Characterizing the Microscopic Anisotropic Permeabilities of Tight Oil Reservoirs Impacted by Heterogeneous Minerals

Abstract

:1. Introduction

- (1)

- In terms of process flow, the event of minor hydraulic fracturing with no proppant is only based on water injection rather than fracture making, sand filling, and displacement in the true hydraulic fracturing process;

- (2)

- For the injection fluid type, fluid in the event of minor hydraulic fracturing with no proppant is purely water, as opposed to fracturing fluid with high viscosity and high shear in the true hydraulic fracturing process.

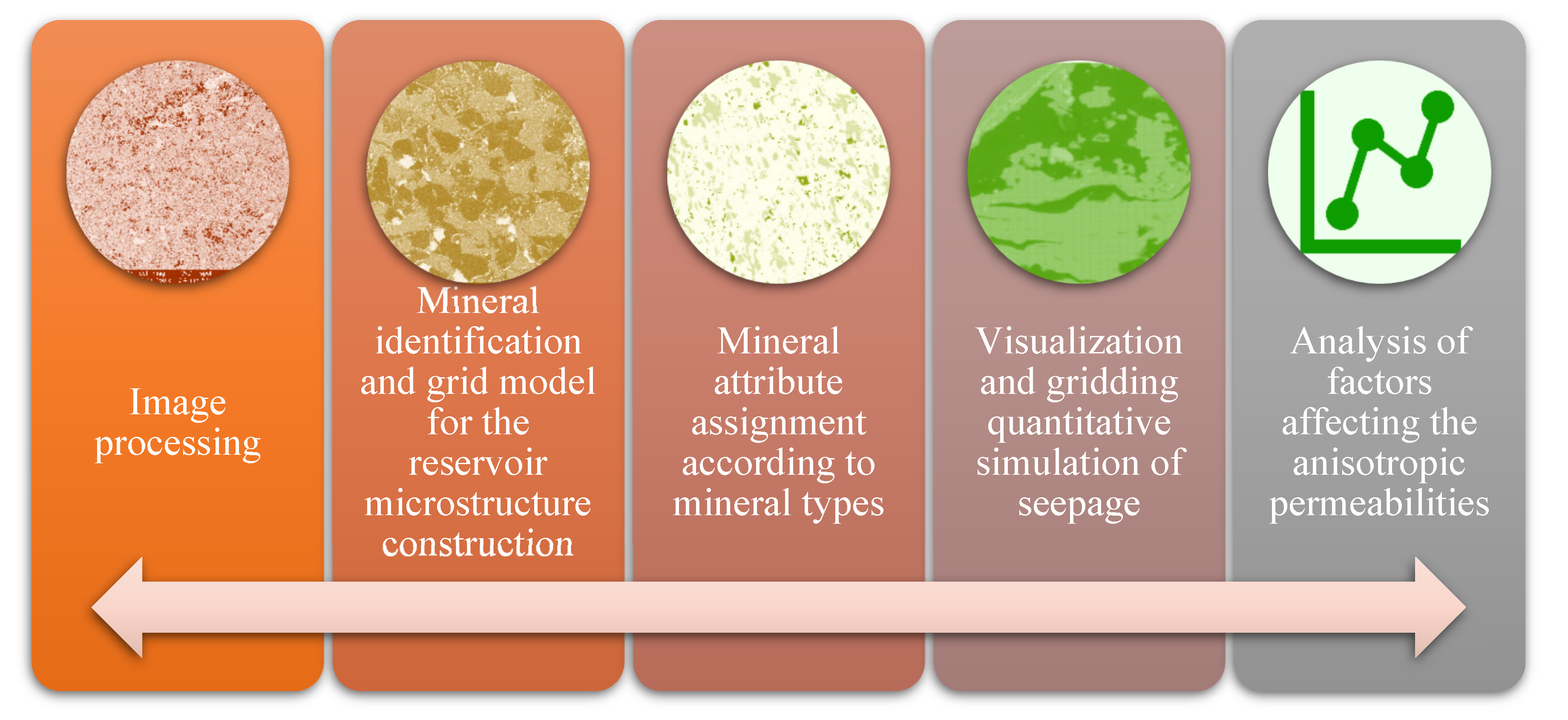

2. Methodology

2.1. The Concept of “Two-Dimensional Permeability”

2.2. Flow Simulation

3. Results and Discussions

