Demand Response Coupled with Dynamic Thermal Rating for Increased Transformer Reserve and Lifetime

Abstract

:1. Introduction

- ▪

- A valid PWL model for the thermal model of an oil-immersed transformer is derived, and its adequacy for the problem stated in the paper is confirmed.

- ▪

- A co-optimization problem for DR design (rated power and energy) and management is formulated and solved with the consideration of thermal and aging limitations over different time horizons and for different reserve margins.

- ▪

- DTR based on the temperature limit is proved to be more efficient than DTR based on design temperature for use with DR.

- ▪

- It is proved that if DR is used to shave about 1% of the total energy consumption (a full DR capacity is activated only 2–3 h per year), a transformer reserve can be increased to accommodate 75% more load connection. In these simulations, it is assumed that the thermal state of a transformer is in the quasi-worst situation by using many safety margins: the worst load growth is aligned with the maximal ambient temperature as well as N-1 condition over the whole year. Hence, the calculated DR, which is needed to mitigate the quasi-worst situation, is on the conservative side.

2. End-Users Side Flexibility for Grid Upgrades Deferral

2.1. Case Study

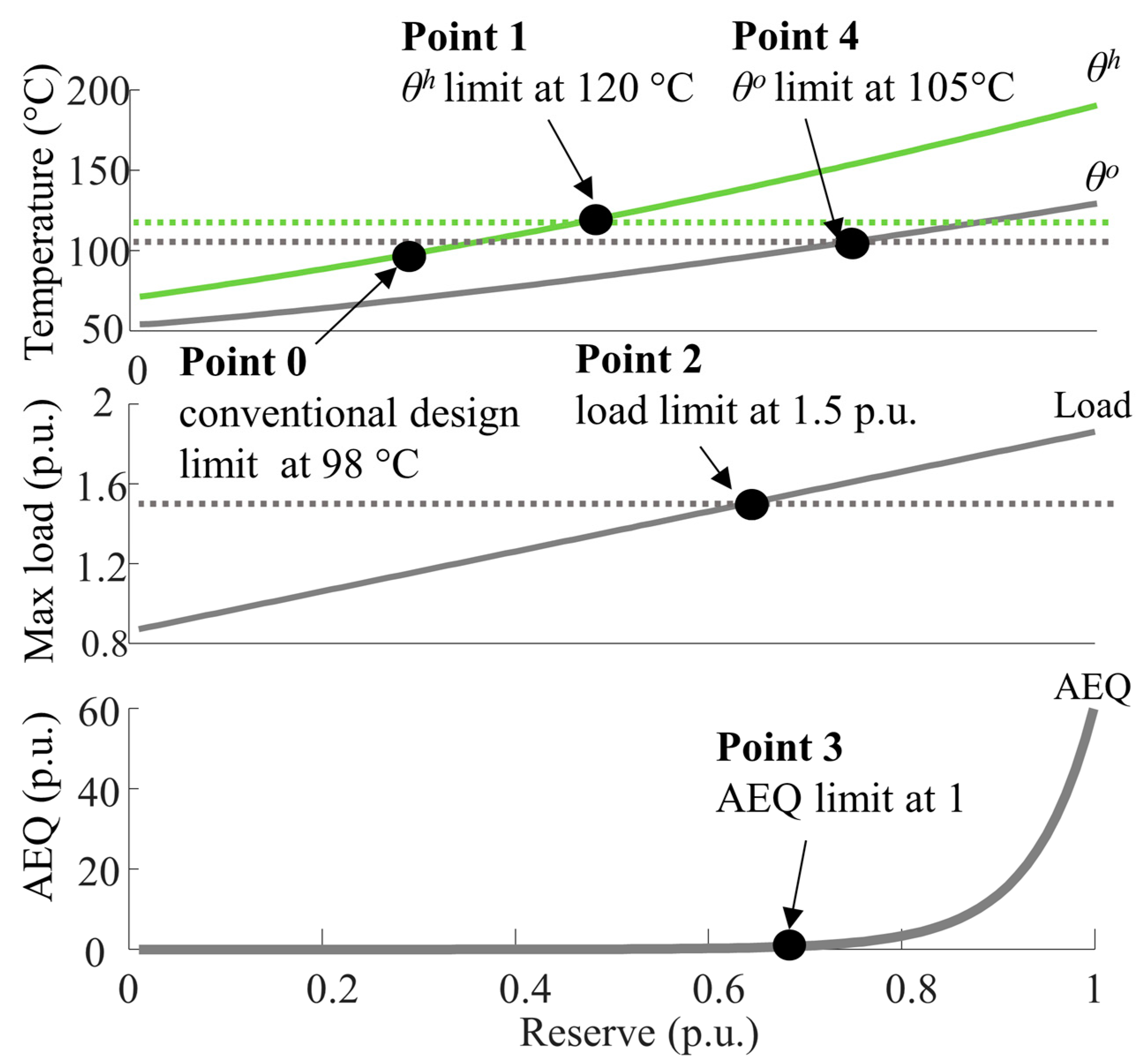

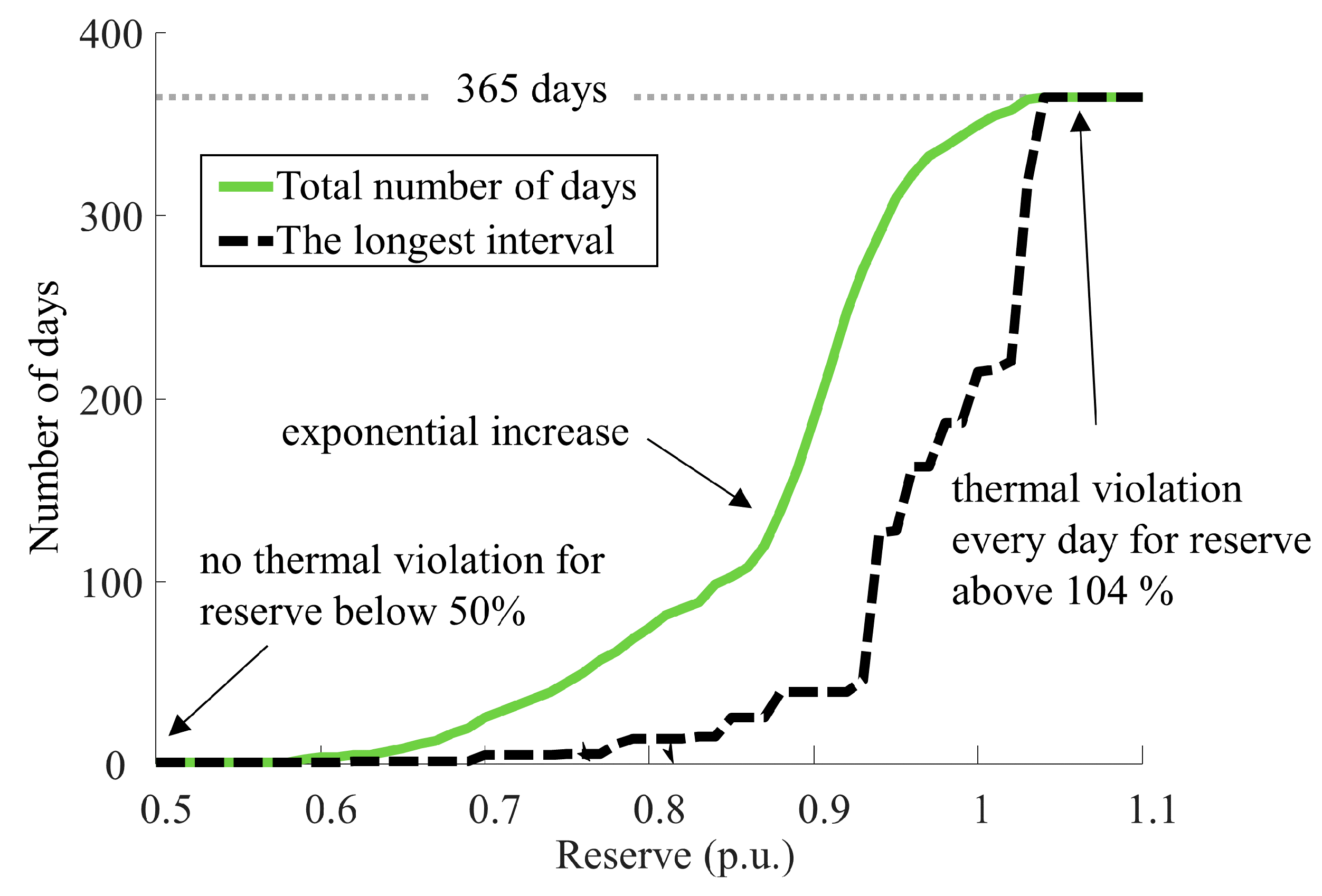

