Research and Application of Fast Plugging Method for Fault Zone Formation in Tarim Basin, China

Abstract

:1. Introduction

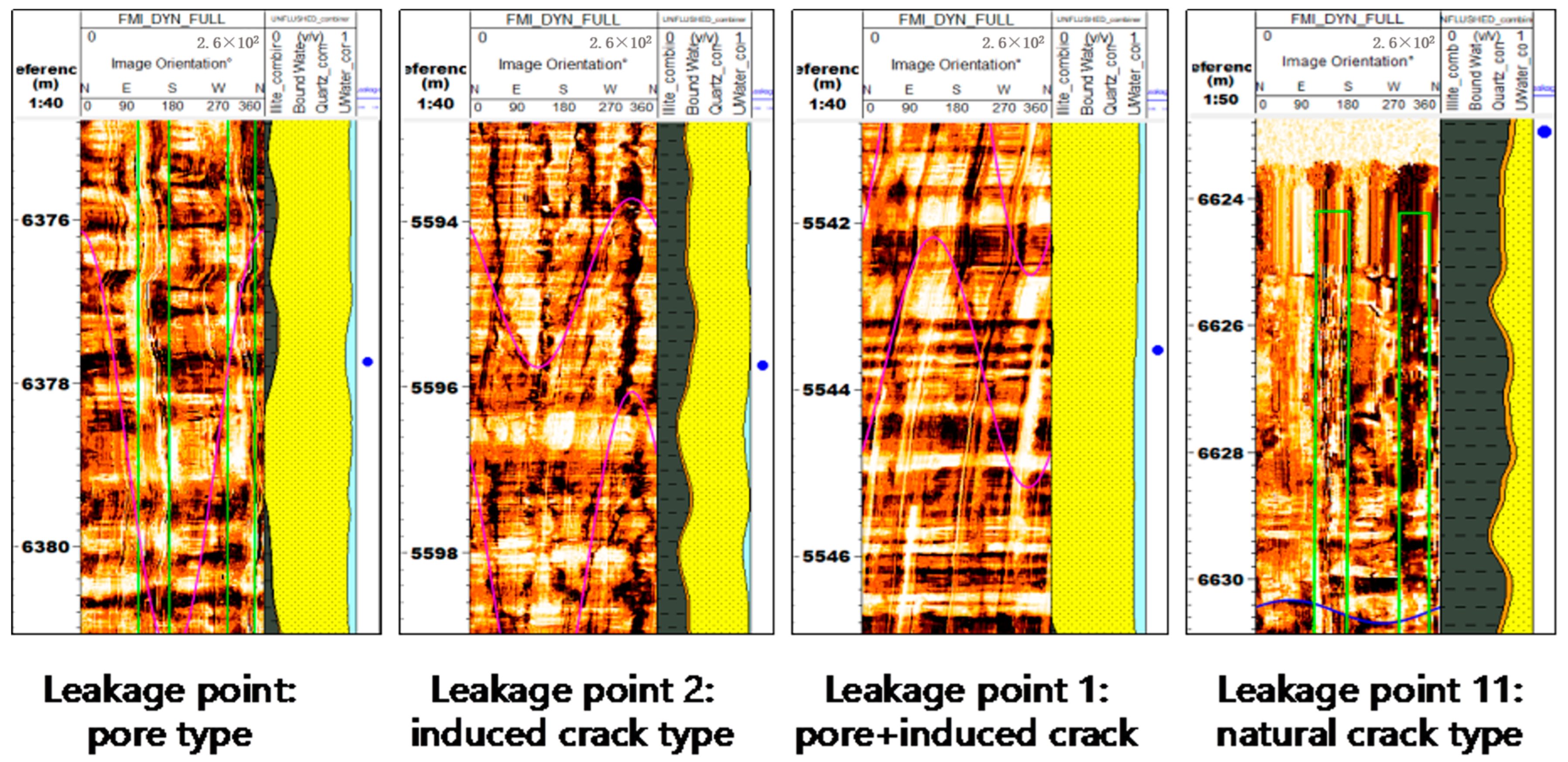

2. Silurian Leakage Characteristics of Shunbei No. 5 Fault Zone

3. Results

3.1. Principle and Method of Rapid Plugging Slurry

3.1.1. Defects of Current Plugging Slurry System

3.1.2. Proposed Solution

- (1)