3.1. High-Pressure Mercy Injection of the Studied Rock Samples

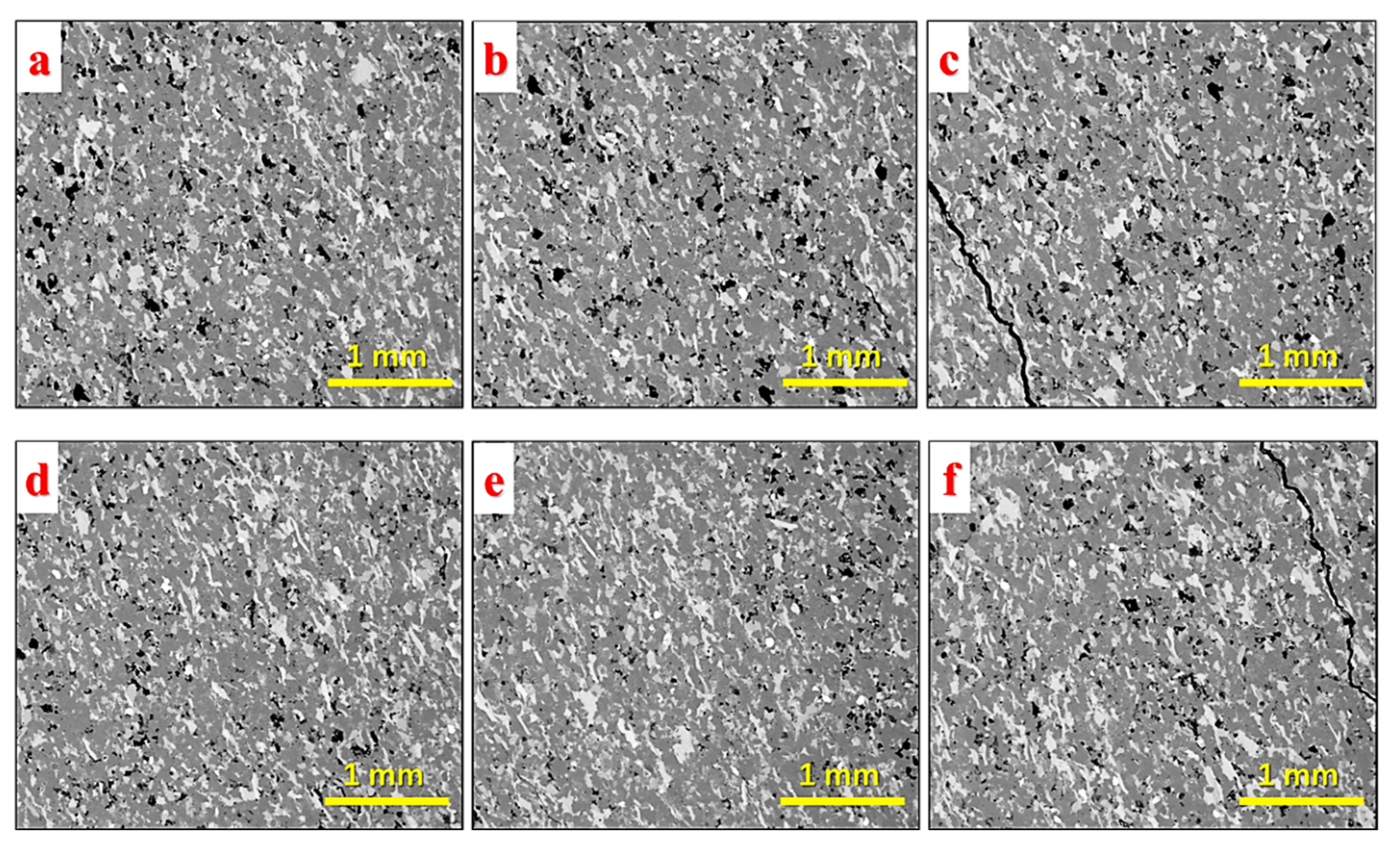

3.2. Imaging Characterization of Tight Rocks

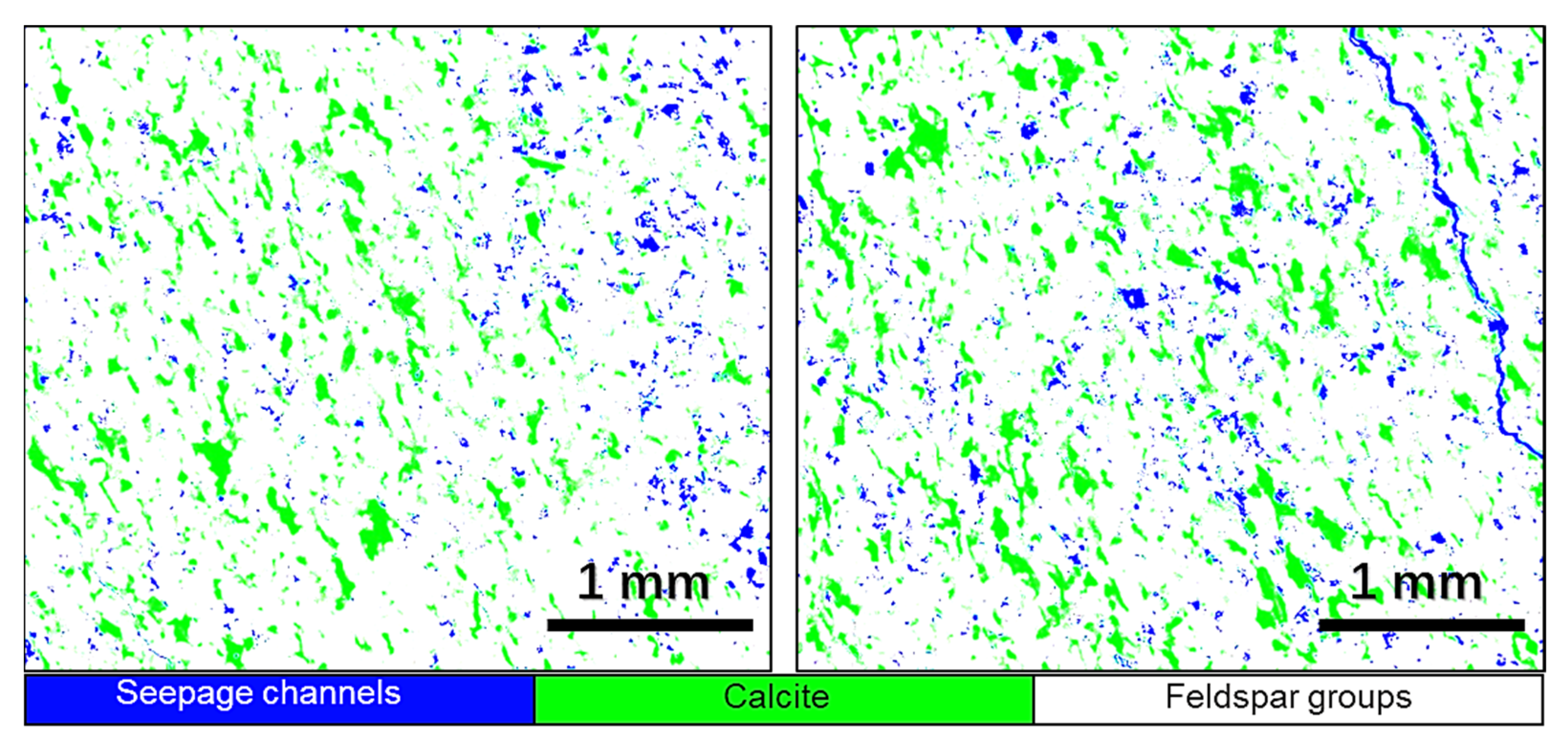

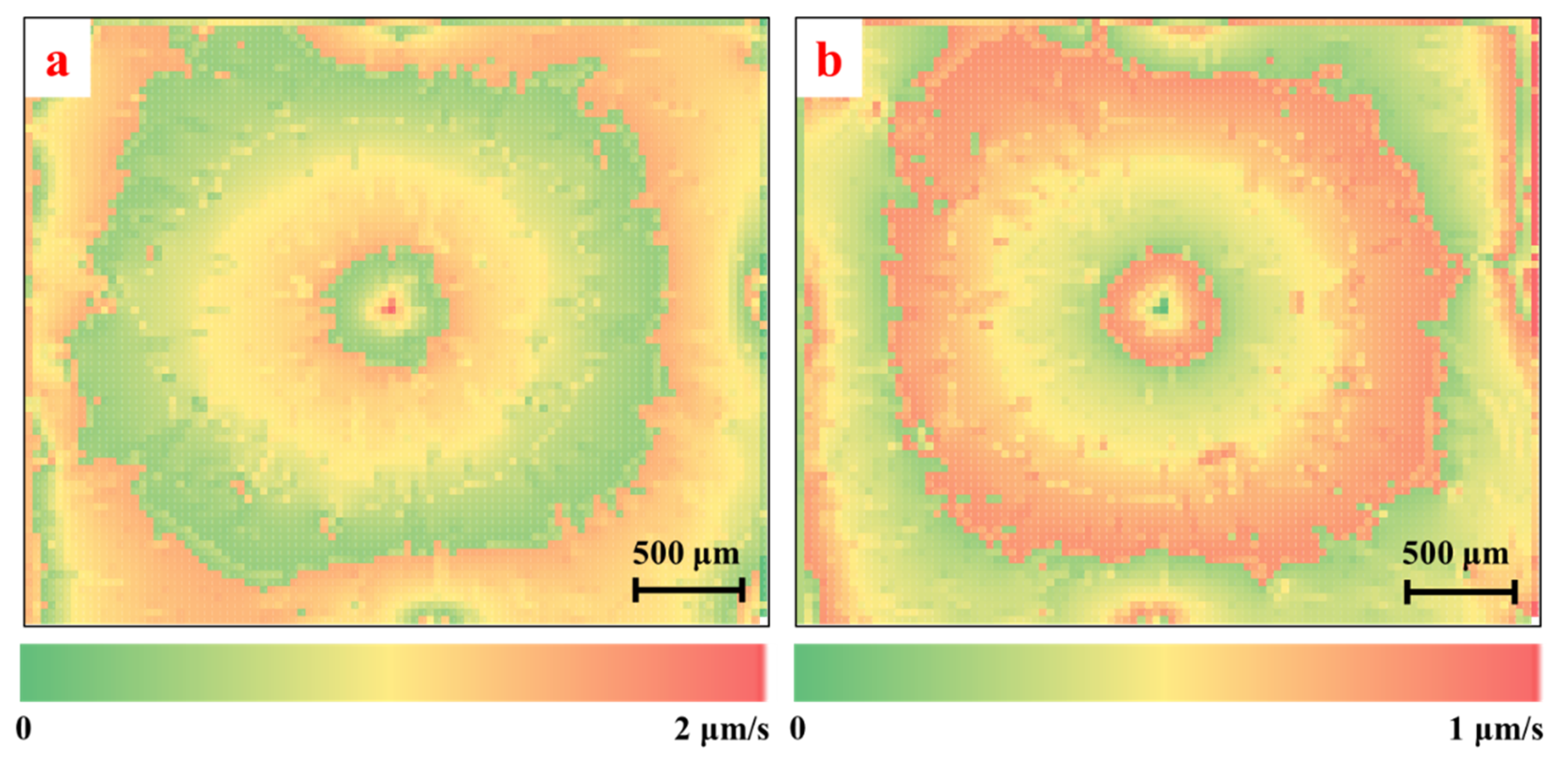

3.3. Microscopic Flow Characteristics

- (1)

- Sample “a”

- (2)

- Sample “b”

- (3)

- Sample “c”

- (4)

- Sample “d”

- (5)

- Sample “e”

- (6)

- Sample “f”

