On the Use of Ultrasonic Flowmeters for Cooling Energy Metering and Sub-Metering in Direct Expansion Systems

Abstract

:1. Introduction

Aim of the Paper

- (a)

- a systematic classification of the existing CCS, with particular reference to the technical characteristics determining the configuration of direct metering systems and of the available direct metering and sub-metering techniques;

- (b)

- an experimental evaluation of the metrological reliability of a clamp-on ultrasonic flowmeter used to measure the cooling energy of a direct expansion system.

2. Direct Metering in Centralized Cooling Systems

- (a)

- Central generation unit;

- (b)

- Distribution system;

- (c)

- Terminal units located at the end-users’ location.

- (i)

- One-dimensional and stationary motion field;

- (ii)

- Single inlet and outlet sections;

- (iii)

- Negligible changes in potential and kinetic energy.

- (a)

- The specific heat transfer fluid, to evaluate its thermodynamic properties (i.e., density and enthalpies);

- (b)

- The type of distribution system;

- (c)

- The type of terminal units;

- (d)

- Regulation modes (e.g., Variable Air Volume, Variable Refrigerant Flow).

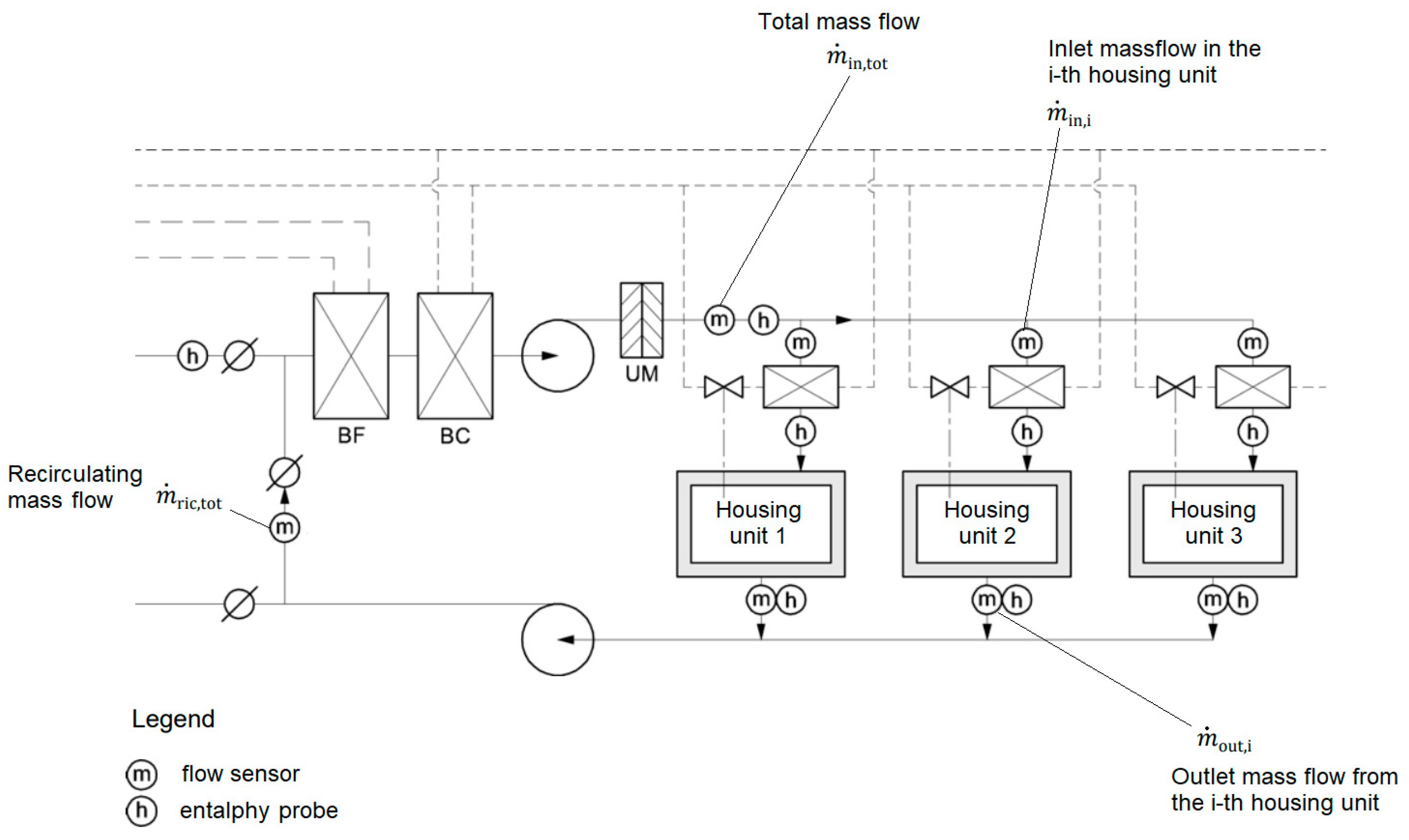

2.1. All-Air Cooling Systems

- Generation system, for the production of cold/hot water;

- An Air Handling Unit (AHU), in which the air undergoes the transformations of cooling, dehumidification, and post-heating;

- Air delivery systems;

- Inlet and extraction vents.

- (a)

- All-air system with dedicated AHU for each end-user. In this case, sub-metering consists of measuring the thermal energy on the primary water circuits (hot/cold coils of the AHUs). In addition, the electricity used for auxiliary systems should also be measured.

- (b)

- Variable Air Volume systems, in which a single AHU serves several housing units. Sub-metering requires the measurement of the inlet air flow at each housing unit together with the inlet specific enthalpy. In the case of air recirculation, the relationship between the inlet and recirculated air flow rates should also be known.

- (c)

- Constant Air Volume systems, in which a single AHU serves several housing units, as in the previous configuration. Enthalpy of delivery and return of humid air must be measured for sub-metering purposes for each end-user (air flow rate is known and constant).

- (d)

- Systems with double hot/cold ducts. In this case, thermal power can be measured before (separately) or after the mixing section.

- and [] are the inlet and outlet air mass flow rates, respectively, in the i-th housing unit;

- and [] are the total air mass flow rate introduced and recirculated, respectively;

- and [] are the specific enthalpies of the inlet and outlet air in the i-th housing unit;

- is the specific enthalpy of the outdoor air;

- is the time [h].

