1. Introduction

The population of Latin America and the Caribbean (LAC) represents 8.55% of the world population [

1], of which 75% is concentrated in countries with emerging economies (32% Brazil, 20% Mexico, and 22% for Colombia, Argentina, Peru and, Chile together) [

1,

2]. The high metabolic rates of this region have obliged governments to design and introduce new approaches to separate their economic growth from the use of resources and, consequently, their environmental impact [

3].

Although the LAC countries have twice the population of the United States (U.S.), they produce a lower global warming effect. This is similar to the case of the Asian giants, where India emits just 24% of the Greenhouse Gases (GHG) produced by China, despite each being home to 18% of the world’s population. Regarding energy consumption, the USA, the European Union (EU), and China consume 4.15, 1.89, and 1.26 times more than the world per capita average respectively, while India and LAC consume 3.88 and 1.47 times less (

Table 1). This indicates that the environmental impact indices generated by each country (and region) are discordant with the number of people living in them.

The emerging economies of LAC must face up to important environmental challenges in order to avoid replicating the throwaway society model of the industrialized nations [

10]. Among the most important problems is the rise in annual temperature caused by the increase of GHGs and the wasteful consumption of energy (from renewable and non-renewable sources); there are also the residues generated by this consumption, such as Construction and Demolition Waste (CDW) and Municipal Solid Waste (MSW), which play an important part due to the quantities involved.

To overcome their own environmental challenges, LAC countries need to set up schemes to achieve economic and social growth that will avoid unsustainable environmental damage, that is, plans in line with the objectives of the new sustainable development agenda, which are governed by three cardinal axes: Eradicating poverty, protecting the planet, and ensuring prosperity for all [

11].

Mexico has the second largest population of the countries in LAC, with more than 129 million inhabitants (80% concentrated in urban areas) [

1]. Over the last ten years it has had economic growth of 2.2% [

12] and, up to 2017, annual population increase of 1.3% [

8] (

Table 2); therefore, an increase in energy needs and consumption of natural resources can be expected in coming years, as well as GHG emissions and the CDW and MSW that generate them.

2. Environmental Challenges in Mexico

In Mexico, the national inventory of greenhouse gases and compounds is closely linked to scientific and technical criteria established by the Intergovernmental Panel on Climate Change (IPCC). It reported that in 2015 a total of 683 million tons (Gg) of CO

2 eq were emitted, of which 71% were Carbon Dioxide (CO

2) and 21% Methane (CH

4). The inventory also counted 148 Gg absorbed by vegetation (mainly forest and jungle), bringing the net emissions balance to 535 Gg of CO

2 eq (

Table 3). Additionally, 1.4% of the total CO

2 and 1.24% of the total CO

2 eq in the world was generated in 2012 (in the LAC group, only surpassed by Brazil) (

Table 2).

Of all the emissions (

Figure 1), the housing sector emits 3.1% of CO

2 eq, derived from compounds of CO

2, CH

4 and Nitrous Oxide (N

2O) generated by the consumption of natural gas, liquid petroleum gas, kerosene and diesel; there is also CH

4 and N

2O due to the burning of firewood in homes, the emissions generated by their operational energy. Other emissions related to the residential sector are those caused by the energy needed for transport (25.1%) and the construction and manufacturing industry (9.3%); the mineral and metal industries (5.5%) and the elimination of solid waste (3.2%). However, the corresponding proportional part of each must be obtained. It is essential to analyze exhaustively the GHGs that generate the activities that are carried out throughout the life cycle of the residential sector, especially social housing. Which, due to its high representation (88%) in the homes of the country, is a dominant relevance.

Moreover, in 2017, Mexico ranked 16th in the list of countries with the highest energy consumption in the world, reporting the third consecutive year with an energy independence index equivalent to 0.76; that is, 24% less energy was produced than necessary for the various consumption activities within the national territory [

14]. This is despite the country’s wealth of natural resources such as gas, coal and renewable energy sources (water, wind, solar and marine energy); however, its economy and energy supply are dependent on fossil fuels, which together with the lack of energy planning is a major cause for concern [

15].