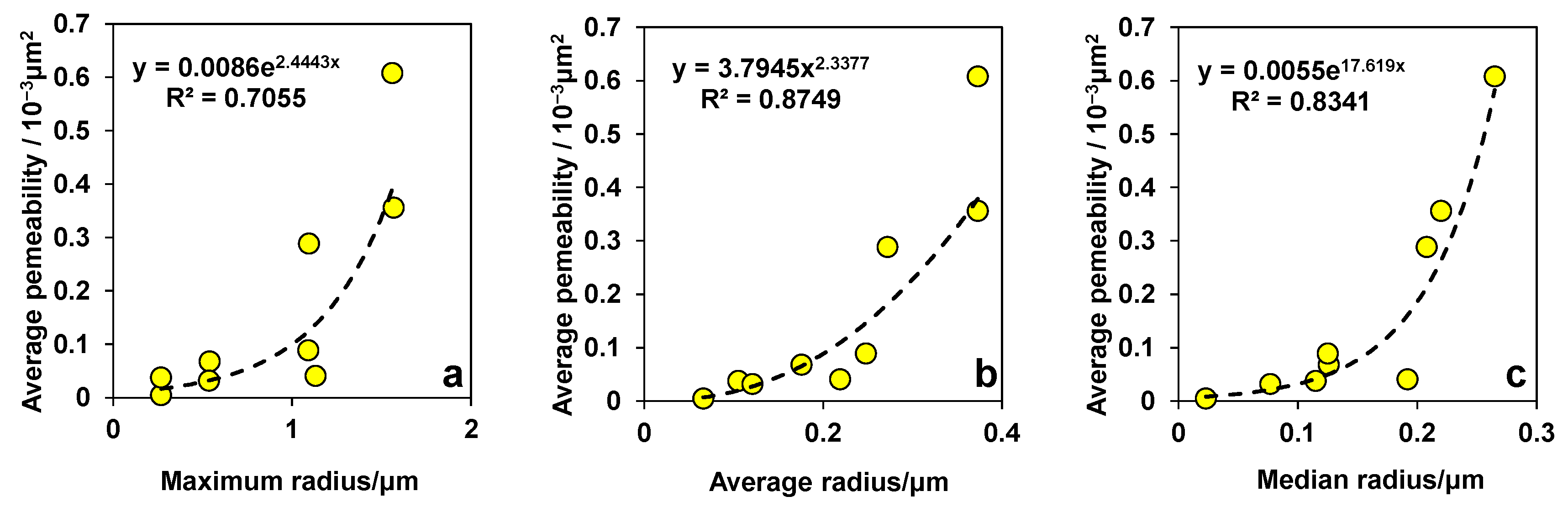

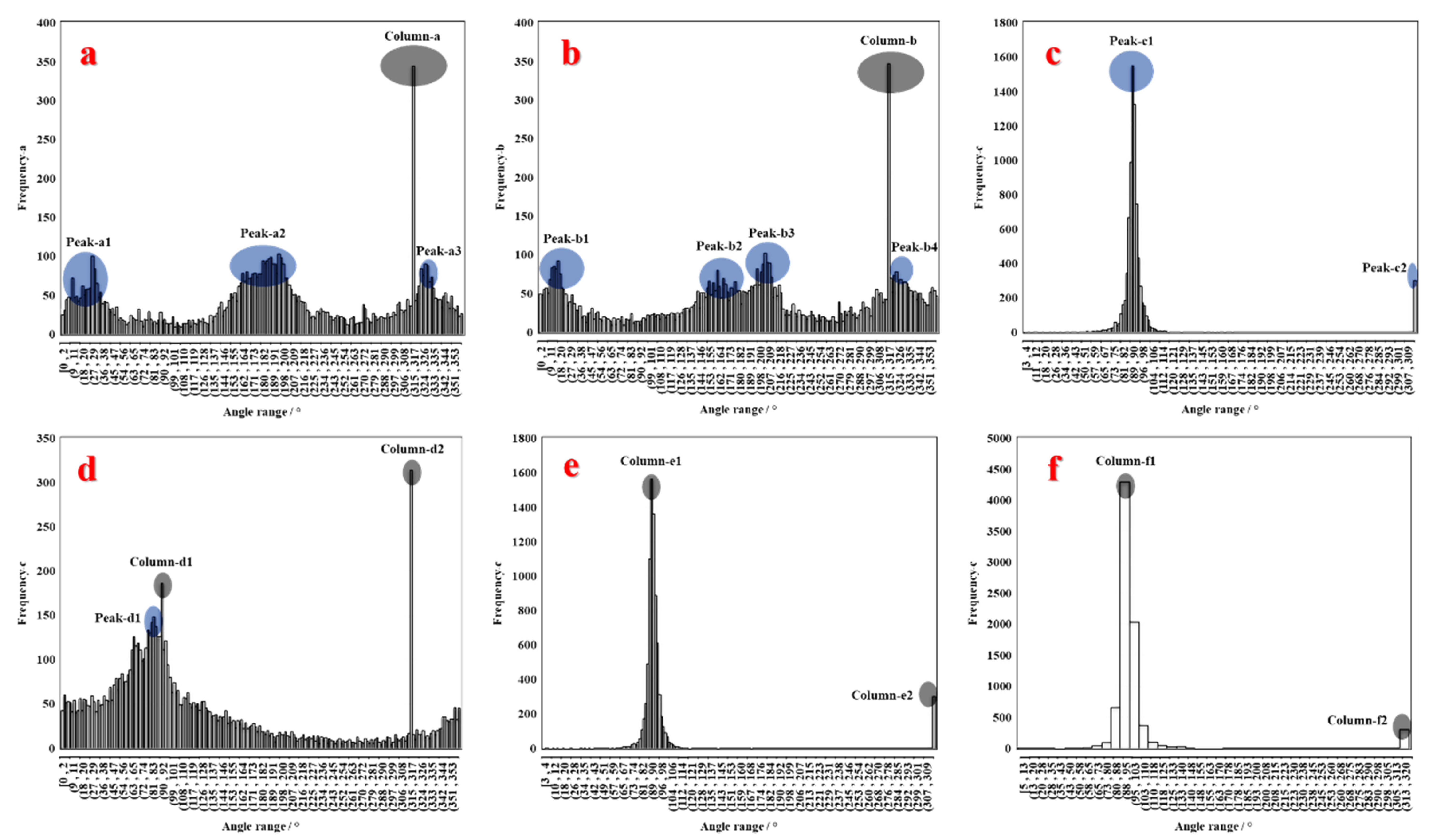

3.4. Mechanism of Flow Anisotropy

4. Conclusions

- (1)

- The concept of “two-dimensional permeability” could be used to characterize the microscopic anisotropic permeabilities of tight oil reservoirs impacted by heterogeneous minerals.

