Effects of Shoot Size and Genotype on Energy Properties of Poplar Biomass in Short Rotation Crops

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site and Plantation Establishment

2.2. Biomass Sampling

2.3. Determination of Energy Properties

2.4. Statistical Analysis

3. Results

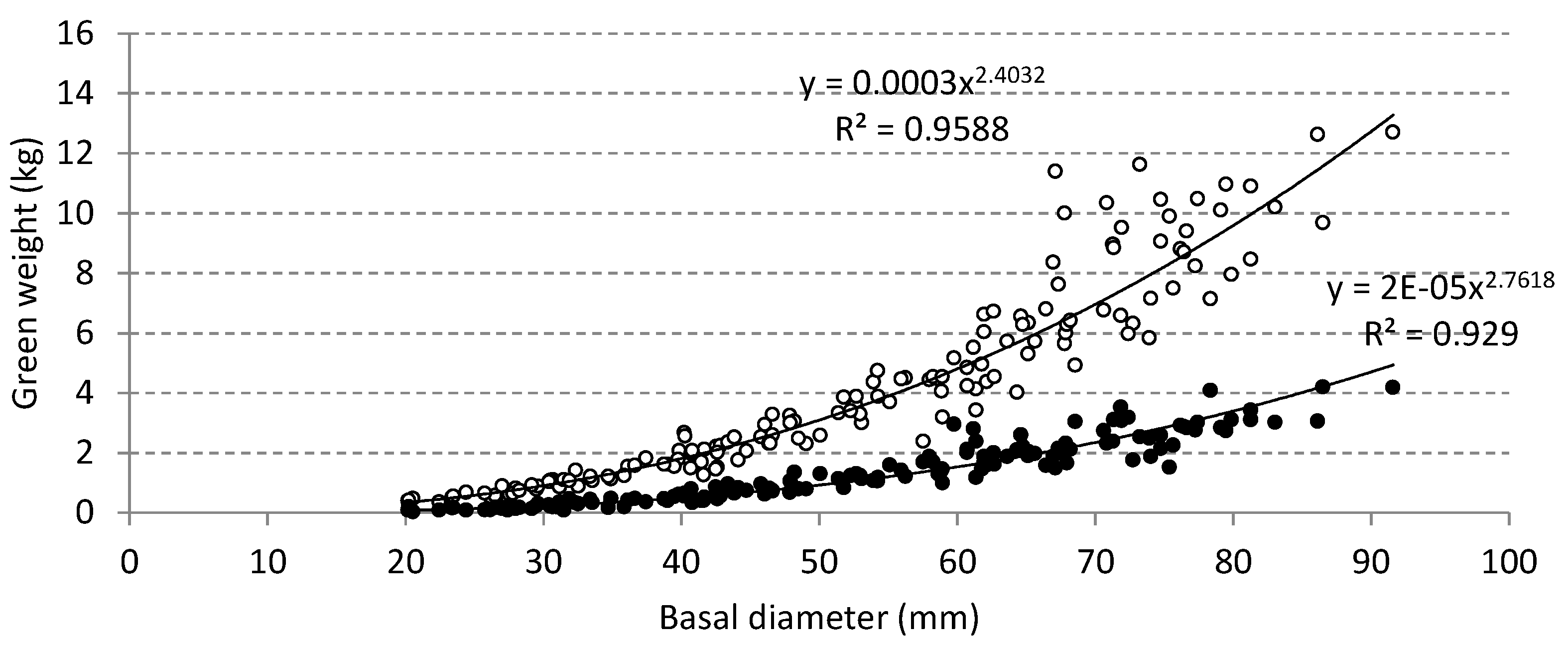

3.1. Biometric Characteristics of the Sampled Trees

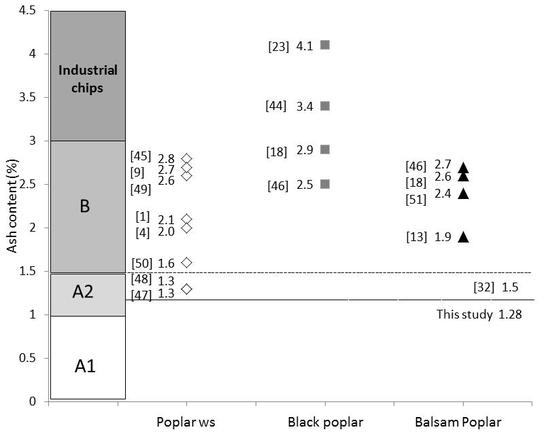

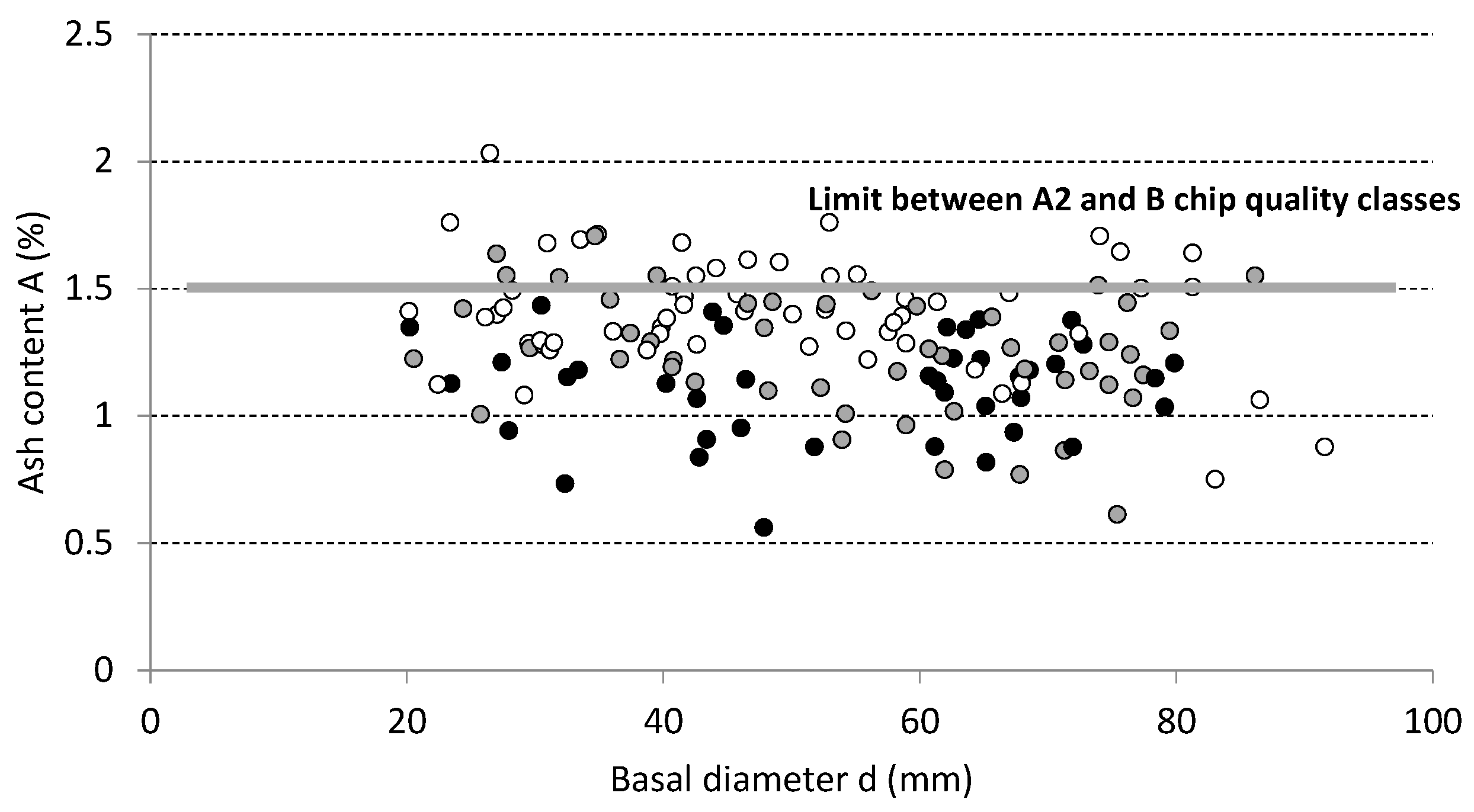

3.2. Calorific Values and Proximate Composition

3.3. Elemental Composition

4. Discussion

4.1. Energy Properties and Biomass Conversion Pathways

4.2. Approaches to Improving the Energy Properties of SRC Poplar Chips

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Zhang, X.; Tu, M.; Paice, M. Routes to potential bioproducts from lignocellulosic biomass lignin and hemicelluloses. Bioenergy Res. 2011, 4, 246–257. [Google Scholar] [CrossRef]

