Retrofit of a 600 MW Down-Fired Pulverized-Coal Furnace for Low NOx Emission

Abstract

:1. Introduction

2. Methodology

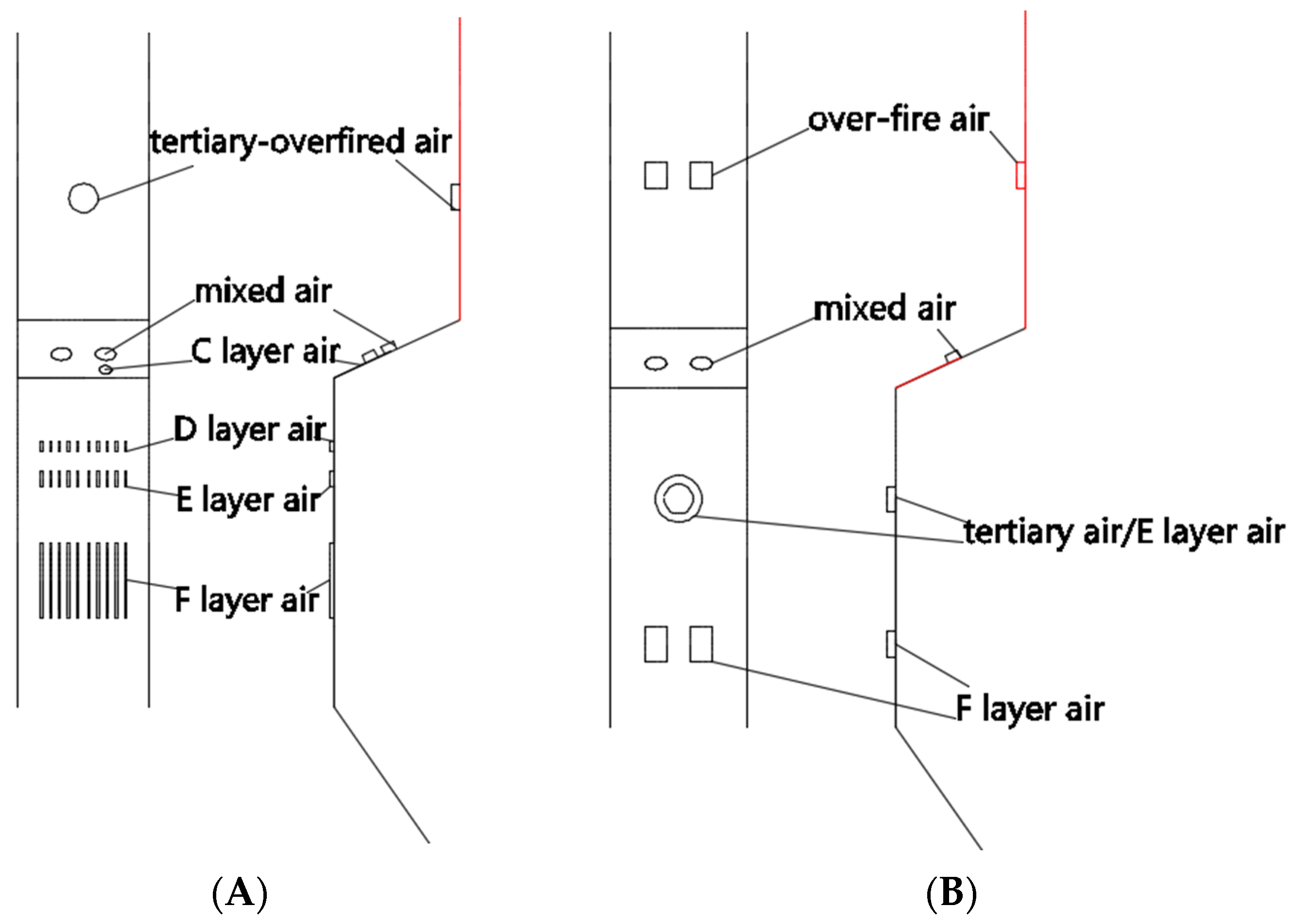

2.1. Original Combustion System

