Experimental Study on the Physical Performance and Flow Behavior of Decorated Polyacrylamide for Enhanced Oil Recovery

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Equipment

2.3. Method

2.3.1. Microstructure Measurement

2.3.2. Salt Tolerance Property Measurement

2.3.3. Viscosity-Improvement Measurement

2.3.4. Viscosity Stability Measurement

2.3.5. Emulsification Property Measurement

2.3.6. Interfacial Tension Measurement

2.3.7. Cores Displacement Experiment

- (1)

- The casted cores were vacuumed for several hours until the weight did not decrease, then the dry weight were measured. Next, saturated the cores with brine (6778 mg/L), the porosities were attained.

- (2)

- The above cores were taken into the thermostat at 45 ℃ for more than 12 h. The simulated oil was injected until the water cut was 0%. Step (1) and (2) were called core treatment in the following text. The initial oil volume (saturation) and irreducible water saturation were obtained.

- (3)

- The brine was injected at a rate of 0.1 mL/min as far as the water-cut equaled 98%, the amount of displaced oil was obtained from the collector. The ratio of displaced oil volume to initial oil volume was the recovery of water flooding.

- (4)

- The chemicals were injected as designed in Table 2, then the chase water was injected again until the water content raised to 98%. As above, the oil volumes from chemicals flooding were attained from collector, based on the initial oil volume, the recovery were calculated. Consequently, the recovery increments were received.