- IEA Bioenergy. Sustainable Production of Woody Biomass for Energy; International Energy Agency: Paris, France, 2002; p. 12.

- UNE-EN ISO 17225-1. Solid Biofuels. Fuel Specifications and Classes—Part 1: General Requirements; AENOR: Madrid, Spain, 2014; p. 62. [Google Scholar]

- Srirangan, K.; Akawi, L.; Moo-Young, M.; Chou, C.P. Towards sustainable production of clean energy carriers from biomass resources. Appl. Energy 2012, 100, 172–186. [Google Scholar] [CrossRef]

- Zanetti, M.; Costa, C.; Greco, R.; Grigolato, S.; Ottaviani, G.; Cavalli, R. How wood fuels’ quality relates to the standards: A class-modelling approach. Energies 2017, 10, 1455. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J.L.T. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-firing of coal and biomass fuel blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Stanturf, J.A.; Oosten, C.V. Operational Poplar and Willow culture. In Poplars and Willows: Trees for Society and the Environment; Isebrands, J., Richardson, J., Eds.; CABI: Wallingford, UK, 2014; pp. 200–257. [Google Scholar]

- Yemshanov, D.; McKenney, D. Fast-growing poplar plantations as a bioenergy supply source for Canada. Biomass Bioenergy 2008, 32, 185–197. [Google Scholar] [CrossRef]

- Gasol, C.M.; Martínez, S.; Rigola, M.; Rieradevall, J.; Anton, A.; Carrasco, J.; Ciria, P.; Gabarrell, X. Feasibility assessment of poplar bioenergy systems in the Southern Europe. Renew. Sustain. Energy Rev. 2009, 13, 801–812. [Google Scholar] [CrossRef]

- Kauter, D.; Lewandowski, L.; Claupein, W. Quantity and quality of harvestable biomass from Populus short rotation coppice for solid fuel use—A review of the physiological basis and management influences. Biomass Bioenergy 2003, 24, 411–427. [Google Scholar] [CrossRef]

- Laureysens, I.; Pellis, A.; Willems, J.; Ceulemans, R. Growth and production of a short rotation coppice culture of poplar. III. Second rotation results. Biomass Bioenergy 2005, 29, 10–21. [Google Scholar] [CrossRef]

- Grau, J.M.; González, F.; Montoto, J.L. Clones de chopo para una nueva populicultura de media y alta montaña. Cuadernos de la SECF 1997, 5, 183–189. [Google Scholar]

- Dillen, S.Y.; Djomo, S.N.; Al Afas, N.; Vanbereven, S.; Ceulemans, R. Biomass yield and energy balance of a short rotation poplar coppice with multiple clones on degraded land during 16 years. Biomass Bioenergy 2013, 56, 157–165. [Google Scholar] [CrossRef]

- Fernández, M.J.; Ciria, P.; Barro, R.; Losada, J.; Pérez, J.; Sixto, H.; Carrasco, J.E. Quality of the biomass produced in short rotation coppices of poplar, willow, black locust and sycamore in two different Spanish locations. In Proceedings of the 21st European Biomass Conference and Exhibition, Copenhagen, Denmark, 3–7 June 2013. [Google Scholar]

- Monedero, E.; Hernández, J.J.; Cañellas, I.; Otero, J.M.; Sixto, H. Thermochemical and physical evaluation of poplar genotypes as short rotation forestry crops for energy use. Energy Convers. Manag. 2016, 129, 131–139. [Google Scholar] [CrossRef]