The national energy balance in 2017 (

Figure 2), shows that the national energy consumption for this year was 9249.75 Petajoules (PJ), of which the 58% corresponding to total energy consumption and 32% to activities inherent to the energy sector (transformation, own consumption, and losses) stand out (

Figure 2a). The total energy consumption (

Figure 2b) in this year was 5362.8 PJ, which is attributed to the internal market or the productive activities of the national economy, of which the housing sector is responsible for 14%, due to the operating requirements of housing [

14]. Additionally, other data needed for this sector is that referring to the proportional part of transport (44%) and industry (35%).

Regarding the waste products (

Table 4), Mexico generates 0.4% of the world total of CDW and 3.4% of the MSW (second in the LAC region), and although the sum of its waste is lower than that of countries such as China (1,130,000,000 t CDW; 328,922,213 t MSW), U.S (548,000,000 t CDW; 240,380,753 t MSW) and India (530,000,000 t CDW), the impact on a national scale should not be ignored as it has limited management protocols and lacks the infrastructure for waste processing [

16].

Of the CDW generated in public and private works, 20% is disposed of in authorized dumps and only 3% is recycled; the rest is used in site levelling, landfills and, inappropriately, in road or street repairs [

16]. In this respect, the NOM-161-SEMARNAT-2011 norm came into effect in 2013, stating that construction waste shall be classified as special handling waste, requiring action to be taken for its reuse and recycling or, where appropriate, for its proper disposal [

17]. In the case of the 44 million MSW generated annually [

18], despite having the General Law for the Prevention and Management of Waste, only 84% are collected, 78.5% are dumped in final disposal sites, and only 9.6% are recycled [

19].

2.1. Life Cycle Assessment in Mexico

Various methods have been used in recent decades to measure the environmental performance of human and natural activities. One of these is the Life Cycle Assessment (LCA). “LCA, has become a key methodology to evaluate the environmental performance of products, services and processes and it is considered a powerful tool for decision makers” [

25]. In Mexico, the LCA was used for the first time in the late 1990s and early 2000s, in a study on waste management carried out by the National Institute of Ecology and Climate [

26]. The methodology has been used in several economic sectors in the country, such as the energy [

27] or mining industries [

28]. According to the study conducted by Valdivia, until 2014 Mexico was the second ranking LAC country in terms of publications referring to LCA (101 articles) [

3].

Until 2010 research using LCA had a preferential focus on waste management issues; from that year onwards, studies focused on topics such as the energy sector, the analysis of carbon and water footprints and the construction sector [

26]. Within the latter, studies have been carried out on the co-processing of municipal waste used as fuel for a cement kiln [

29], as well as the publication of a book on LCA in construction, where topics such as social housing (SH) are analyzed [

30].

The housing sector began to attract attention in 2006, when the government introduced life cycle thinking into the National Housing Law [

31]. In this respect, Cerón-Palma et al. (2013) measured the Global Warming Potential (GWP) of the operating energy of a SH [

32]; as well as proposing strategies to reduce energy demand [

33], other studies have focused on optimizing rainwater [

34,

35]. In addition to the LCA, other tools such as the Building Sustainability Rating Systems [

36] and product environmental statements [

31,

37] have been used.

Although in Mexico the use of LCA in the construction and residential sector is basically nil, its application is feasible and can become a valuable tool in the search for environmental solutions as it has been in various regions of the world [

38].

2.2. Housing in Mexico

Housing types in Mexico are classified according to their constructed surface: Economic (30 m

2), popular (42.5 m

2), and traditional (62.5 m

2), known together as SH. There are also medium (97.5 m

2), residential (145 m

2), and residential plus (225 m

2) [

39]. In the last five years, more than 2.58 million housing units have been built, of which 88% are SH (11% economic, 47% popular, 30% traditional), while the remaining 12% corresponds to the medium, residential and residential plus models [

40]. It is estimated that 600,000 new housing units will be needed annually during the next decade [

41].

