Combustion Characteristics and NOx Emission through a Swirling Burner with Adjustable Flaring Angle

Abstract

:1. Introduction

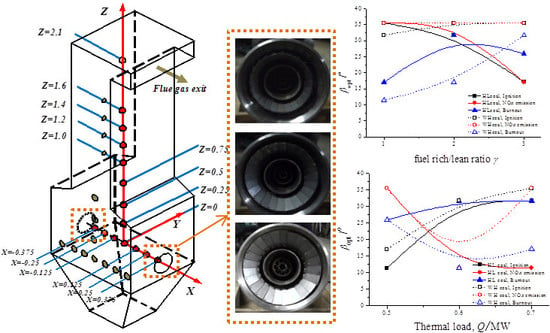

2. Experimental Setup and Research Methods

3. Results and Discussion

3.1. Effect on Fuel Rich/Lean Combustion

3.2. Effect on Load Variation

3.3. Combustion Adjustment Suggestion

4. Conclusions

- (1)

- Under fuel rich/lean combustion conditions, burner ISA β variation could promote ignition characteristic temperatures above 200 °C. For ignition improvement it is suggested to reduce β for HL coal but to augment it for WH coal when rich/lean ratio γ increases. NOx emissions are less affected by β than γ, but variation of β has a further reduction effect on NOx emissions than fixed β. Rising β could promote burnout for both coals if γ increases for fuel rich/lean combustion.

- (2)

- Under fuel rich/lean combustion conditions, burner ISA β diminution could promote ignition for both coals when load decreases. Under the same load, the optimal β obtains about 50–100 °C higher ignition characteristic temperature than the worst β condition. Variation of β can reduce NOx emissions by about 50 ppm and enhance burnout about 10% compared with the worst β conditions under the same load.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Variables | |

| a | depth of furnace (m) |

| x, y, z | depth, width and height coordinate of the furnace (m) |

| X, Y, Z | dimensionless of depth, width and height of the furnace (-) |

| V | air ratio |

| n | swirl number |

| α | excess air ratio |

| β | inner secondary air flaring angle (°) |

| w | mass fraction (%) |

| ψ | char burnout |

| Q | thermal load |

| γ | ratio of rich(inner) to lean(outer) for pulverized coal concentration |

| T | temperature |

| Abbreviations | |

| IPA | inner primary air |

| OPA | outer primary air |

| ISA | inner secondary air |

| OSA | outer secondary air |

| Subscripts | |

| 1/2, 3/4 | inner/outer primary air, inner/outer secondary air |

| k | input coal |

| x | char sample |

| opt | optimization |

| ig | ignition |

| max | maximum |

References

- Chang, S.; Zhuo, J.; Meng, S.; Qin, S.; Yao, Q. Clean coal technologies in China: Current status and future perspectives. Engineering 2016, 2, 447–459. [Google Scholar] [CrossRef]

- Guan, G. Clean coal technologies in Japan: A review. Chin. J. Chem. Eng. 2017, 25, 689–697. [Google Scholar] [CrossRef]

- Zhang, L.; He, C.; Yang, A.; Yang, Q.; Han, J. Modeling and implication of coal physical input-output table in China—Based on clean coal concept. Resour. Conserv. Recycl. 2018, 129, 355–365. [Google Scholar] [CrossRef]

- Gaikwad, P.; Kulkarni, H.; Sreedhara, S. Simplified numerical modelling of oxy-fuel combustion of pulverized coal in a swirl burner. Appl. Therm. Eng. 2017, 124, 734–745. [Google Scholar] [CrossRef]

- Fan, W.; Li, Y.; Guo, Q.; Chen, C.; Wang, Y. Coal-nitrogen release and nox evolution in the oxidant-staged combustion of coal. Energy 2017, 125, 417–426. [Google Scholar] [CrossRef]

- Xiouris, C.Z.; Koutmos, P. Fluid dynamics modeling of a stratified disk burner in swirl co-flow. Appl. Therm. Eng. 2012, 35, 60–70. [Google Scholar] [CrossRef]

- Sanmiguel-Rojas, E.; Burgos, M.A.; del Pino, C.; Fernandez-Feria, R. Three-dimensional structure of confined swirling jets at moderately large reynolds numbers. Phys. Fluids 2008, 20, 044104. [Google Scholar] [CrossRef]

- Kryjak, M.; Dennis, J.; Ridler, G. Nox reduction using advanced techniques in a 175mwth multi-fuel corner-fired boiler. Energy Procedia 2017, 120, 689–696. [Google Scholar] [CrossRef]

- Sung, Y.; Lee, S.; Eom, S.; Moon, C.; Ahn, S.; Choi, G.; Kim, D. Optical non-intrusive measurements of internal recirculation zone of pulverized coal swirling flames with secondary swirl intensity. Energy 2016, 103, 61–74. [Google Scholar] [CrossRef]