- Al Afas, N.; Marron, N.; Van Dongen, S.; Laureysens, I.; Ceulemans, R. Dynamics of biomass production in a poplar coppice culture over three rotations (11 years). Forest Ecol. Manag. 2008, 255, 1883–1891. [Google Scholar] [CrossRef]

- Fiala, M.; Bacenetti, J.; Scaravonati, A.; Bergonzi, A. Short rotation coppice in northern Italy: Comprenhensive Sustainability. In Proceedings of the 18th European Biomass Conference and Exhibition, Lyon, France, 3–7 May 2010. [Google Scholar]

- Cañellas, I.; Huelin, P.; Hernández, M.J.; Ciria, P.; Calvo, R.; Gea-Izquierdo, G.; Sixto, H. The effect of density on short rotation Populus sp. Plantations in the Mediterranean area. Biomass Bioenergy 2012, 46, 645–652. [Google Scholar] [CrossRef]

- Benetka, V.; Novotná, K.; Štochlová, P. Biomass production of P. nigra clones grown in short rotation coppice systems in three different environments over four rotations. iForest 2014, 7, 233–239. [Google Scholar] [CrossRef]

- Tharakan, P.J.; Volk, T.A.; Abrahamson, L.P.; White, E.H. Energy feedstock characteristics of willow and hybrid poplar clones at harvest age. Biomass Bioenergy 2003, 25, 571–580. [Google Scholar] [CrossRef]

- Villanueva, M.; Proupín, J.; Rodríguez Añón, J.A.; Fraga-Grueiro, L.; Salgado, J.; Barros, N. Energetic characterization of forest biomass by calorimetry and thermal analysis. J. Therm. Anal. Calorim. 2011, 104, 61–67. [Google Scholar] [CrossRef]

- UNE-EN ISO 18125. Solid Biofuels. Determination of Calorific Value; AENOR: Madrid, Spain, 2017; p. 71. [Google Scholar]

- UNE-EN ISO 18122. Solid Biofuels. Determination of Ash Content; AENOR: Madrid, Spain, 2016; p. 14. [Google Scholar]

- UNE-EN ISO 18123. Solid Biofuels. Determination of the Content of Volatile Matter; AENOR: Madrid, Spain, 2016; p. 16. [Google Scholar]

- UNE-EN ISO 16948. Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen; AENOR: Madrid, Spain, 2015; p. 16. [Google Scholar]

- UNE-EN ISO 16967. Solid Biofuels. Determination of Major Elements Al, Ca, Fe, Mg, P, K, Si, Na and Ti; AENOR: Madrid, Spain, 2015; p. 20. [Google Scholar]

- UNE-EN ISO 16994. Solid Biofuels. Determination of Total Content of Sulfur and Chlorine; AENOR: Madrid, Spain, 2017; p. 18. [Google Scholar]

- R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- UNE-EN ISO 17225-4. Solid Biofuels. Fuel Specifications and Classes—Part 4: Wood Chips for Non-Industrial Use; AENOR: Madrid, Spain, 2014; p. 14. [Google Scholar]

- San Miguel, G.; Corona, B.; Ruíz, D.; Landholmb, D.; Laina, R.; Tolosana, E.; Sixto, H.; Cañellas, I. Environmental, energy and economic analysis of a biomass supply chain based on a poplar short rotation coppice in Spain. J. Clean Prod. 2015, 94, 93–101. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Magagnotti, N. Using modified foragers to harvest shortrotation poplar plantations. Biomass Bioenergy 2009, 33, 817–821. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels-significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 3): Gasification technologies. Bioresour. Technol. 2002, 83, 55–63. [Google Scholar] [CrossRef]

- Elder, T.; Groom, L.H. Pilot scale gasification of woody biomass. Biomass Bioenergy 2011, 35, 3522–3528. [Google Scholar] [CrossRef]

- Kloss, S.; Zehetner, F.; Dellantonio, A.; Hamid, R.; Ottner, F.; Liedtke, V.; Schwanninger, M.; Gerzabek, M.H.; Soja, G. Characterization of Slow Pyrolysis Biochars: Effects of Feedstocks and Pyrolysis Temperature on Biochar Properties. J. Environ. Qual. 2012, 41, 990–1000. [Google Scholar] [CrossRef]