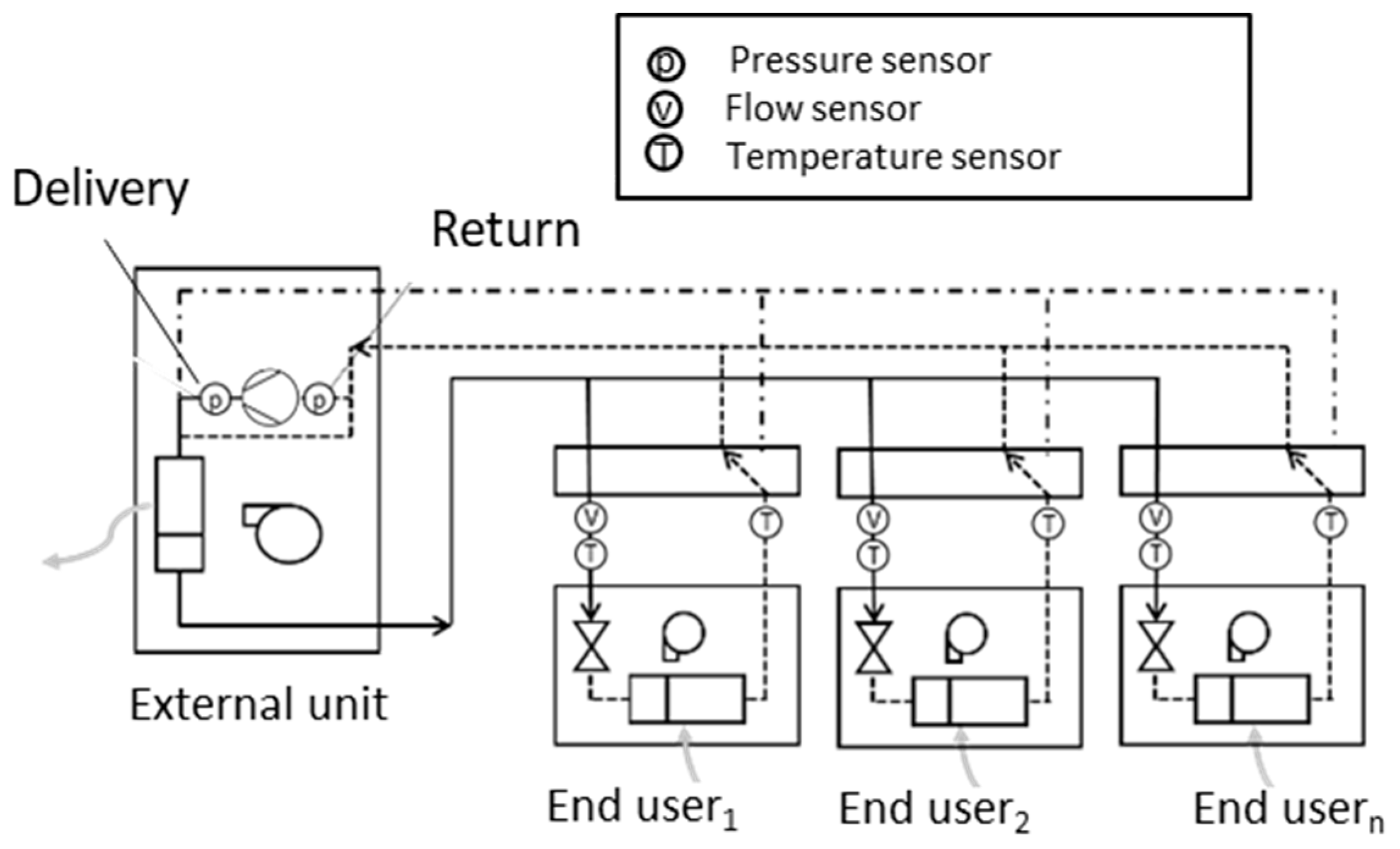

2.2. All-Water Cooling Systems

- Generation system, for the production of cold/hot water;

- Water distribution pipes (two pipes or four pipes to obtain independent circuits for hot and cold water);

- Emission systems. Different terminal units can be used, from the simplest single-coil ones (e.g., fan-coils, convectors, or radiant panels) to multiple-coil units.

- and [K] are the flow and return temperatures, respectively;

- [] is the specific heat (average) of the heat transfer fluid.

- Thermal energy subtracted (cooling and dehumidification);

- Thermal energy provided (heating, post-heating, and humidification).

