A Multi-Scale Fractal Approach for Coal Permeability Estimation via MIP and NMR Methods

Abstract

:1. Introduction

2. Experimental Implementations

2.1. Coal Samples

2.2. Experimental Facilities and Procedures

2.3. MIP and NMR Theory

2.4. Experimental Data Analysis

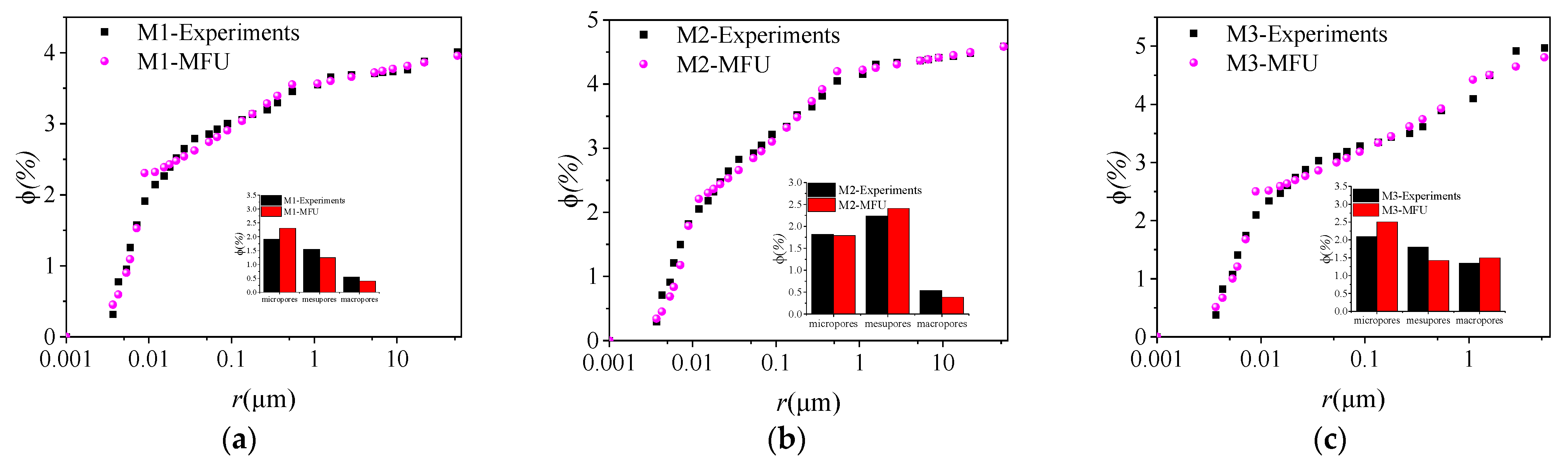

