Failure Modes, Effects and Criticality Analysis for Wind Turbines Considering Climatic Regions and Comparing Geared and Direct Drive Wind Turbines

Abstract

1. Introduction

- (1)

- Determining impacts of climatic regions on wind turbine subsystem annual failure rate and downtime per failure values by using failure data from an identical turbine model.

- (2)

- Investigating wind turbine subsystem and component failure causes, effects and criticalities considering climatic regions.

- (3)

- Defining the differences in annual failure rate and downtime for direct drive and geared wind turbines and revealing differences in failure causes of such failures, effects and criticalities.

2. Materials and Methods

2.1. Climatic Regions

- Cfa: Temperate-without dry season-hot summer

- Cfb: Temperate-without dry season-warm summer

- Dfb: Cold-without dry season-warm summer

- Dfc: Cold-without dry season-cold summer

2.2. Reliability Data

2.3. FMECA Approach and Components

2.3.1. Failure Modes

2.3.2. Failure Causes

2.3.3. Failure Effects

2.3.4. Criticality of Failure Modes

- (1)

- Annual failure rates and downtime per failure values are determined.

- (2)

- Downtime and cost criticality values are computed for every subsystem for wind turbines.

- (3)

- The failures in wind turbines in different climatic regions are sorted.

- (4)

- Failure rates, downtime per failures, failure modes, and effects of different subsystems in different climatic regions are determined and their downtime and cost criticality values are computed.

- (5)

- The results are compared between climatic regions and targeted turbine population.

3. Results

3.1. Investigation of Climatic Region Impact on WT Reliability and Availability

3.2. FMECA Results Considering Climatic Regions

3.3. Direct-Drive and Geared-Drive Reliability and Availability Comparison Controlling the Climatic Region Effect

3.4. FMECA Results on Direct-Drive and Geared-Drive Wind Turbines

4. Discussion

5. Conclusions

- Considering climatic regions in FMECA revealed differences in failure rate and downtime behaviors of subsystems in the wind turbines that were not reported in the previous studies.