2.3. Air–Water Cooling Systems

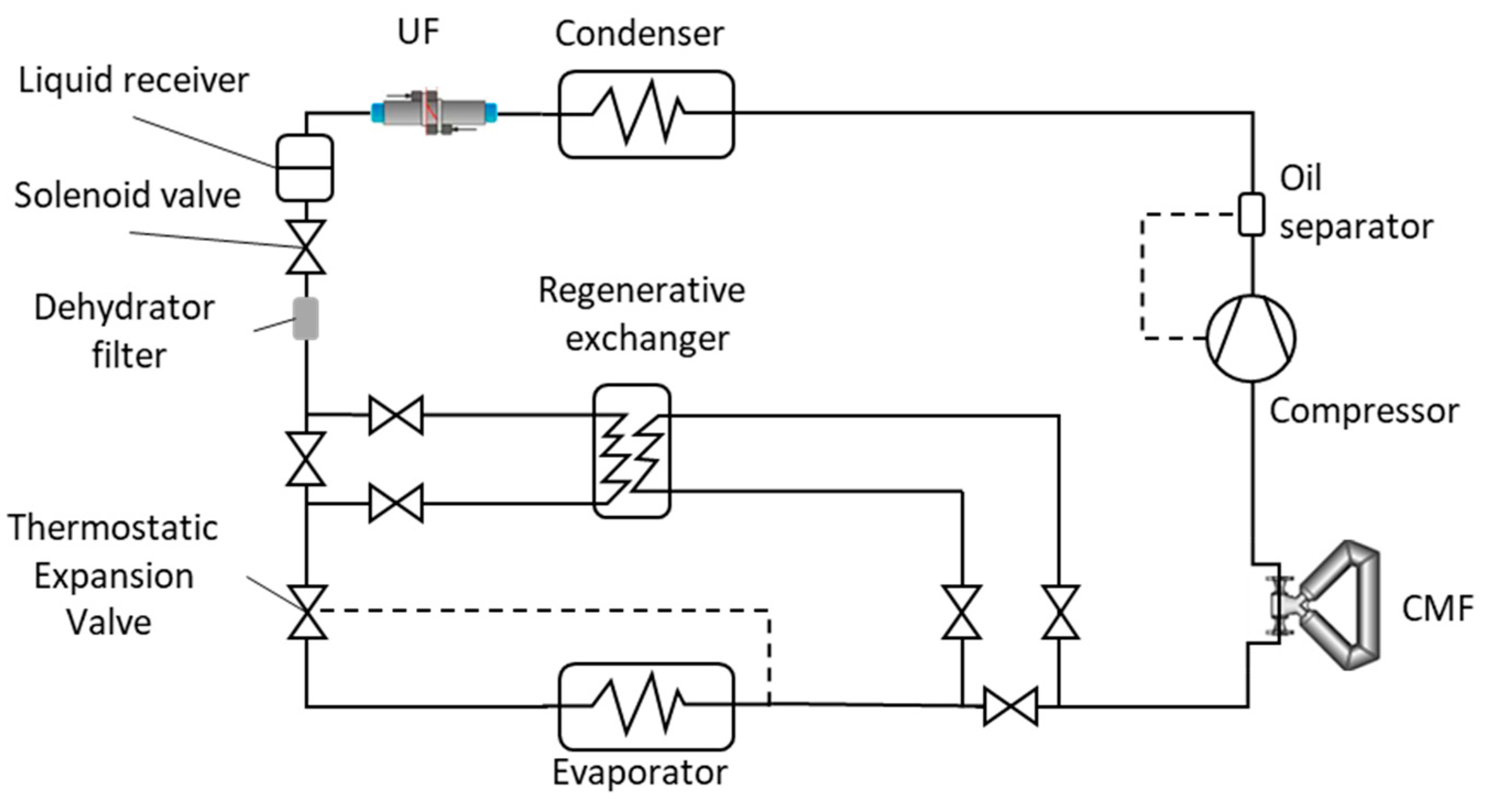

2.4. Direct Expansion Cooling Systems

- An outdoor unit, including the compressor and a heat exchanger, acting as condenser or evaporator in cooling or heating application, respectively;

- Several indoor units, each one including an electronic thermostatic valve, a heat exchanger, a fan, and a diverter valve.

- The refrigerant pressure at the inlet and outlet sections of the compressor;

- The refrigerant temperature at the inlet and outlet sections of the i-th internal unit;

- The refrigerant enthalpy at the inlet and outlet sections of the i-th internal unit;

- The refrigerant density ;

- The refrigerant volume flow rate at the inlet section of the i-th internal unit.