2.4.1. Experimental Data of MIP

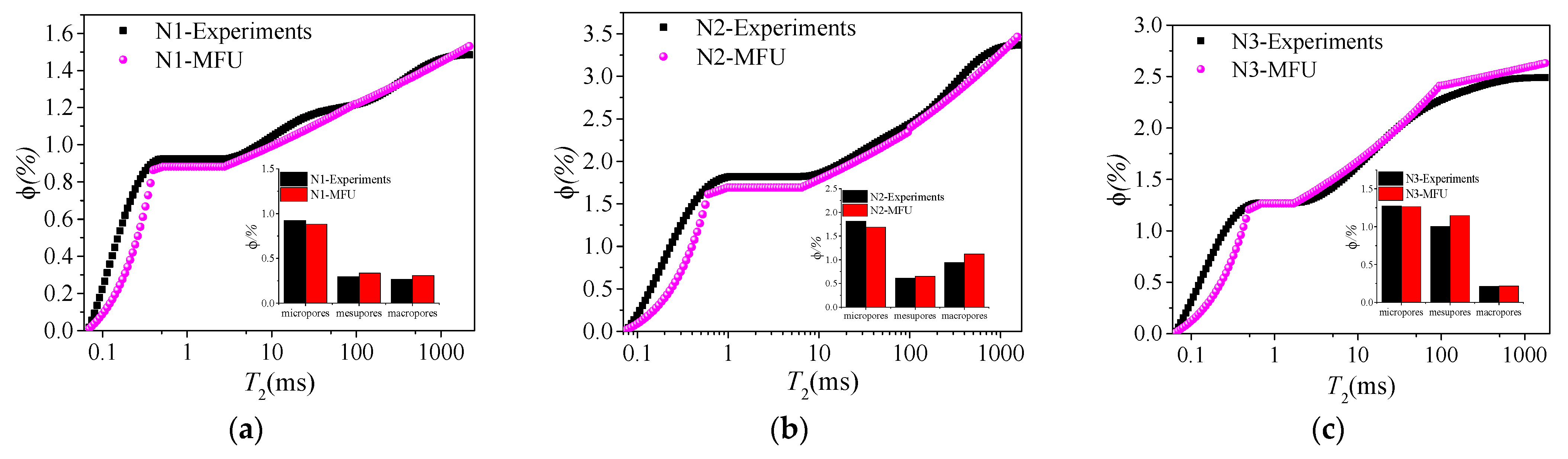

2.4.2. Experimental Data of NMR

3. Permeability Formulas Derivation Based on MFU

3.1. Fractal Characteristics of Porous Media

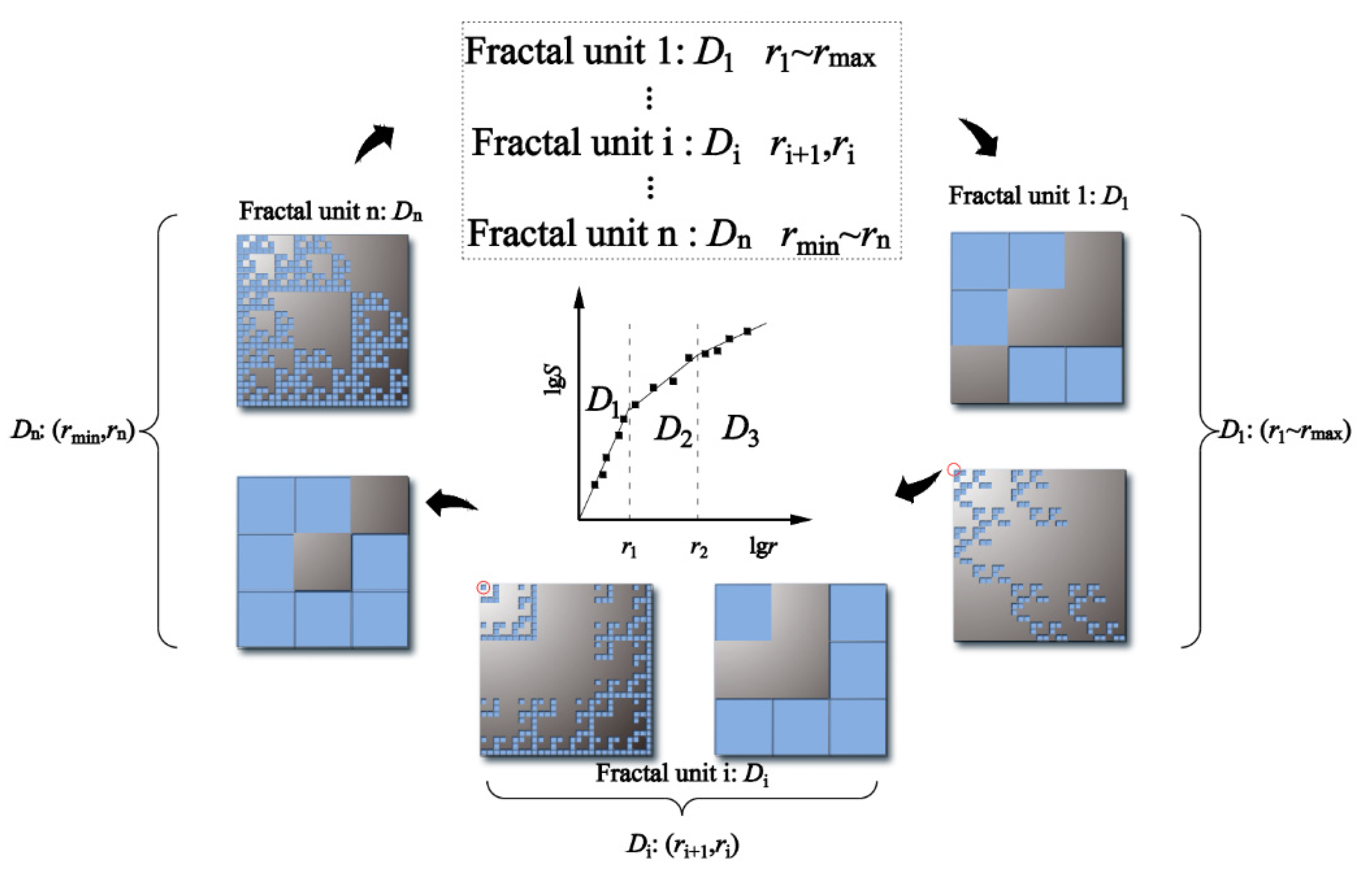

3.2. Multi-Scale Fractal Dimension Characteristics Units Model

3.3. Multi-Scale Fractal Permeability Expression