2.2. Problem Statement

2.3. Methodology

3. Integrated Design and Management of Demand Response

3.1. Transformer Thermal Model and Aging

3.2. Problem Formulation

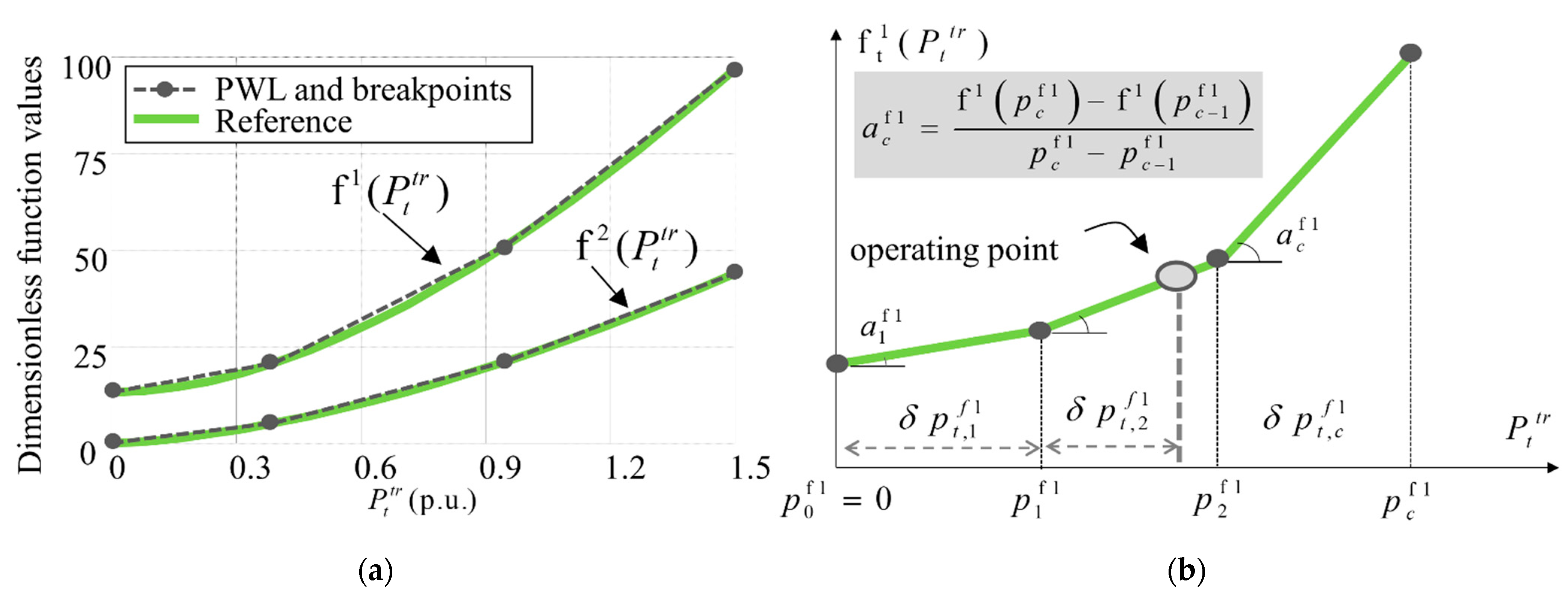

3.3. Simplified Formulation for Thermal Constraints

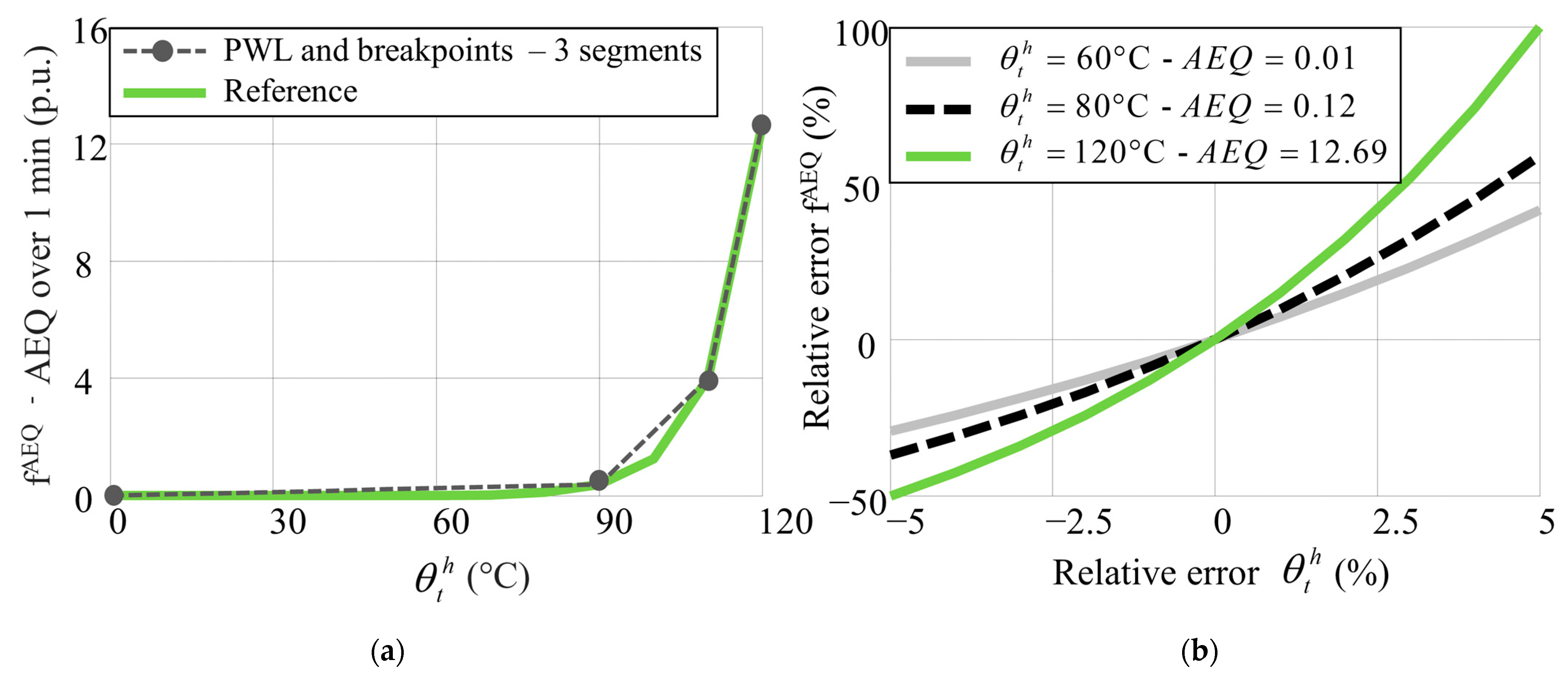

3.4. Approximate Aging Model

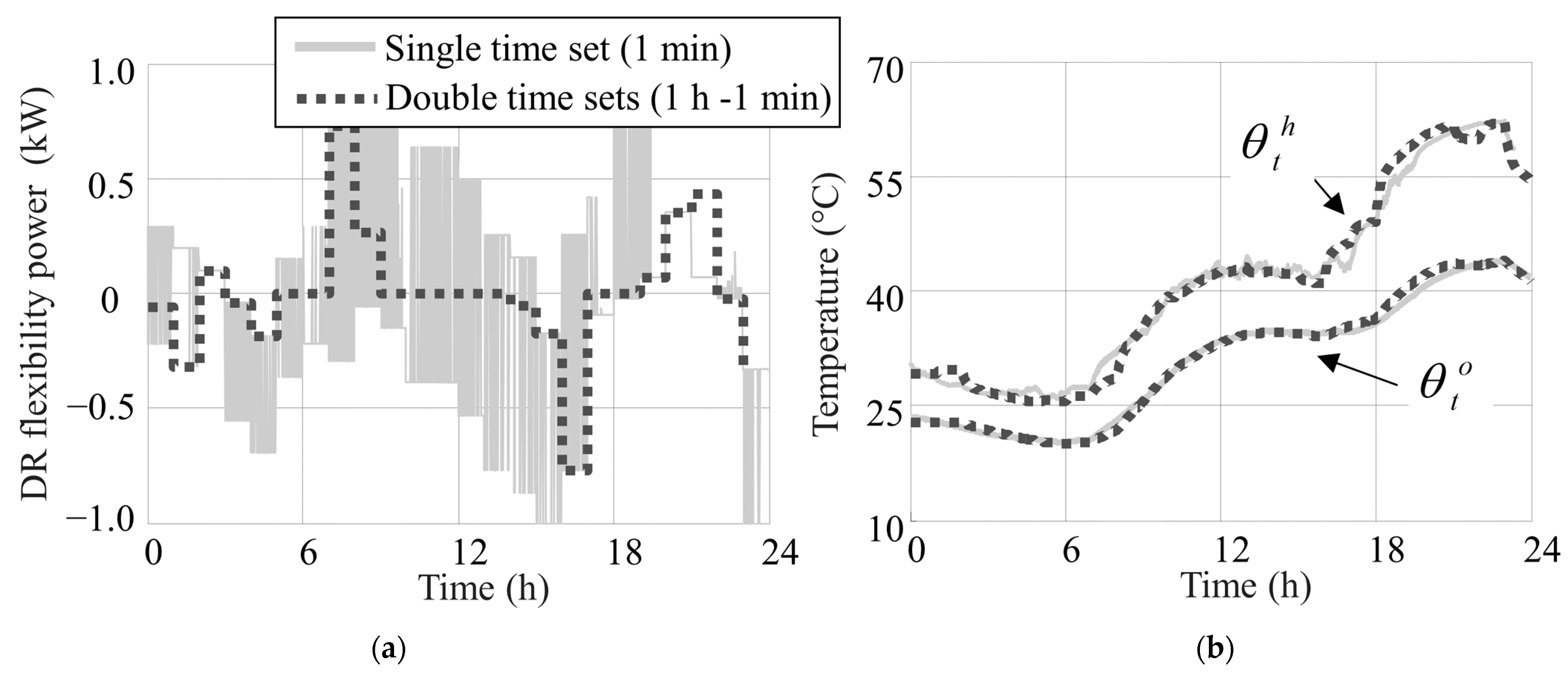

3.5. Multiple Time Sets

4. Results and Discussion

4.1. Validation Runs for the Integrated Management and Design of DR

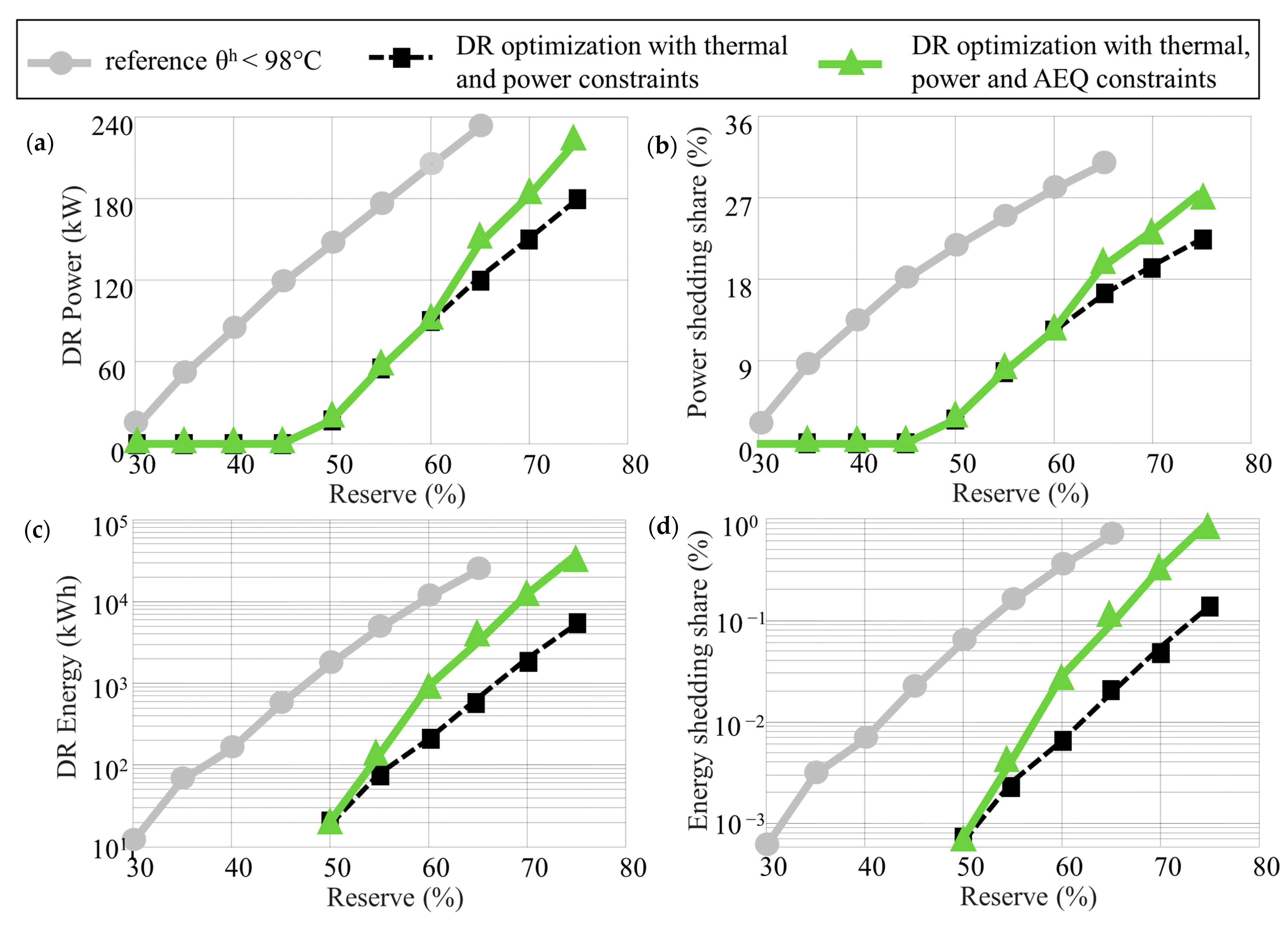

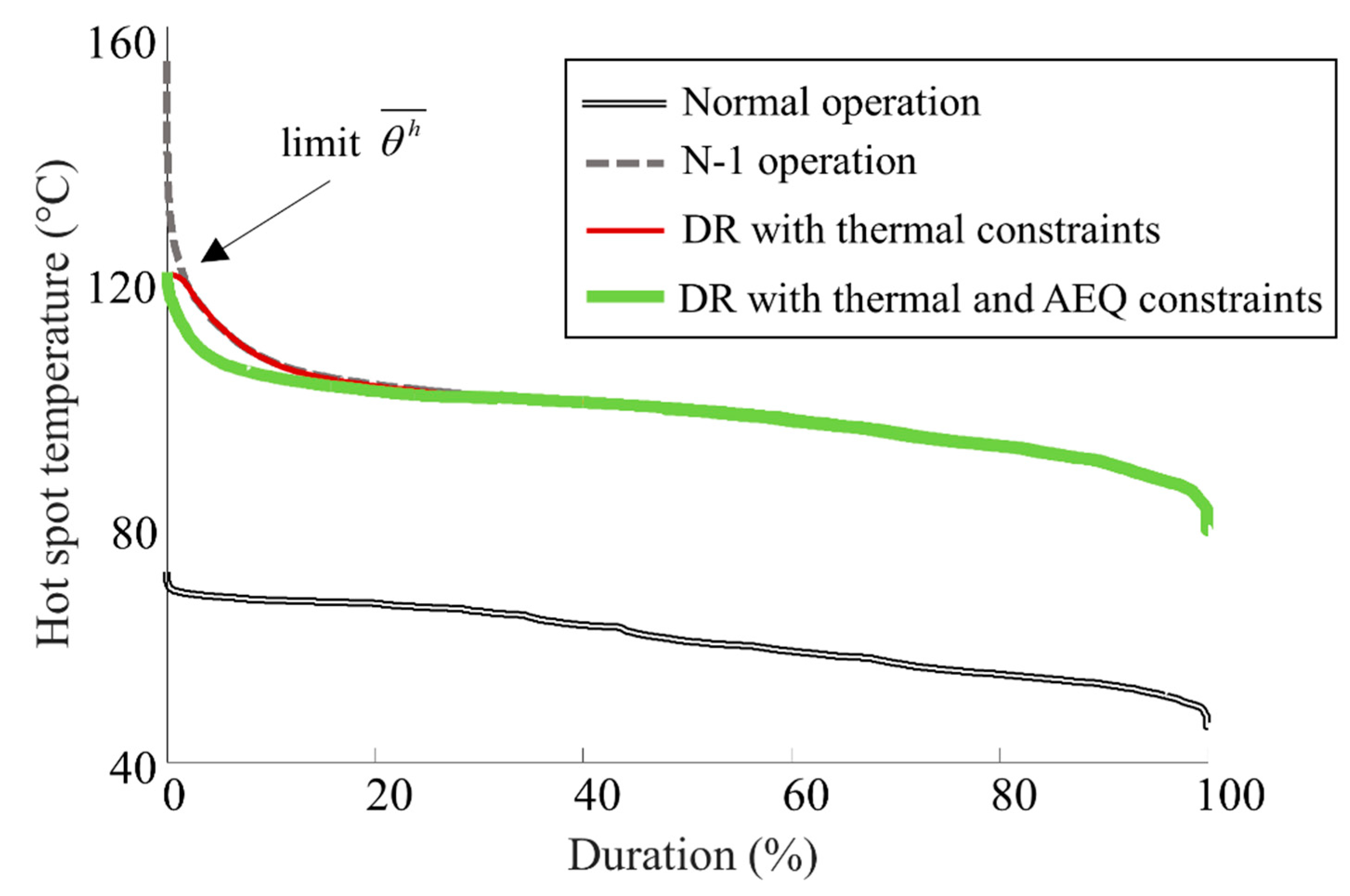

4.2. Results for Different Reserve Margins

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Renewable Energy Agency. Global Energy Transformation: A Roadmap to 2050; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2018; ISBN 978-92-9260-059-4. [Google Scholar]

- International Renewable Energy Agency. Electrification with Renewables. Driving the Transformation of Energy Services; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; ISBN 9789292601089. [Google Scholar]

- van Ruijven, B.J.; De Cian, E.; Sue Wing, I. Amplification of future energy demand growth due to climate change. Nat. Commun. 2019, 10, 2762. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cavlovic, M. Universal Procedure for Determining the Optimal Connection to the Distribution Network. In Proceedings of the CIRED 2019, Madrid, Spain, 3–6 June 2019. [Google Scholar]