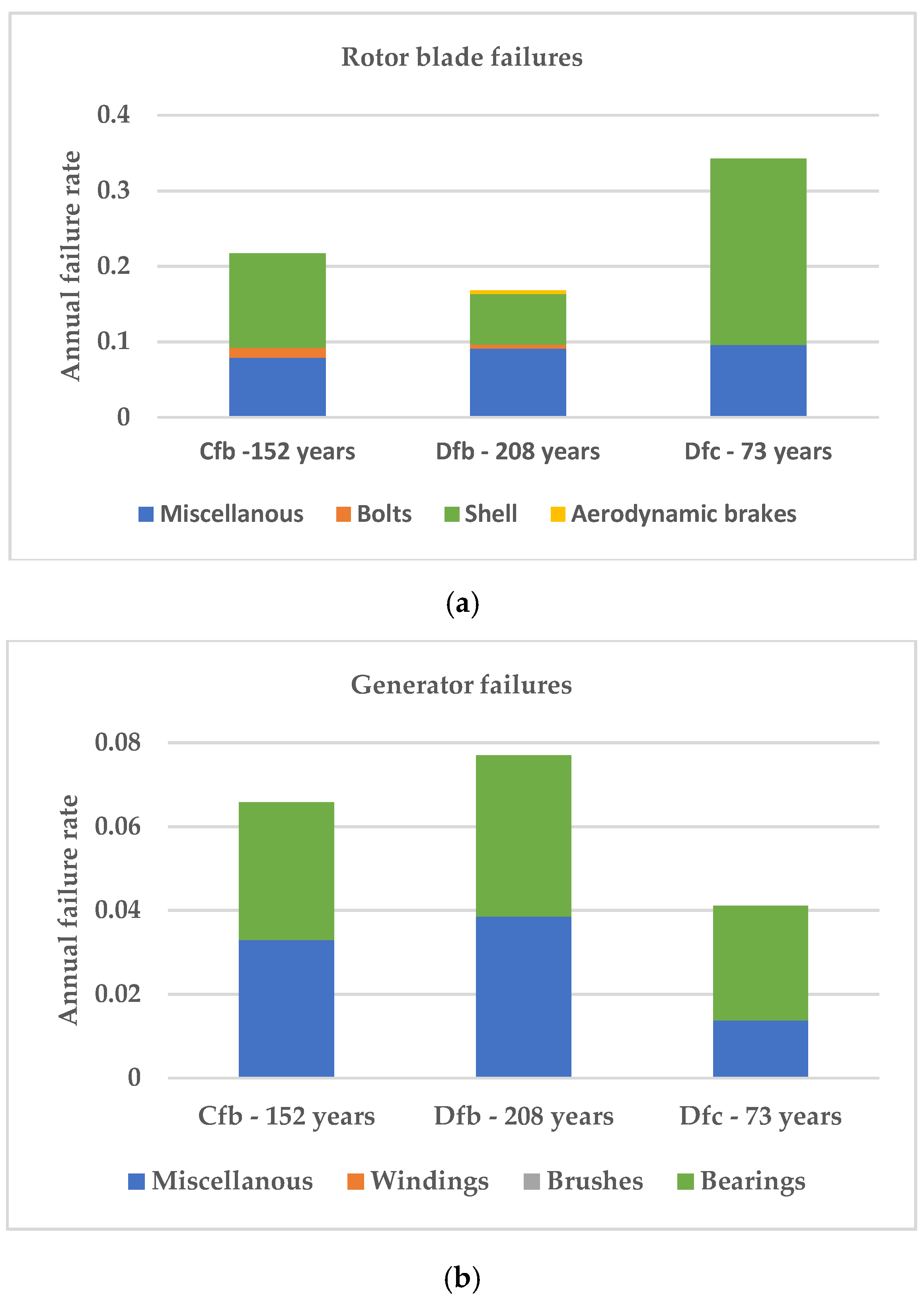

- Climatic regions have an impact on the critical subsystems and failure causes in wind turbines. This implies that the wind turbine operations and maintenance strategies for subsystems should be arranged taking local climatic conditions of the turbines into account. For example, rotor blade downtimes and failure rates are impacted by colder climates where longer downtime and higher failure rates are observed. Also, lightning became an important failure cause in cold climatic regions for rotor blade failures.

- In most of the subsystems direct-drive wind turbines seemed to have a higher failure rate than geared-drive wind turbine in the same climatic region. Direct-drive technology would be thought to be an ideal design for offshore applications because of its less complexity, however this study shows opposite. To come to a solid conclusion though, this comparison should be done with and extensive data with many different make and models of wind turbines in the future.

Author Contributions

Funding

Conflicts of Interest

References

- GWEC (2017). Global Wind Report 2016—Annual Market Update. Available online: http://gwec.net/publications/global-wind-report-2/global-wind-report-2016// (accessed on 3 March 2018).

- IEC 60050-192:2018. International Electrotechnical Vocabulary—Part 192: Reliability. Available online: http://www.electropedia.org/iev/iev.nsf/display?openform&ievref=192-01-24 (accessed on 15 June 2018).

- IEC 60050-192:2018. International Electrotechnical Vocabulary—Part 192: Availability. Available online: http://www.electropedia.org/iev/iev.nsf/display?openform&ievref=192-01-23 (accessed on 15 June 2018).

- Teng, S.-H.; Ho, S.-Y. Failure Mode and Effects Analysis an Integrated Approach for Product Design and Process Control. Int. J. Qual. Reliab. Manag. 1996, 13, 8–26. [Google Scholar] [CrossRef]

- Andrawus, J.A.; Watson, J.; Kishk, M.; Adam, A. The Selection of a Suitable Maintenance Strategy for Wind Turbines. Wind Eng. 2006, 30, 471–486. [Google Scholar] [CrossRef]

- Arabian-Hoseynabadi, H.; Oraee, H.; Tavner, P.J. Failure Modes and Effects Analysis (FMEA) for Wind Turbines. Int. J. Electr. Power Energy Syst. 2010, 32, 817–824. [Google Scholar] [CrossRef]

- Das, M.K.; Panja, S.C.; Chowdhury, S.; Chowdhury, S.P.; Elombo, A.I. Expert-Based FMEA of Wind Turbine System. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011. [Google Scholar]

- Fischer, K.; Besnard, F.; Bertling, L. Reliability-Centered Maintenance for Wind Turbines Based on Statistical Analysis and Practical Experience. IEEE Trans. Energy Convers. 2012, 27, 184–195. [Google Scholar] [CrossRef]

- Dinmohammadi, F.; Shafiee, M. A fuzzy-FMEA risk assessment approach for offshore wind turbines. Int. J. Progn. Health Manag. 2013, 4, 59–68. [Google Scholar]

- Shafiee, M.; Fateme, D. An FMEA-Based Risk Assessment Approach for Wind Turbine Systems: A Comparative Study of Onshore and Offshore. Energies 2014, 7, 619–642. [Google Scholar] [CrossRef]