4. Results and Discussion

4.1. Fractal Characteristics of Pore Size Distribution

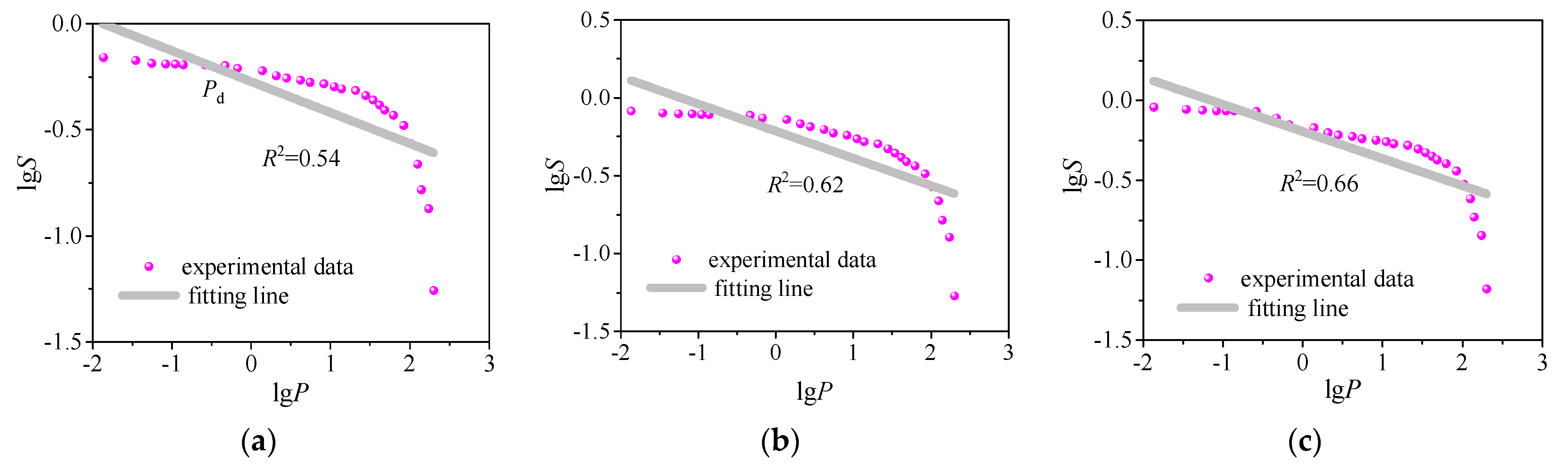

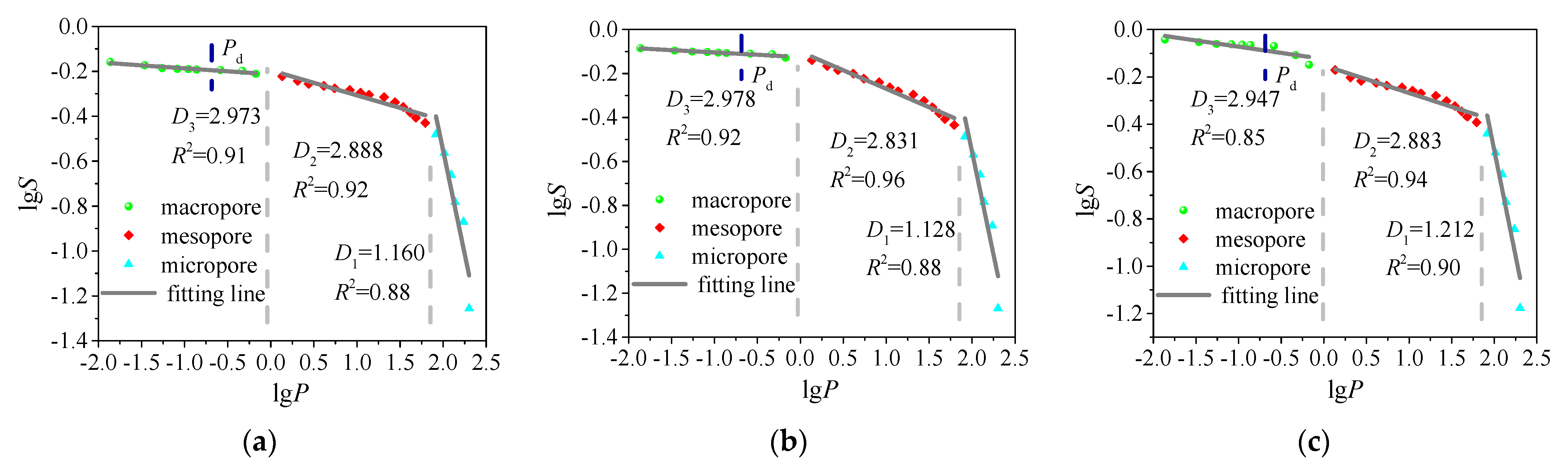

4.1.1. Fractal Characteristics of Pore Size Distribution Base on MIP

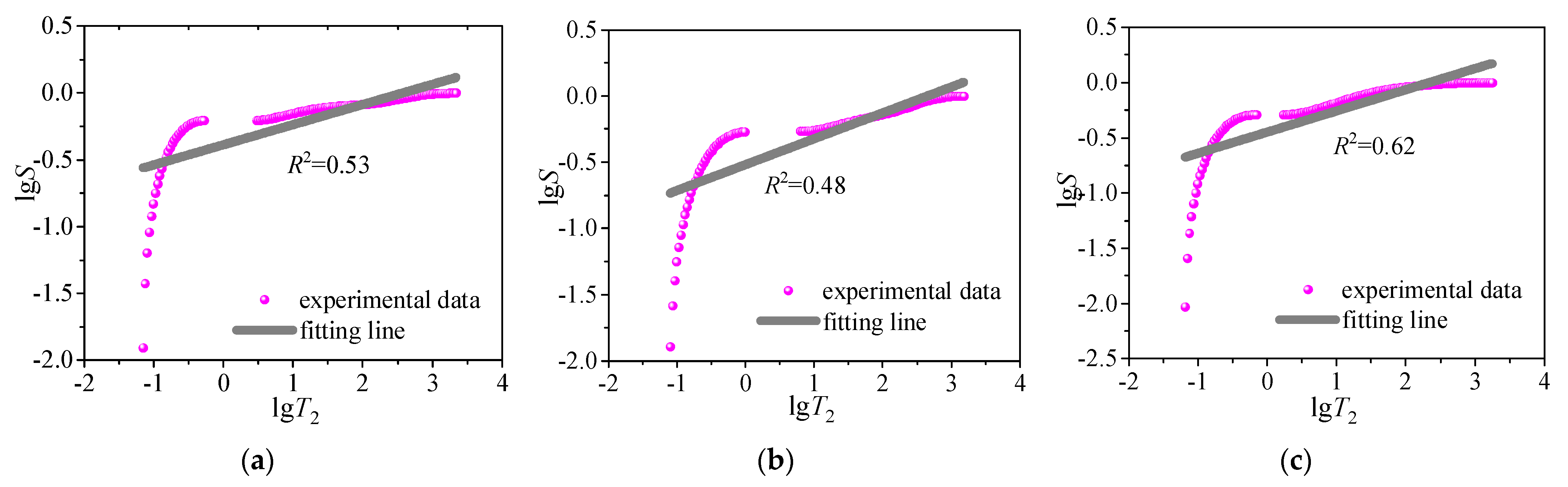

4.1.2. Fractal Characteristics of Pore Size Distribution Base on NMR

4.2. The Permeability Contribution of the Different Fractal Dimension

4.3. Comparison of the Pore Structure from MFU and Experiments

4.4. The Permeability Predicted Results Base on the MFU

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Acronyms and Symbols | Explanation |