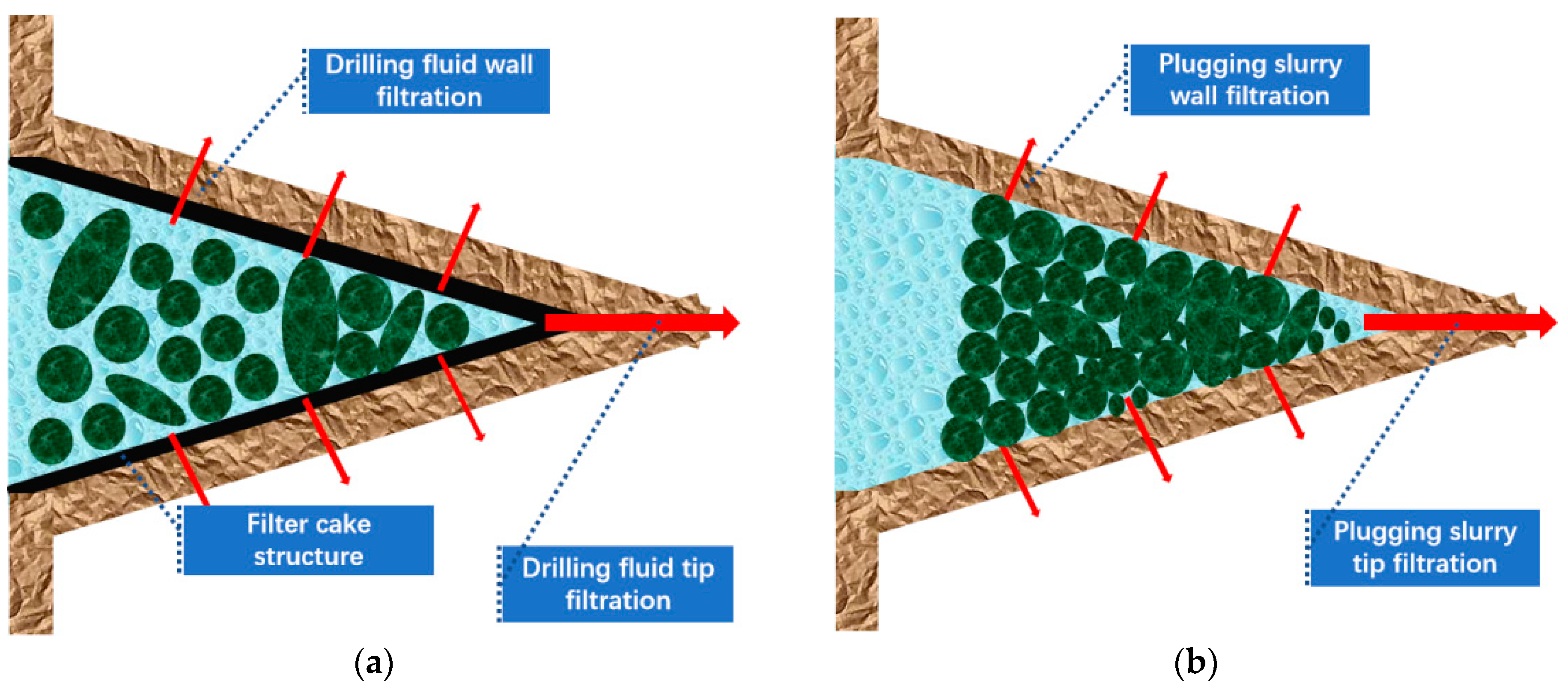

- After the plugging slurry prepared by the drilling fluid enters the fracture, the drilling fluid acting as the carrier fluid needs to be drained as quickly as possible under the premise of ensuring the safety of the fracture. However, the nature of the drilling fluid itself determines that it is easy to drain the relatively dense plugging layer or mud cake on the two walls of the fracture, which directly leads to the rapid loss of the drilling fluid.

