Computational Prediction of Susceptibility to Biofilms Growth: Two-Dimensional Analysis of Critical Construction Details

Abstract

:1. Introduction

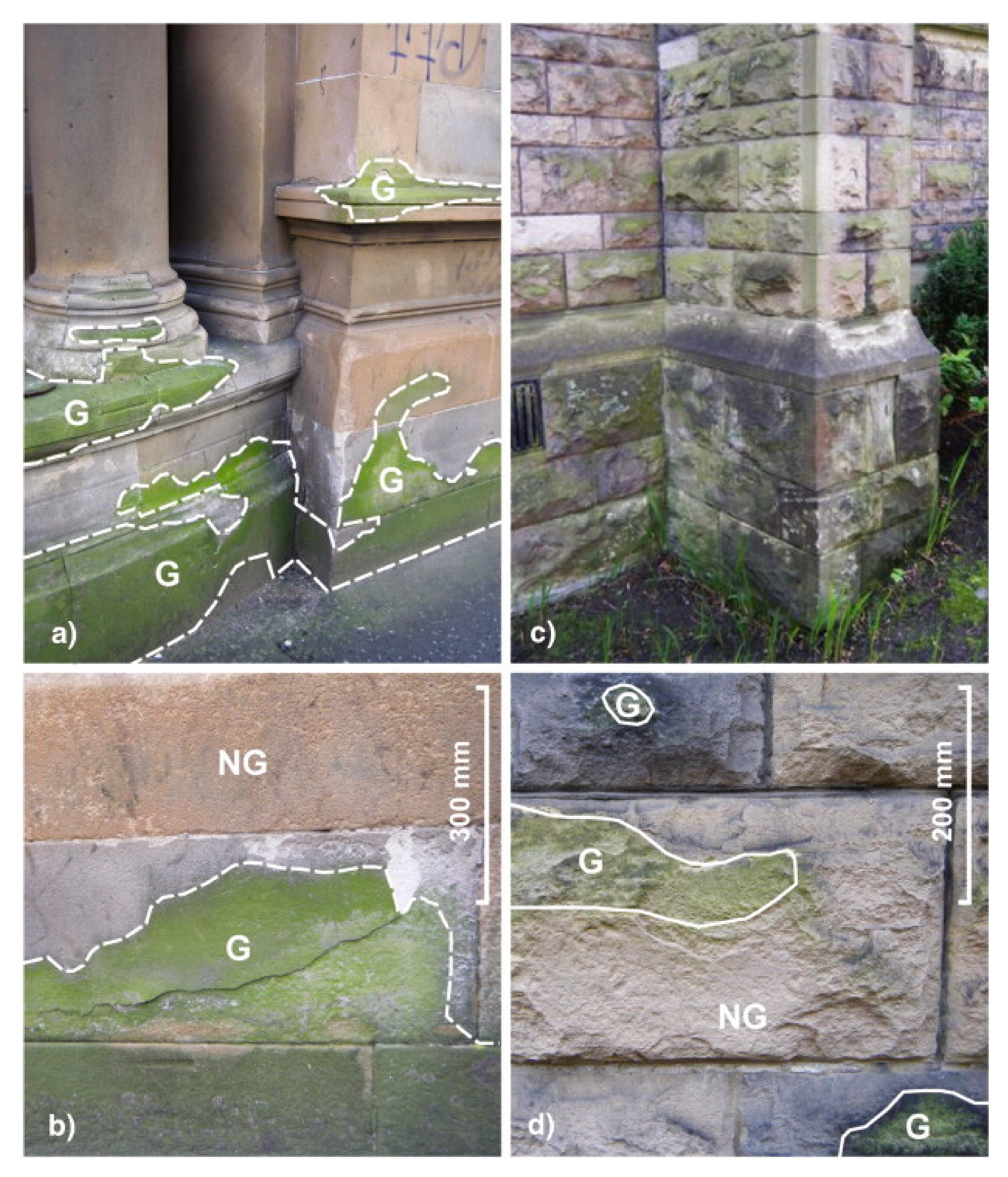

2. Critical Construction Details

3. Biofilms

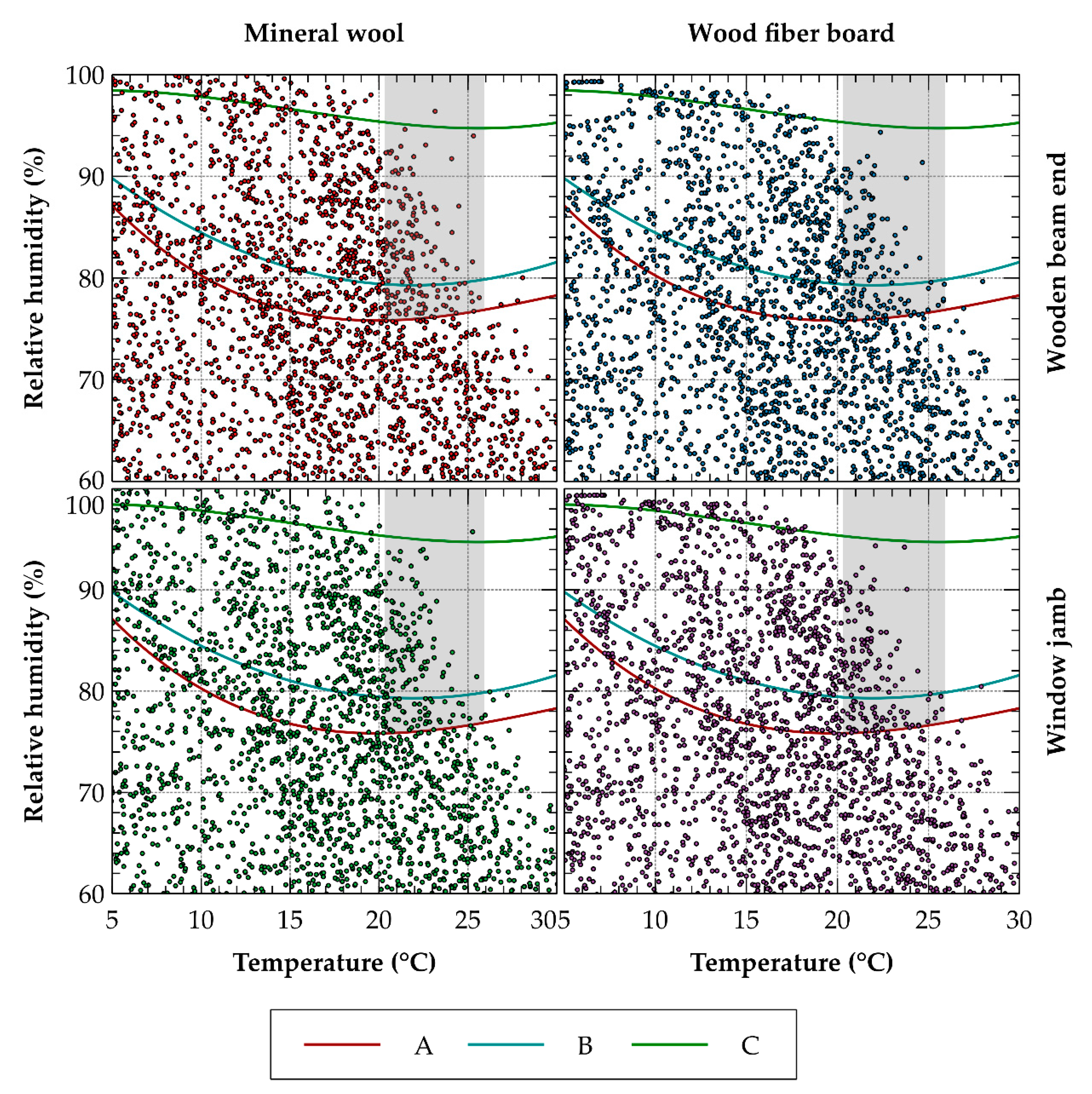

4. Computational Modeling of Hygrothermal Performance

4.1. Mathematical Model

4.2. Material Properties

4.3. Boundary Conditions

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cansino, J.M.; Pablo-Romero, M.P.; Roman, R.; Yniguez, R. Promoting renewable energy sources for heating and cooling in EU-27 countries. Energy Policy 2011, 39, 3803–3812. [Google Scholar] [CrossRef]

- European Union (EU). Energy Performance of Building Directive II; The European Parliament and the council of the European Union: Brussels, Belgium, 2010. [Google Scholar]