3. Experimental Setup and Tests

- Rotary scroll compressor characterized by a displacement of 10.8 cm3 and able to provide a cooling capacity of 2.55 kW when operating at 220 V (AC) and 50 Hz (single-phase);

- Thermostatic expansion valve with external equalization, with operating temperatures between −40 °C and +10 °C and maximum operating pressures of 45.5 bar;

- Finned-tube evaporator, with a nominal volume air flow rate of 1400 m3/h;

- Finned-tube condenser, with a nominal volume air flow rate of 2200 m3/h;

- Tube-in-tube internal heat exchanger (not used in this experimental campaign);

- 10 mm diameter copper pipes with a thickness of 1 mm;

- R410a as heat transfer fluid.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Global Energy & CO2 Status Report—The Latest Trends in Energy and Emissions in 2018; IEA: Paris, France, 2019. [Google Scholar]

- Yan, D.; Hong, T.; Dong, B.; Mahdavi, A.; D’Oca, S.; Gaetani, I.; Feng, X. IEA EBC Annex 66: Definition and simulation of occupant behavior in buildings. Energy Build. 2017, 156, 258–270. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Directive 2002/91/EC of the European Parliament and of the council of 16 December 2002 on the Energy Performance of Buildings. Off. J. Eur. Commun. 2002, 46, 65–71. [Google Scholar]

- Shaikh, P.H.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Ibrahim, T. A review on optimized control systems for building energy and comfort management of smart sustainable buildings. Renew. Sustain. Energy Rev. 2014, 34, 409–429. [Google Scholar] [CrossRef]

- IEA. Is Cooling the Future of Heating? IEA: Paris, France, 2020; Available online: https://www.iea.org/commentaries/is-cooling-the-future-of-heating (accessed on 1 June 2023).

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Costa, A.; Keane, M.M.; Torrens, J.I.; Corry, E. Building operation and energy performance: Monitoring, analysis and optimisation toolkit. Appl. Energy 2013, 101, 310–316. [Google Scholar] [CrossRef]

- Szczurek, A.; Dolega, A.; Maciejewska, M. Profile of occupant activity impact on indoor air—Method of its determination. Energy Build. 2018, 158, 1564–1575. [Google Scholar] [CrossRef]

- Klein, L.; Kwak, J.; Kavulya, G.; Jazizadeh, F.; Becerik-Gerber, B.; Varakantham, P.; Tambe, M. Coordinating occupant behavior for building energy and comfort management using multi-agent systems. Autom Constr. 2012, 22, 525–536. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Cooling Opportunities for Energy-Efficient Air Conditioning Together Secure Sustainable, n.d. Available online: www.iea.org/t&c/ (accessed on 1 June 2023).

- Mugnini, A.; Coccia, G.; Polonara, F.; Arteconi, A. Potential of district cooling systems: A case study on recovering cold energy from liquefied natural gas vaporization. Energies 2019, 14, 3027. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Council Directive Directive 93/76/EEC of 13 September 1993 to Limit Carbon Dioxide Emissions by Improving Energy Efficiency (SAVE). Off. J. L 1993, 237, 28–30. [Google Scholar]

- European Commission. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Off. J. Eur. Union 2010, 18, 2010. [Google Scholar]

- European Commission. Commission Staff Working Document Guidance Note on Directive 2012/27/EU on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EC, and Repealing Directives 2004/8/EC and 2006/32/EC; Official Journal of the European Union: Luxembourg, 2013.

- EN 15459; Energy Performance of Buildings—Economic Evaluation Procedure for Energy Systems in Buildings. European Committee for Standardization: Brussels, Belgium, 2007.

- Zheng, M.; Fang, R.; Yu, Z. Life Cycle Assessment of Residential Heating Systems: A Comparison of Distributed and Centralized Systems. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 287–292. [Google Scholar] [CrossRef]

- Hong, T.; Yan, D.; D’Oca, S.; Chen, C.F. Ten questions concerning occupant behavior in buildings: The big picture. Build. Environ. 2017, 114, 518–530. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Saeidi, S.; Rizzuto, T.; Roetzel, A.; Kooima, R. Potential and challenges of immersive virtual environments for occupant energy behavior modeling and validation: A literature review. J. Build. Eng. 2018, 19, 302–319. [Google Scholar] [CrossRef]