- Katzer, C.; Babul, K.; Klatt, M.; Krautz, H.J. Quantitative and qualitative relationship between swirl burner operatingconditions and pulverized coal flame length. Fuel Process. Technol. 2017, 156, 138–155. [Google Scholar] [CrossRef]

- Song, M.; Zeng, L.; Chen, Z.; Li, Z.; Kuang, M. Aerodynamic characteristics of a 350-mwe supercritical utility boiler with multi-injection and multi-staging: Effects of the inner and outer secondary air distribution in the burner. J. Energy Inst. 2018, 91, 65–74. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Che, M.; Zeng, L.; Li, Z.; Song, M. Effect of different inner secondary-air vane angles on combustion characteristics of primary combustion zone for a down-fired 300-mwe utility boiler with overfire air. Appl. Energy 2016, 182, 29–38. [Google Scholar] [CrossRef]

- Ti, S.; Chen, Z.; Li, Z.; Min, K.; Zhu, Q.; Chen, L.; Wang, Z. Effect of outer secondary air vane angles on combustion characteristics and nox emissions for centrally fuel rich swirl burner in a 600-mwe wall-fired pulverized-coal utility boiler. Appl. Therm. Eng. 2017, 125, 951–962. [Google Scholar] [CrossRef]

- Ti, S.; Chen, Z.; Kuang, M.; Li, Z.; Zhu, Q.; Zhang, H.; Wang, Z.; Xu, G. Numerical simulation of the combustion characteristics and no x emission of a swirl burner: Influence of the structure of the burner outlet. Appl. Therm. Eng. 2016, 104, 565–576. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Q.; Wang, B.; Zeng, L.; Che, M.; Zhang, X.; Li, Z. Anthracite combustion characteristics and no x formation of a 300 mw e down-fired boiler with swirl burners at different loads after the implementation of a new combustion system. Appl. Energy 2017, 189, 133–141. [Google Scholar] [CrossRef]

- Li, S.; Chen, Z.; Li, X.; Jiang, B.; Li, Z.; Sun, R.; Zhu, Q.; Zhang, X. Effect of outer secondary-air vane angle on the flow and combustion characteristics and nox formation of the swirl burner in a 300-mw low-volatile coal-fired boiler with deep air staging. J. Energy Inst. 2017, 90, 239–256. [Google Scholar] [CrossRef]

- Jing, J.; Li, Z.; Liu, G.; Chen, Z.; Ren, F. Influence of different outer secondary air vane angles on flow and combustion characteristics and nox emissions of a new swirl coal burner. Energy Fuels 2010, 24, 346–354. [Google Scholar] [CrossRef]

- Luo, R.; Zhang, Y.; Li, N.; Zhou, Q.; Sun, P. Experimental study on flow and combustion characteristic of a novel swirling burner based on dual register structure for pulverized coal combustion. Exp. Therm. Fluid Sci. 2014, 54, 136–150. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Y.; Liu, H.; Hang, Q. Numerical simulation of the combustion characteristics of a low nox swirl burner: Influence of the primary air pipe. Fuel 2014, 130, 168–176. [Google Scholar] [CrossRef]

- Luo, R.; Li, N.; Zhang, Y.; Wang, D.; Liu, T.; Zhou, Q.; Chen, X. Effect of the adjustable inner secondary air-flaring angle of swirl burner on coal-opposed combustion. J. Energy Eng. 2016, 142, 04015018. [Google Scholar] [CrossRef]

- Song, M.; Zeng, L.; Yang, X.; Chen, Z.; Li, Z. Influence of the mass ratio of pulverized-coal in fuel-rich flow to that in fuel-lean flow on the gas/particle flow and particle distribution characteristics in a 600 mwe down-fired boiler. Exp. Therm. Fluid Sci. 2018, 91, 363–373. [Google Scholar] [CrossRef]

- Zeng, L.; Li, Z.; Cui, H.; Zhang, F.; Chen, Z.; Zhao, G. Effect of the fuel bias distribution in the primary air nozzle on the slagging near a swirl coal burner throat. Energy Fuels 2009, 23, 4893–4899. [Google Scholar] [CrossRef]

- Zhou, H.; Ma, W.; Zhao, K.; Yang, Y.; Qiu, K. Experimental investigation on the flow characteristics of rice husk in a fuel-rich/lean burner. Fuel 2016, 164, 1–10. [Google Scholar] [CrossRef]