- Giada, G.; Caponetto, R.; Nocera, F. Hygrothermal properties of raw earth materials: A literature review. Sustainability 2019, 11, 5342. [Google Scholar] [CrossRef] [Green Version]

- Murmu, A.L.; Patel, A. Towards sustainable bricks production: An overview. Constr. Build. Mater. 2018, 165, 112–125. [Google Scholar] [CrossRef]

- Qu, X.L.; Zhao, X.G. Previous and present investigations on the components, microstructure and main properties of autoclaved aerated concrete—A review. Constr. Build. Mater. 2017, 135, 505–516. [Google Scholar] [CrossRef]

- Kim, J.T.; Yu, C.W.F. Sustainable development and requirements for energy efficiency in buildings—The Korean perspectives. Indoor Built Environ. 2018, 27, 734–751. [Google Scholar] [CrossRef]

- Kamel, E.; Memari, A.M. State-of-the-Art review of energy smart homes. J. Archit. Eng. 2019, 25. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. External thermal insulation composite systems: Critical parameters for surface hygrothermal behaviour. Adv. Mater. Sci. Eng. 2014, 2014, 650752. [Google Scholar] [CrossRef] [Green Version]

- Vereecken, E.; Roels, S. Capillary active interior insulation: Do the advantages really offset potential disadvantages? Mater. Struct. 2015, 48, 3009–3021. [Google Scholar] [CrossRef]

- Webb, A.L. Energy retrofits in historic and traditional buildings: A review of problems and methods. Renew. Sustain. Energy Rev. 2017, 77, 748–759. [Google Scholar] [CrossRef]

- Vereecken, E.; Van Gelder, L.; Janssen, H.; Roels, S. Interior insulation for wall retrofitting—A probabilistic analysis of energy savings and hygrothermal risks. Energy Build. 2015, 89, 231–244. [Google Scholar] [CrossRef] [Green Version]

- Orlik-Kożdoń, B. Interior insulation of masonry walls—selected problems in the design. Energies 2019, 12, 3895. [Google Scholar] [CrossRef] [Green Version]

- Vereecken, E.; Roels, S. A comparison of the hygric performance of interior insulation systems: A hot box-cold box experiment. Energy Build. 2014, 80, 37–44. [Google Scholar] [CrossRef]

- Vereecken, E.; Roels, S. Wooden beam ends in combination with interior insulation: An experimental study on the impact of convective moisture transport. Build. Environ. 2019, 148, 524–534. [Google Scholar] [CrossRef]

- Guiamet, P.; Crespo, M.; Lavin, P.; Ponce, B.; Gaylarde, C.; de Saravia, S.G. Biodeterioration of funeral sculptures in La Recoleta Cemetery, Buenos Aires, Argentina: Pre- and post-intervention studies. Colloids Surf. B Biointerfaces 2013, 101, 337–342. [Google Scholar] [CrossRef] [PubMed]

- Villegas-Sanchez, R.; Arroyo, F. The cathedral of Jerez De La Frontera (Cadiz, Spain): Stone degradation and conservation. J. Cult. Herit. 2013, 14, E113–E116. [Google Scholar] [CrossRef]

- Jurado, V.; Miller, A.Z.; Cuezva, S.; Fernandez-Cortes, A.; Benavente, D.; Rogerio-Candelera, M.A.; Reyes, J.; Canaveras, J.C.; Sanchez-Moral, S.; Saiz-Jimenez, C. Recolonization of mortars by endolithic organisms on the walls of San Roque church in Campeche (Mexico): A case of tertiary bioreceptivity. Constr. Build. Mater. 2014, 53, 348–359. [Google Scholar] [CrossRef]

- Becerra, J.; Ortiz, P.; Zaderenko, A.P.; Karapanagiotis, I. Assessment of nanoparticles/nanocomposites to inhibit micro-algal fouling on limestone facades. Build. Res. Inf. 2020, 48, 180–190. [Google Scholar] [CrossRef]

- Zarzuela, R.; Carbu, M.; Gil, M.L.A.; Cantoral, J.M.; Mosquera, M.J. Ormosils loaded with SiO2 nanoparticles functionalized with Ag as multifunctional superhydrophobic/biocidal/consolidant treatments for buildings conservation. Nanotechnology 2019, 30, 18. [Google Scholar] [CrossRef]