- Janda, K.B. Buildings don’t use energy: People do. Archit. Sci. Rev. 2011, 54, 15–22. [Google Scholar] [CrossRef]

- Carlsson, A.; Engström, C.; Jönsson, B. Individual metering and charging in existing buildings. Report 2015, 34, 538. [Google Scholar]

- Department of Energy and Climate Change (DECC). The Metering and Billing of District Heating, District Cooling, and Communal Heating and Hot Water Systems—Government Response to the ‘Implementing the Energy Efficiency Directive as It Applies to the Metering and Billing of Heating and Cooling’ Consultation. 2014. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/379049/EED_Government_response_-_261114_version.pdf (accessed on 30 April 2023).

- European Commission. Directive 2014/32/EU of the European Parliament and of the Council of 26 February 2014 on the Harmonisation of the Laws of the Member States relating to the Making Available on the Market of Measuring Instruments (Recast). Off. J. L 2014, 96, 149. [Google Scholar]

- Ficco, G.; Frattolillo, A.; Malengo, A.; Puglisi, G.; Saba, F.; Zuena, F. Field verification of thermal energy meters through ultrasonic clamp-on master meters. Measurement 2020, 151, 107152. [Google Scholar] [CrossRef]

- Dell’Isola, M.; Ficco, G.; Arpino, F.; Cortellessa, G.; Canale, L. A novel model for the evaluation of heat accounting systems reliability in residential buildings. Energy Build. 2017, 150, 281–293. [Google Scholar] [CrossRef]

- Ficco, G.; Canale, L.; Lanza, L.; Malengo, A.; Saba, F.; Dell’Isola, M. On the metrological reliability of subsequent verification of thermal energy meters. Measurement 2023, 216, 112898. [Google Scholar] [CrossRef]

- Canale, L.; Dell’Isola, M.; Ficco, G.; Di Pietra, B.; Frattolillo, A. Estimating the impact of heat accounting on Italian residential energy consumption in different scenarios. Energy Build. 2018, 168, 385–398. [Google Scholar] [CrossRef]

- Cholewa, T.; Siuta-Olcha, A. Long term experimental evaluation of the influence of heat cost allocators on energy consumption in a multifamily building. Energy Build. 2015, 104, 122–130. [Google Scholar] [CrossRef]

- Dell’Isola, M.; Ficco, G.; Canale, L.; Frattolillo, A.; Bertini, I. A new heat cost allocation method for social housing. Energy Build. 2018, 172, 67–77. [Google Scholar] [CrossRef]

- She, X.; Cong, L.; Nie, B.; Leng, G.; Peng, H.; Chen, Y.; Zhang, X.; Wen, T.; Yang, H.; Luo, Y. Energy-efficient and -economic technologies for air conditioning with vapor compression refrigeration: A comprehensive review. Appl. Energy 2018, 232, 157–186. [Google Scholar] [CrossRef]

- Aprea, C.; Ceglia, F.; Llopis, R.; Maiorino, A.; Marrasso, E.; Petruzziello, F.; Sasso, M. Expanded Total Equivalent Warming Impact analysis on experimental standalone fresh-food refrigerator. Energy Convers. Manag. X 2022, 15, 100262. [Google Scholar] [CrossRef]

- Aprea, C.; Maiorino, A. An experimental investigation of the global environmental impact of the R22 retrofit with R422D. Energy 2011, 36, 1161–1170. [Google Scholar] [CrossRef]

- Prabakaran, R.; Sivalingam, V.; Kim, S.C.; Kumar, P.G.; Kumar, G.P. Future refrigerants with low global warming potential for residential air conditioning system: A thermodynamic analysis and MCDM tool optimization. Environ. Sci. Pollut. Res. 2022, 29, 78414–78428. [Google Scholar] [CrossRef]

- Nair, V. HFO refrigerants: A review of present status and future prospects. Int. J. Refrig. 2021, 122, 156–170. [Google Scholar] [CrossRef]