- (2)

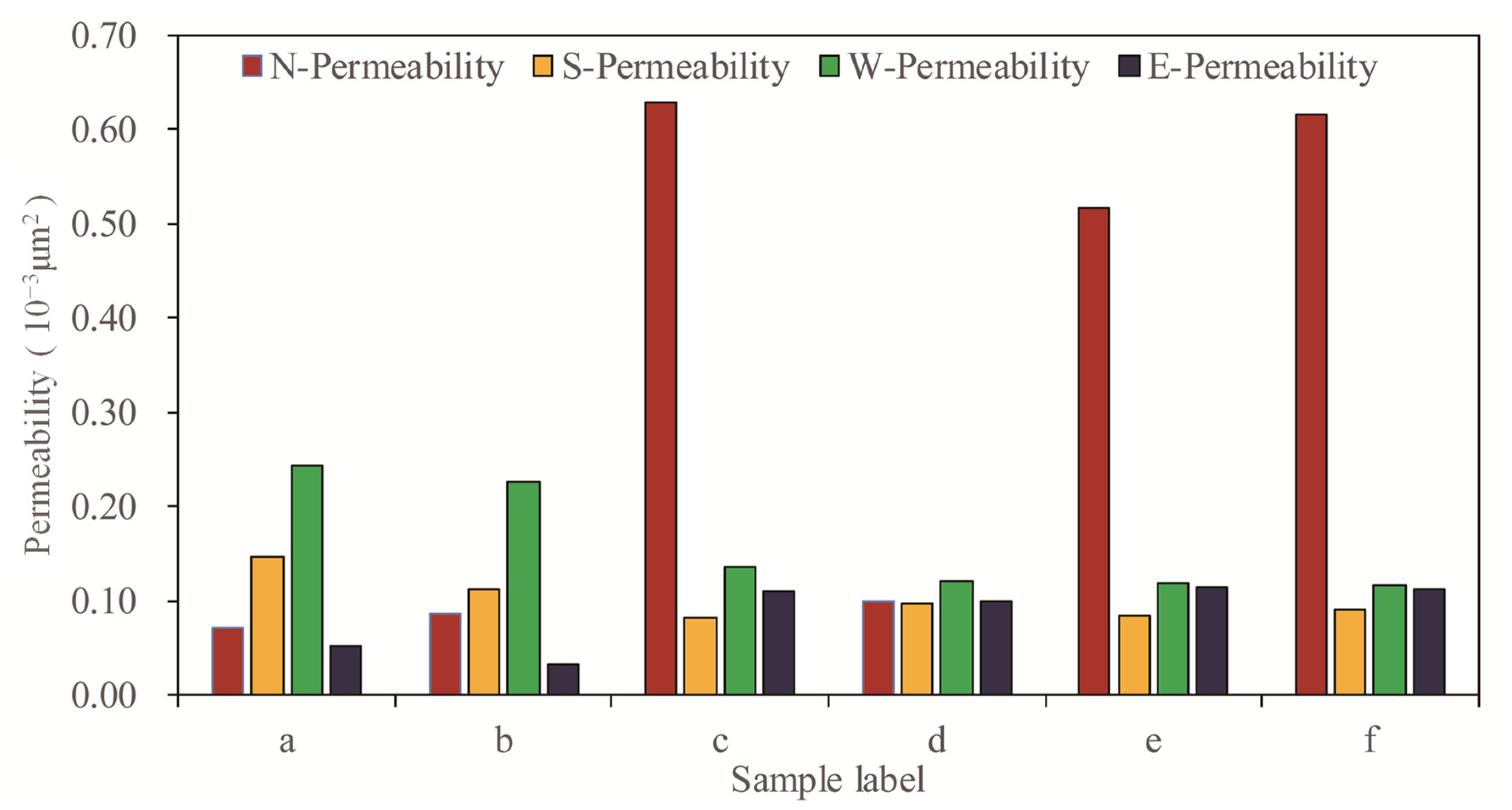

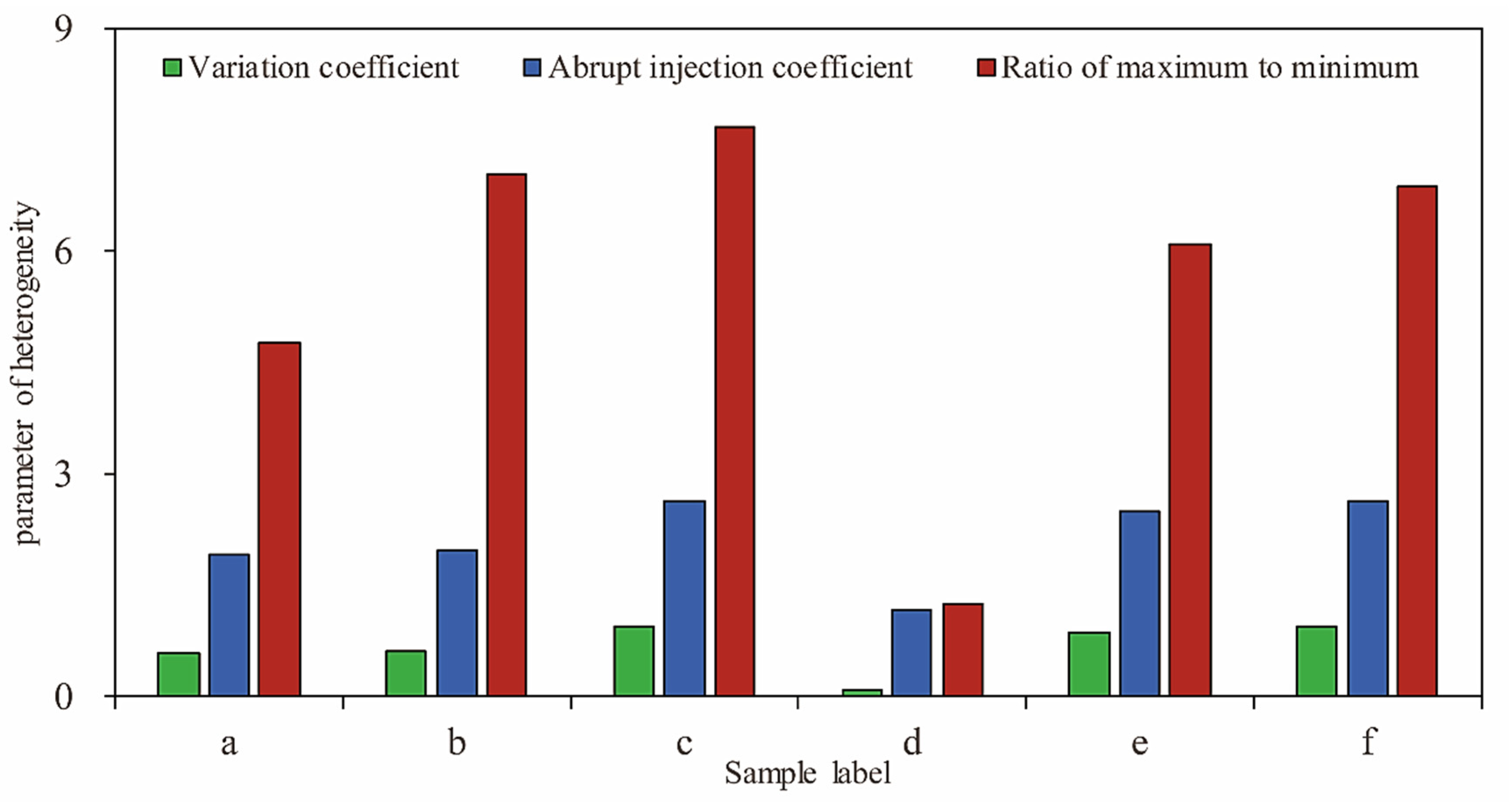

- As to the two-dimensional permeability, the ratio of maximum to minimum is between 1.25 and 7.67, with an average value of 5.62. The fluid flow in tight reservoirs has significant heterogeneity in plane, and there are several dominant flow channels.

- (3)

- The homogeneity of pore throat distribution, the development of micro-cracks, and the orientation of pore-throat minerals are the most important factors affecting flow direction angles.

Author Contributions

Funding

Conflicts of Interest

References

- Anyim, K.; Gan, Q. Fault zone exploitation in geothermal reservoirs: Production optimization, permeability evolution and induced seismicity. Adv. Geo-Energy Res. 2020, 4, 1–12. [Google Scholar] [CrossRef]

- Zhang, B.; He, Q.; Lin, Z.; Li, Z. Experimental study on the flow behaviour of water-sand mixtures in fractured rock specimens. Int. J. Min. Sci. Technol. 2021, 31, 377–385. [Google Scholar] [CrossRef]

- Xue, Y.; Ranjith, P.G.; Dang, F.; Liu, J.; Wang, S.; Xia, T.; Gao, Y. Analysis of deformation, permeability and energy evolution characteristics of coal mass around borehole after excavation. Nonrenew. Resour. 2020, 29, 3159–3177. [Google Scholar] [CrossRef]

- Yu, G.; Xu, F.; Cui, Y.; Li, X.; Kang, C.; Lu, C.; Li, S.; Bai, L.; Du, S. A new method of predicting the saturation pressure of oil reservoir and its application. Int. J. Hydrogen Energy 2020, 45, 30244–30253. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, C. Evaluating the potential of carbonate sub-facies classification using NMR longitudinal over transverse relaxation time ratio. Adv. Geo-Energy Res. 2021, 5, 87–103. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Cheng, Q.; Gao, Z. Evolution of anisotropic coal permeability under the effect of heterogeneous deformation of fractures. Nat. Resour. Res. 2021, 30, 3623–3642. [Google Scholar] [CrossRef]