- Sinha, Y.; Steel, J.A. A Progressive Study into Offshore Wind Farm Maintenance Optimisation Using Risk Based Failure Analysis. Renew. Sustain. Energy Rev. 2015, 42, 735–742. [Google Scholar] [CrossRef]

- Kahrobaee, S.; Asgarpoor, S. Risk-Based Failure Mode and Effect Analysis for Wind Turbines (RB-FMEA). 2011 N. Am. Power Symp. 2011, 1–7. [Google Scholar] [CrossRef]

- Sheng, S.; Paul, V. Wind Turbine Drivetrain Condition Monitoring—An Overview. Available online: https://www.researchgate.net/profile/Shuangwen_Sheng/publication/255247583_Wind_Turbine_Drivetrain_Condition_Monitoring_-_An_Overview/links/545a4ec50cf25c508c307c63.pdf (accessed on 29 July 2018).

- Tavner, P.J.; Higgins, A.; Arabian, H.; Long, H.; Feng, Y. Using an FMEA Method to Compare Prospective Wind Turbine Design Reliabilities. In Proceedings of the European Wind Energy Conference, Warsaw, Poland, 20–23 April 2010. [Google Scholar]

- Bharatbhai, M.G. Failure mode and effect analysis of repower 5 MW wind turbine. Int. J. Adv. Res. Eng. Sci. Technol. 2015, 2, 2393–9877. [Google Scholar]

- Tazi, N.; Châtelet, E.; Bouzidi, Y. Using a Hybrid Cost-FMEA Analysis for Wind Turbine Reliability Analysis. Energies 2017, 10, 276. [Google Scholar] [CrossRef]

- Karyotakis, A. On the Optimization of Operation and Maintenance Strategies for Offshore Wind Farms. Ph.D. Thesis, Department of Mechanical Engineering, University College London, London, UK, 2011. [Google Scholar]

- Besnard, F. On Maintenance Optimization for Offshore Wind Farms. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2013. [Google Scholar]

- Shafiee, M.; Patriksson, M.; Strömberg, A.-B.; Bertling, L. A Redundancy Optimization Model Applied to Offshore Wind Turbine Power Converters. In Proceedings of the IEEE PowerTech Conference, Grenoble, France, 16–20 June 2013. [Google Scholar] [CrossRef]

- Estimation of Turbine Reliability Figures within the DOWEC Project. Available online: https://www.ecn.nl/fileadmin/ecn/units/wind/docs/dowec/10048_004.pdf (accessed on 7 June 2018).

- Faulstich, S.; Lyding, P.; Hahn, B. Electrical components of wind turbines, a substantial risk for the availability. In Proceedings of the European Wind Energy Conference and Exhibition (EWEC), Warsaw, Poland, 20–23 April 2010. [Google Scholar]

- Vindkraft. Available online: http://vindstat.com/files/M%C3%A5nadsrapport-201606.pdf (accessed on 7 June 2018).

- Stenberg, A. Analys av Vindkraftsstatistik i Finland (Wind Turbine Analysis in Finland). Available online: http://www.vtt.fi/files/projects/windenergystatistics/diplomarbete.pdf (accessed on 6 June 2018).

- Herman, K.; Walker, R.; Winikson, M. Availability Trends Observed at Operational Wind Farms. In Proceedings of the European Wind Energy Conference & Exhibition (EWEC) 2008, Brussels, Belgium, 31 March–3 April 2008. [Google Scholar]

- Tavner, P.J.; Greenwood, D.M.; Whittle, M.W.G.; Gindele, R.; Faulstich, S.; Hahn, B. Study of Weather and Location Effects on Wind Turbine Failure Rates. Wind Energy 2013, 16, 175–187. [Google Scholar] [CrossRef]

- Slimacek, V.; Lindqvist, B.H. Reliability of Wind Turbines Modeled by a Poisson Process with Covariates, Unobserved Heterogeneity and Seasonality. Wind Energy 2016, 19, 1991–2002. [Google Scholar] [CrossRef]

- Reder, M.; Yürüşen, N.Y.; Melero, J.J. Data-Driven Learning Framework for Associating Weather Conditions and Wind Turbine Failures. Reliab. Eng. Syst. Saf. 2018, 169, 554–569. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Huang, I.-K.; Chi, K.-N. Failure Analysis of Wind Turbine Blade under Critical Wind Loads. Eng. Fail. Anal. 2013, 27, 99–118. [Google Scholar] [CrossRef]