2.3.8. Displacement Experiment in Etched-Glass Micromodel

3. Results and Discussion

3.1. Microstructure of the DP

3.2. Physical Properties of the DP

3.2.1. Salt Tolerance Property Analysis

3.2.2. Viscosification Property Analysis

3.2.3. Viscosity Stability Analysis

3.2.4. Emulsification Property Analysis

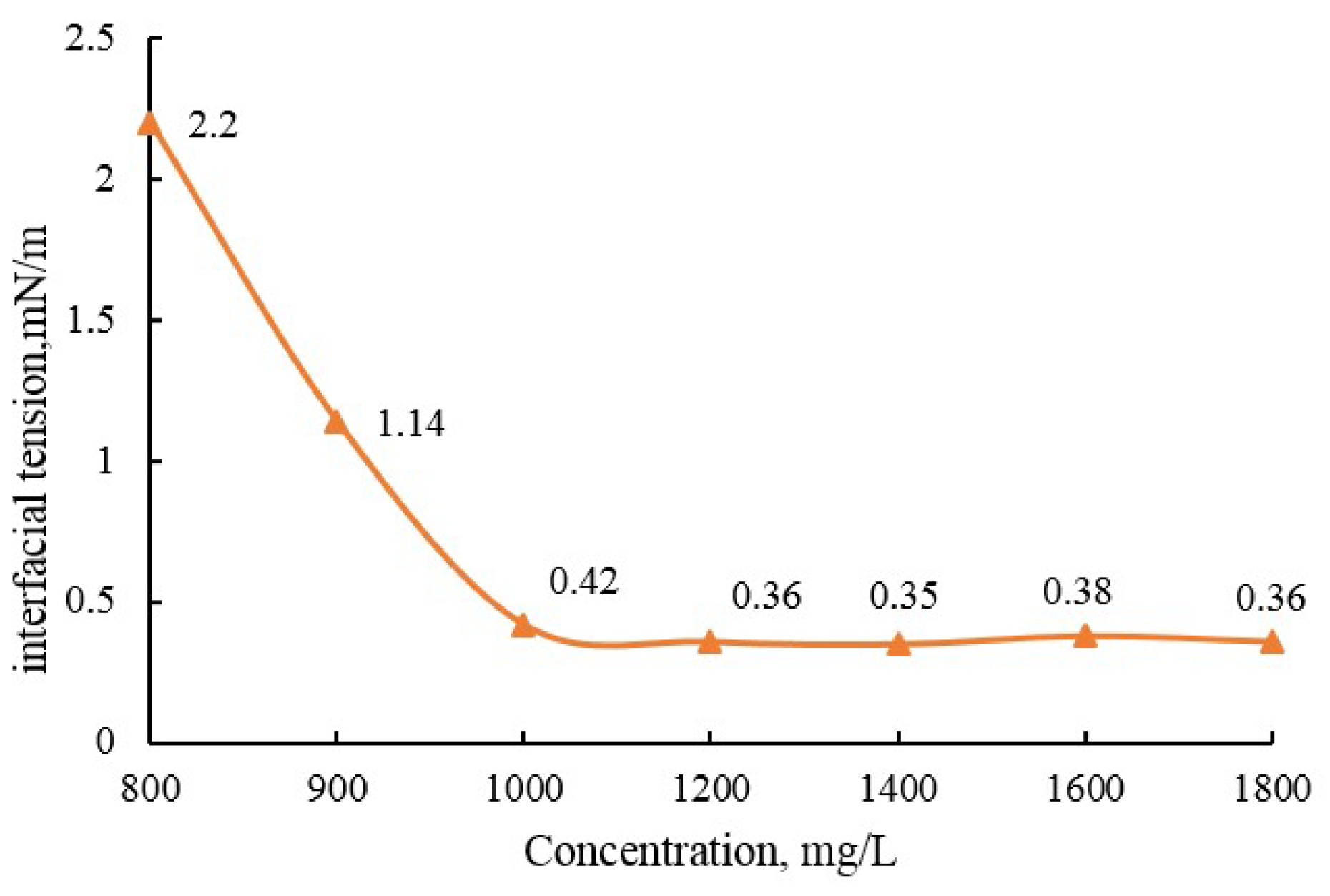

3.2.5. Interfacial Tension Analysis

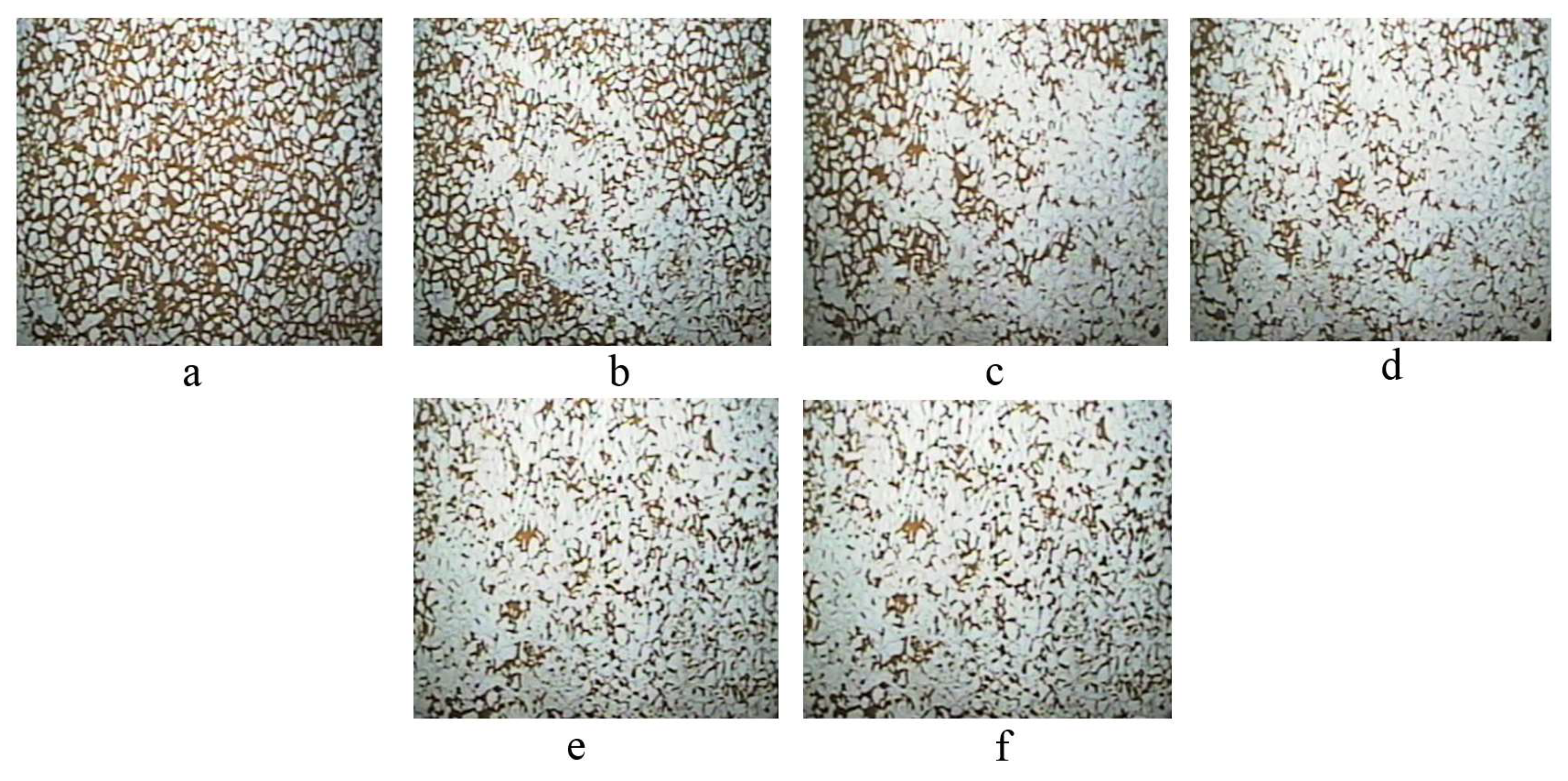

3.3. Oil Displacement Mechanism and Flow Behavior in Etching Glass model

3.3.1. Displacement Mechanism of DP

3.3.2. Flow Behavior of DP in Non-Homogeneous Porous Media

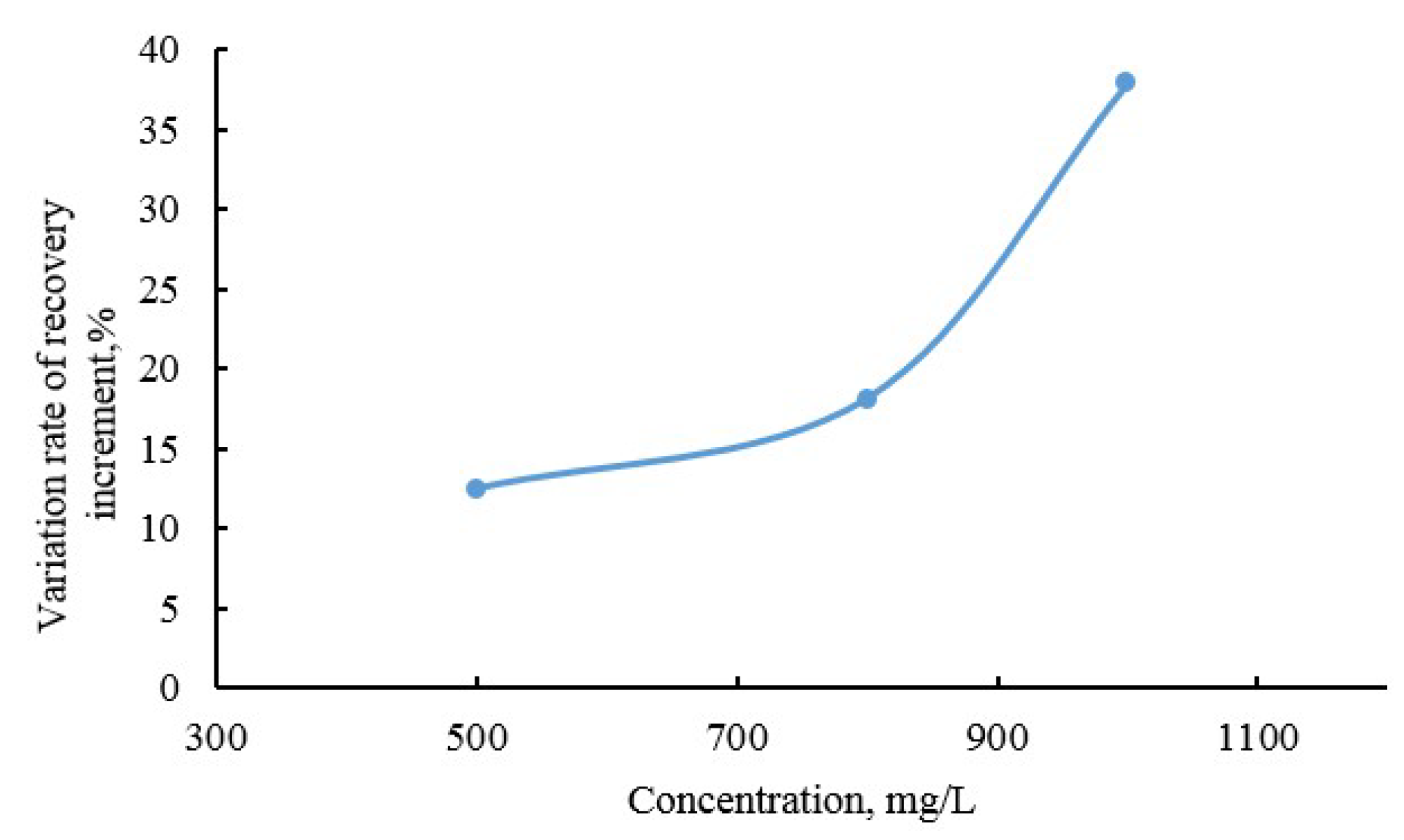

3.4. Comparing Efficiency of Oil Displacement and Concentration Reduction Multi-Slug Injection of DP

4. Conclusions

- (1)

- The DP simultaneously possessed characteristics of polymer and surfactant, exhibiting good salt tolerance, viscosification, viscosity stability, lower interfacial tension, and emulsification properties.