- Kwapinski, W.; Byrne, C.M.P.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H.B. Biochar from biomass and waste. Waste Biomass Valorization 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Bridgwater, T. Challenges and opportunities in fast pyrolysis of biomass: Part I. Johnson Matthey Technol. Rev. 2018, 62, 118–130. [Google Scholar] [CrossRef]

- Elliott, D.C.; Hart, T.R.; Neuenschwander, G.G.; Rotness, L.J.; Zacher, A.H. Catalytic hydroprocessing of biomass fast pyrolysis bio-oil to produce hydrocarbon products. Environ. Prog. Sustain. Energy 2009, 28, 441–449. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Ebeling, J.M. Correlations of physical and chemical properties of terrestrial biomass with conversion. In Symposium Papers—Energy from Biomass and Wastes; Inst of Gas Technology: Des Plaines, IL, USA, 1985; pp. 371–403. [Google Scholar]

- Pannacci, E.; Bartolini, S.; Covarelli, G. Evaluation of four poplar clones in a short rotation forestry in Central Italy. Ital. J. Agron. 2009, 4, 191–198. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.; Frandsen, F.J.; Glarborg, P.; Sebastián, F.; Royo, J. Partitioning of K, Cl, S and P during combustion of poplar and brassica energy crops. Fuel 2014, 134, 209–219. [Google Scholar] [CrossRef]

- Carmona, R.; Nuñez, T.; Alonso, M.F. Biomass yield and quality of an energy dedicated crop of poplar (Populus spp.) clones in the Mediterranean zone of Chile. Biomass Bioenergy 2015, 74, 96–102. [Google Scholar] [CrossRef]

- Esteghlalian, A.; Hashimoto, A.G.; Fenske, J.J.; Penner, M.H. Modeling and optimization of the dilute-sufuric-acid pretreatment of corn stover, poplar and swithgrass. Bioresour. Technol. 1997, 59, 129–136. [Google Scholar] [CrossRef]

- Brown, R.C. Biorenewable Resource. Engineering New Products from Agriculture; Iowa State Press: Iowa City, IA, USA, 2003; p. 17. [Google Scholar]

- Du, S.; Yang, H.; Qian, K.; Wang, X.; Chen, H. Fusion and transformation properties of the inorganic components in biomass ash. Fuel 2014, 117, 1281–1287. [Google Scholar] [CrossRef]

- Pari, L.; Ciriello, A.; Gallucci, F. Consequence of SRF poplar wood harvesting method on energy content preservation. In Proceedings of the 16th European Biomass Conference & Exibition, Valencia, Spain, 2–6 June 2008; p. 6. [Google Scholar]

- Bungart, R.; Hüttl, R.F. Production of biomass for energy in post-mining landscapes and nutrient dynamics. Biomass Bioenergy 2001, 20, 181–187. [Google Scholar] [CrossRef]

- Heilman, P.E.; Stettler, R.F. Nutritional concerns in selection of black cottonwood and hybrid clones for short rotation. Can. J. For. Res. 1986, 16, 860–863. [Google Scholar] [CrossRef]

- Bergante, S.; Facciotto, G.; Minotta, G. Identification of the main site factors and management intensity affecting the establishment of Short-Rotation-Coppices (SRC) in Northern Italy through stepwise regression analysis. Cent. Eur. J. Biol. 2010, 5, 522–530. [Google Scholar] [CrossRef]

- Filbakk, T.; Jirjis, R.; Nurmi, J.; Høibø, O. The effect of bark content on quality parameters of Scots pine (Pinus sylvestris L.) pellets. Biomass Bioenergy 2011, 35, 3342–3349. [Google Scholar] [CrossRef]

- Oliveira, N.; Sixto, H.; Cañellas, I.; Rodríguez Soalleiro, R.; Pérez Cruzado, C. Productivity model and reference diagram for short rotation biomass crops of poplar grown in Mediterranean environments. Biomass Bioenergy 2015, 72, 309–320. [Google Scholar] [CrossRef]