- Pinar Pérez, J.M.; García Márquez, F.P.; Tobias, A.; Papaelias, M. Wind Turbine Reliability Analysis. Renew. Sustain. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; Mcmahon, T.A. Updated World Map of the Koppen-Geiger Climate Classification. Hydrol. Earth Syst. Sci. Discus. 2007, 4, 439–473. [Google Scholar] [CrossRef]

- Pfaffel, S.; Faulstich, S.; Rohrig, K. Performance and Reliability of Wind Turbines: A Review. Energies 2017, 10, 1904. [Google Scholar] [CrossRef]

- Faulstich, S.; Hahn, B.; Tavner, P.J. Wind Turbine Downtime and Its Importance for Offshore Deployment. Wind Energy 2011, 14, 327–337. [Google Scholar] [CrossRef]

- Andrawus, J. Maintenance Optimization for Wind Turbines. Ph.D. Thesis, Robert Gordon University, Aberdeen, UK, 2008. [Google Scholar]

- Amirat, Y.; Benbouzid, M.E.H.; Al-Ahmar, E.; Bensaker, B.; Turri, S. A Brief Status on Condition Monitoring and Fault Diagnosis in Wind Energy Conversion Systems. Renew. Sustain. Energy Rev. 2009, 13, 2629–2636. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind Turbine Condition Monitoring: State-of-the-Art Review, New Trends, and Future Challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Wind Turbine Design Cost and Scaling Model. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.581.6248&rep=rep1&type=pdf (accessed on 18 August 2018).

- Poore, R.; Watford, C. Development of an Operations and Maintenance Cost Model to Identify Cost of Energy Savings for Low Wind Speed Turbines; National Renewable Energy Laboratory (NREL): Albuquerque, NM, USA, 2008. [Google Scholar]

| 1st | 2nd | 3rd | Description | Criteria |

|---|---|---|---|---|

| C | - | - | Temperate | Thot ≥ 10 & 0 < Tcold < 18 |

| - | s | - | - Dry Summer | Psdry < 40 & Psdry < Pwwet/3 |

| - | w | - | - Dry Winter | Pwdry < Pswet/10 |

| - | f | - | - Without dry season | Not (Cs) or (Cw) |

| - | - | a | - Hot Summer | Thot ≥ 22 |

| - | - | b | - Warm Summer | Not (a) & Tmon10 ≥ 4 |

| - | - | c | - Cold Summer | Not (a or b) & 1 ≤ Tmon10 < 4 |

| D | - | - | Cold | Thot ≥ 10 & Tcold ≤ 0 |

| - | s | - | - Dry Summer | Psdry < 40 & Psdry < Pwwet/3 |

| - | w | - | - Dry Winter | Pwdry < Pswet/10 |

| - | f | - | - Without dry season | Not (Ds) or (Dw) |

| - | - | a | - Hot Summer | Thot ≥ 22 |

| - | - | b | - Warm Summer | Not (a) & Tmon10 ≥ 4 |

| - | - | c | - Cold Summer | Not (a, b or d) |

| - | - | d | - Very Cold Winter | Not (a or b) & Tcold < –38 |

| Specifications | Direct-Drive WTs | Geared-Drive WTs | Control Group of WTs (Geared-Drive) | |||

|---|---|---|---|---|---|---|

| All | Cfb | Dfb | Dfc | |||

| Number of WTs | 48 | 15 | 39 | 15 | 18 | 6 |

| Operation Years | 493 turbine-years | 152 turbine-years | 432 | 152 | 208 | 73 |

| Capacity | 500 kW | 500 kW | 500 kW | |||

| Rotor Diameter | 40 m | 39 m | 39 m | |||

| Cut-in/Cut-out Wind Speed | 2.5 m/s–25 m/s | 4 m/s–25 m/s | 4 m/s–25 m/s | |||

| Generator Type/Speed | Synchronous/38 rpm | Asynchronous/1522 rpm | Asynchronous/1522 rpm | |||

| Rotor Speed | 38 rpm | 30 rpm | 30 rpm | |||

| Blade Material | GFK/Epoxy | GFK/Epoxy | GFK/Epoxy | |||

| Subsystems of Wind Turbines | Components of Wind Turbines |

|---|---|

| Hub | Hub body, pitch mechanism, pitch bearings |

| Structure | Foundations, tower/tower bolts, nacelle frame, nacelle cover and ladder |