- (2)

- The drilling fluid flows to the crack tip intensively, further inducing the crack to continue to extend and causing more serious leakage problems. At the same time, the drilling fluid and plugging materials in the plugging slurry cannot be separated, and the plugging slurry is in the slurry state, which cannot achieve the plugging effect.

3.2. Development of Plugging Materials

- (1)

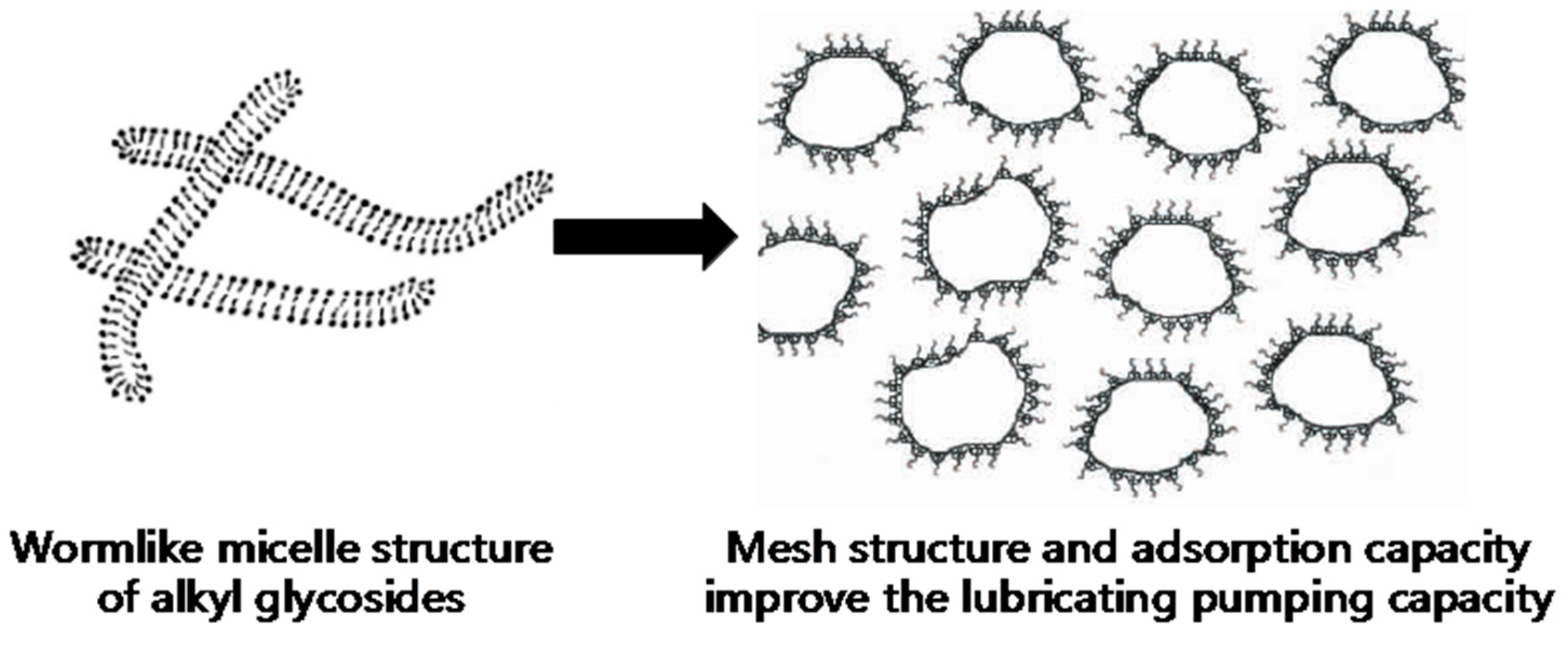

- Plugging mainstream: M-Fluid

- (2)

- Micro-elastic high-strength main plugging agent: M-Block

- (3)

- Filling agent: Filling-Seal

4. Discussion

4.1. Construction of Fast Plugging Slurry System and Evaluation of Plugging Effect

4.1.1. Construction of Plugging Slurry System

4.1.2. Evaluation of Plugging Action Time

4.1.3. Large-Particle Sand Bed Simulation Fracture Plugging

4.1.4. Dynamic Plugging Evaluation of Small Core

4.1.5. Full-Size Core Fracture Plugging Evaluation

4.1.6. Evaluation of Dual-Core Multi-form Fracture Plugging

4.2. Application

5. Conclusions

- (1)

- Based on the low-filtration characteristics of the drilling fluid, the plugging slurry prepared with the drilling fluid cannot be quickly filtered after entering the fracture, resulting in a low plugging success rate. The rapid plugging technology uses a special plugging slurry to quickly filter the carrier fluid, and the materials are quickly concentrated to form a high-shear-resistance plugging barrier.