- Fiala, M.; Bacenetti, J. Economic, energetic and environmental impact in short rotation coppice harvesting operations. Biomass Bioenergy 2012, 42, 107–113. [Google Scholar] [CrossRef]

- De Bell, D.S.; Clendenen, G.W.; Harrington, C.A.; Zasada, J.C. Tree growth and stand development in short-rotation Populus plantings: 7-year results for two clones at three spacings. Biomass Bioenergy 1996, 11, 253–269. [Google Scholar] [CrossRef]

- Laureysens, I.; Deraedt, W.; Ceulemans, R. Population dynamics in a 6-year-old coppice culture of poplar: II. Size variability and one-sided competition of shoots and stools. For. Ecol. Manag. 2005, 218, 115–128. [Google Scholar] [CrossRef]

- Verlinden, M.S.; Broeckx, L.S.; Ceulemans, R. First vs. second rotation of a poplar short rotation coppice: Above-ground biomass productivity and shoot dynamics. Biomass Bioenergy 2015, 73, 174–185. [Google Scholar] [CrossRef] [Green Version]

- Hofmann-Schielle, C.; Jug, A.; Makeschin, F.; Rehfuess, K.E. Short-rotation plantations of balsam poplars, aspen and willows on former arable land in the Federal Republic of Germany. I. Site-growth relationships. For. Ecol. Manag. 1999, 121, 41–55. [Google Scholar] [CrossRef]

- Gilbe, C.; Oöhman, M.; Lindström, E.; Boström, D.; Backman, R.; Samuelsson, R.; Burvall, J. Slagging characteristics during residential combustion of biomass pellets. Energy Fuels 2008, 22, 3536–3543. [Google Scholar] [CrossRef]

- Vega-Nieva, D.J.; Ortiz Torres, L.; Míguez Tabares, J.L.; Morán, J. Measuring and Predicting the Slagging of Woody and Herbaceous Mediterranean Biomass Fuels on a Domestic Pellet Boiler. Energy Fuels 2016, 30, 1085–1095. [Google Scholar] [CrossRef]

| Genotype | Sample Size (n) | N | H (m) | D (mm) | Y (Mg ha−1) | PB (%) |

|---|---|---|---|---|---|---|

| AF2 | 40 | 1.19 (0.03) | 4.0 | 44.9 (22.4–91.6) | 5.9 | 23.7 (6.8–34.7) |

| AF6 | 40 | 1.41 (0.05) | 4.2 | 46.3 (24.4–76.6) | 8.0 | 23.0 (10.5–36.4) |

| BEAUPRÉ | 40 | 1.10 (0.02) | 4.6 | 50.7 (20.3–79.9) | 21.5 | 28.0 (13.8–38.2) |

| I-214 | 30 | 1.58 (0.05) | 4.8 | 50.2 (26.1–81.3) | 20.7 | 23.5 (15.4–41.7) |

| MONVISO | 40 | 1.21 (0.03) | 3.6 | 37.7 (19.2–55.1) | 6.5 | 24.5 (16.6–33.5) |

| RASPALJE | 50 | 1.05 (0.01) | 4.7 | 47.3 (23.5–79.1) | 21.7 | 21.9 (14.6–33.6) |

| TRICHOBEL | 40 | 1.01 (0.01) | 5.7 | 54.5 (20.6–86.1) | 27.5 | 18.9 (7.7–25.4) |

| UNAL | 34 | 1.04 (0.01) | 4.3 | 47.4 (20.4–73.9) | 13.8 | 25.7 (13.1–37.1) |

| Variable | Unit | G. Effect (p Level) | d Effect (p Level) | Average | SD | Minimum | Maximum | Typical Values * |