| Rotor Blades | Blade bolts, blade shell and aerodynamic brakes |

| Mechanical Brake | Brake disc, brake pads and brake shoe |

| Drive Train | Rotor bearings, drive shafts and couplings |

| Gearbox | Bearings, wheels, gear shaft and sealings |

| Generator | Generator windings, generator brushes and bearings |

| Yaw System | Yaw bearings, yaw motor, wheels and pinions |

| Sensors | Anemometer/wind vane, vibration switch, temperature, oil pressure switch, power sensor and revolution counter |

| Hydraulic System | Hydraulic pump, pump motor, valves and hydraulic pipes/hoses |

| Electrical System | Converter, fuses, switches and cables/connections |

| Control System | Electronic control unit, relay, measurement cables and connections |

| Failure Locations | Failure Causes | Failure Effects |

|---|---|---|

| Structures Failures | High wind | Overspeed |

| Rotor Blade Failures | Grid failure | Overload |

| Mechanical Brake Failures | Lightning | Noise |

| Drive Train Failures | Icing | Vibration |

| Gearbox Failures | Malfunction of control system | Reduced power |

| Generator Failures | Component wear or failure | Causing follow-up damage |

| Yaw System Failures | Loosening of parts | Plant stoppage |

| Sensor Failures | Other causes | Other consequences |

| Hydraulic System Failures | Cause unknown | - |

| Electrical System Failures | - | - |

| Control System Failures | - | - |

| Hub Failures | - | - |

| Subsystem | Replacement Cost $ [36,37] | AFR | Downtime per Failure | Cost of Lost Energy Production | CCN ($) | DCN (h) |

|---|---|---|---|---|---|---|

| Rotor blades | 47,584 | 0.26 | 22 | 0.33 × 500 × 22 × 0.26 × 0.12 = $112 | 47,584 × 0.26 + 112 = $12,621 | 22 × 0.26 = 6 h |

| Subsystems | Downtime Criticality Number (h) | Cost Criticality Number ($) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Average (432 Turbine Years) | Cfb (152 Turbine Years) | Dfb (207 Turbine Years) | Dfc (73 Turbine Years) | Replacement Cost ($) [36,37] | Average (432) | Cfb (152) | Dfb (207) | Dfc (73) | |

| Hub | 3 | 2 | 4 | 2 | 38,271 | 10,205 | 11,388 | 11,535 | 3236 |

| Rotor blades | 8 | 6 | 2 | 44 | 47,584 | 12,052 | 12,621 | 8365 | 21,958 |

| Generator | 23 | 48 | 4 | 12 | 43,298 | 11,939 | 13,792 | 13,033 | 3860 |

| Electric | 16 | 13 | 10 | 39 | 59,804 | 33,307 | 33,709 | 33,307 | 32,274 |

| Sensors | 9 | 3 | 15 | 4 | 25,000 | 6429 | 5817 | 6639 | 7304 |

| Control System | 9 | 12 | 8 | 9 | 10,000 | 4796 | 5574 | 4492 | 3766 |

| Gearbox | 9 | 3 | 16 | 4 | 51,750 | 15,551 | 15,788 | 18,434 | 6368 |

| Mechanical Brake | 7 | 2 | 11 | 6 | 1185 | 251 | 130 | 370 | 150 |

| Drive Train | 1 | 0 | 1 | 3 | 13,912 | 558 | 645 | 441 | 695 |

| Hydraulic System | 9 | 10 | 9 | 5 | 6114 | 2573 | 3142 | 2526 | 1272 |

| Yaw System | 2 | 2 | 2 | 1 | 15,900 | 2252 | 2134 | 2427 | 2025 |

| Structural Parts/Housing | 0 | 0 | 1 | 0 | 132,257 | 10,987 | 6867 | 15,861 | 6664 |

| Subsystems | Direct-Drive-500Kw (493 Turbine Years) | Geared-Drive-200 kW (524 Turbine Years) | Geared-Drive-300 kW (508 Turbine Years) | Geared-Drive-500 kW (152 Turbine Years) | ||||

|---|---|---|---|---|---|---|---|---|

| Annual Failure Rate | Downtime Per Failure (h) | Annual Failure Rate | Downtime Per Failure (h) | Annual Failure Rate | Downtime Per Failure (h) | Annual Failure Rate | Downtime Per Failure (h) | |