2.2. New Combustion System

2.3. Numerical Simulation

3. Results and Discussion

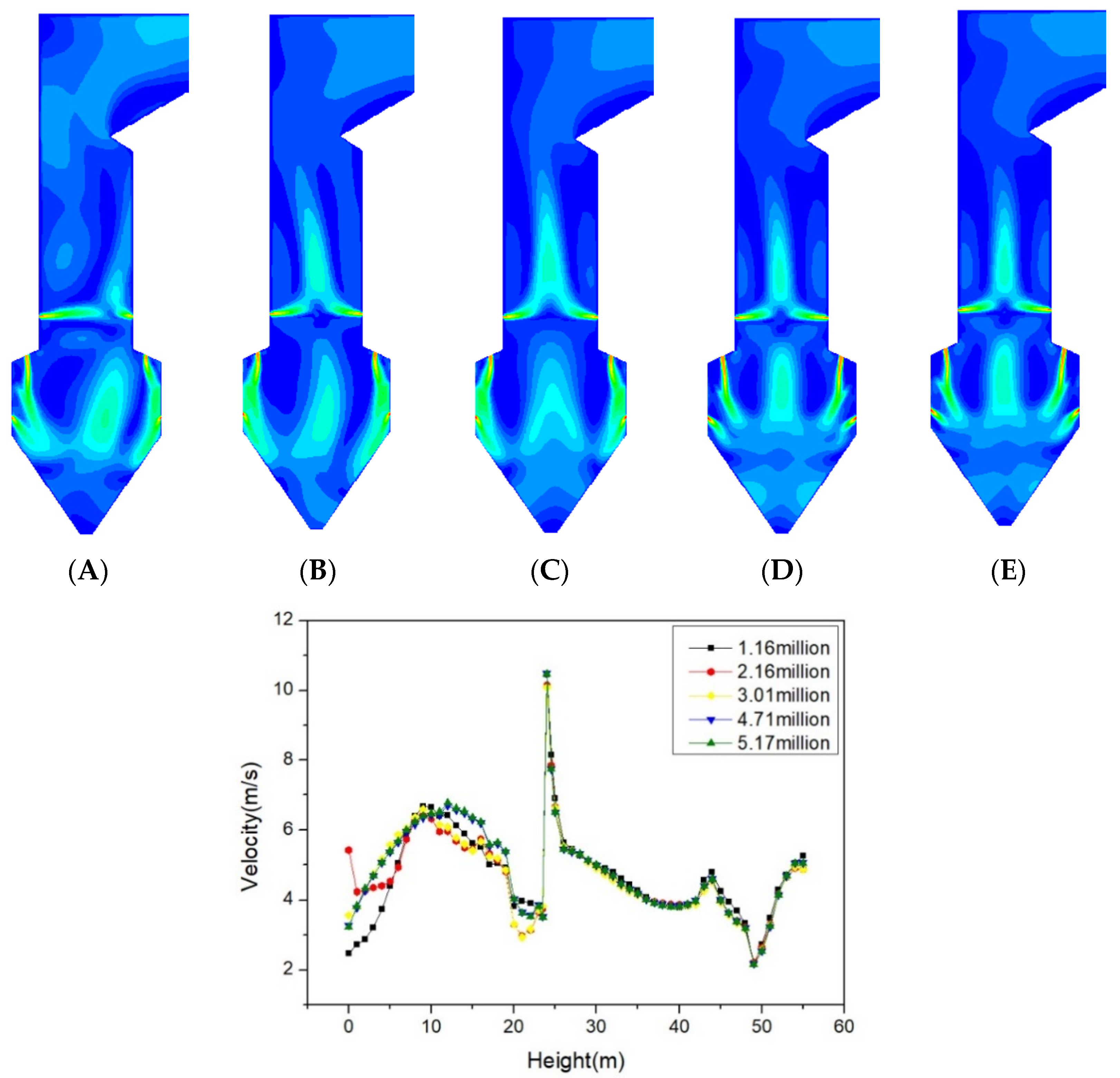