Due to the high representation of the SH, the National Development Plan 2013–2018 has promoted the issue of sustainable construction in this sector [

31]. As a result, in the last decade, Mexico has stood out among the middle-high income level countries due to its Finance Program for Housing Solutions, which aims to provide more sustainable SH. These actions have been considered exemplary with respect to global good practices [

36].

According to data compiled up to 2010 by the National Housing Commission (CONAVI), 86% of the housing stock is in use (80.12% permanent use and 5.65% temporary use), while 14% is unoccupied [

42]. Until 2015, the inventory of occupied housing showed 31,949,709 private units with an average of 3.7 habitants each [

43]; of these, 73% are single-family, 19% are two-family, and 7% are multifamily housing. Multifamily housing is mainly concentrated in the states with the highest population density of the Republic (41% in Mexico City, 15% Mexico State, 7% in Jalisco and 5% in Puebla), while it is practically nil in the rest of the country (an average of 1% per state) due to the persistence of the single-family dwelling [

44].

Housing in Mexico has great challenges to face; on the one hand, there are impacts generated throughout its use, and on the other hand, there are environmental impacts arising from the incorporated stages of materials and processes necessary for construction. National inventories of energy and greenhouse gases and compounds have clearly established the impacts generated by the residential sector in its operation (B6, Operational energy [

45]); however, it is necessary to define the environmental burdens that are generated from the incorporated activities of its life cycle to consider a “from the cradle to the grave” approach.

2.3. Objectives of the Study

The objectives of this research are (1) to identify the state of the most relevant environmental impacts occurring in Mexico, emphasizing the residential sector, and (2) to achieve an approximation of the environmental impacts generated by this sector. To reach the latter objective, an LCA methodology applied to a representative SH of the Mexican ambit will be used; the elements that make up its envelope will be varied, resulting in a total of six options to be analyzed throughout its life cycle.

4. Results

The analyzed SH generates an environmental burden (including all the stages of A to C) of 17 t CO

2 eq, 252.5 Gigajoules (GJ) eq, 104.3 kg antimony eq, and 9.4 t Paradichlorobenzene (1,4-DCB) eq (average of the six options). Of these, just the construction of the SH (finished product A1 to A5) generates a load of 13 t CO

2 eq, 165 GJ eq, 71 kg antimony eq, and 7 t 1,4-DCB eq (

Table 11), i.e., more than 70% of the average impacts of all the categories analyzed when the embodied stages of the life cycle are considered.

The product stage is established as that of greatest contribution (A1 to A3: 57% CED, 61% ADP, 71% HTP-GWP), followed by that of replacement (B4: 6% GWP, 8% ADP, 12% CED, 15% HTP) and maintenance (B2: 6% HTP, 7% GWP, 9% ADP-CED); it is therefore established that the stages with greater environmental effects are those involving finished products (A1 to A3, B2 and B4: 78% CED-ADP; 85% GWP; 91% HTP), in this case, those used in constructing the building, the paint for its maintenance, and the replaceable objects (windows and doors). Meanwhile, the stages referring to the processes produce significantly less effect; from greater to lesser, they are those relating to transport (A4 + C2: 3.3% HTP, 7.7% GWP, 9.3% CED, 10.1% ADP), to construction/demolition (A5-C1: 3.7% HTP, 6.1% GWP, 7.6% ADP, 9% CED), and lastly, to their final disposition (C4: 1.5% GWP, 1.6% HTP, 3.7% CED and 3.9% ADP) (

Figure 7).