- Mason, T.; Curry, T.; Wilson, D. Capital Costs for Transmission and Substations. Recommendations for WECC Transmission Expansion Planning Western Electricity Coordinating Council; Black & Veatch Corporation: Overland Park, KS, USA, 2012. [Google Scholar]

- DNV GL Energy Transition Outlook 2018—DNV GL. Available online: https://eto.dnv.com/2018/ (accessed on 1 March 2021).

- Willis, H.L.; Schrieber, R. Aging Power Delivery Infrastructures, 2nd ed.; Power Engineering (Willis); CRC Press: Boca Raton, FL, USA, 2013; Volume 20132771, ISBN 978-1-4398-0403-2. [Google Scholar]

- Esmat, A.; Usaola, J.; Moreno, M.A. Congestion Management in Smart Grids with Flexible Demand Considering the Payback Effect. In Proceedings of the 2016 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT-Europe), Slovenia Ljubljana, Slovenia, 9–12 October 2016; IEEE: Scottsdale, AZ, USA, 2016; pp. 1–6. [Google Scholar]

- Li, R.; Wang, W.; Chen, Z.; Jiang, J.; Zhang, W. A Review of Optimal Planning Active Distribution System: Models, Methods, and Future Researches. Energies 2017, 10, 1715. [Google Scholar] [CrossRef] [Green Version]

- Chiodo, E.; Lauria, D.; Mottola, F.; Pisani, C. Lifetime characterization via lognormal distribution of transformers in smart grids: Design optimization. Appl. Energy 2016, 177, 127–135. [Google Scholar] [CrossRef]