3.1. Verification of Numerical Simulation Reliability

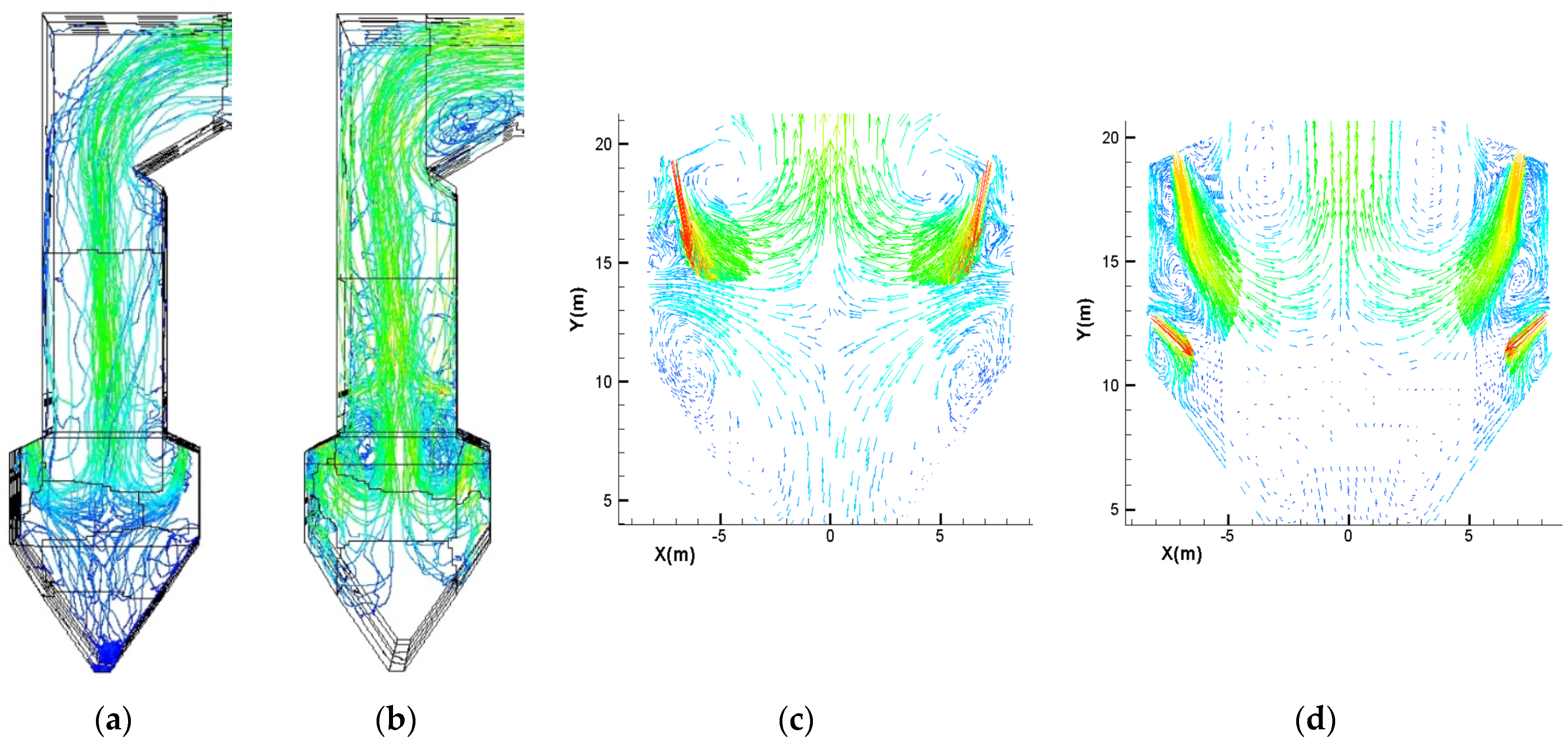

