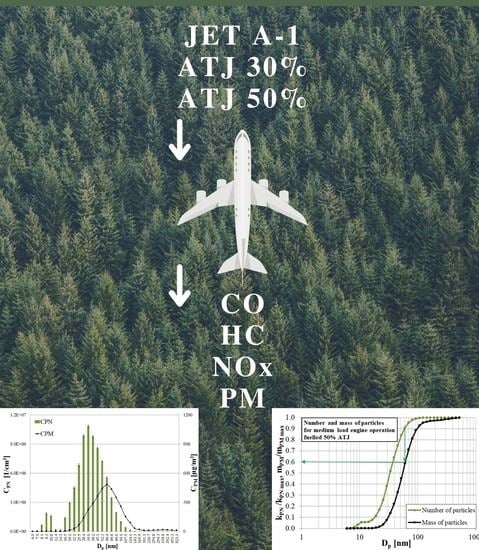

Overview of Sustainable Aviation Fuels with Emission Characteristic and Particles Emission of the Turbine Engine Fueled ATJ Blends with Different Percentages of ATJ Fuel

Abstract

:1. Introduction

2. Sustainable Aviation Fuels

- Reducing carbon dioxide emissions throughout the life cycle;

- Limited need for fresh water;

- No need for deforestation and no competition with food production for land for cultivation.

3. Requirements for Alternative Aviation Fuels

3.1. Operational Requirements

3.2. Physicochemical Requirements

3.3. Environmental Requirements

4. Experimental

- A flame ionization detector (FID), which uses the change of electric potential resulting from the ionization of molecules in the flame; it is used to determine the total concentration of hydrocarbons,

- A non-dispersive ultraviolet (NDUV) analyzer that uses ultraviolet radiation to measure the concentration of nitrogen oxide and dioxide

- A non-dispersive infrared (NDIR) analyzer using radiation infrared to measure the concentration of carbon monoxide and dioxide, and

- An electrochemical analyzer for determining the oxygen concentration in the exhaust gas.

5. Results and Discussion

5.1. Concentration of Harmful Exhaust Gas Compounds

5.2. Particles Concentration

5.2.1. Low Engine Load

5.2.2. Medium Engine Load

5.2.3. High Engine Load

5.2.4. Analysis of the Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- IRENA. Biofuels for Aviation, Technology Brief; International Renewable Energy Agency: Abu Dhabi, UAE, 2017. [Google Scholar]

- Bosch, J.; Hoefnagels, R.; Jong, S.; Slade, R. Aviation Biofuels: Strategically Important, Technically Achievable, Tough to Deliver; Grantham Institute, Imperial College London: London, UK, 2017. [Google Scholar]

- Airbus Global Market Forecast, Cities, Airports & Aircraft, 2019–2038. 2019. Available online: http://gmf.airbus.com/assets/pdf/Airbus_Global_Market_Forecast_2019-2038.pdf?v=1.0.1 (accessed on 14 January 2020).

- European Aviation Environmental Report 2019, EASA, EEA, Eurocontrol. Available online: https://ec.europa.eu/transport/sites/transport/files/2019-aviation-environmental-report.pdf (accessed on 12 January 2020).

- Merkisz, J.; Idzior, M.; Lijewski, P.; Fuć, P.; Karpiuk, W. The Analysis of the Quality of Fuel Spraying in Relation to Selected Rapeseed Oil Fuels for the Common Rail System; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Braun-Unkhoff, M.; Riedel, U. Alternative fuels in aviation. CEAS Aeronaut. J. 2015, 6, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Hakes, J. A Declaration of Energy Independence: How Freedom from Foreign Oil Can Improve National Security, Our Economy, and the Environment; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Renewable Energy Directive, European Commission. Available online: https://ec.europa.eu/energy/topics/renewable-energy/renewable-energy-directive/overview_en (accessed on 10 March 2021).