- (2)

- The experiment conducted in an etching glass model indicated that the displacement mechanism of DP included viscoelasticity, viscosification, lower interfacial tension, and emulsification. The flow behaviors were concluded to be ‘pull and drag’, ‘entrainment’, and ‘bridging’.

- (3)

- Oil displacement experimental results clearly illustrated that the recovery increment of DP was about 11–16% higher than that of polymer flooding when the concentration was more than 800 mg/L. Additionally, the mode of concentration reduction multi-slug injection was favorable to enhance recovery by means of profile control, especially for a low permeability layer.

Author Contributions

Funding

Conflicts of Interest

References

- Pye, D.J. Improved secondary recovery by control of water mobility. SPE J. 1964, 16, 911–916. [Google Scholar] [CrossRef]

- Sandiford, B.B. Laboratory and field studies of water floods using polymer solutions to increase oil recoveries. SPE J. 1964, 16, 917–922. [Google Scholar] [CrossRef]

- Riahinezhad, M.; Romero-Zerón, L.; McManus, N.; Penlidis, A. Evaluating the performance of tailor-made water-soluble copolymers for enhanced oil recovery polymer flooding applications. Fuel 2017, 203, 269–278. [Google Scholar] [CrossRef]

- Shi, L.T.; Chen, L.; Ye, Z.B.; Zhou, W.; Zhang, J.; Yang, J.; Jin, J.B. Effect of polymer solution structure on displacement efficiency. Pet. Sci. 2012, 9, 230–235. [Google Scholar] [CrossRef]

- Salmo, I.C.; Pettersen, Ø.; Skauge, A. Polymer flooding at an adverse mobility ratio: Acceleration of oil production by crossflow into water channels. Energy Fuels 2017, 31, 5948–5958. [Google Scholar] [CrossRef]