- Flexibility: The Path to Low-Carbon, Low-Cost Electricity Grids—CPI. Available online: https://www.climatepolicyinitiative.org/publication/flexibility-path-low-carbon-low-cost-electricity-grids/ (accessed on 1 March 2021).

- Martínez Ceseña, E.A.; Good, N.; Mancarella, P. Electrical network capacity support from demand side response: Techno-economic assessment of potential business cases for small commercial and residential end-users. Energy Policy 2015, 82, 222–232. [Google Scholar] [CrossRef]

- Martinez Cesena, E.A.; Mancarella, P. Distribution Network Capacity Support from Flexible Smart Multi-Energy Districts. In Proceedings of the 2016 IEEE PES Transmission & Distribution Conference and Exposition-Latin America (PES T&D-LA), Morelia, Mexico, 21–24 September 2016; IEEE: Scottsdale, AZ, USA, 2016; pp. 1–6. [Google Scholar]

- Flexibility Model of Integrated Energy Sources for the Strategic Planning of Distribution Networks. Available online: http://www.cired.net/publications/workshop2018/pdfs/Submission%200525%20-%20Paper%20(ID-21419).pdf (accessed on 1 March 2021).

- Esmat, A.; Usaola, J. DSO congestion management using demand side flexibility. In Proceedings of the CIRED Workshop 2016, Helsinki, Finland, 14–15 June 2016; Institution of Engineering and Technology, IET: Stevenage, UK, 2016; Volume 2016, p. 197. [Google Scholar]