- (2)

- The main plugging body M-Fluid, micro-elastic high-strength main plugging agent M-Block and Filling-Seal are developed to form a special plugging slurry for the Silurian formation in the Shunbei No. 5 fault zone. With the increase of temperature, the filtration rate of the plugging slurry increases rapidly, and the filtration time decreases rapidly. The filtration rate is approximately 0.31~0.79 mL/s. Combined with the low-filtration property of the drilling fluid, an efficient plugging technology is constructed.

- (3)

- Various plugging evaluation experiments such as plugging action time, a large-particle sand bed-simulated fracture, small core and full-size core artificial fractures, a dual-core multi-form fracture and so on have been carried out in the laboratory. The experiments show that the pressure-bearing capacity of the plugging barrier exceeds 5 MPa, the pressure-bearing effect is good in field application, and the special plugging technology has a good plugging effect. Finally, the plugging ability for Z-shaped fractures, cross-shaped fractures, parallel double fractures, 90° angle double fractures and 45° angle double fractures was evaluated. The results showed that the plugging system cooperated with the drilling fluid to form a plugging barrier with high strength and shear resistance, which could better meet the plugging requirements.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lakatos, I. Role of Chemical Ior/Eor Methods in the 21st Century. In Proceedings of the 18th World Petroleum Congress, Johannesburg, South Africa, 25–29 September 2005; OnePetro: Richardson, TX, USA, 2005. [Google Scholar]

- Jiao, F. Practice and knowledge of volumetric development of deep fractured-vuggy carbonate reservoirs in Tarim Basin, NW China. Petroleum Explor. Develop. 2019, 46, 576–582. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, S.; Zhang, Y.; Zeng, J.; Mu, W. Use of nonlinear chaos inversion in predicting deep thin lithologic hydrocarbon reservoirs: A case study from the Tazhong oil field of the Tarim Basin, ChinaDeep thin reservoirs prediction. Geophysics 2016, 81, B221–B234. [Google Scholar] [CrossRef]

- Jiang, T.; Sun, X. Development of Keshen ultra-deep and ultra-high pressure gas reservoirs in the Kuqa foreland basin, Tarim Basin: Understanding and technical countermeasures. Nat. Gas Ind. B 2019, 6, 16–24. [Google Scholar] [CrossRef]

- Deng, S.; Zhao, R.; Kong, Q.; Li, Y.; Li, B. Two distinct strike-slip fault networks in the Shunbei area and its surroundings, Tarim Basin: Hydrocarbon accumulation, distribution, and controlling factors. AAPG Bull. 2022, 106, 77–102. [Google Scholar] [CrossRef]

- Ma, Y.; Cai, X.; Yun, L.; Li, Z.; Li, H.; Deng, S.; Zhao, P. Practice and theoretical and technical progress in exploration and development of Shunbei ultra-deep carbonate oil and gas field, Tarim Basin, NW China. Petroleum Explor. Develop. 2022, 49, 20. [Google Scholar] [CrossRef]

- Lu, Y. Hydrocarbon accumulation of ultra-deep Ordovician fault-karst reservoirs in Shunbei area. Xinjiang Petroleum Geol. 2021, 42, 40. [Google Scholar]

- Pang, X.; Lin, H.; Zheng, D.; Li, H.; Zou, H.; Pang, H.; Hu, T.; Guo, F.; Li, H. Basic characteristics, dynamic mechanism and development direction of the formation and distribution of deep and ultra-deep carbonate reservoirs in China. J. Geomech. 2020, 26, 673–695. [Google Scholar]