- Li, M.; Romero-Zerón, L.; Marica, F.; Balcom, B.J. Polymer flooding enhanced oil recovery evaluated with magnetic resonance imaging and relaxation time measurements. Energy Fuels 2017, 31, 4904–4914. [Google Scholar] [CrossRef]

- Meybodi, H.E.; Kharrat, R.; Wang, X. Study of microscopic and macroscopic displacement behaviors of polymer solution in water-wet and oil-wet media. Transp. Porous Media 2011, 89, 97–120. [Google Scholar] [CrossRef]

- De Oliveira, L.F.L.; Schiozer, D.J.; Delshad, M. Impacts of polymer properties on field indicators of reservoir development projects. J. Pet. Sci. Eng. 2016, 147, 346–355. [Google Scholar] [CrossRef]

- Janiga, D.; Czarnota, R.; Stopa, J.; Wojnarowski, P.; Kosowski, P. Performance of nature inspired optimization algorithms for polymer enhanced oil recovery process. J. Pet. Sci. Eng. 2017, 154, 354–366. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.C.; Zhou, J.F. Microscopic roles of “viscoelasticity” in hpma polymer flooding for eor. Transp. Porous Media 2011, 86, 199–214. [Google Scholar] [CrossRef]

- Wang, D.M.; Cheng, J.C.; Yang, Q.Y. Viscous-elastic polymer can increase micro-scale displacement efficiency in cores. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar]

- Xia, H.F.; Wang, D.M.; Liu, Z.C. Study on the mechanism of polymer solution with visco-elastic behavior increasing microscopic displacement efficiency. Acta Petrolei Sin. 2001, 22, 60–65. [Google Scholar]

- Wang, D.M.; Cheng, J.C.; Xia, H.F. Improvement of displacement efficiency of cores by driving forces parallel to the oil–water interface of viscous-elastic fluids. Acta Petrolei Sin. 2002, 23, 47–52. [Google Scholar]

- Zhong, H.Y.; Zhang, W.D.; Yin, H.J.; Liu, H.Y. Study on mechanism of viscoelastic polymer transient flow in porous media. Geofluids 2017, 2017. [Google Scholar] [CrossRef]

- Sharafi, M.S.; Jamialahmadi, M.; Hoseinpour, S.A. Modeling of viscoelastic polymer flooding in core-scale for prediction of oil recovery using numerical approach. J. Mol. Liq. 2018, 250, 295–306. [Google Scholar] [CrossRef]

- Maghzi, A.; Kharrat, R.; Mohebbi, A.; Ghazanfari, M.H. The impact of silica nanoparticles on the performance of polymer solution in presence of salts in polymer flooding for heavy oil recovery. Fuel 2014, 123, 123–132. [Google Scholar] [CrossRef]

- Silva, I.P.G.; Aguiar, A.A.; Rezende, V.P.; Monsores, A.L.M.; Lucas, E.F. A polymer flooding mechanism for mature oil fields: Laboratory measurements and field results interpretation. J. Pet. Sci. Eng. 2018, 161, 468–475. [Google Scholar] [CrossRef]

- Wang, Q.M.; Liao, G.Z.; Niu, J.G. Practice and Understanding of Polymer Flooding Technology. Pet. Geol. Oilfield Dev. Daqing 1999, 18, 3–7. [Google Scholar]

- Manrique, E.J.; Thomas, C.P.; Ravikiran, R. EOR: Current Status and Opportunities. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, Oklahoma, 24–28 April 2010. [Google Scholar]

- Howe, A.M.; Clarke, A.; Giernalczyk, D. Flow of concentrated viscoelastic polymer solutions in porous media: Effect of mw and concentration on elastic turbulence onset in various geometries. Soft Matter 2015, 11, 6419–6431. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.H.; Qi, J.L.; Yin, X.M.; Yang, Y.; Bing, S.X.; Zhang, B.H. Simulation of fluid-solid coupling during formation and evolution of high-permeability channels. Pet. Explor. Dev. 2009, 36, 498–502. [Google Scholar]