- Jiang, S.; Zeng, Y.; Cheng, L.; Tian, L.; Zhao, J.; Yan, B.; Wang, X.; Li, C. Substation Capacity Planning Method Considering Interruptible Load. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–8 November 2018; IEEE: Scottsdale, AZ, USA, 2018; pp. 496–500. [Google Scholar]

- Mullen, C. Interactions between Demand Side Response, Demand Recovery, Peak Pricing and Electricity Distribution Network Capacity Margins. Ph.D. Thesis, School of Electrical and Electronic Engineering, Newcastle University, Newcastle upon Tyne, UK, 2018. [Google Scholar]

- Elmakis, D.; Braunstein, A.; Naot, Y. A probabilistic method for establishing the transformer capacity in substations based on the loss of transformer expected life. IEEE Trans. Power Syst. 1988, 3, 353–360. [Google Scholar] [CrossRef]

- Elmakis, D.; Braunstein, A.; Naot, Y. A Probabilistic Method for Establishing the Transformer Capacity Reserve Criteria for HV/MV Substations. IEEE Trans. Power Syst. 1986, 1, 158–164. [Google Scholar] [CrossRef]

- Sen, P.K.; Pansuwan, S.; Malmedal, K.; Martinoo, O.; Simoes, M.G. Transformer Overloading and Assessment of Loss-of-Life for Liquid-Filled Transformers. Power Syst. Eng. Res. Cent. 2011, 1–106. Available online: https://pserc.wisc.edu/publications/reports/2011_reports/T-25_Final-Report_Feb-2011.pdf (accessed on 1 March 2021).