- Smith, M.M.; Hao, Y.; Carroll, S.A. Development and calibration of a reactive transport model for carbonate reservoir porosity and permeability changes based on CO2 core-flood experiments. Int. J. Greenh. Gas Control 2017, 57, 73–88. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, Y.; Li, T.; Zhang, X. A numerical investigation of gas flow behavior in two-layered coal seams considering interlayer interference and heterogeneity. Int. J. Min. Sci. Technol. 2021, 31, 699–716. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L. Permeability characteristics of broken coal and rock under cyclic loading and unloading. Nat. Resour. Res. 2019, 28, 1055–1069. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, X.; Zhao, Y.; Zhou, Y.; Shan, B. Effect of pore throat structure on micro-scale flow characteristics of tight gas reservoirs. Nat. Gas. Ind. B 2020, 7, 160–167. [Google Scholar] [CrossRef]

- Jia, L.; Li, K.; Shi, X.; Zhao, L.; Linghu, J. Application of gas wettability alteration to improve methane drainage performance: A case study. Int. J. Min. Sci. Technol. 2021, 31, 621–629. [Google Scholar] [CrossRef]

- Xu, J.; Wu, K.; Yang, S.; Cao, J.; Chen, Z. Nanoscale free gas transport in shale rocks: A hard-sphere based model. In SPE Unconventional Resources Conference; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Xu, J.; Wu, K.; Li, Z.; Pan, Y.; Li, R.; Li, J.; Chen, Z. A model for gas transport in dual-porosity shale rocks with fractal structures. Ind. Eng. Chem. Res. 2018, 57, 6530–6537. [Google Scholar] [CrossRef]

- Xu, J.; Wu, K.; Li, R.; Li, Z.; Li, J.; Xu, Q.; Li, L.; Chen, Z. Nanoscale pore size distribution effects on gas production from fractal shale rocks. Fractals 2019, 27, 1950142. [Google Scholar] [CrossRef]

- Hatami, M.; Bayless, D.; Sarvestani, A. Poroelastic effects on gas transport mechanisms and influence on apparent permeability in shale. Int. J. Rock Mech. Min. Sci. 2022, 153, 105102. [Google Scholar] [CrossRef]

- Lu, Y. Higher-order Knudsen’s permeability correction model for rarefied gas in micro-scale channels. Nat. Gas. Ind. B 2019, 6, 502–508. [Google Scholar] [CrossRef]

- Wang, G.; Qin, X.; Han, D.; Liu, Z. Study on flow and deformation characteristics of coal microstructure by 3D reconstruction of CT images at high temperatures. Int. J. Min. Sci. Technol. 2021, 31, 175–185. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X. Unification of flow equations in tubes and in porous media. Xinjiang Pet. Geol. 2007, 28, 252–253. (In Chinese) [Google Scholar]