- Cui, C.Z.; Li, K.K.; Yang, Y.; Huang, Y.S.; Cao, Q. Identification and quantitative description of large pore path in unconsolidated sandstone reservoir during the ultra-high water-cut stage. J. Pet. Sci. Eng. 2014, 122, 10–17. [Google Scholar]

- Zhang, P.; Huang, W.Z.; Jia, Z.F.; Zhou, C.Y.; Guo, M.L.; Wang, Y.F. Conformation and adsorption behavior of associative polymer for enhanced oil recovery using single molecule force spectroscopy. J. Polym. Res. 2014, 21, 523. [Google Scholar] [CrossRef]

- Lai, N.J.; Li, S.T.; Liu, L.; Li, Y.X.; Li, J.; Zhao, M.Y. Synthesis and rheological property of various modified nano-sio2/am/aa hyperbranched polymers for oil displacement. Russ. J. Appl. Chem. 2017, 90, 480–491. [Google Scholar] [CrossRef]

- Li, F.; Luo, Y.; Hu, P.; Yan, X.M. Intrinsic viscosity, rheological property, and oil displacement of hydrophobically associating fluorinated polyacrylamide. J. Appl. Polym. Sci. 2016, 134, 44672. [Google Scholar] [CrossRef]

- You, Q.; Wang, K.; Tang, Y.C.; Zhao, G.; Liu, Y.F.; Zhao, M.W.; Li, Y.Y.; Dai, C.L. Study of a novel self-thickening polymer for improved oil recovery. Ind. Eng. Chem. Res. 2015, 54, 9667–9674. [Google Scholar] [CrossRef]

- Cheraghian, G. Effect of nano titanium dioxide on heavy oil recovery during polymer flooding. Pet. Sci. Technol. 2016, 7, 633–641. [Google Scholar] [CrossRef]

- Cheraghian, G. Thermal resistance and application of nanoclay on polymer flooding in heavy oil recovery. Pet. Sci. Technol. 2015, 17–18, 1580–1586. [Google Scholar] [CrossRef]

- Cheraghian, G. Effects of titanium dioxide nanoparticles on the efficiency of surfactant flooding of heavy oil in a glass micromodel. Pet. Sci. Technol. 2016, 3, 260–267. [Google Scholar] [CrossRef]

- Cheraghian, G. Improved Heavy Oil Recovery by Nanofluid Surfactant Flooding-An Experimental Study. In Proceedings of the 78th EAGE Conference and Exhibition, Vienna, Austria, 30 May–2 June 2016. [Google Scholar]

- Cheraghian, G. Evaluation of clay and fumed silica nanoparticles on adsorption of surfactant polymer during enhanced oil recovery. J. Jpn. Pet. Inst. 2017, 2, 85–94. [Google Scholar] [CrossRef]

- Cheraghian, G. Synthesis and properties of polyacrylamide by nanoparticles, effect nanoclay on stability polyacrylamide solution. Micro Nano Lett. 2017, 1, 40–44. [Google Scholar] [CrossRef]

- Kang, W.L.; Jiang, J.T.; Lu, Y.; Xu, D.R.; Wu, H.R.; Yang, M.; Zhou, Q.; Tang, X.C. The optimum synergistic effect of amphiphilic polymers and the stabilization mechanism of a crude oil emulsion. Pet. Sci. Technol. 2017, 35, 1180–1187. [Google Scholar] [CrossRef]

- Shu, Q.L.; Yu, T.T.; Gu, L.; Fan, Y.L.; Geng, J.; Fan, H.M. Viscosifying ability and oil displacement efficiency of new biopolymer in high salinity reservoir. J. China Univ. Pet. (Ed. Nat. Sci.) 2018, 42, 171–178. [Google Scholar]