- Li, Z.; Li, S.; Zhu, Q.; Zhang, X.; Li, G.; Liu, Y.; Chen, Z.; Wu, J. Effects of particle concentration variation in the primary air duct on combustion characteristics and nox emissions in a 0.5-mw test facility with pulverized coal swirl burners. Appl. Therm. Eng. 2014, 73, 859–868. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Jing, J.; Wang, F.; Chen, L.; Wu, S. The influence of fuel bias in the primary air duct on the gas/particle flow characteristics near the swirl burner region. Fuel Process. Technol. 2008, 89, 958–965. [Google Scholar] [CrossRef]

- Gu, Y.; Xu, J.; Chen, D.; Wang, Z.; Li, Q. Overall review of peak shaving for coal-fired power units in China. Renew. Sustain. Energy Rev. 2016, 54, 723–731. [Google Scholar] [CrossRef]

- Li, S.; Chen, Z.; He, E.; Jiang, B.; Li, Z.; Wang, Q. Combustion characteristics and no x formation of a retrofitted low-volatile coal-fired 330 mw utility boiler under various loads with deep-air-staging. Appl. Therm. Eng. 2017, 110, 223–233. [Google Scholar] [CrossRef]

- Luo, R.; Fu, J.; Li, N.; Zhang, Y.; Zhou, Q. Combined control of secondary air flaring angle of burner and air distribution for opposed-firing coal combustion. Appl. Therm. Eng. 2015, 79, 44–53. [Google Scholar] [CrossRef]

- Beér, J.M.; Chomiak, J.; Smoot, L.D. Fluid dynamics of coal combustion: A review. Prog. Energy Combust. Sci. 1984, 10, 177–208. [Google Scholar] [CrossRef]

- Sung, Y.; Choi, G. Non-intrusive optical diagnostics of co- and counter-swirling flames in a dual swirl pulverized coal combustion burner. Fuel 2016, 174, 76–88. [Google Scholar] [CrossRef]

- Li, Z.; Jing, J.; Chen, Z.; Ren, F.; Xu, B.; Wei, H.; Ge, Z. Combustion characteristics and no x emissions of two kinds of swirl burners in a 300-mwe wall-fired pulverized-coal utility boiler. Combust. Sci. Technol. 2008, 180, 1370–1394. [Google Scholar] [CrossRef]

- Sung, Y.; Moon, C.; Eom, S.; Choi, G.; Kim, D. Coal-particle size effects on no reduction and burnout characteristics with air-staged combustion in a pulverized coal-fired furnace. Fuel 2016, 182, 558–567. [Google Scholar] [CrossRef]

| Fuel | Proximate Analysis/% | Ultimate Analysis/% | NCV (Net Calorific Value)/MJ·kg−1 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mar | Aar | Vdaf | Car | Har | Nar | Oar | Sar | ||

| HL coal | 6.80 | 13.59 | 38.00 | 65.67 | 3.95 | 0.85 | 8.60 | 0.54 | 24.93 |

| WH coal | 1.39 | 43.94 | 32.08 | 42.87 | 2.70 | 0.66 | 8.01 | 0.43 | 16.29 |

| Num | Parameter | Variable Symbol | Unit | Value |

|---|---|---|---|---|

| 1 | Coal | - | - | HL coal, WH coal |

| 2 | Ratio of rich(inner) to lean(outer) for pulverized coal concentration | γ | - | 1, 2, 3 |

| 3 | Thermal load | Q | MW | 0.7, 0.6, 0.5 |

| 4 | Swirl number | n | - | n1 = 0, n2 = 0, n3 = 0.95, n4 = 0 |

| 5 | OPA flaring angle | βOPA | ° | 14 |

| 6 | ISA flaring angle | β | ° | 11.4, 17.1, 26.0, 31.7, 35.5 |

| 7 | OSA flaring angle | βOSA | ° | 24 |

| 8 | Air temperature | T0 | K | 343 |

| 9 | Excess air coefficient | α | - | 1.2 |

| 10 | Air ratio | V | - | V1 = 0.1, V2 = 0.1, V3 = 0.6, V4 = 0.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Luo, R.; Dou, Y.; Zhou, Q. Combustion Characteristics and NOx Emission through a Swirling Burner with Adjustable Flaring Angle. Energies 2018, 11, 2173. https://doi.org/10.3390/en11082173

Zhang Y, Luo R, Dou Y, Zhou Q. Combustion Characteristics and NOx Emission through a Swirling Burner with Adjustable Flaring Angle. Energies. 2018; 11(8):2173. https://doi.org/10.3390/en11082173

Chicago/Turabian StyleZhang, Yafei, Rui Luo, Yihua Dou, and Qulan Zhou. 2018. "Combustion Characteristics and NOx Emission through a Swirling Burner with Adjustable Flaring Angle" Energies 11, no. 8: 2173. https://doi.org/10.3390/en11082173