- Misra, A.; Castillo, I.F.; Muller, D.P.; Gonzalez, C.; Eyssautier-Chuine, S.; Ziegler, A.; de la Fuente, J.M.; Mitchell, S.G.; Streb, C. Polyoxometalate-ionic liquids (POM-ILs) as anticorrosion and antibacterial coatings for natural stones. Angew. Chem. Int. Ed. 2018, 57, 14926–14931. [Google Scholar] [CrossRef] [Green Version]

- Vojtkova, H. Algae and their biodegradation effects on building materials in the Ostrava industrial agglomeration. In Proceedings of the 1st International Conference on Advances in Environmental Engineering (AEE), Ostrava, Czech Republic, 28–30 November 2017. [Google Scholar]

- Rosado, T.; Silva, M.; Galvao, A.; Mirao, J.; Candeias, A.; Caldeira, A.T. A first insight on the biodegradation of limestone: The case of the World Heritage Convent of Christ. Appl. Phys. A Mater. Sci. Process 2016, 122, 7. [Google Scholar] [CrossRef]

- Guillitte, O.; Dreesen, R. Laboratory chamber studies and petrographic analysis as bioreceptivity assessment tools of building-materials. Sci. Total Environ. 1995, 167, 365–374. [Google Scholar] [CrossRef]

- Segers, F.J.J.; van Laarhoven, K.A.; Wosten, H.A.B.; Dijksterhuis, J. Growth of indoor fungi on gypsum. J. Appl. Microbiol. 2017, 123, 429–435. [Google Scholar] [CrossRef] [PubMed]

- Shirakawa, M.A.; Beech, I.B.; Tapper, R.; Cincotto, M.A.; Gambale, W. The development of a method to evaluate bioreceptivity of indoor mortar plastering to fungal growth. Int. Biodeterior. Biodegrad. 2003, 51, 83–92. [Google Scholar] [CrossRef]

- Tran, T.H.; Hoang, N.D. Predicting colonization growth of algae on mortar surface with artificial neural network. J. Comput. Civil Eng. 2016, 30, 8. [Google Scholar] [CrossRef]

- Tran, T.H.; Hoang, N.D. Estimation of algal colonization growth on mortar surface using a hybridization of machine learning and metaheuristic optimization. Sadhana Acad. Proc. Eng. Sci. 2017, 42, 929–939. [Google Scholar] [CrossRef] [Green Version]

- Marquez-Penaranda, J.F.; Sanchez-Silva, M.; Husserl, J.; Bastidas-Arteaga, E. Effects of biodeterioration on the mechanical properties of concrete. Mater. Struct. 2016, 49, 4085–4099. [Google Scholar] [CrossRef]

- Graziani, L.; Quagliarini, E.; Osimani, A.; Aquilanti, L.; Clementi, F.; D’Orazio, M. The influence of clay brick substratum on the inhibitory efficiency of TiO2 nanocoating against biofouling. Build. Environ. 2014, 82, 128–134. [Google Scholar] [CrossRef]

- Gaylarde, C.C.; Gaylarde, P.M. A comparative study of the major microbial biomass of biofilms on exteriors of buildings in Europe and Latin America. Int. Biodeterior. Biodegrad. 2005, 55, 131–139. [Google Scholar] [CrossRef]

- Gaylarde, P.M.; Shirakawa, M.A.; John, V.; Gambale, W.; Gaylarde, C.C. Statistical analysis of fungicide activity in paint films on two buildings. Surf. Coat. Int. Part B Coat. Trans. 2004, 87, 261–264. [Google Scholar] [CrossRef]

- Gil, M.; Martins, M.R.; Carvalho, M.L.; Souto, C.; Longelin, S.; Cardoso, A.; Mirao, J.; Candeias, A.E. Microscopy and microanalysis of an extreme case of salt and biodegradation in 17th century wall paintings. Microsc. Microanal. 2015, 21, 606–616. [Google Scholar] [CrossRef] [Green Version]

- Rosado, T.; Gil, M.; Caldeira, A.T.; Martins, M.D.; Dias, C.B.; Carvalho, L.; Mirao, J.; Candeias, A.E. Material characterization and biodegradation assessment of mural paintings: Renaissance frescoes from santo aleixo church, southern portugal. Int. J. Arch. Herit. 2014, 8, 835–852. [Google Scholar] [CrossRef]