- Yadali Jamaloei, B.; Kharrat, R.; Torabi, F. Analysis and correlations of viscous fingering in low-tension polymer flooding in heavy oil reservoirs. Energy Fuels 2010, 24, 6384–6392. [Google Scholar] [CrossRef]

- Zhao, G.; Dai, C.L.; You, Q. Characteristics and displacement mechanisms of the dispersed particle gel soft heterogeneous compound flooding system. Pet. Explor. Dev. 2018, 45, 481–490. [Google Scholar] [CrossRef]

- Wei, P.; Pu, W.F.; Sun, L.; Pu, Y.; Wang, S.; Fang, Z.K. Oil recovery enhancement in low permeable and severe heterogeneous oil reservoirs via gas and foam flooding. J. Pet. Sci. Eng. 2018, 163, 340–348. [Google Scholar] [CrossRef]

- Liu, S.H.; Zhang, D.H.; Yan, W.; Puerto, M.; Hirasaki, G.J.; Miller, C.A. Favorable attributes of alkaline-surfactant-polymer flooding. SPE J. 2008, 13, 5–16. [Google Scholar] [CrossRef]

- Lai, N.J.; Zhang, Y.; Wu, T.; Zhou, N.; Liu, Y.Q.; Ye, Z.B. Effect of sodium dodecyl benzene sulfonate to the displacement performance of hyperbranched polymer. Russ. J. Appl. Chem. 2016, 89, 70–79. [Google Scholar] [CrossRef]

- Han, P.H.; Su, W.M.; Lin, H.C.; Gao, S.L.; Cao, R.B.; Li, Y.Q. Evaluation and comparison of different EOR techniques after polymer flooding. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2011, 26, 44–48. [Google Scholar]

- Li, K.X.; Jing, X.Q.; He, S.; Ren, H.; Wei, B. Laboratory study displacement efficiency of viscoelastic surfactant solution in eor. Energy Fuels 2016, 30, 4467–4474. [Google Scholar] [CrossRef]

- Zhu, Y.; Gao, W.B.; Li, R.S.; Li, Y.Q.; Yuan, J.S.; Kong, D.B.; Liu, J.Y.; Yue, Z.C. Action laws and application effect of enhanced oil recovery by adjustable-mobility polymer flooding. Acta Petrolei Sin. 2018, 2, 189–200. [Google Scholar]

- Cao, R.B.; Han, P.H.; Sun, G. Oil displacement efficiency evaluation of variable viscosity polymer slug alternative injection. Oil Drill. Prod. Technol. 2011, 6, 88–91. [Google Scholar]

- Li, Y.Q.; Liang, S.Q.; Lin, L.H. Comparison and evaluation on injection patterns of polymer driving. Pet. Geol. Recov. Effic. 2010, 6, 58–60. [Google Scholar]

- Fu, M.L.; Zhou, K.H.; Zhao, L.; Zhang, D.H. Research on viscosity stability of polymer solution made up by sewage. OGRT 2000, 7, 6–8. [Google Scholar]

- Czarnota, R.; Janiga, D.; Stopa, J.; Wojnarowski, P. Wettability Investigation as a Prerequisite During Selecting Enhanced Oil Recovery Methods For Sandstone and Dolomite Formations. In Proceedings of the 17th International Multidisciplinary Scientific Geo Conference, Albena, Bulgaria, 29 June–5 July 2017; Volume 14, pp. 1013–1020. [Google Scholar]

- Kutter, B.L. Effects of capillary number, bond number, and gas solubility on water saturation of sand specimens. Can. Geotech. J. 2013, 50, 133–144. [Google Scholar] [CrossRef]

- Zhou, Y.Z.; Yin, D.Y.; Cao, R.; Zhang, C.L. The mechanism for pore-throat scale emulsion displacing residual oil after water flooding. J. Pet. Sci. Eng. 2018, 163, 519–525. [Google Scholar] [CrossRef]