- Alfi, M.; Hosseini, S.A.; Enriquez, D.; Zhang, T. A new technique for permeability calculation of core samples from unconventional gas reservoirs. Fuel 2018, 235, 301–305. [Google Scholar] [CrossRef]

- Liu, H.; Gao, S.; Ye, L.; Zhu, W.; An, W. Change laws of water invasion performance in fractured–porous water-bearing gas reservoirs and key parameter calculation methods. Nat. Gas Ind. B 2021, 8, 57–66. [Google Scholar] [CrossRef]

- Lu, C.; Ma, L.; Guo, J.; Xiao, S.; Zheng, Y.; Yin, C. Effect of acidizing treatment on microstructures and mechanical properties of shale. Nat. Gas Ind. B 2020, 7, 254–261. [Google Scholar] [CrossRef]

- Tang, J.; Zhu, J.; Shao, T.; Wang, J.; Jiang, Y. A coal permeability model with variable fracture compressibility considering triaxial strain condition. Nat. Resour. Res. 2021, 30, 1577–1595. [Google Scholar] [CrossRef]

- Dai, C.; Liu, H.; Wang, Y.; Li, X.; Wang, W. A simulation approach for shale gas development in China with embedded discrete fracture modeling. Mar. Pet. Geol. 2019, 100, 519–529. [Google Scholar] [CrossRef]

- Luo, A.; Li, Y.; Wu, L.; Peng, Y.; Tang, W. Fractured horizontal well productivity model for shale gas considering stress sensitivity, hydraulic fracture azimuth, and interference between fractures. Nat. Gas Ind. B 2021, 8, 278–286. [Google Scholar] [CrossRef]

- Wood, D.A. The natural gas sector needs to be mindful of its sustainability credentials. Adv. Geo-Energy Res. 2020, 4, 229–232. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Jiang, W.; Zhang, H.; Feng, Y.; Yang, Z. Characteristics, current exploration practices, and prospects of continental shale oil in China. Adv. Geo-Energy Res. 2022, 6, 454–459. [Google Scholar] [CrossRef]

- Xue, P.; Zhang, L.; Liang, Q.; Sun, X.; Zhao, Q.; Qi, P. Thermodynamic characteristics of CH4 adsorption by continental shale: A case study of the Upper Triassic Yanchang shale in the Yanchang Gasfield, Ordos Basin. Nat. Gas Ind. B 2020, 7, 269–277. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, D.; Xia, Y.; Zeng, J.; Qiao, J.; Xu, X.; Cai, J. Spontaneous imbibition characteristics and influencing factors of Chang 7 shale oil reservoirs in Longdong area, Ordos basin. Earth Sci. 2022, 47, 3045–3055. (In Chinese) [Google Scholar]

- Wang, B.; Sun, J.; Shen, F.; Li, W.; Zhang, W. Mechanism of wellbore instability in continental shale gas horizontal sections and its water-based drilling fluid countermeasures. Nat. Gas Ind. B 2020, 7, 680–688. [Google Scholar] [CrossRef]

- Du, S.; Shi, Y.; Guan, P.; Zhang, Y. New inspiration on effective development of tight reservoir in secondary exploitation by using rock mechanics method. Energy Explor. Exploit. 2016, 34, 3–18. [Google Scholar] [CrossRef]

- Du, S.; Zhao, Y.; Jin, J.; Kou, G.; Shi, Y.; Huang, X. Significance of the secondary pores in perthite for oil storage and flow in tight sandstone reservoir. Mar. Pet. Geol. 2019, 110, 178–188. [Google Scholar] [CrossRef]

- Halim, M.C.; Hamidi, H.; Akisanya, A.R. Minimizing formation damage in drilling operations: A critical point for optimizing productivity in sandstone reservoirs intercalated with clay. Energies 2021, 15, 162. [Google Scholar] [CrossRef]

- Zeng, Z. Frac-n-Flow testing to screen brittle fracture stages in Wolfcamp formation, Permian basin, USA. Energies 2021, 14, 5450. [Google Scholar] [CrossRef]

- Du, S. Anisotropic rock poroelasticity evolution in ultra-low permeability sandstones under pore pressure, confining pressure, and temperature: Experiments with Biot’s coefficient. Acta Geol. Sin. Engl. Ed. 2021, 95, 937–945. [Google Scholar] [CrossRef]

- Khurpade, P.D.; Kshirsagar, L.K.; Nandi, S. Characterization of heterogeneous petroleum reservoir of Indian Sub-continent: An integrated approach of hydraulic flow unit—Mercury intrusion capillary pressure—Fractal model. J. Pet. Sci. Eng. 2021, 205, 108788. [Google Scholar] [CrossRef]

- Milad, M.; Junin, R.; Sidek, A.; Imqam, A.; Tarhuni, M. Huff-n-puff technology for enhanced oil recovery in shale/tight oil reservoirs: Progress, gaps, and perspectives. Energy Fuels 2021, 35, 17279–17333. [Google Scholar] [CrossRef]

- Zeng, Y.; Du, S.; Zhang, X.; Zhang, B.; Liu, H. The crucial geometric distinctions of microfractures as the indispensable transportation channels in hydrocarbon-rich shale reservoir. Energy Rep. 2020, 6, 2056–2065. [Google Scholar] [CrossRef]

- Radwan, A.E.; Nabawy, B.S.; Kassem, A.A.; Hussein, W.S. Implementation of rock typing on waterflooding process during secondary recovery in oil reservoirs: A case study, El Morgan oil field, Gulf of Suez, Egypt. Nonrenew. Resour. 2021, 30, 1667–1696. [Google Scholar] [CrossRef]

- Abitkazy, T.; Du, S.; Xu, F.; Shi, Y. Pore structure characterization of clay minerals in the Lower Karamay formation conglomerate reservoir in the Junggar basin and its impact on hydrocarbon storage and seepage. Acta Geol. Sin. Engl. Ed. 2019, 95, 558–569. [Google Scholar] [CrossRef]