- Shi, W.; Cheng, J.; Liu, Y.; Gao, M.; Tao, L.; Bai, J.; Zhu, Q. Engineering, Pressure transient analysis of horizontal wells in multibranched fault-karst carbonate reservoirs: Model and application in SHB oilfield. J. Pet. Sci. Eng. 2023, 220, 111167. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, S.; Zhang, Y.; Yang, M.; Yan, L.; Zhao, Y.; Zhang, J.; Wang, X.; Zhou, X.; Wang, H. Petroleum geological conditions and exploration potential of Lower Paleozoic carbonate rocks in Gucheng Area, Tarim Basin, China. Petroleum Explor. Develop. 2019, 46, 1165–1181. [Google Scholar] [CrossRef]

- Fang, J.; Lyu, Z.; He, Z.; Li, Y.; Yu, P. Application of Chemical Gel LCM on Well Shunbei-3. DC Fluid 2017, 34, 5. [Google Scholar]

- Jianbo, L.; Zhiwei, W.; Maolin, L.; Engineering, W. New technology for leak plugging in Permian igneous rocks at Shunbei 1-1H well. DC Fluid 2017, 29, 4. [Google Scholar]

- Xiao, N.; Lijuan, P.; Yuhui, Z.; Fluid, Y. Drilling fluid technology for long open hole section of Well SHB1-6H. DC Fluid 2016, 33, 5. [Google Scholar]

- Xinjian, G.; Fluid, Y. Controlling Mud Losses in Well Shunbei 52X with High Temperature Chemical Gels. DC Fluid 2019, 36, 5. [Google Scholar]

- Jianchun, G.; Sinica, H. Microscopic mechanism of the damage caused by gelout process of fracturing fluids. Acta Petroleum Sin. 2012, 33, 5. [Google Scholar]

- Chunming, H. Acid Leakoff Mechanism and Leakoff Control Technology in Fractured Carbonate Reservoirs. Ph.D. Thesis, Southwest Petroleum University, Sichuan, China, 2013. [Google Scholar]

- Gao, W. Deep Well Drilling Technology for Large Size Borehole Basalt Wells in the Shunbei Block. Chem. Eng. Equip. 2018, 10, 2. [Google Scholar]

- Pan, J.; Li, D. Technology of Preventing and Controlling Mud Losses into the Permian lgneous Rocks in Shunbei Oilfiled. DC Fluid 2018, 35, 6. [Google Scholar]

- Xiao, X.-y.; Shi, D.-j.; Li, G.-n.; Yu, P.-z. Plugging while Drilling Technology for Permian in Shunbei Area of Tarim Basin. Drill. Eng. 2017, 44, 5. [Google Scholar]

- Sheng, F.; Bitao, S.; Zengwei, C.; Daqi, L.; Jinhua, L.; Zengshou, C. Technology for enhancing pressure bearing capacity of fractured Silurian system in Well Shunbei 5–8. DC Fluid 2019, 36, 431–436. [Google Scholar]

- Xiongjun, W.; Yongxue, L.; Bitao, S.; Junbin, J.; Xiaoqiang, D. Oil base drilling fluid technology for drilling broken Ordovician formation in Shunbei block. DC Fluid 2020, 37, 701–708. [Google Scholar]

- Izyurov, V.; Kharitonov, A.; Semenikhin, I.; Korsunov, E.; Gassan, A.; Tikhonov, E.; Jadan, G.; Stashko, V.; Blagonadeshniy, I.; Manikhin, A. Selecting Bridging Agents’ Particle Size Distribution for Optimum Plugging While Drilling in Permeable Zones. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 22–24 October 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Shaofei, L.; Jinsheng, S.; Yingrui, B.; Kaihe, L.; Zhang, S.; Chengyuan, X.; Cheng, R.; Fan, L. Formation mechanisms of fracture plugging zone and optimization of plugging particles. Petroleum Explor. Develop. 2022, 49, 684–693. [Google Scholar]

- Gaurina-Međimurec, N.; Pašić, B.; Mijić, P.; Medved, I. Drilling fluid and cement slurry design for naturally fractured reservoirs. Appl. Sci. 2021, 11, 767. [Google Scholar] [CrossRef]