| MFU | Multi-scale fractal dimension characteristics units model |

| MIP | Mercury injection porosimetry |

| NMR | Nuclear magnetic resonance |

| LTNA | Low temperature N2 adsorption |

| Micro-CT | Micro X-ray computed tomography |

| CPMG | Carr-Purcell-Meiboom-Gill |

| T2 | Transverse relaxation time |

| r | Pore radius |

| rmax | Maximum pore radius |

| rmin | Minimum pore radius |

| γ | Interfacial tension |

| θ | Three-phase contact angle |

| P | Mercury intrusion pressure |

| ρ | Surface relaxivity |

| SA | Surface area |

| V | Pore volume |

| Vsample | Volume of the sample |

| Vu | Volume of unit |

| F | Shape factor of pore |

| c | Shape factor of pore |

| Pd | Displacement pressures |

| ϕ | Porosity of coal sample |

| α | Factor of fractal coefficient |

| Df | Fractal dimension |

| S | Cumulative pore volume fraction when the pore radius is less than or equal to the pore radius r |

| μ | Fluid viscosity |

| ΔPf | Pressure gradient along the tortuous capillary |

| τ | Average tortuosity of the capillaries |

| τi | Average tortuosity of the capillaries with radii between ri−1 and ri |

| L | Straight length of the capillary |

| Qi | Flow rate for the capillaries with radii between ri−1 and ri |

| Q | Total flow rate for the whole cross-sectional area |

| ϕi | Porosity of the capillaries with radii between ri−1 and ri |

| k | Permeability |

| DMIP | Fractal dimension of total pore structure measured by mercury injection porosimetry |

| DNMR | Fractal dimension of total pore structure measured by nuclear magnetic resonance |

| D1 | Fractal dimension of micropore |

| D2 | Fractal dimension of mesopore |

| D3 | Fractal dimension of macropore |

| D | Theory fractal dimension |

| dE | Euclidean space dimension |

| Kj | Permeability contribution of capillaries of radius rj |

| Ki | Cumulative permeability contribution of the capillaries with radii between ri−1 and ri |

| Wj | Pore aperture distribution frequency of capillaries of radius rj |

| WTj | T2 distribution frequency of capillaries of transverse relaxation time T2j |

References

- Bear, J. Dynamics of Fluids in Porous Media; Elsevier Science: New York, NY, USA, 1972. [Google Scholar]

- Nguyen, V.H.; Rohan, E.; Naili, S. Multiscale simulation of acoustic waves in homogenized heterogeneous porous media with low and high permeability contrasts. Int. J. Eng. Sci. 2016, 101, 92–109. [Google Scholar] [CrossRef]

- Hosa, A.; Curtis, A.; Wood, R. Calibrating Lattice Boltzmann flow simulations and estimating uncertainty in the permeability of complex porous media—ScienceDirect. Adv. Water Resour. 2016, 94, 60–74. [Google Scholar] [CrossRef] [Green Version]

- Mandelbrot Benoit, B.; Wheeler John, A. The fractal geometry of nature. Fractal GeomNat 1983, 51, 286–287. [Google Scholar] [CrossRef]

- Xie, H. Fractals in Rock Mechanics; A.A.Balkema Publishers: Rotterdam, The Netherlands, 1993. [Google Scholar]

- Friesen, W.I.; Mikula, R.J. Mercury porosimetry of coals Pore volume distribution and compressibility. Fuel 1988, 67, 1516–1520. [Google Scholar] [CrossRef]

- Friesen, W.I.; Laidlaw, W.G. Porosimetry of Fractal Surfaces. J. Colloid Interface Sci. 1993, 160, 226–235. [Google Scholar] [CrossRef]

- Xia, Y.; Cai, J.; Wei, W.; Hu, X.; Wang, X.I.N.; Ge, X. A new method for calculating fractal dimensions of porous media based on pore size distribution. Fractals 2018, 26, 1850006. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Z.; Zhang, Z.; Li, J. Fractal characteristics of reservoir rock pore structure based on NMR T2 distribution. J. Oil Gas Technol. 2007, 29, 80–86. [Google Scholar] [CrossRef]