- Shi, G.; Kou, G.; Du, S.; Wei, Y.; Zhou, W.; Zhou, B.; Li, Q.; Wang, B.; Guo, H.; Lou, Q.; et al. What role would the pores related to brittle minerals play in the process of oil migration and oil & water two-phase imbibition? Energy Rep. 2020, 6, 1213–1223. [Google Scholar]

- Rajkumar, P.; Pranesh, V.; Kesavakumar, R. Influence of CO2 retention mechanism storage in Alberta tight oil and gas reservoirs at Western Canadian Sedimentary Basin, Canada: Hysteresis modeling and appraisal. J. Pet. Explor. Prod. Technol. 2021, 11, 327–345. [Google Scholar] [CrossRef]

- Syed, F.I.; Muther, T.; Van, V.P.; Dahaghi, A.K.; Negahban, S. Numerical trend analysis for factors affecting eor performance and co2 storage in tight oil reservoirs. Fuel 2022, 316, 123370. [Google Scholar] [CrossRef]

- Guo, D.; Lv, P.; Zhao, J.; Zhang, C. Research progress on permeability improvement mechanisms and technologies of coalbed deep-hole cumulative blasting. Int. J. Coal Sci. Technol. 2020, 7, 329–336. [Google Scholar] [CrossRef]

- Gao, Q.; Han, S.; Cheng, Y.; Li, Y.; Yan, C.; Han, Z. Apparent permeability model for gas transport through micropores and microfractures in shale reservoirs. Fuel 2021, 285, 119086. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Zhang, C.; Zhou, J.; Li, Y.; Sun, Z. Characteristic strength and acoustic emission properties of weakly cemented sandstone at different depths under uniaxial compression. Int. J. Coal Sci. Technol. 2021, 8, 1288–1301. [Google Scholar] [CrossRef]

- Liu, H.; Guo, C.; Xu, C. Study on the two-component gas apparent permeability model in shale nanopores considering Knudsen number correction. J. Pet. Sci. Eng. 2022, 213, 110405. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Wang, H.; Xu, C. Exploration on molecular dynamics simulation methods of microscopic wetting process for coal dust. Int. J. Coal Sci. Technol. 2021, 8, 205–216. [Google Scholar] [CrossRef]

- Zuo, J.; Yang, R.; Gong, M.; Ma, X.; Wang, Y. Fracture characteristics of iron ore under uncoupled blast loading. Int. J. Min. Sci. Technol. 2022, 32, 657–667. [Google Scholar] [CrossRef]

- Shan, L.; Bai, X.; Liu, C.; Feng, Y.; Liu, Y.; Qi, Y. Super-resolution reconstruction of digital rock CT images based on residual attention mechanism. Adv. Geo-Energy Res. 2022, 6, 157–168. [Google Scholar] [CrossRef]

- Hu, D.; Wei, Z.; Liu, R.; Wei, X.; Chen, F.; Liu, Z. Enrichment control factors and exploration potential of lacustrine shale oil and gas: A case study of Jurassic in the Fuling area of the Sichuan Basin. Nat. Gas Ind. B 2022, 9, 1–8. [Google Scholar] [CrossRef]

- Wang, G.; Li, Y.; Wang, E.; Huang, Q.; Wang, S.; Li, H. Experimental study on preparation of nanoparticle-surfactant nanofluids and their effects on coal surface wettability. Int. J. Min. Sci. Technol. 2022, 32, 387–397. [Google Scholar] [CrossRef]

- Chen, K.; Li, J.; Tang, X.; Shen, J.; Wang, P.; Peng, J.; Meng, J. Key geological factors for shale gas accumulation in the Wufeng–Longmaxi Fms in the central Yangtze area. Nat. Gas Ind. B 2021, 8, 1–12. [Google Scholar] [CrossRef]

| Mineral | Chemical Formula | P Wave Transit Time/μs/m | S Wave Transit Time/μs/m | Density/g/cm3 | Young’s Modulus/GPa | Poisson Ratio |

|---|---|---|---|---|---|---|

| K-feldspar | KAlSi3O8 | 226 | 414 | 2.53 | 38.07 | 0.29 |

| Na-feldspar | NaAlSi3O8 | 154 | 321 | 2.59 | 67.89 | 0.35 |

| Oligoclase | (Ca,Na)[Al(Al,Si)Si2O8] | 160 | 295 | 2.7 | 80.09 | 0.29 |

| Labradorite | (Ca,Na)[Al(Al,Si)Si2O8] | 153 | 282 | 2.7 | 87.54 | 0.29 |

| Ca-feldspar | CaAl2Si2O8 | 148 | 293 | 2.74 | 84.68 | 0.33 |

| Calcite | CaCO3 | 151 | 292 | 2.71 | 83.75 | 0.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Ge, H.; Wei, Y.; Wang, Y.; Jia, K.; Xu, N.; Zhang, Y.; Du, S. Characterizing the Microscopic Anisotropic Permeabilities of Tight Oil Reservoirs Impacted by Heterogeneous Minerals. Energies 2022, 15, 6552. https://doi.org/10.3390/en15186552

Wang Z, Ge H, Wei Y, Wang Y, Jia K, Xu N, Zhang Y, Du S. Characterizing the Microscopic Anisotropic Permeabilities of Tight Oil Reservoirs Impacted by Heterogeneous Minerals. Energies. 2022; 15(18):6552. https://doi.org/10.3390/en15186552

Chicago/Turabian StyleWang, Ziqiang, Hongkui Ge, Yun Wei, Yi Wang, Kerui Jia, Ning Xu, Yuankai Zhang, and Shuheng Du. 2022. "Characterizing the Microscopic Anisotropic Permeabilities of Tight Oil Reservoirs Impacted by Heterogeneous Minerals" Energies 15, no. 18: 6552. https://doi.org/10.3390/en15186552