- European Parliament; Council of the European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources (recast). Off. J. Eur. Union 2018, PE/48/2018/REV/1, 82–209. [Google Scholar]

- Atmanli, A.; Yilmaz, N. An experimental assessment on semi-low temperature combustion using waste oil biodiesel/C3-C5 alcohol blends in a diesel engine. Fuel 2019, 260, 116357. [Google Scholar] [CrossRef]

- IATA. Sustainable Aviation Fuels Fact Sheet; International Air Transport Association: Montreal, QC, Canada, 2019. [Google Scholar]

- Saha, S.; Sharma, A.; Purkayastha, S.; Pandey, K.; Dhingra, S. Bio-plastics and Biofuel: Is it the Way in Future Development for End Users? In Plastics to Energy Fuel, Chemicals, and Sustainability Implications; Plastics Design Library Series; Elsevier: Amsterdam, The Netherlands, 2019; pp. 365–376. [Google Scholar]

- ATAG. Beginner’s Guide to Sustainable Aviation Fuel; Air Transport Action Group: Geneva, Switzerland, 2017. [Google Scholar]

- Carriquiry, M.A.; Du, X.; Timilsina, G.R. Second generation biofuels: Economics and policies. Energy Policy 2011, 39, 4222–4234. [Google Scholar] [CrossRef] [Green Version]

- Oregon State University. Generation of Biofuels; Bioenergy Education Initiative, Oregon State University: Corvallis, OR, USA.

- Kostova, B. Current Status of Alternative Aviation Fuels; U.S. Department of Energy: Washington, DC, USA, 2017.

- Shonnard, D.R.; Williams, L.; Kalnes, T.N. Camelina-Derived Jet Fuel and Diesel: Sustainable Advanced Biofuels. Environ. Prog. Sustain. Energy 2010, 29, 382–392. [Google Scholar] [CrossRef]

- Power-to-Liquids Potentials and Perspectives for the Future Supply of Renewable Aviation Fuel, German Enivronment Agency. 2016. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/377/publikationen/161005_uba_hintergrund_ptl_barrierrefrei.pdf (accessed on 10 March 2021).

- Schmidt, P.; Batteiger, V.; Roth, A.; Weindorf, W.; Raksha, T. Power-to-Liquids as Renewable Fuel Option for Aviation: A Review. Chem. Ing. Tech. 2018, 90, 127–140. [Google Scholar] [CrossRef]

- RAND Corporation. Infrastructure, Safety and Environment; RAND Corporation: Santa Monica, CA, USA, 2009. [Google Scholar]

- ICAO. Sustainable Aviation Fuels Guide; International Civil Aviation Organization: Montreal, QC, Canada, 2018. [Google Scholar]

- ASTM. ASTM Standardization News, D7566 Takes Flight; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- CAAFI Commercial Aviation Alternative Fuel Initiative, Fuel Qualification. Available online: http://www.caafi.org/focus_areas/fuel_qualification.html (accessed on 13 August 2020).

- Karpiuk, W.; Borowczyk, T.; Idzior, M.; Smolec, R. The Evaluation of the Impact of Design and Operating Parameters of Common Rail System Fueled by Bio-Fuels on the Emission of Harmful Compounds. In Proceedings of the 2016 International Conference on Sustainable Energy, Environment and Information Engineering (SEEIE 2016), Bangkok, Thailand, 20–21 March 2016. [Google Scholar]

- IATA. Sustainable Aviation Fuels Roadmap; International Air Transport Association: Montreal, QC, Canada, 2015. [Google Scholar]

- Chevron Products Company, Aviation Fuels Technical Review. 2007. Available online: https://skybrary.aero/bookshelf/books/2478.pdf (accessed on 10 March 2021).

- Biomass Magazine. PNNL Technology Clears Way for Ethanol-Derived Jet Fuel. 2018. Available online: http://biomassmagazine.com/articles/15369/pnnl-technology-clears-way-for-ethanol-derived-jet-fuel (accessed on 12 January 2020).

- Csonka, S. The State of Sustainable Aviation Fuel (SAF); CAAFI Webinar Series; International Civil Aviation Organization: Montreal, QC, Canada, 2020. [Google Scholar]

- Zschocke, A.; Scheuermann, S.; Ortner, J. High Biofuel Blends in Aviation (HBBA), ENER/C2/2012/420-1, Final Report; Lufthansa: Cologne, Germany, 2012. [Google Scholar]

- Johnston, G. Alcohol to Jet—Isobutanol, ICAO Seminarium on Alternative Fuels 2017; ICAO: Montreal, QC, Canada, 2017. [Google Scholar]

- LanzaTech. No Carbon Left Behind: Alcohol-to-Jet. 2018. Available online: https://www.iata.org/contentassets/8dc7f9f4c38247ae8f007998295a37d5/jennifer-holmgren-vf-panel-session-2.pdf (accessed on 10 March 2021).