| Hub | 0.54 | 20 | 0.10 | 10 | 0.15 | 12 | 0.30 | 7 |

| Rotor blades | 0.28 | 55 | 0.09 | 16 | 0.08 | 75 | 0.26 | 22 |

| Generator | 0.54 | 39 | 0.10 | 8 | 0.15 | 90 | 0.30 | 163 |

| Electric | 0.74 | 14 | 0.32 | 19 | 1.15 | 17 | 0.56 | 23 |

| Sensors | 0.49 | 14 | 0.05 | 13 | 0.30 | 15 | 0.23 | 14 |

| Control System | 1.06 | 12 | 0.36 | 16 | 0.52 | 20 | 0.53 | 23 |

| Gearbox | 0.00 | 0 | 0.09 | 39 | 0.15 | 138 | 0.30 | 11 |

| Mechanical Brake | 0.02 | 31 | 0.01 | 6 | 0.13 | 23 | 0.08 | 22 |

| Drive Train | 0.02 | 43 | 0.03 | 6 | 0.08 | 52 | 0.05 | 6 |

| Hydraulic System | 0.02 | 13 | 0.11 | 9 | 0.40 | 15 | 0.48 | 21 |

| Yaw System | 0.20 | 28 | 0.09 | 8 | 0.38 | 28 | 0.13 | 13 |

| Structural Parts/Housing | 0.26 | 47 | 0.04 | 16 | 0.19 | 26 | 0.05 | 5 |

| Subsystems | Downtime Criticality Number (hours) | Cost Criticality Number ($) | ||||||

|---|---|---|---|---|---|---|---|---|

| 500 kW Direct-Drive (493 Turbine Years) | 500 kW Geared-Drive (152 Turbine Years) | Direct Drive Turbine Replacement Cost ($) [36,37] | Cost of Lost Energy Production ($) | 500 kW Direct-Drive (493 Turbine Years) | Geared-Drive Turbine Replacement Cost ($) [36,37] | Cost of Lost Energy Production ($) | 500 kW Geared-Drive (152 Turbine Years) | |

| Hub | 11 | 2 | 38,200 | 208 | 20,646 | 38,271 | 43 | 11,388 |

| Rotor blades | 15 | 6 | 51,262 | 301 | 14,569 | 47,584 | 112 | 12,621 |

| Generator | 21 | 48 | 120,463 | 416 | 64,865 | 43,298 | 957 | 13,792 |

| Electric | 11 | 13 | 59,804 | 211 | 44,461 | 59,804 | 256 | 33,709 |

| Sensors | 7 | 3 | 25,000 | 139 | 12,343 | 25,000 | 63 | 5817 |

| Control System | 13 | 12 | 10,000 | 256 | 10,900 | 10,000 | 240 | 5574 |

| Gearbox | 0 | 3 | 13,097 | 0 | 0 | 51,750 | 67 | 15,788 |

| Mechanical Brake | 1 | 2 | 1185 | 15 | 44 | 1185 | 35 | 130 |

| Drive Train | 1 | 0 | 13,997 | 20 | 338 | 13,912 | 5 | 645 |

| Hydraulic System | 0 | 10 | 6114 | 5 | 127 | 6114 | 199 | 3142 |

| Yaw System | 5 | 2 | 16,260 | 109 | 3305 | 15,900 | 33 | 2134 |

| Structural Parts/Housing | 12 | 0 | 228,095 | 238 | 58,511 | 132,257 | 5 | 6867 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozturk, S.; Fthenakis, V.; Faulstich, S. Failure Modes, Effects and Criticality Analysis for Wind Turbines Considering Climatic Regions and Comparing Geared and Direct Drive Wind Turbines. Energies 2018, 11, 2317. https://doi.org/10.3390/en11092317

Ozturk S, Fthenakis V, Faulstich S. Failure Modes, Effects and Criticality Analysis for Wind Turbines Considering Climatic Regions and Comparing Geared and Direct Drive Wind Turbines. Energies. 2018; 11(9):2317. https://doi.org/10.3390/en11092317

Chicago/Turabian StyleOzturk, Samet, Vasilis Fthenakis, and Stefan Faulstich. 2018. "Failure Modes, Effects and Criticality Analysis for Wind Turbines Considering Climatic Regions and Comparing Geared and Direct Drive Wind Turbines" Energies 11, no. 9: 2317. https://doi.org/10.3390/en11092317

APA StyleOzturk, S., Fthenakis, V., & Faulstich, S. (2018). Failure Modes, Effects and Criticality Analysis for Wind Turbines Considering Climatic Regions and Comparing Geared and Direct Drive Wind Turbines. Energies, 11(9), 2317. https://doi.org/10.3390/en11092317