|---|---|---|---|---|---|---|---|---|

| D | Mm | - | 47.3 | 14.8 | 19.2 | 91.6 | - | |

| W | (%) | <0.0001 | 0.004 | 56.0 | 4.4 | 36.8 | 67.5 | - |

| P | kg·dm−3 | <0.0001 | <0.0001 | 0.41 | 0.03 | 0.36 | 0.51 | - |

| A | (%) | <0.0001 | 0.0128 | 1.28 | 0.25 | 0.56 | 2.03 | 2.0 |

| VS | (%) | <0.0001 | - | 86.7 | 1.3 | 82.4 | 89.2 | - |

| FC | (%) | <0.0001 | - | 13.0 | 1.2 | 9.5 | 16.0 | - |

| HHV0 | kJ·kg−1 | 0.0195 | - | 17,919 | 184 | 17,425 | 18,488 | 19,800 |

| LHVW | kJ·kg−1 | <0.0001 | 0.0165 | 14,818 | 434 | 13,715 | 16,426 | 18,400 |

| Variable | Unit | Genotype Effect (p Level) | d Effect (p Level) | Average | Standard Deviation | Minimum | Maximum | Typical Values * |

|---|---|---|---|---|---|---|---|---|

| C | (%) | <0.0001 | 0.0265 | 46.5 | 0.37 | 46.2 | 47.9 | 48.0 |

| N | (%) | <0.0001 | <0.0001 | 0.60 | 0.15 | 0.25 | 1.09 | 0.4 |

| H | (%) | 0.0073 | - | 6.70 | 0.15 | 0.25 | 1.09 | 6.2 |

| Na | (mg·kg−1) | 0.0005 | 0.0058 | 37.0 | 14.3 | 19.8 | 170 | 25.0 |

| K | (mg·kg−1) | <0.0001 | <0.0001 | 3016 | 658 | 1472 | 4901 | 2500 |

| Ca | (mg·kg−1) | 0.0025 | <0.0001 | 1671 | 563 | 665 | 3315 | 5000 |

| Mg | (mg·kg−1) | <0.0001 | <0.0001 | 918 | 498 | 231 | 2484 | 500 |

| S | (mg·kg−1) | 0.0160 | 0.0020 | 350 | 134 | 92 | 680 | 300 |

| Cl | (mg·kg−1) | <0.0001 | - | 205 | 100 | 2 | 362 | <100 |

| P | (mg·kg−1) | <0.0001 | - | 500 | 199 | 212 | 1127 | 1000 |

| Al | (mg·kg−1) | <0.0001 | - | 41 | 21 | 2 | 105 | 10 |

| Fe | (mg·kg−1) | - | - | 18 | 14 | 2 | 116 | 30 |

| Conversion Pathway | Optimal Biomass Properties | References |

|---|---|---|

| Combustion in domestic thermal facilities, <1 MWth | Very low ash (<1.5%), low W (<25 or 35%), very high VS, very low alkali, low N and S | [23,36] |

| Combustion in CHP industrial facilities, >1 MWth | Low ash (<3 or 5%), medium-low W (<50%), high VS, low alkali | [9,35] |

| Gasification (downdraft of fluidized bed) | Low ash (<5%), very low W (<15%, dryer), limited particle size, high VS | [37,38] |

| Slow pyrolysis to biochar | Low W (<30%), high C and nutrient content, low trace elements, high FC | [39,40] |

| Fast pyrolysis to bio-oil | Very low ash (<2.5%), feed grinded to very small particle size (2–6 mm), very low W (<10%, dryer), low N, S and trace elements | [41,42] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eimil-Fraga, C.; Proupín-Castiñeiras, X.; Rodríguez-Añón, J.A.; Rodríguez-Soalleiro, R. Effects of Shoot Size and Genotype on Energy Properties of Poplar Biomass in Short Rotation Crops. Energies 2019, 12, 2051. https://doi.org/10.3390/en12112051

Eimil-Fraga C, Proupín-Castiñeiras X, Rodríguez-Añón JA, Rodríguez-Soalleiro R. Effects of Shoot Size and Genotype on Energy Properties of Poplar Biomass in Short Rotation Crops. Energies. 2019; 12(11):2051. https://doi.org/10.3390/en12112051

Chicago/Turabian StyleEimil-Fraga, Cristina, Xurxo Proupín-Castiñeiras, Jose Antonio Rodríguez-Añón, and Roque Rodríguez-Soalleiro. 2019. "Effects of Shoot Size and Genotype on Energy Properties of Poplar Biomass in Short Rotation Crops" Energies 12, no. 11: 2051. https://doi.org/10.3390/en12112051