- Bunn, M.; Das, B.P.; Seet, B.C.; Baguley, C. Empirical Design Method for Distribution Transformer Utilization Optimization. IEEE Trans. Power Deliv. 2019, 34, 1803–1813. [Google Scholar] [CrossRef]

- Kostin, V.N.; Minakova, T.E.; Kopteva, A.V. Urban Substations Transformers allowed Loading. In Proceedings of the 2018 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg, Russia, 29 January–1 February 2018; IEEE: Scottsdale, AZ, USA, 2018; Volume 2018, pp. 692–695. [Google Scholar]

- Daminov, I.; Prokhorov, A.; Moiseeva, T.; Caire, R.; Alvarez-Herault, M.-C. Application of Dynamic Transformer Ratings to Increase the Reserve of Primary Substations for New Load Interconnection. Available online: https://www.cired-repository.org/handle/20.500.12455/708 (accessed on 1 March 2021).

- Gourisetti, S.N.G.; Kirkham, H.; Sivaraman, D. A review of transformer aging and control strategies. In Proceedings of the 2017 North American Power Symposium (NAPS), Morgantown, WV, USA, 17–19 September 2017; IEEE: Scottsdale, AZ, USA, 2017; pp. 1–6. [Google Scholar]

- Sousa, J.C.S.; Saavedra, O.R.; Lima, S.L. Decision Making in Emergency Operation for Power Transformers With Regard to Risks and Interruptible Load Contracts. IEEE Trans. Power Deliv. 2018, 33, 1556–1564. [Google Scholar] [CrossRef]

- Teja S, C.; Yemula, P.K. Architecture for demand responsive HVAC in a commercial building for transformer lifetime improvement. Electr. Power Syst. Res. 2020, 189, 106599. [Google Scholar] [CrossRef]

- Davison, P.J.; Lyons, P.F.; Taylor, P.C. Temperature sensitive load modelling for dynamic thermal ratings in distribution network overhead lines. Int. J. Electr. Power Energy Syst. 2019, 112, 1–11. [Google Scholar] [CrossRef]

- Zhou, B.; Cao, Y.; Li, C.; Wu, Q.; Liu, N.; Huang, S.; Wang, H. Many-criteria optimality of coordinated demand response with heterogeneous households. Energy 2020, 207, 118267. [Google Scholar] [CrossRef]

- Van Der Klauw, T.; Gerards, M.E.T.; Hurink, J.L. Using demand-side management to decrease transformer ageing. In Proceedings of the IEEE PES Innovative Smart Grid Technologies Conference Europe, Ljubljana, Slovenia, 9–12 October 2016. [Google Scholar]

- Liu, J.; Xiao, J.; Zhou, B.; Wang, Z.; Zhang, H.; Zeng, Y. A two-stage residential demand response framework for smart community with transformer aging. In Proceedings of the 2017 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Bangalore, India, 8–10 November 2017; IEEE: Scottsdale, AZ, USA, 2017; pp. 1–6. [Google Scholar]

- Soleimani, M.; Kezunovic, M. Mitigating Transformer Loss of Life and Reducing the Hazard of Failure by the Smart EV Charging. IEEE Trans. Ind. Appl. 2020, 56, 5974–5983. [Google Scholar] [CrossRef]

- Mohsenzadeh, A.; Kapourchali, M.H.; Chengzong, P.; Aravinthan, V. Impact of smart home management strategies on expected lifetime of transformer. In Proceedings of the 2016 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Dallas, TX, USA, 3–5 May 2016; IEEE: Scottsdale, AZ, USA, 2016; pp. 1–5. [Google Scholar]

- Brinkel, N.B.G.; Schram, W.L.; AlSkaif, T.A.; Lampropoulos, I.; van Sark, W.G.J.H.M. Should we reinforce the grid? Cost and emission optimization of electric vehicle charging under different transformer limits. Appl. Energy 2020, 276, 115285. [Google Scholar] [CrossRef]

- Humayun, M.; Ali, M.; Safdarian, A.; Degefa, M.Z.; Lehtonen, M. Optimal use of demand response for lifesaving and efficient capacity utilization of power transformers during contingencies. In Proceedings of the IEEE Power and Energy Society General Meeting 2015, Denver, CO, USA, 26–30 July 2015. [Google Scholar]

- Humayun, M.; Degefa, M.Z.; Safdarian, A.; Lehtonen, M. Utilization improvement of transformers using demand response. IEEE Trans. Power Deliv. 2015, 30, 202–210. [Google Scholar] [CrossRef]

- Humayun, M.; Safdarian, A.; Ali, M.; Degefa, M.Z.; Lehtonen, M. Optimal capacity planning of substation transformers by demand response combined with network automation. Electr. Power Syst. Res. 2016, 134, 176–185. [Google Scholar] [CrossRef]

- Humayun, M.; Safdarian, A.; Degefa, M.Z.; Lehtonen, M. Demand Response for Operational Life Extension and Efficient Capacity Utilization of Power Transformers During Contingencies. IEEE Trans. Power Syst. 2015, 30, 2160–2169. [Google Scholar] [CrossRef]

- Salehi, J.; Haghifam, M.-R. Determining the optimal reserve capacity margin of Sub-Transmission (ST) substations using Genetic Algorithm. Int. Trans. Electr. Energy Syst. 2014, 24, 492–503. [Google Scholar] [CrossRef]

- Kannan, S.; Au, M.T. Probabilistic approach in sizing distribution transformers. In Proceedings of the 2010 IEEE 11th International Conference on Probabilistic Methods Applied to Power Systems, Singapore, 14–17 June 2010; IEEE: Scottsdale, AZ, USA, 2010; pp. 599–603. [Google Scholar]

- Helmi, B.A.; D’Souza, M.; Bolz, B.A. The application of power factor correction capacitors to reserve spare capacity of existing main transformers. In Proceedings of the Industry Applications Society 60th Annual Petroleum and Chemical Industry Conference, Chicago, IL, USA, 23–25 September 2013; IEEE: Scottsdale, AZ, USA, 2013; pp. 1–6. [Google Scholar]