- Wood, D.A. Techniques used to calculate shale fractal dimensions involve uncertainties and imprecisions that require more careful consideration. Adv. Geo-Energy Res. 2021, 5, 153–165. [Google Scholar] [CrossRef]

- Pia, G.; Sanna, U. Intermingled fractal units model and electrical equivalence fractal approach for prediction of thermal conductivity of porous materials. Appl. Therm. Eng. 2013, 61, 186–192. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, D.; Cai, Y.; Yao, Y. Fractal characterization of pore–fracture in low-rank coals using a low-field NMR relaxation method. Fuel 2016, 181, 218–226. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, G.; Dong, Y.; Danesh, N.N.; Chen, Z.; Zhang, T. Comparison of low-field NMR and microfocus X-ray computed tomography in fractal characterization of pores in artificial cores. Fuel 2017, 210, 217–226. [Google Scholar] [CrossRef]

- Ramakrishnan, B.; Pitchumani, R. Fractal permeation characteristics of preforms used in liquid composite molding. Polym. Compos. 2000, 21, 281–296. [Google Scholar] [CrossRef]

- Pitchumani, R.; Ramakrishnan, B. A fractal geometry model for evaluating permeabilities of porous preforms used in liquid composite molding. Int. J. Heat Mass Transf. 1999, 42, 2219–2232. [Google Scholar] [CrossRef]

- Peng, X.; Yu, B. Developing a new form of permeability and Kozeny–Carman constant for homogeneous porous media by means of fractal geometry—ScienceDirect. Adv. Water Resour. 2008, 31, 74–81. [Google Scholar] [CrossRef]

- Chen, X.; Yao, G. An improved model for permeability estimation in low permeable porous media based on fractal geometry and modified Hagen-Poiseuille flow. Fuel 2017, 210, 748–757. [Google Scholar] [CrossRef]

- Chen, Z.-L.; Wang, N.-T.; Sun, L.; Tan, X.-H.; Deng, S. Prediction method for permeability of porous media with tortuosity effect based on an intermingled fractal units model. Int. J. Eng. Sci. 2017, 121, 83–90. [Google Scholar] [CrossRef]

- Luo, Y.; Xia, B.; Li, H.; Hu, H.; Wu, M.; Ji, K. Fractal permeability model for dual-porosity media embedded with natural tortuous fractures. Fuel 2021, 295, 120610. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Gao, F.; Xu, R.; Yue, F. A multi-field coupling model of gas flow in fractured coal seam. Adv. Geo-Energy Res. 2021, 5, 104–118. [Google Scholar] [CrossRef]

- Zhou, H.; Sun, X.; Xie, H.; Xue, D.J.; Ren, W.G.; Liu, Z.L.; Li, X.N.; Hou, W. The determination of surface relaxivity and application to coal spontaneous imbibition. Fuel 2022, 309, 122165. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. J. Arch. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Mitchell, J.; Staniland, J.; Chassagne, R.; Mogensen, K.; Frank, S.; Fordham, E. Mapping oil saturation in a limestone plug with low-field magnetic resonance. J. Pet. Sci. Eng. 2013, 108, 14. [Google Scholar] [CrossRef]

- Kenyon, W.E. Nuclear magnetic resonance as a petrophysical measurement. Nucl. Geophys. 1992, 6, 153–171. [Google Scholar] [CrossRef]

- Brownstein, K.R.; Tarr, C.E. Importance of Classical Diffusion in NMR Studies of Water in Biological Cells. Phys. Rev. A 1979, 19, 2446–2453. [Google Scholar] [CrossRef]

- IUPAC. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1982, 54, 2201–2218. [Google Scholar] [CrossRef]

- Hodot, B.B. Outburst of Coal and Coalbed Gas (Chinese Translation); China Industry Press: Beijing, China, 1966. [Google Scholar]

- Babadagli, T.; Develi, K. Fractal characteristics of rocks fractured under tension. Theor. Appl. Fract. Mech. 2003, 39, 73–88. [Google Scholar] [CrossRef]