- Barberousse, H.; Ruot, B.; Yepremian, C.; Boulon, G. An assessment of facade coatings against colonisation by aerial algae and cyanobacteria. Build. Environ. 2007, 42, 2555–2561. [Google Scholar] [CrossRef]

- Garciapichel, F.; Wingard, C.E.; Castenholz, R.W. Evidence regarding the uv sunscreen role of a mycosporine-like compound in the cyanobacterium gloeocapsa sp. Appl. Environ. Microbiol. 1993, 59, 170–176. [Google Scholar] [CrossRef] [Green Version]

- Tiano, P.; Accolla, P.; Tomaselli, L. Phototrophic biodeteriogens on lithoid surfaces—An ecological study. Microbial Ecol. 1995, 29, 299–309. [Google Scholar] [CrossRef] [PubMed]

- Künzel, H.M.; Sedlbauer, K. Biological growth on stucco. In Proceedings of the Buildings VIII/Proceedings, Atlanta, GA, USA, 2–7 December 2001; pp. 1–5. [Google Scholar]

- Kobetičová, K.; Nábělková, J.; Kočí, V. Identification of biofilm composition covering lime-based materials. MATEC Web Conf. 2019, 282, 02067. [Google Scholar] [CrossRef] [Green Version]

- Vereecken, E.; Roels, S. Review of mould prediction models and their influence on mould risk evaluation. Build. Environ. 2012, 51, 296–310. [Google Scholar] [CrossRef] [Green Version]

- Rowan, N.J.; Johnstone, C.M.; McLean, R.C.; Anderson, J.G.; Clarke, J.A. Prediction of toxigenic fungal growth in buildings by using a novel modelling system. Appl. Environ. Microbiol. 1999, 65, 4814–4821. [Google Scholar] [CrossRef] [Green Version]

- Clarke, J.A.; Johnstone, C.M.; Kelly, N.J.; McLean, R.C.; Anderson, J.A.; Rowan, N.J.; Smith, J.E. A technique for the prediction of the conditions leading to mould growth in buildings. Build. Environ. 1999, 34, 515–521. [Google Scholar] [CrossRef]

- Dubosc, A.; Escadeillas, G.; Blanc, P.J. Characterization of biological stains on external concrete walls and influence of concrete as underlying material. Cem. Concr. Res. 2001, 31, 1613–1617. [Google Scholar] [CrossRef]

- Madera, J.; Koci, J.; Koci, V.; Kruis, J. Parallel modeling of hygrothermal performance of external wall made of highly perforated bricks. Adv. Eng. Softw. 2017, 113, 47–53. [Google Scholar] [CrossRef]

- Koci, V.; Koci, J.; Madera, J.; Pavlik, Z.; Gu, X.L.; Zhang, W.P.; Cerny, R. Thermal and hygric assessment of an inside-insulated brick wall: 2D critical experiment and computational analysis. J. Build. Phys. 2018, 41, 497–520. [Google Scholar] [CrossRef]

- Jerman, M.; Palomar, I.; Koci, V.; Cerny, R. Thermal and hygric properties of biomaterials suitable for interior thermal insulation systems in historical and traditional buildings. Build. Environ. 2019, 154, 81–88. [Google Scholar] [CrossRef]

- Černý, R. Complex System of Methods for Directed Design and Assessment of Functional Properties of Building Materials and its Applications; Czech Technical University: Prague, Czech Republic, 2013; p. 509. [Google Scholar]

- Koci, V.; Cachova, M.; Konakova, D.; Vejmelkova, E.; Jerman, M.; Keppert, M.; Madera, J.; Cerny, R. Heat and moisture transport and storage parameters of bricks affected by the environment. Int. J. Thermophys. 2018, 39, 63. [Google Scholar] [CrossRef]

- Koci, V.; Madera, J.; Jerman, M.; Zumar, J.; Konakova, D.; Cachova, M.; Vejmelkova, E.; Reiterman, P.; Cerny, R. Application of waste ceramic dust as a ready-to-use replacement of cement in lime-cement plasters: An environmental-friendly and energy-efficient solution. Clean Technol. Environ. Policy 2016, 18, 1725–1733. [Google Scholar] [CrossRef]