Previous research has dealt with the embodied impacts of a building (or its elements), studying different stages such as A1 to A4 [

80], A1 to A5 [

66,

79,

81], A and C [

51] and A to C [

48,

49,

82,

83]; similar to this study, these works found that the greatest environmental detriment occurs in stage A1 to A3, with values ranging from 85% to 99% for those who evaluated up to A1 to A5 [

51,

66,

79,

80,

81] and from 60% to 80% for those who evaluated the complete cycle (A to C) [

48,

49,

82,

83]. For the rest of the stages, the results depended on the different criteria established in each study, so there are still discrepancies in the results obtained. Nevertheless, the data obtained in this work is found within the previously reported intervals; for example, the studies that evaluated B1-B5 reported values ranging from 11% to 25% [

48,

49], those that studied A4, from 1% to 9% [

51,

66,

79,

80,

81], those that evaluated A5 from 1% to 8% [

49,

51,

66,

79,

80,

81], while those that studied the C stages showed intervals from 1% to 3% [

48,

51] up to 23% [

49], this stage showing the most variation.

Figure 7 shows how the greater variability occurs when a wood or PVC window is changed to aluminum for the HTP, going from 11–12% to 19% of the total damage. This can be attributed to the high amounts of contamination produced in the aluminum production process, which includes substances such as CO

2, Sulfur Dioxide (SO

2), Polycyclic Aromatic Hydrocarbons (HAP), Perfluorocarbons (PFC), Tetrafluoromethane (CF

4) and Hexafluoroethane (C

2F

6) [

84]. Similar to the study by Yasantha et al. (2007), where it was found that although wooden windows have a better environmental (and economic) performance, aluminum windows were preferred socially [

85].

On the other hand, the damage caused by A1 to A3 is more evident for the GWP (70–72%), which is because the most representative materials used in the SH (concrete, steel, ceramic pieces, mortar) are linked with the emission of GHGs [

13,

66,

67,

86], due to the chemical reactions in their manufacturing processes and the high content of carbonates in their basic components, such as limestone or clay [

87,

88]. The greatest variation found in the impact categories was in stage A1 to A3, with a difference of 14% between the GWP (72%) and the CED (58%). This difference in the representation of the CED is spread over the rest of the stages, above all in B4 and B2 (because the manufacture of paint and window materials is more closely linked to energy consumption [

86,

89] than to GHG emissions) and in A5 and C1 (for the energy used by the machinery).

Analyzing each impact category separately (

Figure 8), it was seen that the least favorable option in all cases was that of the reference (PE-AL), which is more pronounced in the stages A1 to A3 and B4. Previous studies have found that the production of aluminum (stages A1 to A3 or B4) requires high energy consumption [

89], up to six times that of steel per unit of weight [

86], as well as the inherent contaminants [

84]. Therefore, the least favorable of the six combinations analyzed is that which includes heavy material with a moderate load potential and light material with a high load potential.

Furthermore, when the stages with higher variability are discarded (A1 to A3 and B4,

Figure 8), it can be seen that the options using PU are more favorable than those using PE, which can be attributed to the fact that the pumice aggregates are lighter than the conventional ones [

90]. This coincides with previous research that recommends the use of volcanic materials—among them pumice—as they may significantly reduce the environmental damage [

91]. Therefore, the options with the best environmental performance in all the impact categories were the PU-WO and the PU-PV.

Given the importance of the construction industry in the use of energy [

47] and GHG emissions [

92], in

Figure 9 these categories are dealt with separately, breaking the CED down into its proportional Renewable (Re) and Non-Renewable parts (n-Re). The percentage of CED (n-Re) for all cases is significantly higher than the CED (Re), being 84.8% for stage A, 67.6% for stage B and 98.8% for stage C of the CED total. Of the three stages, B makes greater use of renewable sources due to the use of wood in the doors and windows, followed by A, especially when the options PE-WO and PU-WO are evaluated. Some authors mention the advantages of using wood due to the low energy requirements of its manufacture [

76]. Similarly, it can be seen that stage C is practically dependent on CED (n-Re), due to the machinery (C1) and vehicles (C2) used.