- Yu, B.; Cheng, P. A fractal permeability model for bi-dispersed porous media. Int. J. Heat Mass Transf. 2002, 45, 2983–2993. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Zou, J.; Gentzis, T.; Rezaee, R.; Bubach, B.; Carvajal-Ortiz, H. Multifractal analysis of gas adsorption isotherms for pore structure characterization of the Bakken Shale. Fuel 2018, 219, 296–311. [Google Scholar] [CrossRef] [Green Version]

- Paz-Ferreiro, J.; da Luz, L.; Lado, M.; Vázquez, E.V. Specific Surface Area and Multifractal Parameters of Associated Nitrogen Adsorption and Desorption Isotherms in Soils from Santa Catarina, Brazil. Vadose Zone J. 2013, 12, 185–192. [Google Scholar] [CrossRef]

- Denn, M.M. Process Fluid Mechanics; Prentice-Hall: Englewood Cliffs, NJ, USA, 1980. [Google Scholar]

- Yu, B.; Li, J. A Geometry Model for Tortuosity of Flow Path in Porous Media. Chin. Phys. Lett. 2004, 21, 1569–1571. [Google Scholar] [CrossRef]

- Zhou, H.; Zhong, J.; Ren, W.G.; Wang, X.; Yi, H. Characterization of pore-fracture networks and their evolution at various measurement scales in coal samples using X-ray μCT and a fractal method. Int. J. Coal Geol. 2018, 189, 35–49. [Google Scholar] [CrossRef]

| Sample | Pd (MPa) | rmax (μm) | Maximum Mercury Saturation (%) | Residual Mercury Saturation (%) | Mercury Withdrawal Efficiency (%) | Φ (%) | ||

|---|---|---|---|---|---|---|---|---|

| Micro-Pore | Meso-Pore | Macro-Pore | ||||||

| M1 | 0.261 | 2.814 | 69.492 | 20.065 | 71.126 | 1.912 | 1.546 | 0.552 |

| M2 | 0.261 | 2.813 | 82.271 | 28.761 | 65.041 | 1.819 | 2.233 | 0.538 |

| M3 | 0.138 | 5.332 | 90.877 | 30.690 | 66.230 | 2.096 | 1.799 | 1.348 |

| Sample | Φ (%) | ||

|---|---|---|---|

| Micropore | Mesopore | Macropore | |

| N1 | 0.925 | 0.295 | 0.265 |

| N2 | 1.814 | 0.614 | 0.940 |

| N3 | 1.273 | 1.005 | 0.212 |

| MIP | NMR | ||||||

|---|---|---|---|---|---|---|---|

| M1 | M2 | M3 | N1 | N2 | N3 | ||

| Di | D1 | 1.160 | 1.128 | 1.212 | 1.984 | 2.002 | 2.089 |

| D2 | 2.888 | 2.831 | 2.883 | 2.913 | 2.884 | 2.835 | |

| D3 | 2.973 | 2.978 | 2.947 | 2.926 | 2.868 | 2.968 | |

| k (mD) | Xu | 2.015 | 2.240 | 8.277 | 37.3351 | 37.409 | 46.958 |

| multi-scale fractal permeability model | 0.018 | 0.024 | 0.275 | 0.0360 | 0.0302 | 0.0157 | |

| Experiment | 0.026 | 0.073 | 0.336 | - | 0.0347 | 0.0099 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, W.; Zhou, H.; Zhong, J.; Xue, D.; Wang, C.; Liu, Z. A Multi-Scale Fractal Approach for Coal Permeability Estimation via MIP and NMR Methods. Energies 2022, 15, 2807. https://doi.org/10.3390/en15082807

Ren W, Zhou H, Zhong J, Xue D, Wang C, Liu Z. A Multi-Scale Fractal Approach for Coal Permeability Estimation via MIP and NMR Methods. Energies. 2022; 15(8):2807. https://doi.org/10.3390/en15082807

Chicago/Turabian StyleRen, Weiguang, Hongwei Zhou, Jiangcheng Zhong, Dongjie Xue, Chaosheng Wang, and Zelin Liu. 2022. "A Multi-Scale Fractal Approach for Coal Permeability Estimation via MIP and NMR Methods" Energies 15, no. 8: 2807. https://doi.org/10.3390/en15082807