- Jasiński, R. Evaluation of Nanoparticles Mass and Size Emissions from Aircraft Engines. Ph.D. Thesis, Poznan University of Technology, Poznań, Poland, 2019. [Google Scholar]

- Merkisz, J.; Pielecha, J. The on-road exhaust emissions characteristics of SUV vehicles fitted with diesel engines. Siln. Spalinowe 2011, 50, 58–72. [Google Scholar]

- Braun-Unkhoff, M.; Riedel, U.; Wahl, C. About the Emissions of Alternative Jet Fuels. CEAS Aeronaut. J. 2017, 8, 167–180. [Google Scholar] [CrossRef] [Green Version]

- Riebl, S.; Braun-Unkhoff, M.; Riedel, U. A study on the emissions of alternative aviation fuels. J. Gas Turbines Power 2017, 139, 081503. [Google Scholar] [CrossRef] [Green Version]

- Lobo, P.; Durdina, L.; Smallwood, G.J.; Rindlisbacher, T.; Siegerist, F.; Black, E.A.; Yu, Z.; Mensah, A.A.; Hagen, D.E.; Miake-Lye, R.C.; et al. Measurement of aircraft engine non-volatile PM emissions: Results of the Aviation-Particle Regulatory Instrumentation Demonstration Experiment (A-PRIDE) 4 Campaign. Aerosol Sci. Technol. 2015, 49, 472–484. [Google Scholar] [CrossRef] [Green Version]

- Park, K.; Cao, F.; Kittelson, D.B.; McMurry, P.H. Relationship between particle mass and mobility for diesel exhaust particles. Environ. Sci. Technol. 2003, 37, 577–583. [Google Scholar] [CrossRef] [PubMed]

- Petzold, A.; Marsh, R.; Johnson, M.; Miller, M.; Sevcenco, Y.; Delhaye, D.; Ibrahim, A.; Williams, P.; Bauer, H.; Crayford, A.; et al. Evaluation of methods for measuring particulate matter emissions from gas turbines. Environ. Sci. Technol. 2011, 45, 3562–3568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| No. | Property Name | Unit of Measure | Requirements acc. to ASTM D7566 |

|---|---|---|---|

| 1 | Density at 15 °C | kg/m3 | from 775 to 840 |

| 2 | Viscosity at −20 °C | mm2/s | max 8.0 |

| 3 | Viscosity at −40 °C | mm2/s | max 12 |

| 4 | Calorific value | MJ/kg | min 42.8 |

| 5 | Aroma content | % | min 8, max 25 |

| 6 | Naphthalene content | % | max 3.0 |

| 7 | Flash-point | °C | min 38 |

| 8 | Crystallization temperature | °C | max −47 |

| 9 | Distillation: | ||

| Start distillation temperature | °C | - | |

| 10% distils to temperature | °C | max 205 | |

| End distillation temperature | °C | max 300 | |

| Residue | % | max 1.5 | |

| Loss | % | max 1.5 | |

| 10 | Lubricity | mm | max 0.85 |

| Annex | Process | Raw Material | Approval Date | Blending Limit |

|---|---|---|---|---|

| A1 | Fischer-Tropsch Synthetic Paraffinic Kerosene (FT-SPK) | Biomass (wood waste, grass, municipal solid waste) | 2009 | up to 50% |

| A2 | Hydroprocessed Esters and Fatty Acids (HEFA-SPK) | Oily biomass, e.g., algae, jatropha, camelina | 2011 | up to 50% |

| A3 | Hydroprocessed Fermented Sugars to Synthetic Isoparaffins (HFS-SIP) | Bacterial conversion of sugars into hydrocarbons | 2014 | 10% |

| A4 | FT-SPK with aromatics (FT-SPK/A) | Renewable biomass, i.e., municipal solid waste, agricultural and wood waste | 2015 | up to 50% |