- Deng, S.; Huang, Y.; Hu, X.; Wang, H.; Zhao, H.; He, J. Nano-Film-Forming Plugging Drilling Fluid and Bridging Cross-Linking Plugging Agent Are Used to Strengthen Wellbores in Complex Formations. ACS Omega 2022, 7, 22804–22810. [Google Scholar] [CrossRef] [PubMed]

- Xiaoming, S.; Zhanghua, L.; Junwei, F.; Xiong, H.; Ruoning, W.; Yuan, Y. Lost circulation material for abnormally high temperature and pressure fractured-vuggy carbonate reservoirs in Tazhong block, Tarim Basin, NW China. Petroleum Explor. Develop. 2019, 46, 173–180. [Google Scholar]

- Fan, X.; Zhao, P.; Zhang, Q.; Zhang, T.; Zhu, K.; Zhou, C.J.M. A polymer plugging gel for the fractured strata and its application. Materials 2018, 11, 856. [Google Scholar] [CrossRef]

- Jia, H.; Yang, X.; Li, S.; Yu, P.; Zhang, J.J.C.; Physicochemical, S.A.; Aspects, E. Nanocomposite gel of high-strength and degradability for temporary plugging in ultralow-pressure fracture reservoirs. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 585, 124108. [Google Scholar] [CrossRef]

- Yang, L.; Zhijiang, K.; Zhaojie, X.; Zheng, S. Theories and practices of carbonate reservoirs development in China. Petroleum Explor. Develop. 2018, 45, 712–722. [Google Scholar]

- Zhu, G.; Zhang, S.; Su, J.; Meng, S.; Yang, H.; Hu, J.; Zhu, Y. Secondary accumulation of hydrocarbons in Carboniferous reservoirs in the northern Tarim Basin, China. J. Pet. Sci. Eng. 2013, 102, 10–26. [Google Scholar] [CrossRef]

- Carroll, A.R.; Graham, S.A.; Chang, E.Z.; McKnight, C. Sinian through Permian tectonostratigraphic evolution of the northwestern Tarim basin, China. Geol. Soc. Am. Mem. 2001, 194, 37. [Google Scholar]

- Li, H. Development Characteristics of Silurian Strike-Slip Faults and Fractures and Their Effects on Drilling Leakage in Shunbei Area of Tarim Basin. Front. Earth Sci. 2023, 10, 938765. [Google Scholar] [CrossRef]

- Jiaxue, L.; Jinjun, H.; Pingya, L.; Shuqi, W.; Tao, H.; Fluid, L. Researches on Mud Losses Prevention and Control. DC Fluid 2008, 25, 4. [Google Scholar]

- Jinsheng, S.; Jiadong, Z.; Daquan, H.; Fluld, W. Study and application of ultra-low permeable drilling fluid: Lost circulation prevention and control. DC Fluid 2005, 22, 4. [Google Scholar]

- Fang, J.; Zhang, Y.; Li, S.; Yu, P.; Li, Y. Acid-soluble temporary plugging technology for ultra-deep fractured carbonate reservoirs in Block 1 of the Shunbei Area. Petroleum Dirll. Tech. 2020, 48, 17–22. [Google Scholar]

- Wang, G.; Wang, F.; Zhang, J.; Hu, H.; Wang, X.; Li, J. Application of a Composite Gel Lost Circulation Material in the Top Section of Wells Drilled in the Central Region of the Mountain of Fire. DC Fluid 2017, 34, 49–53. [Google Scholar]

| Liquid Type | Temperature (°C) | Filtration Time (s) | Filtration Loss (mL) | Filtration Rate (mL/s) |

|---|---|---|---|---|

| Quick plugging slurry | 15 | 784 | 85 | 0.11 |

| 40 | 487 | 85 | 0.17 | |

| 80 | 273 | 85 | 0.31 | |

| 120 | 124 | 85 | 0.69 | |

| 160 | 107 | 85 | 0.79 | |

| Drilling fluid | 120 | 1800 | 12 | 0.0067 |

| Compression (Mpa) | Action Process | Loss of Plugging Slurry or Drilling Fluid (mL) |

|---|---|---|

| 1 | The plugging slurry is pressurized at 1 Mpa to quickly filter out. | The plugging slurry is filtered |