- Zhao, D.; Zhong, M.; Zhang, X.; Su, X. Energy consumption predicting model of VRV (Variable refrigerant volume) system in office buildings based on data mining. Energy 2016, 102, 660–668. [Google Scholar] [CrossRef]

- Yu, X.; Yan, D.; Sun, K.; Hong, T.; Zhu, D. Comparative study of the cooling energy performance of variable refrigerant flow systems and variable air volume systems in office buildings. Appl. Energy 2016, 183, 725–736. [Google Scholar] [CrossRef] [Green Version]

- Kwon, L.; Hwang, Y.; Radermacher, R.; Kim, B. Field performance measurements of a VRF system with sub-cooler in educational offices for the cooling season. Energy Build. 2012, 49, 300–305. [Google Scholar] [CrossRef]

- Aynur, T.N.; Hwang, Y.; Radermacher, R. Experimental evaluation of the ventilation effect on the performance of a vrv system in cooling mode—Part I: Experimental evaluation. HVAC R Res. 2008, 14, 615–630. [Google Scholar] [CrossRef]

- Sekine, N.; Furuhashi, Y.; Kametani, S. The Simple Performance Evaluation Method of VRF System Using Volumetric Efficiency of Compressor. In International Refrigeration and Air Conditioning Conference; Rurdue University: West Lafayette, IN, USA, 2012. [Google Scholar]

- Xiao, H.; Yang, Z.; Shi, J.; Wang, B.; Shi, W. Methods for performance metering of indoor units in variable refrigerant flow systems based on built-in sensors. Appl. Therm. Eng. 2021, 196, 117268. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Ian, H.B.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.0; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. [CrossRef]

- Cheong, K.-H.; Furuichi, N.; Doihara, R.; Kamazawa, S.; Kasai, S.; Hosobuchi, N. A comparison between a Coriolis meter and a combination method of a volumetric positive-displacement flowmeter and a densitometer in measuring liquid fuel mass flow at low flow rates. Meas. Sens. 2021, 18, 100321. [Google Scholar] [CrossRef]

- Leontidis, V.; Cuvier, C.; Caignaert, G.; Dupont, P.; Roussette, O.; Fammery, S.; Nivet, P.; Dazin, A. Experimental validation of an ultrasonic flowmeter for unsteady flows. Meas. Sci. Technol. 2018, 29, 045303. [Google Scholar] [CrossRef] [Green Version]

- EN 1434-1; Thermal Energy Meters—Part 1: General Requirements n.d. European Standard: Plzen, Czech, 2022.

- JCGM—Joint Committee for Guides. In Metrology, JCGM 100:2008—Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement; JCGM: Glasgow, Scotland, 2008.

- ISO/IEC 17043:2010; Conformity Assessment—General Requirements for Proficiency Testing. International Organisation for Standardization: Geneva, Switzerland, 2010.

| Type | Metering System (Generator) | Sub-Metering System (Terminal Units) |

|---|---|---|

| All-air cooling system |

|

|

| All-water cooling system |

|

|

| Air–water cooling system | As mixed cooling systems consist of both air- and water-based components, a combination of metering and sub-metering devices related to all-air and all-water systems is required. | |

| Direct expansion cooling system |

|

|

| Test | Indoor Air Temperature | Outdoor Air Temperature | Compressor Frequency |

|---|---|---|---|

| 23/29 °C | 23 °C | 29 °C | 30 Hz |

| 40 Hz | |||

| 50 Hz | |||

| 20/35 °C | 20 °C | 35 °C | 30 Hz |

| 40 Hz | |||

| 50 Hz |

| Indoor Air Temperature | Outdoor Air Temperature | Compressor Frequency | #Test | n | CMF [kg/min] | UF [kg/min] | RE [%] | ||