The results found for the CO

2 eq emissions and the consumption of incorporated energy are figures that are found in the list of effects reported by other researchers (

Table 12). The information has been compared with that of residential, office, and commercial buildings, all of which have similar characteristics in terms of the materials used in their construction (reinforced concrete framework and traditional masonry). The majority evaluate the same components of the building (including the structure and envelope) which enables comparison. In SH the interior partitions are also evaluated.

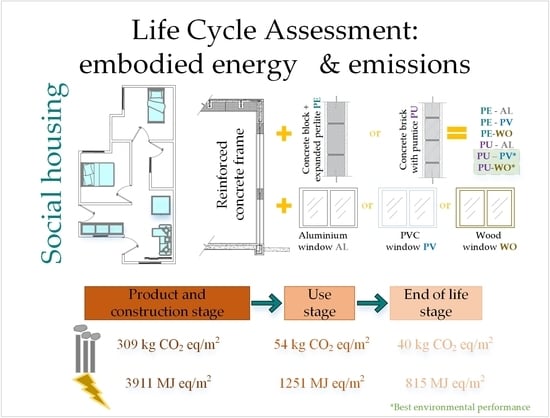

The SH analyzed emits 309 kg CO

2 eq/m

2 and needs 3911 MJ eq to perform stages A1 to A5; it also emits 54 kg CO

2 eq/m

2 and needs 1251 MJ eq for stages B2 and B4, similar to what was reported by Iddon et al. (2013) [

93], Islam et al. (2015) [

48] and Gustavsson et al. (2010) [

94]. Additionally, when the impacts of the SH are compared with multi-story commercial or office buildings, although the results alternate within the same level of effect, the values tend to be higher in an interval of 30% to 40%. The stage showing most variation was C; as each study focused on specific end of life scenarios, their comparison was not feasible.

For stages A and B, the level of comparison is especially interesting, as each study was carried out in different geographical regions and with different databases. Therefore, it can be argued that the LCA is an objective methodology which allows global results in the residential sector to be obtained and it has been possible to standardize them, above all in the Product Stage (A1 to A3).

Considering the representativeness of the housing types in Mexico (11% economic, 47% popular, 30% traditional, 12% medium, residential, and residential plus [

40], each of which was assigned 4%), it was possible to obtain an approximation of the effects of their embodied stages. One square meter of construction (A1 to A5) produces 309 kg of CO

2 eq and needs 3,911 MJ; as about 600,000 new housing units are built annually in Mexico [

41], the total annual effect of the residential sector in stages A1 to A5 (until the finished house) is 11,275.8 Gg CO

2 eq and 142.5 PJ eq of energy (

Table 13).

Additionally, using the national inventory of CO

2 eq emissions and compounds, these figures represent 2.1% of the net emissions (taking absorption into account), and 1.7% if total emissions are considered. Added to the 4% emissions from the housing sector due to consumption of natural gas, liquid petroleum gas, kerosene, diesel, and firewood in the operating stage [

13], this means that 6.1% of the annual emissions may be attributed to the residential sector. Similarly, as regards the national energy inventory [

14], the figures represent 2,7% of the annual consumption. This, when added to the 14% operational energy consumption, gives an estimated total of 16.7% of energy attributed to the residential sector (

Table 14).

Although it is evident that performance in the housing sector in Mexico is steadily improving, it is essential to deal with the accelerated changes that are being caused by environmental damage, not only at a regional level but also at a global one. The residential sector has an enormous potential to reduce these environmental burdens (including those of greatest concern today, such as climate change and the depletion of resources and non-renewable energy), throughout the various sectors that are required for its praxis. In this regard, it is necessary to opt for locally available materials, with high percentages of reuse, with thermal properties that enable energy optimization and, of course, that these should come where possible from renewable resources or from the discreet use of non-renewable resources.

On the other hand, while the importance of SH in the residential sector is indisputable, there is also a need to apply sustainability criteria to medium and residential housing. Although their representativeness is lower, in this work it was estimated that the resources invested in them (because of their size) could generate loads greater than 30% in GWP and CED, and the application of eco-technologies could be economically feasible (limitation present in the SH).