| 1 | The drilling fluid is pressurized at 1 Mpa, and the filtration is stopped for 6 min. | 36 |

| 2 | The drilling fluid is pressurized at 2 Mpa, and the filtration is stopped for 4 min. | 14 |

| 3 | The drilling fluid is pressurized at 3 Mpa, and the filtration is stopped for 2 min. | 7 |

| 4 | The drilling fluid is pressurized at 4 Mpa, and the filtration is only a very slow drop. | ≈1 |

| 5 | The drilling fluid is pressurized at 5 Mpa, only a small amount of droplets are suspended at the outlet, the pressure is stable for 60 min, and there is no re-filtration. | ≈0 |

| Core | Compression (Mpa) | Plugging Effect | Cumulative Drilling Fluid Filtration (mL) |

|---|---|---|---|

| C23-1 | 1 | Rapid loss of plugging slurry | The plugging slurry is filtered |

| 5 | 184 s drilling fluid filtrate stopped flowing out | 14 | |

| C23-2 | 1 | Rapid loss of plugging slurry | The plugging slurry is filtered |

| 5 | 215 s drilling fluid filtrate stopped flowing out | 17 |

| Compression (Mpa) | Action Process | Loss of Plugging Slurry or Drilling Fluid (mL) |

|---|---|---|

| 1 | The plugging slurry is pressurized at 1 Mpa to quickly filter out. | The plugging slurry is filtered |

| 1 | The drilling fluid is pressurized at 1 Mpa, and the filtration is stopped for 8 min. | 114 |

| 2 | The drilling fluid is pressurized at 2 Mpa, and the filtration is stopped for 6 min. | 46 |

| 3 | The drilling fluid is pressurized at 3 Mpa, and the filtration is stopped for 6 min. | 18 |

| 4 | The drilling fluid is pressurized at 4 Mpa, and the filtration is stopped for 92 s. | 3 |

| 5 | The drilling fluid is pressurized at 5 Mpa, only a small amount of droplets are suspended at the outlet, the pressure is stable for 60 min, and there is no re-filtration. | ≈0 |

| Experiment No | Fracture Morphology | Compression (MPa) | Plugging Effect | Cumulative Drilling Fluid Filtration (ML) |

|---|---|---|---|---|

| 1 | Zigzag | 5 | 353 s drilling fluid filtrate stops flowing out | 64 |

| Cross-bonding | 5 | 281 s drilling fluid filtrate stops flowing out | 32 | |

| 2 | Parallel double crack | 5 | 215 s drilling fluid filtrate stops flowing out | 20 |

| Cross-bonding | 5 | 267 s drilling fluid filtrate stops flowing out | 29 | |

| 3 | Zigzag | 5 | 367 s drilling fluid filtrate stops flowing out | 78 |

| 45° angle double crack | 5 | 248 s drilling fluid filtrate stops flowing out | 35 | |

| 4 | Parallel double crack | 5 | 169 s drilling fluid filtrate stops flowing out | 15 |

| 90° angle double crack | 5 | 227 s drilling fluid filtrate stops flowing out | 23 | |

| 5 | 45° angle double crack | 5 | 221 s drilling fluid filtrate stops flowing out | 27 |

| 90° angle double crack | 5 | 194 s drilling fluid filtrate stopped flowing out | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Fan, S.; Fang, J.; Yu, Y.; Zhang, J.; Li, S.; Xu, P. Research and Application of Fast Plugging Method for Fault Zone Formation in Tarim Basin, China. Energies 2023, 16, 4330. https://doi.org/10.3390/en16114330

He Z, Fan S, Fang J, Yu Y, Zhang J, Li S, Xu P. Research and Application of Fast Plugging Method for Fault Zone Formation in Tarim Basin, China. Energies. 2023; 16(11):4330. https://doi.org/10.3390/en16114330

Chicago/Turabian StyleHe, Zhong, Sheng Fan, Junwei Fang, Yang Yu, Jun Zhang, Shuanggui Li, and Peng Xu. 2023. "Research and Application of Fast Plugging Method for Fault Zone Formation in Tarim Basin, China" Energies 16, no. 11: 4330. https://doi.org/10.3390/en16114330