Experimental Study of Influence of Core Wettability on Imbibition Properties

Abstract

:1. Introduction

- ①

- Effect of rock wettability on imbibition

- ②

- Effect of rock pore structure on imbibition

- ③

- Effect of clay minerals on imbibition

2. Imbibition Experiment

2.1. Experimental Cores

- (1)

- Choose the size and mass of quartz sands and clay minerals according to the needed experimental core permeability;

- (2)

- Choose type and proportion of the wetting control agent and sands according to experiment need;

- (3)

- Mix the sands, clay minerals, and wetting control agent well;

- (4)

- Put the mixed material into the mold and press it with a hydraulic press;

- (5)

- Heat curing;

- (6)

- Test the permeability and WI of the core.

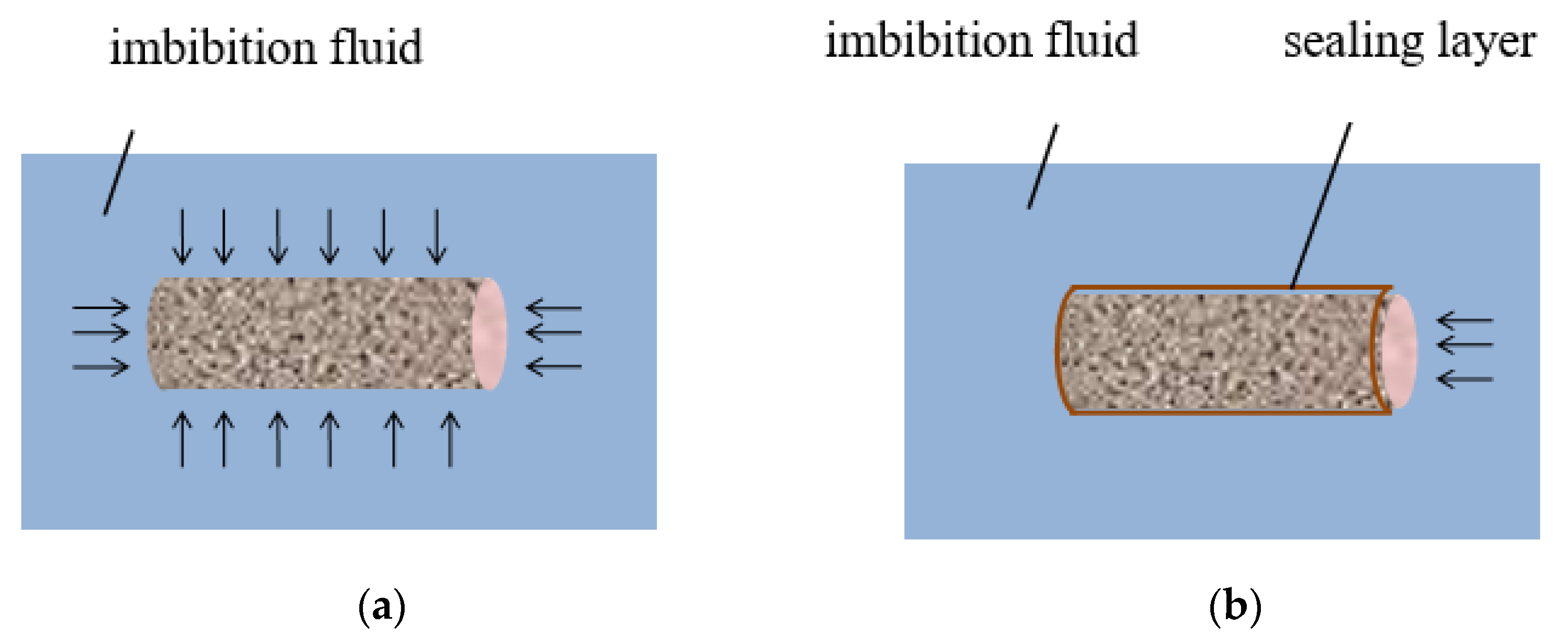

2.2. Experimental Method

2.3. Experimental Condition

3. Results and Discussion