- Jerman, M.; Cerny, R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Czech Office for Standards, Metrology and Testing. Thermal Protection of Buildings—Part 2: Requirements; Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2011. [Google Scholar]

- Hansen, T.K.; Bjarlov, S.P.; Peuhkuri, R. The effects of wind-driven rain on the hygrothermal conditions behind wooden beam ends and at the interfaces between internal insulation and existing solid masonry. Energy Build. 2019, 196, 255–268. [Google Scholar] [CrossRef]

- Orlik-Kozdon, B.; Steidl, T. Impact of internal insulation on the hygrothermal performance of brick wall. J. Build. Phys. 2017, 41, 120–134. [Google Scholar] [CrossRef]

- Schmidt, O. Indoor wood-decay basidiomycetes: Damage, causal fungi, physiology, identification and characterization, prevention and control. Mycol. Progress 2007, 6, 261–279. [Google Scholar] [CrossRef]

- Kopecky, P.; Stanek, K.; Bures, M.; Richter, J.; Ryparova, P.; Tywoniak, J. Experimental investigations of wooden beam ends in masonry with interior insulation: Measured data in real-scale experimental walls exposed to semi-continental climatic conditions. J. Build. Phys. 2019, 43, 147–170. [Google Scholar] [CrossRef]

| Solid Brick [47] | Wood | Lime Cement Mortar/Plaster [48] | Mineral Wool [45] | Wood Fiber Board [49] | |

|---|---|---|---|---|---|

| Bulk density (kg·m−3) | 1831 | 417 | 1244 | 70 | 54 |

| Open porosity (%) | 27.09 | 35.50 | 49.80 | 96.9 | 96.35 |

| Thermal conductivity (W·m−1·K−1) | 0.59–1.74 | 0.13–0.29 | 0.30–0.94 | 0.04–0.70 see Figure 6 | 0.05–0.45 see Figure 6 |

| Specific heat capacity (J·kg−1·K−1) | 825–1254 | 1501–2733 | 1054–1592 | 810–3850 | 2130 |

| Water vapor diffusion resistance factor (-) | 8.8–22.1 | 31.99–134.85 | 5.52–7.52 | 1.2–2.4 | 1.12–2.69 |

| Moisture diffusivity (m2·s−1) | 1.08 × 10−6 | 1.04 × 10−9 | 3.27 × 10−8 | 8.50 × 10−6 | 1.14 × 10−6 |

| Hygroscopic moisture content (m3·m−3) | 0.0036 | 0.0342 | 0.0144 | 0.0003 see Figure 7 | 0.0031 see Figure 7 |

| Parameter | Value | |

|---|---|---|

| Temperature (see Figure 8) | Average | 9.8 °C |

| Maximal | 34.1 °C | |

| Minimal | −13.9 °C | |

| 20–25 °C zone | 857 h | |

| Relative humidity (see Figure 8) | Average | 76.0% |

| 80%–100% zone | 4314 h | |

| Rainfalls | 570.9 mm | |

| Wind | see Figure 9a | |

| Sun radiation | see Figure 9b | |

| Type of Detail | Thermal Insulation | A | B | C |

|---|---|---|---|---|

| Wooden beam end | Mineral wool | 180 | 120 | 1 |

| Wooden beam end | Wood fiber board | 154 | 101 | 0 |

| Window jamb | Mineral wool | 170 | 116 | 1 |

| Window jamb | Wood fiber board | 153 | 98 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kočí, V.; Kočí, J.; Maděra, J.; Žák, J.; Černý, R. Computational Prediction of Susceptibility to Biofilms Growth: Two-Dimensional Analysis of Critical Construction Details. Energies 2020, 13, 293. https://doi.org/10.3390/en13020293

Kočí V, Kočí J, Maděra J, Žák J, Černý R. Computational Prediction of Susceptibility to Biofilms Growth: Two-Dimensional Analysis of Critical Construction Details. Energies. 2020; 13(2):293. https://doi.org/10.3390/en13020293

Chicago/Turabian StyleKočí, Václav, Jan Kočí, Jiří Maděra, Jaroslav Žák, and Robert Černý. 2020. "Computational Prediction of Susceptibility to Biofilms Growth: Two-Dimensional Analysis of Critical Construction Details" Energies 13, no. 2: 293. https://doi.org/10.3390/en13020293