- Turnham, V.; Blair, S.M.; Booth, C.D.; Turner, P. Increasing Distribution Network Capacity using Automation to Reduce Carbon Impact. In Proceedings of the 12th IET International Conference on Developments in Power System Protection (DPSP 2014), Copenhagen, Denmark, 31 March–3 April 2014; Volume 2014, pp. 1–6. [Google Scholar]

- IEC. IEC 60076-7 Power Transformer—Part 7: Loading Guide for Oil-Immersed Power Transformers; IEC: Geneva, Switzerland, 2018. [Google Scholar]

- Norris, E.T. The thermal rating of transformers. J. Inst. Electr. Eng. 1928, 66, 841–854. [Google Scholar] [CrossRef]

- Sealey, W.C.; Hodtum, J.B. Overloading of Transformers—Cases Not Covered by the General Rules. Trans. Am. Inst. Electr. Eng. 1944, 63, 149–153. [Google Scholar] [CrossRef]

- Norris, E.T. Loading of power transformers. Proc. Inst. Electr. Eng. 1967, 114, 228. [Google Scholar] [CrossRef]

- Sandels, C.; Widén, J.; Nordström, L. Forecasting household consumer electricity load profiles with a combined physical and behavioral approach. Appl. Energy 2014, 131, 267–278. [Google Scholar] [CrossRef]

- House Load Electricity—File Exchange—MATLAB Central. Available online: https://fr.mathworks.com/matlabcentral/fileexchange/63375-house-load-electricity (accessed on 1 March 2021).

- MeteoBlue Ambient Temperature History over 30 Years for Grenoble Region. Available online: https://www.meteoblue.com/en/historyplus (accessed on 1 March 2021).

- Viafora, N.; Holboll, J.; Kazmi, S.H.H.; Olesen, T.H.; Sorensen, T.S. Load dispatch optimization using dynamic rating and optimal lifetime utilization of transformers. In Proceedings of the 2019 IEEE Milan PowerTech, PowerTech 2019, Milan, Italy, 23–27 June 2019. [Google Scholar]

- Degefa, M.Z.; Humayun, M.; Safdarian, A.; Koivisto, M.; Millar, R.J.; Lehtonen, M. Unlocking distribution network capacity through real-time thermal rating for high penetration of DGs. Electr. Power Syst. Res. 2014, 117, 36–46. [Google Scholar] [CrossRef]

- Watson, A.; Weller, R. Temperature correction factor applied to substation capacity analysis. In Proceedings of the 18th International Conference and Exhibition on Electricity Distribution (CIRED 2005), Turin, Italy, 6–9 June 2005; IET: Stevenage, UK, 2005; Volume 2005, pp. 1–4. [Google Scholar]

- Susa, D.; Nordman, H. IEC 60076-7 loading guide thermal model constants estimation. Int. Trans. Electr. Energy Syst. 2013, 23, 946–960. [Google Scholar] [CrossRef]

- Das, B.; Jalal, T.S.; McFadden, F.J.S. Comparison and extension of IEC thermal models for dynamic rating of distribution transformers. In Proceedings of the 2016 IEEE International Conference on Power System Technology (POWERCON), Wollongong, NSW, Australia, 28 September–1 October 2016; IEEE: Scottsdale, AZ, USA, 2016; pp. 1–8. [Google Scholar]

- Wang, L.; Zhang, X.; Villarroel, R.; Liu, Q.; Wang, Z.; Zhou, L. Top-oil temperature modelling by calibrating oil time constant for an oil natural air natural distribution transformer. IET Gener. Transm. Distrib. 2020, 14, 4452–4458. [Google Scholar] [CrossRef]

- Rigo-Mariani, R.; Chea Wae, S.O.; Mazzoni, S. Impact of the Economic Environment Modelling for the Optimal Design of a Multi-Energy Microgrid. In Proceedings of the 46th Annual Conference of the IEEE Industrial Electronics Society IECON, Singapore, 18–21 October 2020. [Google Scholar]

- Rigo-Mariani, R.; Chea Wae, S.O.; Mazzoni, S.; Romagnoli, A. Comparison of optimization frameworks for the design of a multi-energy microgrid. Appl. Energy 2020, 257, 113982. [Google Scholar] [CrossRef]

- Lofberg, J. YALMIP: A toolbox for modeling and optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation (IEEE Cat. No.04CH37508), New Orleans, LA, USA, 26 April–1 May 2004; IEEE: Scottsdale, AZ, USA, 2004; pp. 284–289. [Google Scholar]

- Liu, Y.; Sioshansi, R.; Conejo, A.J. Multistage Stochastic Investment Planning With Multiscale Representation of Uncertainties and Decisions. IEEE Trans. Power Syst. 2017, 33, 781–791. [Google Scholar] [CrossRef]

- Mégel, O.; Mathieu, J.L.; Andersson, G. Scheduling distributed energy storage units to provide multiple services under forecast error. Int. J. Electr. Power Energy Syst. 2015, 72, 48–57. [Google Scholar] [CrossRef]

- Flexibility in the Energy Transition a Toolbox for Electricity Dsos Flexibility in the Energy Transition i a Toolbox for Electricity DSOs. Available online: https://www.edsoforsmartgrids.eu/flexibility-in-the-energy-transition-a-toolbox-for-electricity-dsos/ (accessed on 1 March 2021).

- Dorostkar-Ghamsari, M.R.; Fotuhi-Firuzabad, M.; Safdarian, A.; Hoshyarzade, A.S.; Lehtonen, M. Improve capacity utilization of substation transformers via distribution network reconfiguraion and load transfer. In Proceedings of the EEEIC 2016—International Conference on Environment and Electrical Engineering, Florence, Italy, 7–10 June 2016. [Google Scholar]

- Kumar, K.; Satsangi, S.; Kumbhar, G.B. Extension of life of distribution transformer using Volt-VAr optimisation in a distribution system. IET Gener. Transm. Distrib. 2019, 13, 1777–1785. [Google Scholar] [CrossRef]

- Godina, R.; Rodrigues, E.M.G.; Matias, J.C.O.; Catalão, J.P.S. Smart electric vehicle charging scheduler for overloading prevention of an industry client power distribution transformer. Appl. Energy 2016, 178, 29–42. [Google Scholar] [CrossRef]

- Powell, S.; Kara, E.C.; Sevlian, R.; Cezar, G.V.; Kiliccote, S.; Rajagopal, R. Controlled workplace charging of electric vehicles: The impact of rate schedules on transformer aging. Appl. Energy 2020, 276, 115352. [Google Scholar] [CrossRef]