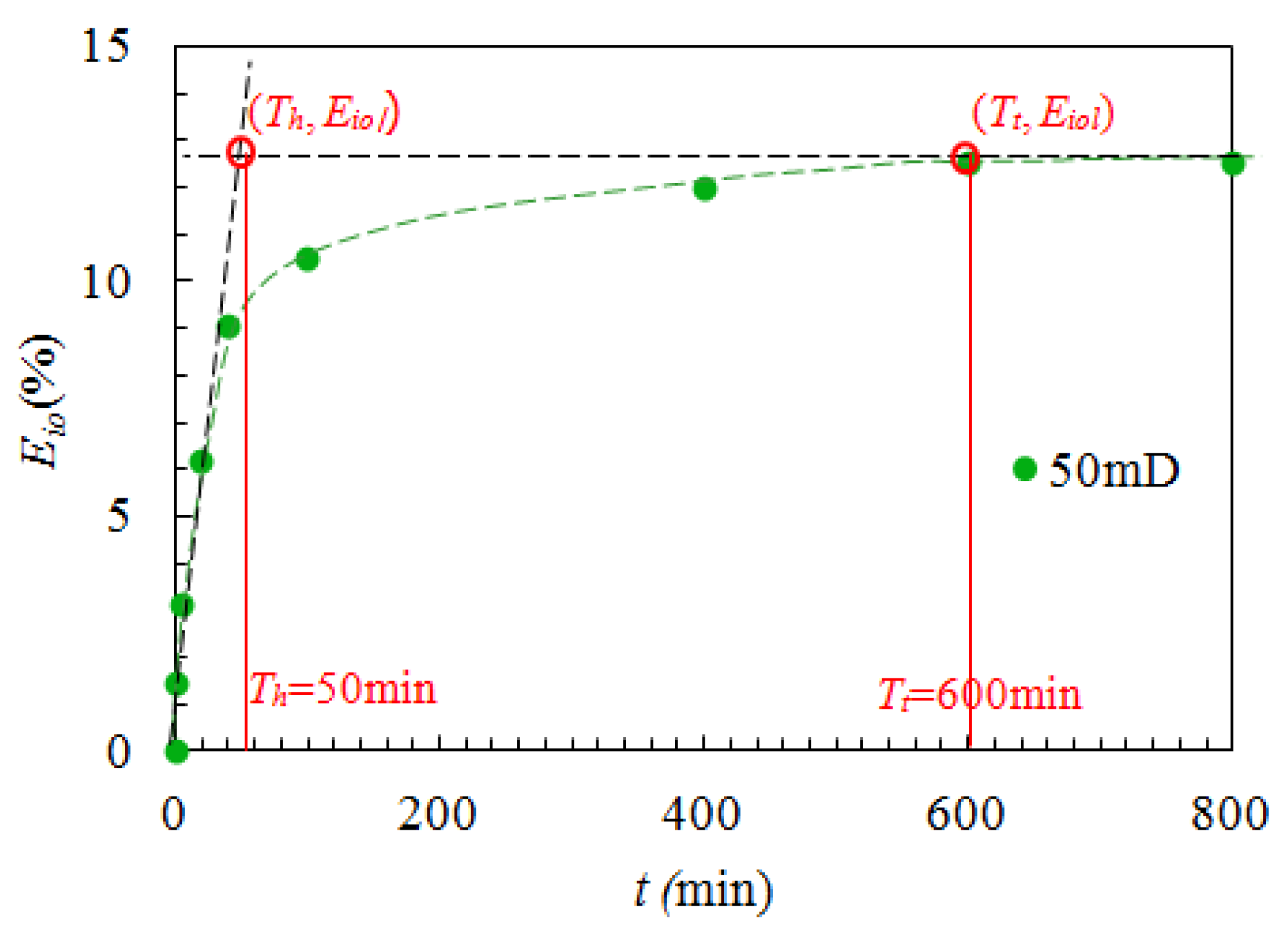

3.1. Dynamic Characteristics and Characteristic Parameters of Imbibition

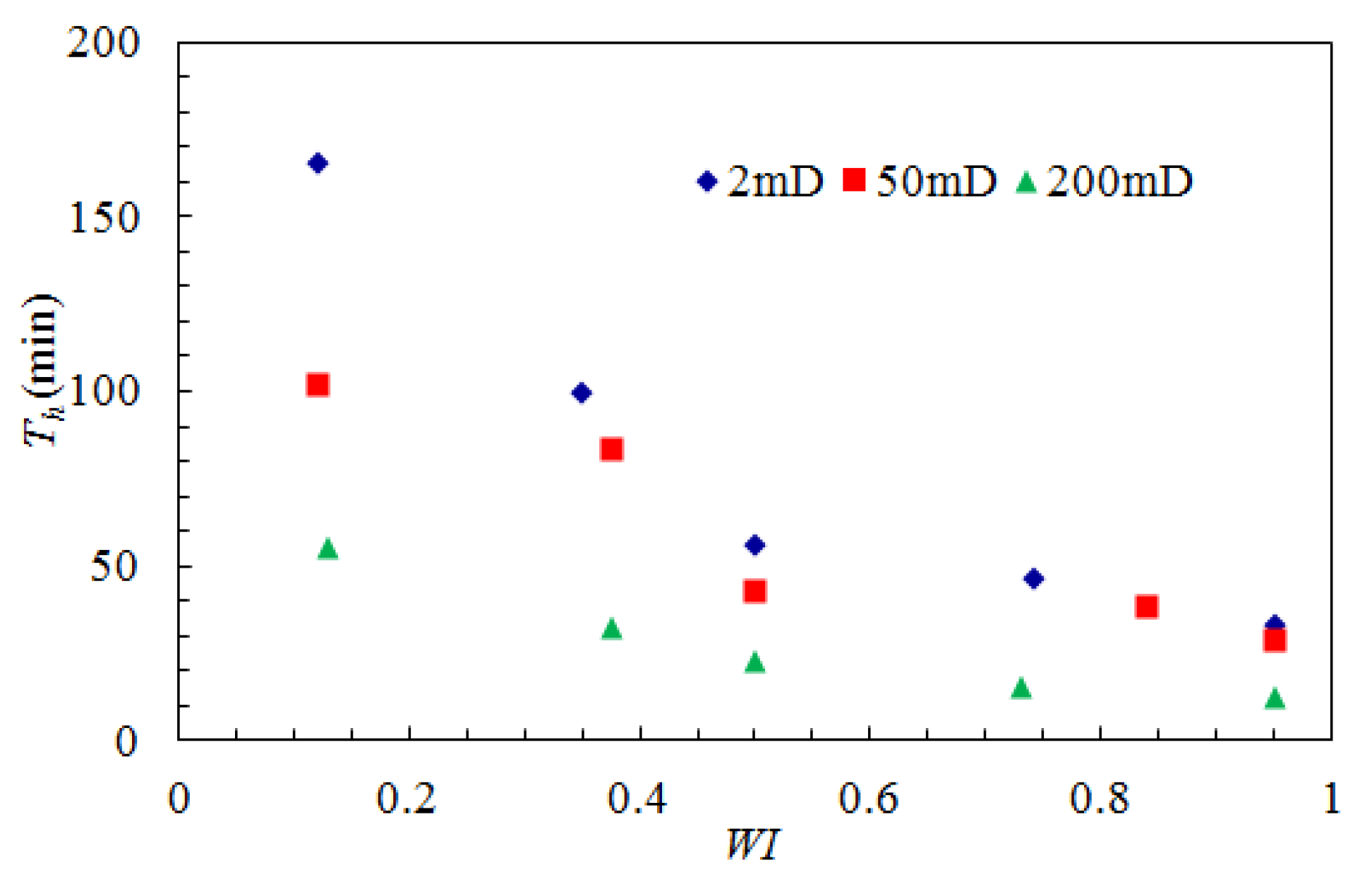

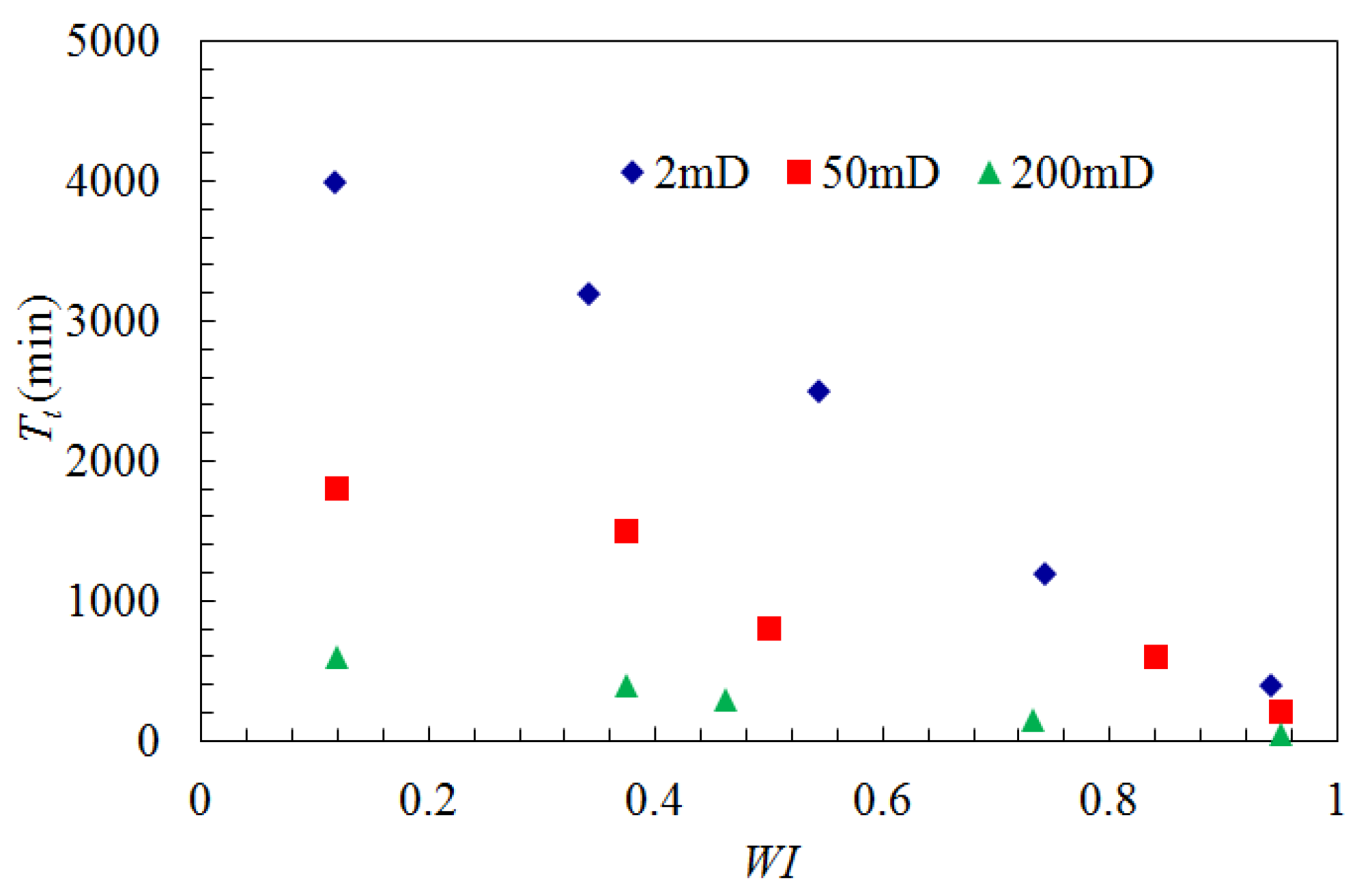

3.2. Relationship between the Characteristic Time of Imbibition and Core Wettability

3.3. Relationship between Oil Imbibition Rate and Core Wettability

3.4. Relationship between the Imbibition Oil Limit Recovery and Core Wettability

4. Conclusions

- (1)