Moreover, while it is true that the LCA is a methodology that has been used in Mexico for decades [

26], extending its application to one of the country’s most demanding sectors would provide opportunities for reducing environmental burdens. This, through knowledge of the most commonly used materials and the processes required throughout the life cycle of a dwelling. This knowledge would enable the best environmental performance options to be chosen, and the opportunities for improvement would be identified.

5. Conclusions

The present study has assessed the environmental impacts generated by an SH throughout its embodied life cycle; a comparison of six alternatives was made by varying their elements (walls and windows), and it was possible to apply the LCA methodology to Mexico’s residential sector with promising results. In addition, a review of the country’s environmental situation focusing on the most relevant problems facing the residential sector was made.

It was found that throughout the cycle the SH analyzed generates an environmental burden of 17 t CO2 eq, 252.5 GJ eq, 104.3 kg antimony eq, and 9.4 t 1.4-DCB eq; the requirements of stages A1 to A5 stand out, exceeding 70% of the impact in all the categories analyzed. In general, the stages with the greatest environmental effect are those containing a finished product (A1 to A3, B2, and B4: 78% CED-ADP; 85% GWP; 91% HTP), while the stages referring to the processes have a considerably lower impact. For A4 + C2 the figures are 3.3% HTP, 7.7% GWP, 9.3% CED, and 10.1% ADP. For A5 + C1 they are 3.7% HTP, 6.1% GWP, 7.6% ADP, and 9% CED. Finally, C4 has 1.5% GWP, 1.6% HTP, 3.7% CED, and 3.9% ADP.

The greatest variability in the results comes from changing the wood or PVC windows for aluminum windows in the HTP category, passing from 11–12% to 19% of the total damage, which is attributed to the aluminum production process.

The most unfavorable of the six cases analyzed was the reference sample (PE-AL), while the options with the best environmental performance were PU-WO and PU-PV for all impact categories. Environmental advantages can arise from using aggregates that could lighten the concrete for configuring the walls, as long as their environmental burden is equal to or less than that of conventional aggregates, and their basic attributes are not reduced.

The SH evaluated emits 309 kg CO2 eq/m2 in A1 to A5, 54 kg CO2 eq/m2 in B2 and B4, and 40 kg CO2 eq/m2 in C1, C2, and C4. It requires 3,911 MJ eq in A1 to A5, 1,251 MJ eq in B2 and B4, and 815 MJ eq in C1, C2, and C4. This data was collated with recent studies and, although they were carried out in different regions and developed with different databases, the results show consistency. Therefore, it was concluded that the methodology generates objective and global results in the residential sector and that, with the continuous improvement in standardization, it is increasingly possible to apply around the planet, especially in stages A1 to A3.

On the other hand, although ecoinvent regularly incorporates information from different regions of the world, it is urgent to create local databases in Latin America or in the case of Mexico expand the number of data for the existing one—mexicaniuh [

96].

Considering the annual amount of the different types of dwellings built and their effect per m2 as obtained in this study, an estimate of the annual impact of the residential sector on the finished housing (A1 to A5) was obtained. This was 11,275.8 Gg CO2 eq, or 2.1% of net emissions. When added to the 4% emitted in the operation of the dwelling (B6) and the compound emissions, according to the national GHG inventory, this gives a total of 6.1% emissions attributed to the residential sector. Similarly, according to the national energy inventory, the estimated energy required by the residential sector in its finished housing phases (A1 to A5) is 142.5 PJ, or 2.7% of annual consumption. When added to the 14% operational energy consumption, this gives a total estimate of 16.7% of energy attributed to the residential sector.

Finally, it will be interesting in future research to obtain the CO2 eq emissions of the residential sector and the energy eq required to carry out phases B and C annually, as well as to know the environmental impacts produced by public and commercial buildings (in addition to civil works), with the aim of obtaining the total burden generated by the construction industry in Mexico.