- Xueqiang, Z.; Pengfei, Z.; Haoyi, T.; Sanshan, Z. Research and Practical Application of Transformer Emergency Standby Calculation and Assessment Method. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–8 November 2018; IEEE: Scottsdale, AZ, USA, 2018; pp. 3659–3666. [Google Scholar]

- Biçen, Y.; Aras, F. Loadability of power transformer under regional climate conditions: The case of Turkey. Electr. Eng. 2014, 96, 347–358. [Google Scholar] [CrossRef]

- Yang, J.; Chittock, L.; Strickland, D.; Harrap, C. Predicting practical benefits of dynamic asset ratings of 33KV distribution transformers. IET Int. Conf. Resil. Transm. Distrib. Netw. 2015, 2015, 60354. [Google Scholar]

- Yang, J.; Bai, X.; Strickland, D.; Jenkins, L.; Cross, A.M. Dynamic Network Rating for Low Carbon Distribution Network Operation—A UK Application. IEEE Trans. Smart Grid 2015, 6, 988–998. [Google Scholar] [CrossRef]

- Salama, M.M.M.; Mansour, D.E.A.; Abdelmaksoud, S.M.; Abbas, A.A. Impact of Long-Term Climatic Conditions on the Ageing and Cost Effectiveness of the Oil-Filled Transformer. In Proceedings of the 2018 20th International Middle East Power Systems Conference, MEPCON 2018—Proceedings, Cairo, Egypt, 18–20 December 2018. [Google Scholar]

- Metwaly, M.K.; Teh, J. Probabilistic Peak Demand Matching by Battery Energy Storage Alongside Dynamic Thermal Ratings and Demand Response for Enhanced Network Reliability. IEEE Access 2020, 8, 181547–181559. [Google Scholar] [CrossRef]

- Pasricha, A.; Crow, M.L. A method of improving transformer overloading beyond nameplate rating. In Proceedings of the 2015 North American Power Symposium (NAPS), Charlotte, NC, USA, 4–6 October 2015; IEEE: Scottsdale, AZ, USA, 2015; pp. 1–6. [Google Scholar]

- Daminov, I.; Prokhorov, A.; Caire, R.; Alvarez-Herault, M.C. Assessment of dynamic transformer rating, considering current and temperature limitations. Int. J. Electr. Power Energy Syst. 2021, 129, 106886. [Google Scholar] [CrossRef]

- Olsen, R. Dynamic Loadability of Cable Based Transmission Grids. Ph.D. Thesis, Department of Electrical Engineering, Technical University of Denmark, Copenhagen, Denmark, 2013. [Google Scholar]

- Alghamdi, A.S.; Desuqi, R.K. A study of expected lifetime of XLPE insulation cables working at elevated temperatures by applying accelerated thermal ageing. Heliyon 2020, 6, e031120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IEC. IEC Standard 60287-2-1; IEC: Geneva, Switzerland, 2015; ISBN 2831886376. [Google Scholar]

- IEEE Standard for Calculating the Current-Temperature Relationship of Bare Overhead Conductors-738-2012. Available online: https://ieeexplore.ieee.org/document/6692858 (accessed on 1 March 2021).

| Limits | Loading Type | ||

|---|---|---|---|

| Normal Cyclic | Long-Term Emergency | Short-Term Emergency | |

| Ptr (p.u.) | 1.5 | 1.8 | 2.0 |

| θh (°C) | 120 | 140 | Not specified |

| θo (°C) | 105 | 115 | Not specified |

| AEQ (p.u. | 1 | >1 possible | Not specified |

| x | y | R | τo | τw | θa |

| 0.8 | 1.6 | 5 | 180 | 4 | 20 |

| θh | Δθhr | Δθor | k11 | k21 | k22 |

| 98 | 23 | 55 | 1 | 1 | 2 |

| Sets | Variables | ||

|---|---|---|---|

| DR flexibility power (kW) | |||

| Generic set of time step (1 min) | Transformer loading (p.u.) | ||

| Set of time step for dispatch (1 h) | , | PWL power in block c at t (p.u.) | |

| Set of PWL blocks | DR flexibility rated power (kW) | ||

| DR flexibility rated energy (kWh) | |||

| Transformer Parameters | |||

| Ambient temperature at time t (°C) | Oil/winding exponent | ||

| Top oil temperature at time t (°C) | Loss ratio, hot-spot factor | ||

| Hot-spot temperature at time t (°C) | Hot-spot factor | ||

| , | Hot-spot to top oil gradients at t (K) | Oil/winding time constant (min) | |

| Rated hot-spot to oil gradient (K) | , | Model coefficients | |

| Rated top oil temperature rise (K) | Transformer rated power (kW) | ||

| Simulation Parameters | |||

| Load to supply at time t (kW) | Lower/upper state of charge (%) | ||

| , | PWL breakpoints in block c | Initial flexibility state of charge (%) | |

| , | PWL slope in block c | Final flexibility state of charge (%) | |

| Number of PWL blocks for θo and θh | 6 | 6 | 6 | 6 | 9 | 12 |

| Number of PWL blocks for AEQ | 3 | 6 | 12 | 18 | 12 | 12 |

| AEQ computed with exact θo and θh | 0.67 | 0.88 | 0.94 | 0.94 | 0.95 | 0.96 |

| AEQ computed with PWL θo and θh | 0.70 | 0.91 | 0.97 | 0.97 | 0.97 | 0.97 |

| AEQ computed with PWL | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daminov, I.; Rigo-Mariani, R.; Caire, R.; Prokhorov, A.; Alvarez-Hérault, M.-C. Demand Response Coupled with Dynamic Thermal Rating for Increased Transformer Reserve and Lifetime. Energies 2021, 14, 1378. https://doi.org/10.3390/en14051378

Daminov I, Rigo-Mariani R, Caire R, Prokhorov A, Alvarez-Hérault M-C. Demand Response Coupled with Dynamic Thermal Rating for Increased Transformer Reserve and Lifetime. Energies. 2021; 14(5):1378. https://doi.org/10.3390/en14051378

Chicago/Turabian StyleDaminov, Ildar, Rémy Rigo-Mariani, Raphael Caire, Anton Prokhorov, and Marie-Cécile Alvarez-Hérault. 2021. "Demand Response Coupled with Dynamic Thermal Rating for Increased Transformer Reserve and Lifetime" Energies 14, no. 5: 1378. https://doi.org/10.3390/en14051378