- The critical time Th for high-speed oil imbibition and the critical time Tt for termination of oil imbibition of ultra-low permeability and high permeability cores decrease with the increase in wettability index WI. The weaker water wettability of the oil layer indicates a longer imbibition period. In addition, ultra-low permeability (tight) oil layers require longer time to effectively discharge the matrix crude oil than the medium–high permeability oil layers.

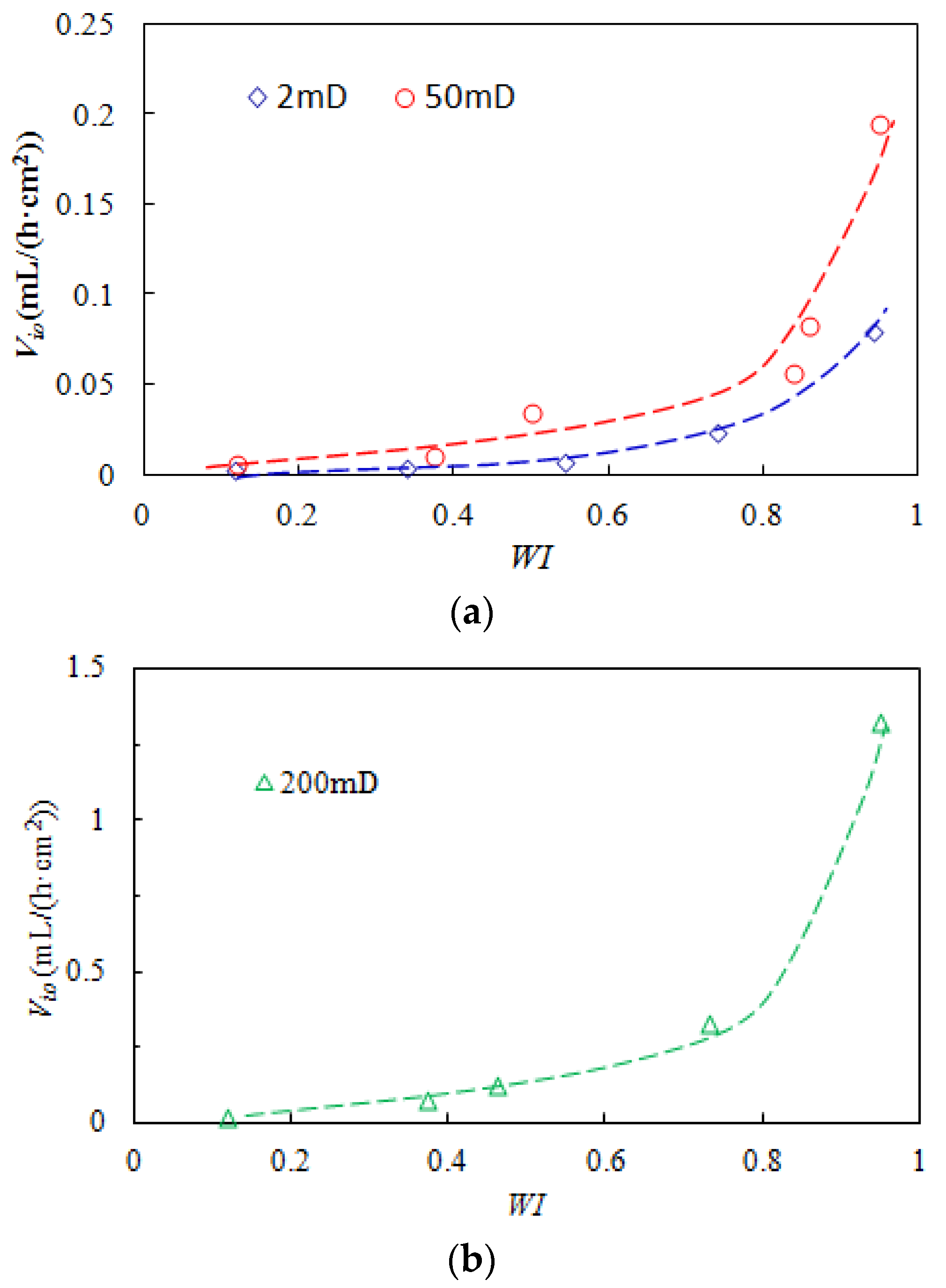

- (2)

- A positive correlation is found between the oil imbibition rate Vio and the wettability index WI. In the weak water-wet region, the oil imbibition rate increases slowly with WI increasing; in the strong water-wet region, the oil imbibition rate increases fast with WI increasing.