- Wang, Y.L.; Jin, J.F.; Bai, B.J.; Wei, M.Z. Study of displacement efficiency and flow behavior of foamed gel in non-homogeneous porous media. PLoS ONE 2015, 10, e0128414. [Google Scholar] [CrossRef] [PubMed]

| Water Type | Content (mg/L) | ||||||

|---|---|---|---|---|---|---|---|

| Na+ + K+ | Ca2+ | Mg2+ | HCO3− | Cl− | SO42− | Total Salinity | |

| Formation water | 2186.3 | 14.9 | 52.4 | 2054.4 | 2267.7 | 54.1 | 6778 |

| Injection water | 231.2 | 34.1 | 24.3 | 225.1 | 88.7 | 36 | 729 |

| Injection wastewater | 1265 | 32.1 | 7.3 | 1708.56 | 780.12 | 9.61 | 4013 |

| Core Number | Permeability (μm2) | Porosity (%) | Initial Oil Saturation (%) | Injection Chemicals and Concentrations (mg/L) |

|---|---|---|---|---|

| 1 | 1.126 | 23.8 | 72.3 | P(1000) |

| 2 | 1.078 | 22.8 | 72.5 | DP(300) |

| 3 | 1.082 | 23.2 | 73.6 | DP(300) |

| 4 | 1.12 | 24.6 | 74.2 | DP(500) |

| 5 | 1.114 | 24.4 | 73.9 | DP(500) |

| 6 | 1.105 | 21.8 | 72.9 | DP(800) |

| 7 | 1.127 | 20.9 | 74.2 | DP(800) |

| 8 | 1.094 | 21.7 | 71.5 | DP(1000) |

| 9 | 1.102 | 23.4 | 72.8 | DP(1000) |

| 10 | 1.15 | 22.4 | 71.6 | P(1000) + DP(1500) + DP(1000) |

| 0.153 | 20.1 | 52.9 |

| Concentration of NaCl (mg/L) | Polymer Viscosity (mPa·s) | DP Viscosity (mPa·s) |

|---|---|---|

| 1000 | 90.75 | 40.60 |

| 3000 | 52.54 | 80.00 |

| 5000 | 37.01 | 329.55 |

| 6000 | 32.24 | 349.85 |

| 7000 | 29.85 | 322.39 |

| 9000 | 22.69 | 220.90 |

| Core Number | Water Flooding Oil Recovery (%) | Recovery Increment (%) | Ultimate Oil Recovery (%) |

|---|---|---|---|

| 1 | 47.5 | 11.2 | 58.7 |

| 2 | 47.3 | 8.6 | 55.9 |

| 3 | 47.6 | 9.1 | 56.7 |

| 4 | 47.5 | 10.2 | 57.7 |

| 5 | 47.2 | 9.7 | 56.9 |

| 6 | 47.4 | 11.4 | 58.8 |

| 7 | 47.7 | 12.1 | 59.8 |

| 8 | 47.8 | 15.8 | 63.6 |

| 9 | 47.2 | 16.6 | 63.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, S.; Liu, Y.; Hu, S.; Shen, A.; Yu, Q.; Yan, H.; Bai, M. Experimental Study on the Physical Performance and Flow Behavior of Decorated Polyacrylamide for Enhanced Oil Recovery. Energies 2019, 12, 562. https://doi.org/10.3390/en12030562

Liang S, Liu Y, Hu S, Shen A, Yu Q, Yan H, Bai M. Experimental Study on the Physical Performance and Flow Behavior of Decorated Polyacrylamide for Enhanced Oil Recovery. Energies. 2019; 12(3):562. https://doi.org/10.3390/en12030562

Chicago/Turabian StyleLiang, Shuang, Yikun Liu, Shaoquan Hu, Anqi Shen, Qiannan Yu, Hua Yan, and Mingxing Bai. 2019. "Experimental Study on the Physical Performance and Flow Behavior of Decorated Polyacrylamide for Enhanced Oil Recovery" Energies 12, no. 3: 562. https://doi.org/10.3390/en12030562