| A5 | Alcohol-to-jet Synthetic Paraffinic Kerosene (ATJ-SPK) | Agricultural waste (corn shoots, grass, straw), cellulosic biomass | 2016 | up to 50% |

| A6 |

Catalytic Hydrothermolysis Synthesized Kerosene (CH-SK, or CHJ) | Vegetable or animal fats, oils and greases | 2020 | up to 50% |

| A7 | Hydroprocessed Hydrocarbons, Esters and Fatty Acids Synthetic Paraffinic Kerosene (HHC-SPK or HC-HEFA-SPK) | Hydrocarbons of biological origin, fatty acid esters, free fatty acids, or a species of Botryococcus braunia algae | 2020 | up to 10% |

| Property | Jet A-1 [According to ASTM D1655 Standard] | ATJ-SPK | 50/50% v ATJ-SPK and Jet A-1 |

|---|---|---|---|

| Crystallization temperature [°C] | −47 | −61 | −54 |

| Flash point [°C] | min 38 | 48 | min 38 |

| Calorific value [MJ/kg] | 42.8 | 43.2 | 43.8 |

| Total sulfur content [%] | max 0.3 | <0.01 | 0.02 |

| Aromas content [%] | 17.3 | 0 | 8.8 |

| Maximum thrust [N] | 100 |

| Fuel consumption (for maximum thrust) [g/min] | 520 |

| Length [mm] | 340 |

| Width [mm] | 115 |

| Weight [kg] | 1.5 |

| Parameters | Value |

|---|---|

| Diameter of the measured particles | 5.6–560 nm |

| Number of measurement channels | 16 channels per decade |

| Resolution | 10 Hz |

| Exhaust sample volume flow rate | 0.6 m3/h |

| Compressed air volume flow rate | 2.4 m3/h |

| Input sample temperature | 10–52 °C |

| Range Name | Engine Operation Load Range [N] | |

|---|---|---|

| Up | To | |

| Low | 10 | 30 |

| Medium | 40 | 60 |

| High | 70 | 100 |

| Engine Operation Load | Tested Fuel | ||

|---|---|---|---|

| Jet A-1 | 30% ATJ | 50% ATJ | |

| Range of dominant diameters in particles number [nm] | |||

| low | 25.5–124.1 | 25.5–107.5 | 19.1–93.1 |

| medium | 25.5–107.5 | 22.1–93.1 | 16.5–80.6 |

| high | 16.5–107.5 | 22.1–93.1 | 16.5–80.6 |

| Range of dominant diameters in particulate matter mass [nm] | |||

| low | 25.5–220.7 | 34.0–165.6 | 25.5–165.6 |

| medium | 29.4–165.5 | 25.5–124.1 | 25.5–124.1 |

| high | 25.5–143.3 | 25.5–143.3 | 22.1–124.1 |

| The most dominant diameter [nm] | |||

| low | 60.4 | 52.3 | 34.0 |

| medium | 52.3 | 34.0 | 34.0 |

| high | 34.0 | 34.0 | 34.0 |

| 90% of relative number particles is less than [nm]: | |||

| low | 100 | 80 | 70 |

| medium | 80 | 70 | 60 |

| high | 70 | 70 | 55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurzawska, P.; Jasiński, R. Overview of Sustainable Aviation Fuels with Emission Characteristic and Particles Emission of the Turbine Engine Fueled ATJ Blends with Different Percentages of ATJ Fuel. Energies 2021, 14, 1858. https://doi.org/10.3390/en14071858

Kurzawska P, Jasiński R. Overview of Sustainable Aviation Fuels with Emission Characteristic and Particles Emission of the Turbine Engine Fueled ATJ Blends with Different Percentages of ATJ Fuel. Energies. 2021; 14(7):1858. https://doi.org/10.3390/en14071858

Chicago/Turabian StyleKurzawska, Paula, and Remigiusz Jasiński. 2021. "Overview of Sustainable Aviation Fuels with Emission Characteristic and Particles Emission of the Turbine Engine Fueled ATJ Blends with Different Percentages of ATJ Fuel" Energies 14, no. 7: 1858. https://doi.org/10.3390/en14071858