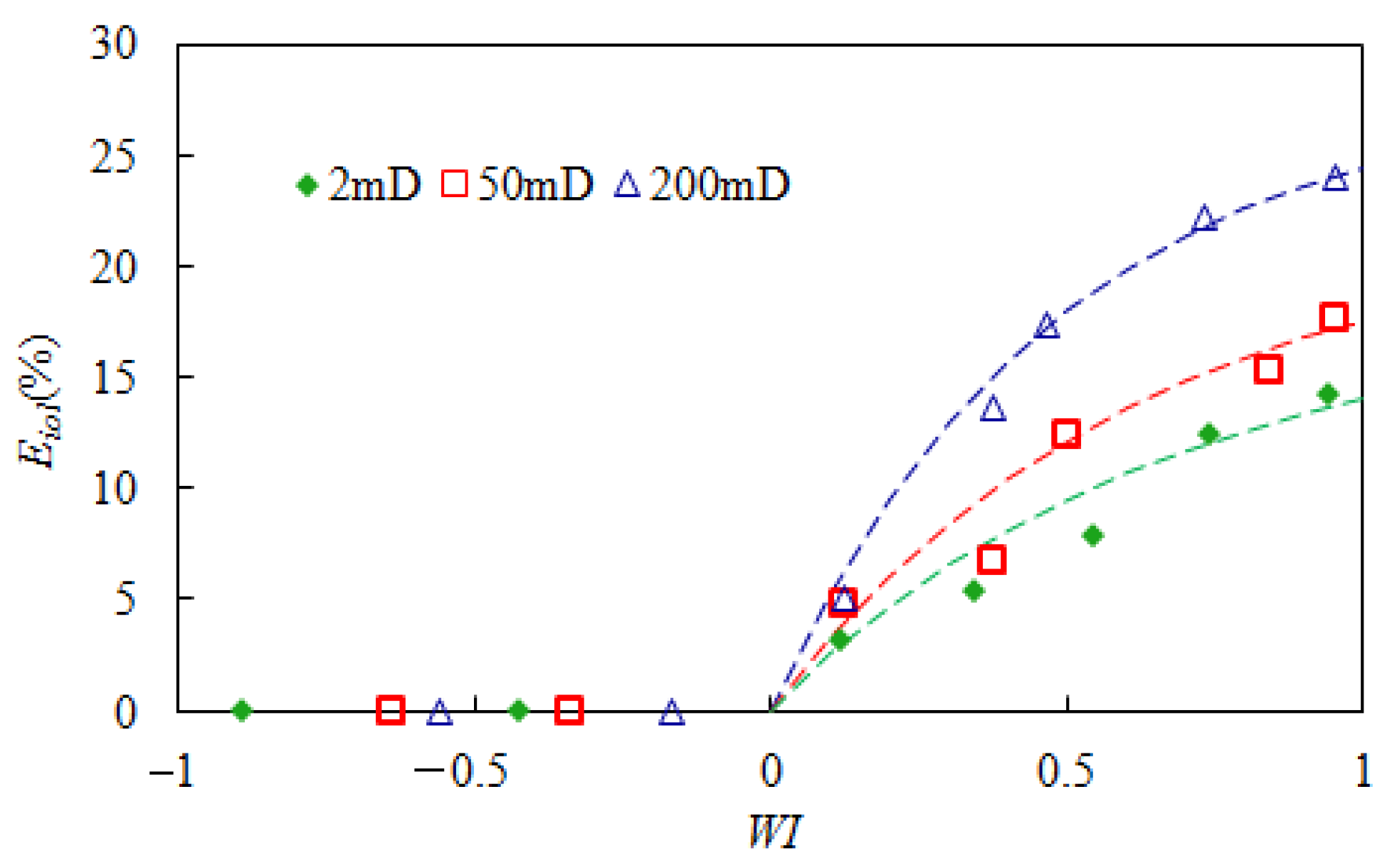

- (3)

- In the water-wet range of the wetting index from 0 to 1.0, a nonlinear positive correlation is found between the imbibition oil limit recovery Eiol of ultra-low permeability and medium–high permeability cores and WI. Compared with the strongly water-wet oil layer, the weakly water-wet oil layer with a wettability index of 0–0.5 has a greater contribution to oil recovery by using the enhanced imbibition method. According to the experimental results, a power exponent model between Eiol and WI was established.