|---|---|---|---|---|---|---|---|---|---|

| Avg. | Std. Dev. | Avg. | Std. Dev. | ||||||

| 23 °C | 29 °C | 30 Hz | #1 | 155 | 0.542 | 0.012 | 0.503 | 0.040 | −7% |

| #2 | 181 | 0.553 | 0.005 | 0.509 | 0.038 | −8% | |||

| #3 | 197 | 0.557 | 0.005 | 0.655 | 0.063 | +18% | |||

| 40 Hz | #4 | 189 | 0.681 | 0.029 | 0.762 | 0.085 | +12% | ||

| #5 | 218 | 0.693 | 0.008 | 0.729 | 0.123 | +5% | |||

| #6 | 238 | 0.694 | 0.007 | 0.722 | 0.098 | +4% | |||

| 50 Hz | #7 | 234 | 0.817 | 0.000 | 0.844 | 0.096 | +4% | ||

| #8 | 214 | 0.814 | 0.004 | 0.822 | 0.088 | +1% | |||

| #9 | 254 | 0.814 | 0.005 | 0.810 | 0.050 | −1% | |||

| 20 °C | 35 °C | 30 Hz | #10 | 169 | 0.515 | 0.003 | 0.482 | 0.036 | −6% |

| #11 | 160 | 0.516 | 0.003 | 0.494 | 0.036 | −4% | |||

| #12 | 158 | 0.514 | 0.004 | 0.644 | 0.054 | +26% | |||

| 40 Hz | #13 | 200 | 0.656 | 0.004 | 0.664 | 0.110 | +1% | ||

| #14 | 216 | 0.655 | 0.005 | 0.639 | 0.053 | −2% | |||

| #15 | 209 | 0.659 | 0.005 | 0.793 | 0.061 | +20% | |||

| 50 Hz | #16 | 374 | 0.761 | 0.004 | 0.763 | 0.077 | +0% | ||

| #17 | 236 | 0.768 | 0.004 | 0.699 | 0.050 | −9% | |||

| #18 | 352 | 0.762 | 0.005 | 0.865 | 0.053 | +14% | |||

| Test | Compressor Frequency [Hz] | CMF [kg/min] | [kg/min] | UF [kg/min] | [kg/min] | RE [%] | |

|---|---|---|---|---|---|---|---|

| 23–29 °C | 30 | 0.551 | 0.001 | 0.556 | 0.010 | 0.9 | 0.489 |

| 40 | 0.689 | 0.002 | 0.738 | 0.015 | 7.0 | 3.301 | |

| 50 | 0.815 | 0.002 | 0.826 | 0.015 | 1.3 | 0.689 | |

| 20–35 °C | 30 | 0.515 | 0.001 | 0.540 | 0.010 | 4.8 | 2.494 |

| 40 | 0.657 | 0.001 | 0.699 | 0.013 | 6.4 | 3.158 | |

| 50 | 0.763 | 0.002 | 0.776 | 0.014 | 1.6 | 0.880 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aprea, C.; Canale, L.; Dell’Isola, M.; Ficco, G.; Frattolillo, A.; Maiorino, A.; Petruzziello, F. On the Use of Ultrasonic Flowmeters for Cooling Energy Metering and Sub-Metering in Direct Expansion Systems. Energies 2023, 16, 4775. https://doi.org/10.3390/en16124775

Aprea C, Canale L, Dell’Isola M, Ficco G, Frattolillo A, Maiorino A, Petruzziello F. On the Use of Ultrasonic Flowmeters for Cooling Energy Metering and Sub-Metering in Direct Expansion Systems. Energies. 2023; 16(12):4775. https://doi.org/10.3390/en16124775

Chicago/Turabian StyleAprea, Ciro, Laura Canale, Marco Dell’Isola, Giorgio Ficco, Andrea Frattolillo, Angelo Maiorino, and Fabio Petruzziello. 2023. "On the Use of Ultrasonic Flowmeters for Cooling Energy Metering and Sub-Metering in Direct Expansion Systems" Energies 16, no. 12: 4775. https://doi.org/10.3390/en16124775