surface effect under impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 84–91. [Google Scholar] [CrossRef]

- Rain, P.; Lesaint, O. Prebreakdown Phenomena in Mineral Oil under Step and Ac Voltage in Large-Gap Divergent Fields. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 692–701. [Google Scholar] [CrossRef]

- Rozga, P.; Stanek, M. Positive Streamer Propagation in Natural Ester and Mineral Oil under Lightning Impulse. In Proceedings of the ISH, Pilsen, Czech Republic, 23–28 August 2015. [Google Scholar]

- Rozga, P.; Stanek, M. Characteristics of streamers developing at inception voltage in small gaps of natural ester, synthetic ester and mineral oil under lightning impulse. IET Sci. Meas. Technol. 2016, 10, 50–57. [Google Scholar] [CrossRef]

- Rozga, P.; Stanek, M. Comparative analysis of lightning breakdown voltage of natural ester liquids of different viscosities supported by light emission measurement. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 991–999. [Google Scholar] [CrossRef]

- Lu, W.; Liu, Q. Effect of cellulose particles on impulse breakdown in ester transformer liquids in uniform electric fields. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2554–2564. [Google Scholar] [CrossRef]

- Weber, K.H.; Endicott, H.S. Extremal Area Effect for Large Area Electrodes for the Electric Breakdown of Transformer Oil. Trans. Am. Inst. Electr. Eng. Part III Power Appar. Syst. 1957, 76, 1091–1096. [Google Scholar] [CrossRef]

- Haegele, S.; Tenbohlen, S.; Fritsche, R.; Rapp, K.J.; Sbravati, A. Characterization of inhomogeneous field breakdown in natural ester liquid compared to mineral oil. In Proceedings of the ICHVE, Chengdu, China, 19–22 September 2016. [Google Scholar] [CrossRef]

- Schwaiger, A. Elektrische Festigkeitslehre, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1925; pp. 450–451. [Google Scholar]

- Girdino, P.; Molfino, P.; Molinari, G. Effect of streamer shape and dimensions on local electric field conditions. IEEE Trans. Electr. Insul. 1988, 23, 4. [Google Scholar] [CrossRef]

- Yamashita, H.; Amano, H. Prebreakdown Phenomena in Hydrocarbon Liquids. IEEE Trans. Electr. Insul. 1988, 23, 403–408. [Google Scholar] [CrossRef]

- Forster, E.O. Critical Assessment of the Electrical Breakdown Process in Dielectric Fluids. IEEE Trans. Electr. Insul. 1985, 20, 891–896. [Google Scholar] [CrossRef]

- Chadband, W.G.; Sufian, T.M. Experimental Support for a Model of Positive Streamer Propagation in Liquid Insulation. IEEE Trans. Electr. Insul. 1985, 20, 239–246. [Google Scholar] [CrossRef]

- Hebner, R.E.; Kelley, E.F.; Forster, E.O.; FitzPatrick, G.J. Observations of Prebreakdown and Breakdown Phenomena in Liquid Hydrocarbons under Non-uniform Field Conditions. In Proceedings of the 1984 Eighth International Conference on Conduction and Breakdown in Dielectric Liquids, Pavia, Italy, 24–27 July 1984. [Google Scholar]

- Lewis, T.J. Electronic Processes in Dielectric Liquids under Incipient Breakdown Stress. IEEE Trans. Electr. Insul. 1985, 2, 123–132. [Google Scholar] [CrossRef]

- Duy, C.T.; Lesaint, O.; Denat, A.; Bonifaci, N. Streamer propagation and breakdown in natural ester at high voltage. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1582–1594. [Google Scholar] [CrossRef]

- Sbravati, A.; Bingenheimer, D.; Rapp, K.J.; Gomes, J.C. Fluid treatment applied for natural esters based fluids: Evaluation of fluid reconditioning and reclaiming. In Proceedings of the CIGRE Study Committee A2, Shanghai, China, 21–25 September 2015. [Google Scholar]

- Rapp, K.J.; McShane, C.P.; Systems, C.P. Long Gap Breakdown of natural ester liquid. In Proceedings of the ICHVE 2010, New Orleans, LA, USA, 11–14 October 2010; pp. 104–107. [Google Scholar]

- Nguyen Ngoc, M.; Lesaint, O.; Bonifaci, N.; Denat, A.; Hassanzadeh, M. A comparison of breakdown properties of natural and synthetic esters at high voltage. In Proceedings of the Annual Report CEIDP, West Lafayatte, IN, USA, 17–20 October 2010. [Google Scholar] [CrossRef]

| 10 mm | 15 mm | 25 mm | 40 mm | 50 mm |

|---|---|---|---|---|

| Sphere | Sphere | Sphere | - | - |

| Blunt point (Bp) 3 mm | Bp 3 mm | Bp 3 mm | - | - |

| Bp 0.8 mm | Bp 0.8 mm | Bp 0.8 mm | - | - |

| Bp 0.6 mm | Bp 0.6 mm | Bp 0.6 mm | - | - |

| Needle 120 µm | - | Needle 120 µm | Needle 120 µm | Needle 120 µm |

| Liquid | Normal Distribution | ||

|---|---|---|---|

| Ud,1% (kV) | Ud,50% (kV) | σ | |

| MO | 291.6 | 356.6 | 28.0 |

| NE | 252.3 | 318.3 | 28.3 |

| Liquid | Weibull Distribution | |||

|---|---|---|---|---|

| Ud,1% (kV) | Ud,50% (kV) | α | β | |

| MO | 248.3 | 358.5 | 370.1 | 11.5 |

| NE | 222.8 | 321.2 | 331.5 | 11.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haegele, S.; Vahidi, F.; Tenbohlen, S.; Rapp, K.J.; Sbravati, A. Lightning Impulse Withstand of Natural Ester Liquid. Energies 2018, 11, 1964. https://doi.org/10.3390/en11081964

Haegele S, Vahidi F, Tenbohlen S, Rapp KJ, Sbravati A. Lightning Impulse Withstand of Natural Ester Liquid. Energies. 2018; 11(8):1964. https://doi.org/10.3390/en11081964

Chicago/Turabian StyleHaegele, Stephanie, Farzaneh Vahidi, Stefan Tenbohlen, Kevin J. Rapp, and Alan Sbravati. 2018. "Lightning Impulse Withstand of Natural Ester Liquid" Energies 11, no. 8: 1964. https://doi.org/10.3390/en11081964