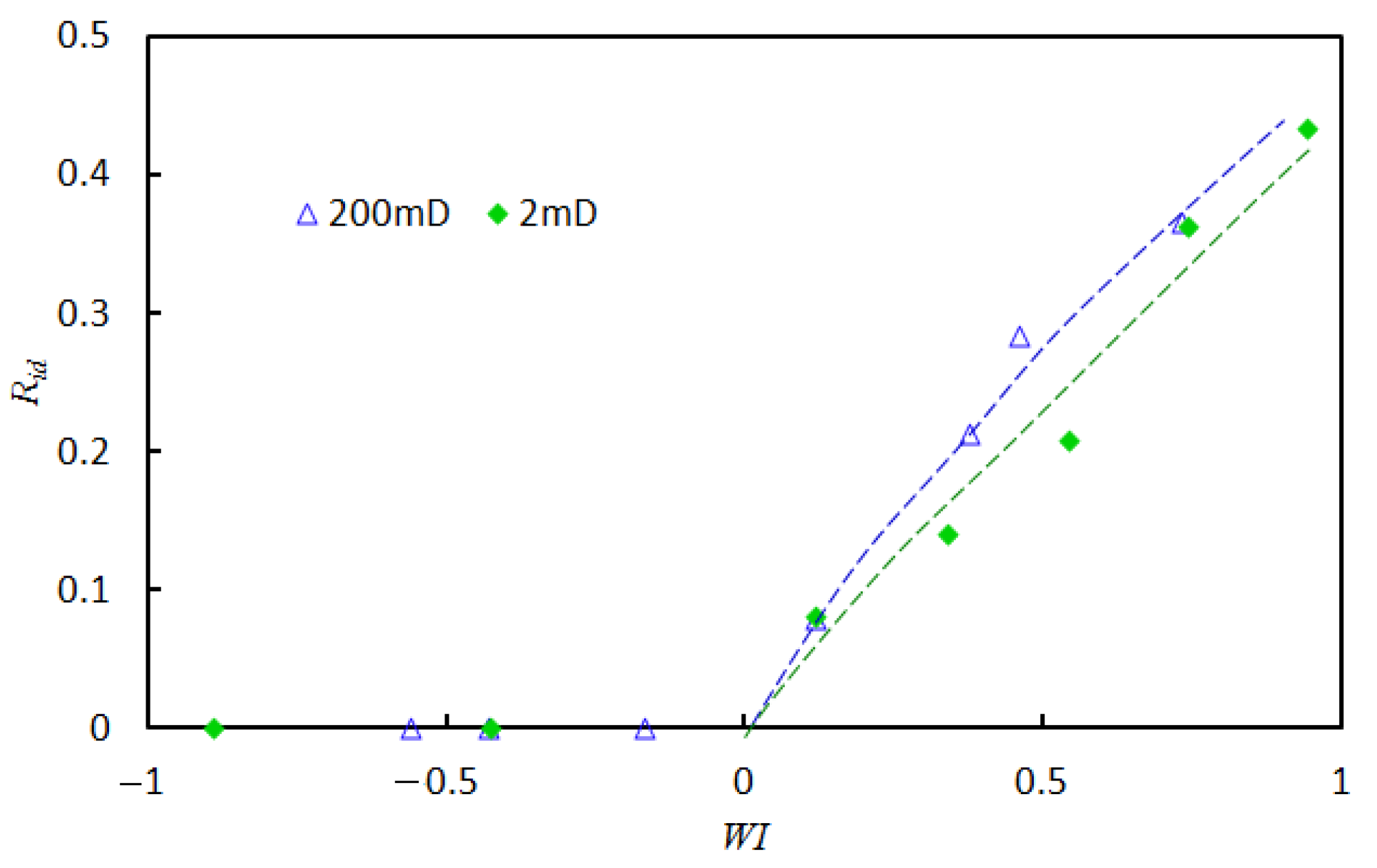

- (4)

- The imbibition–displacement ratio, which characterizes the contribution rate of imbibition recovery to crude oil recovery, increases monotonically with WI increasing. The imbibition–displacement ratio of the ultra-low permeability core is similar to that of the medium–high permeability core. Comprehensively considering that the water-flooding resistance in the ultra-low permeability tight oil layer is extremely large, the imbibition effect is more important in its production than in the medium–high permeability oil layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Eio | imbibition oil recovery, % |

| Eiol | imbibition oil limit recovery, % |

| Qoe | amount of crude oil discharged from the imbibition end face, mL |

| Qoo | original amount of oil in core, mL |

| Rid | ratio of imbibition to displacement, dimensionless parameter |

| Th | critical time of high-rate imbibition, min |

| Tt | critical time of terminal imbibition, min |

| Vio | oil imbibition rate, mL/(cm2·h) |

| WI | wetting index, dimensionless parameter |

| a | coefficient, dimensionless parameter |

| b | coefficient, dimensionless parameter |

| qio | volume of imbibition oil discharged per area, mL/cm2 |

| qiol | limit volume of imbibition oil discharged per area, mL/cm2 |

| t | imbibition time, min |

References

- Li, S.; Liu, W.; Zhang, H.; Xiao, H. Experimental study of spontaneous imbibition in low-permeability reservoir. Acta Pet. Sin. 2007, 28, 109–112. [Google Scholar]

- Roychaudhuri, B.; Tsotsis, T.; Jessen, K. An experimental investigation of spontaneous imbibition in gas shales. J. Pet. Sci. Eng. 2013, 111, 87–97. [Google Scholar] [CrossRef]

- Morrow, N.; Mason, G. Recovery of oil by spontaneous imbibition. Curr. Opin. Colloid Interface Sci. 2001, 6, 321–337. [Google Scholar] [CrossRef]

- Zhu, W.; Ju, Y.; Zhao, M.; Chen, Q.; Yang, Z. Spontaneous imbibition mechanism of flow through porous media and waterflooding in low-permeability fractured sandstone reservoir. Acta Pet. Sin. 2002, 23, 56–59. [Google Scholar]

- Zeng, F.; Zhang, Q.; Guo, J.; Meng, Y.; Shao, X.; Zheng, Y. Capillary imbibition of confined water in nanopores. Capillarity 2020, 3, 8–15. [Google Scholar] [CrossRef]

- Cai, J.; Jin, T.; Kou, J.; Zou, S.; Xiao, J.; Meng, Q. Lucas–Washburn Equation-Based Modeling of Capillary-Driven Flow in Porous Systems. Langmuir 2021, 37, 1623–1636. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Chen, M.; Li, L.; Jian, G. Experimental study on dynamic imbibition mechanism of low permeability reservoirs. Petrol. Explor. Dev. 2009, 36, 86–90. [Google Scholar]

- Wang, R.; Lv, C.; Yue, X.; Lun, Z.M.; Chen, Y.Q. Experimental study on the effects of carbonate water on rock wettability and imbibition recovery. J. Xi’an Shiyou Univ. 2010, 25, 48–50. [Google Scholar]

- Liang, Y.; Lai, F.; Dai, Y.; Shi, H.; Shi, G. An experimental study of imbibition process and fluid distribution in tight oil reservoir under different pressures and temperatures. Capillarity 2021, 4, 66–75. [Google Scholar] [CrossRef]

- Wang, R.; Yue, X.; You, Y.; Liang, J.W. Cyclic waterflooding and imbibition experiments for fratured low-permeability reservoirs. J. Xi’an Shiyou Univ. 2007, 22, 56–59. [Google Scholar]

- Standnes, D.C.; Nogaret, L.A.; Chen, H.L.; Austad, T. An Evaluation of Spontaneous Imbibition of Water into Oil-Wet Carbonate Reservoir Cores Using a Nonionic and a Cationic Surfactant. Energy Fuels 2002, 16, 1557–1564. [Google Scholar] [CrossRef]

- You, Q.; Wang, H.; Zhang, Y.; Liu, Y.; Fang, J.; Dai, C. Experimental study on spontaneous imbibition of recycled fracturing flow-back fluid to enhance oil recovery in low permeability sandstone reservoirs. J. Pet. Sci. Eng. 2018, 166, 375–380. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, C.; Zhao, J.; Wang, Q.; Zhao, J.; Gao, D.; Fu, C. Mechanisms of fracturing fluid spontaneous imbibition behavior in shale reservoir: A review. J. Nat. Gas Sci. Eng. 2020, 82, 103498. [Google Scholar] [CrossRef]

- Wei, F.; Yue, X.; Zhang, J. The influence of Surfactants on Surface Wettability and Spontaneous Imbibition of Water into Oil Wet Low Permeable Limestone Cores. Oilfield Chem. 2004, 21, 52–55. [Google Scholar]

- Zhou, X.; Morrow, N.; Ma, S. Interrelationship of Wettability, Initial Water Saturation, Aging Time, and Oil Recovery by Spontaneous Imbibition and Waterflooding. SPE J. 2000, 5, 199–207. [Google Scholar] [CrossRef]

- Wang, J.; Liu, H.; Qian, G.; Peng, Y.; Gao, Y. Investigations on spontaneous imbibition and the influencing factors in tight oil reservoirs. Fuel 2019, 236, 755–768. [Google Scholar]

- Ren, X.; Li, A.; Memon, A.; Fu, S.; Wang, G.; He, B. Experimental Simulation on Imbibition of the Residual Fracturing Fluid in Tight Sandstone Reservoirs. J. Energy Resour. Technol. 2019, 141, 082905. [Google Scholar] [CrossRef]

- Zaeri, M.R.; Hashemi, R.; Shahverdi, H.; Sadeghi, M. Enhanced oil recovery from carbonate reservoirs by spontaneous imbibition of low salinity water. Pet. Sci. 2018, 15, 564–576. [Google Scholar] [CrossRef] [Green Version]

- Xu, M.; Gupta, A.; Dehghanpour, H. How significant are strain and stress induced by water imbibition in dry gas shales? J. Pet. Sci. Eng. 2019, 176, 428–443. [Google Scholar] [CrossRef]

- Fakcharoenphol, P.; Kurtoglu, B.; Kazemi, H.; Charoenwongsa, S.; Wu, Y.-S. The Effect of Osmotic Pressure on Improve Oil Recovery from Fractured Shale Formations. In Proceedings of the SPE Unconventional Resources Conference, Woodlands, TX, USA, 1–3 April 2014. [Google Scholar] [CrossRef] [Green Version]

- Freer, E.; Svitova, T.; Radke, C. The role of interfacial rheology in reservoir mixed wettability. J. Pet. Sci. Eng. 2003, 39, 137–158. [Google Scholar] [CrossRef]

- Hirasaki, G.; Zhang, D. Surface chemistry of oil recovery from fractured, oil-wet, carbonate formations. SPE J. 2004, 9, 151–162. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Zhang, Q.; Dai, C.; Li, Y.; Lv, W.; Wu, Y.; Cheng, R.; Zhao, M. Experimental investigation of spontaneous imbibition process of nanofluid in ultralow permeable reservoir with nuclear magnetic resonance. Chem. Eng. Sci. 2019, 201, 212–221. [Google Scholar] [CrossRef]

- Liu, J.; Sheng, J.J. Experimental investigation of surfactant enhanced spontaneous imbibition in Chinese shale oil reservoirs using NMR tests. J. Ind. Eng. Chem. 2019, 72, 414–422. [Google Scholar] [CrossRef]

- Wu, K.; Chen, Z.; Li, J.; Xu, J.; Wang, K.; Wang, S.; Dong, X.; Zhu, Z.; Peng, Y.; Jia, X.; et al. Manipulating the flow of nanoconfined water by temperature stimulation. Angew. Chem. Int. Ed. 2018, 57, 8432–8437. [Google Scholar] [CrossRef] [PubMed]

- Hirasaki, G.J.; Miller, C.A.; Puerto, M. Recent Advances in Surfactant EOR. SPE J. 2011, 16, 889–907. [Google Scholar] [CrossRef]

- Austad, T.; Standnes, D.C. Spontaneous imbibition of water into oil-wet carbonates. J. Pet. Sci. Eng. 2003, 39, 363–376. [Google Scholar] [CrossRef]

- Li, A.; Fan, T.; Zhao, L. Experimental study of spontaneous imbibition in low permeability core fractured reservoir. Pet. Geol. Recovery Effic. 2011, 18, 67–69. [Google Scholar]

- Standnes, D. Wettability alteration in chalk1. Preparation of core material and oil properties. J. Pet. Sci. Eng. 2000, 28, 111–121. [Google Scholar] [CrossRef]

- Buckley, J.; Liu, Y.; Monsterleet, S. Mechanisms of wetting alteration by crude oils. SPE J. 1998, 3, 54–61. [Google Scholar] [CrossRef]

- Morrow, N. Wettability and its effect on oil recovery. J. Pet. Technol. 1990, 42, 1476–1484. [Google Scholar] [CrossRef]

- Bi, Z.; Yu, J. Laboratory study on improving oil recovery by changing wettability of solid/liquid interface. Chin. Sci. Bull. 2000, 45, 1721–1727. [Google Scholar]

- Jadhunandan, P.; Morrow, N. Effect of Wettability on Waterflood Recovery for Crude Oil/Brine/Rock Systems. SPE Reserv. Eng. 1995, 10, 40–46. [Google Scholar] [CrossRef]

- Tu, J.; Sheng, J. Experimental and numerical study of surfactant solution spontaneous imbibition in shale oil reservoirs. J. Taiwan Inst. Chem. Eng. 2020, 106, 169–182. [Google Scholar] [CrossRef]

- Gao, L.; Yang, Z.; Shi, Y. Experimental study on spontaneous imbibition characteristics of tight rocks. Adv. Geo-Energy Res. 2018, 2, 292–304. [Google Scholar] [CrossRef]

- Tian, K.; Wu, Y.; Gao, Z.; Chen, Y.; Gao, J. A critical review of enhanced oil recovery by imbibition: Theory and practice. Energy Fuels 2021, 35, 5643–5670. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, H.; Wang, J. A critical review on fundamental mechanisms of spontaneous imbibition and the impact of boundary condition, fluid viscosity and wettability. Adv. Geo-Energy Res. 2017, 1, 1–17. [Google Scholar] [CrossRef]

- Yue, X.; Feng, X.; Fu, Y.; Zhao, J.; Zou, J.; Zhang, B.; Wang, X.; Zhang, J. A Physical Model of Oil and Gas Reservoir and Its Wettability Simulation Method. Chinese Patent 201711223227.2, 11 August 2020. [Google Scholar]

| Permeability of Core (mD) | Measurement of Eiol (%) | Average (%) | Relative Standard Deviation (RSD, %) | ||

|---|---|---|---|---|---|

| #1 | #2 | #3 | |||

| 2 | 7.82 | 7.92 | 8.01 | 7.92 | 1.20 |

| 50 | 12.54 | 12.56 | 12.35 | 12.48 | 0.79 |

| 200 | 17.46 | 17.38 | 17.52 | 17.45 | 0.40 |

| Wettability of Core (WI) | Measurement of Eiol (%) | Average (%) | Variance | |||

|---|---|---|---|---|---|---|

| #1 | #2 | #3 | #4 | |||

| 0.12 | 3.18 | 3.28 | 3.24 | 3.26 | 3.22 | 0.0052 |

| 0.35 | 5.42 | 5.38 | 5.26 | 5.34 | 5.35 | 0.0047 |

| Permeability (mD) | Linear Correlation Coefficient between Time and Wettability Index | |

|---|---|---|

| Th | Tt | |

| 2 | −0.92 | −0.99 |

| 50 | −0.93 | −0.96 |

| 200 | −0.94 | −0.99 |

| Permeability of Core (mD) | Coefficients | Goodness of Fit | |

|---|---|---|---|

| a | b | ||

| 2 | 18.0 | −1.50 | 0.856 |

| 50 | 22.0 | −1.60 | 0.980 |

| 200 | 27.9 | −2.08 | 0.834 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Yue, X.; An, W.; Zou, J. Experimental Study of Influence of Core Wettability on Imbibition Properties. Energies 2022, 15, 3984. https://doi.org/10.3390/en15113984

Feng X, Yue X, An W, Zou J. Experimental Study of Influence of Core Wettability on Imbibition Properties. Energies. 2022; 15(11):3984. https://doi.org/10.3390/en15113984

Chicago/Turabian StyleFeng, Xuegang, Xiang’an Yue, Weiqing An, and Jirui Zou. 2022. "Experimental Study of Influence of Core Wettability on Imbibition Properties" Energies 15, no. 11: 3984. https://doi.org/10.3390/en15113984