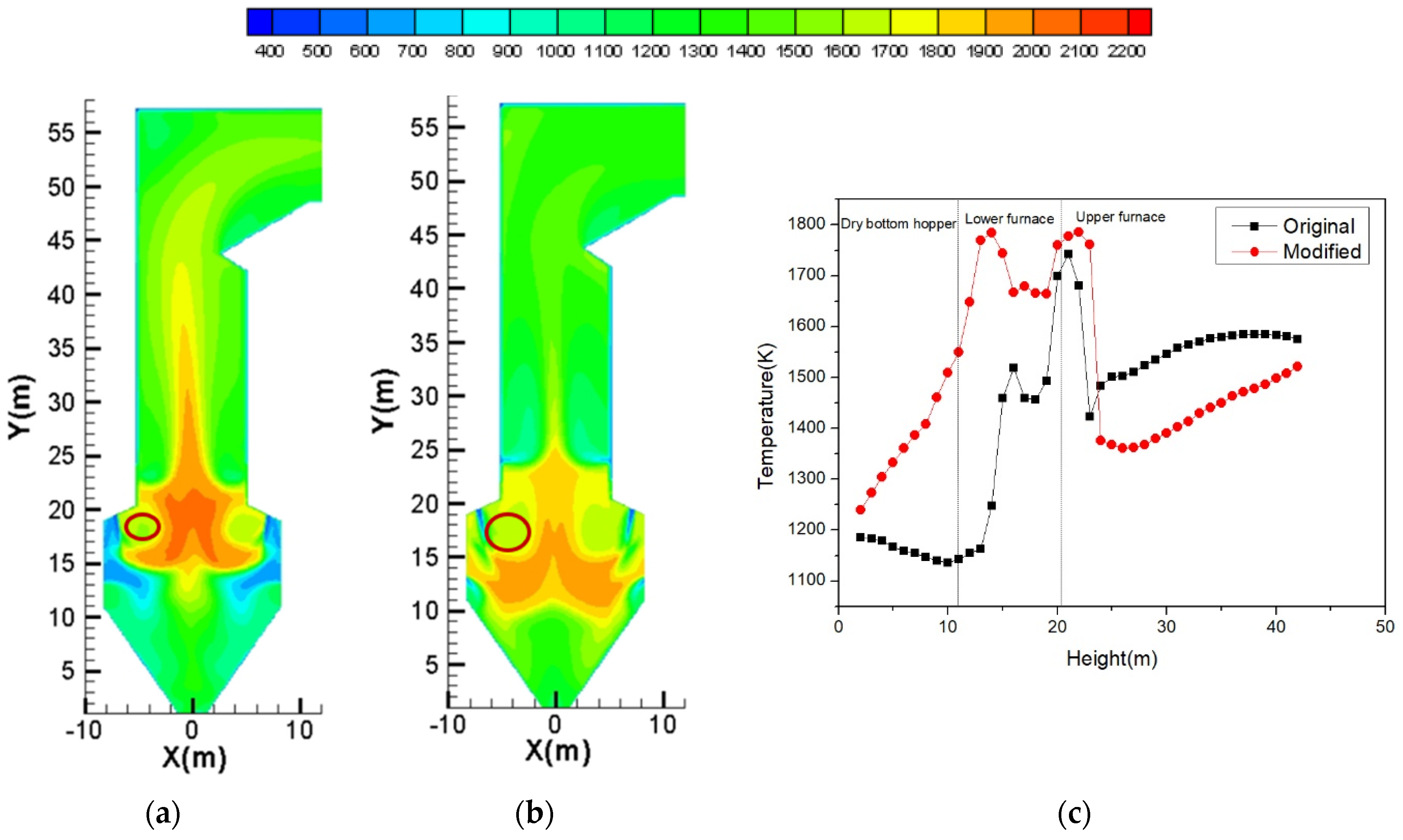

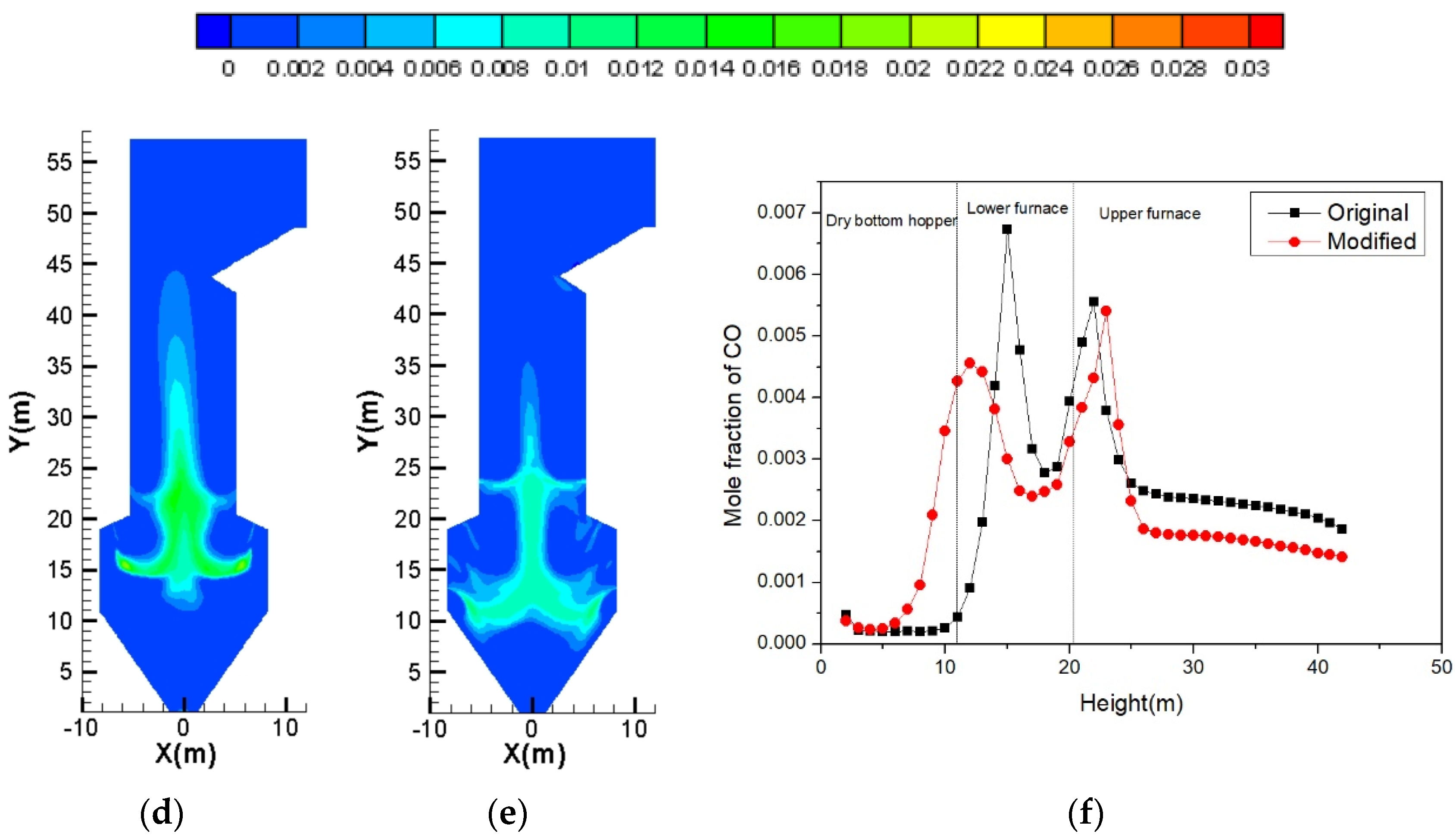

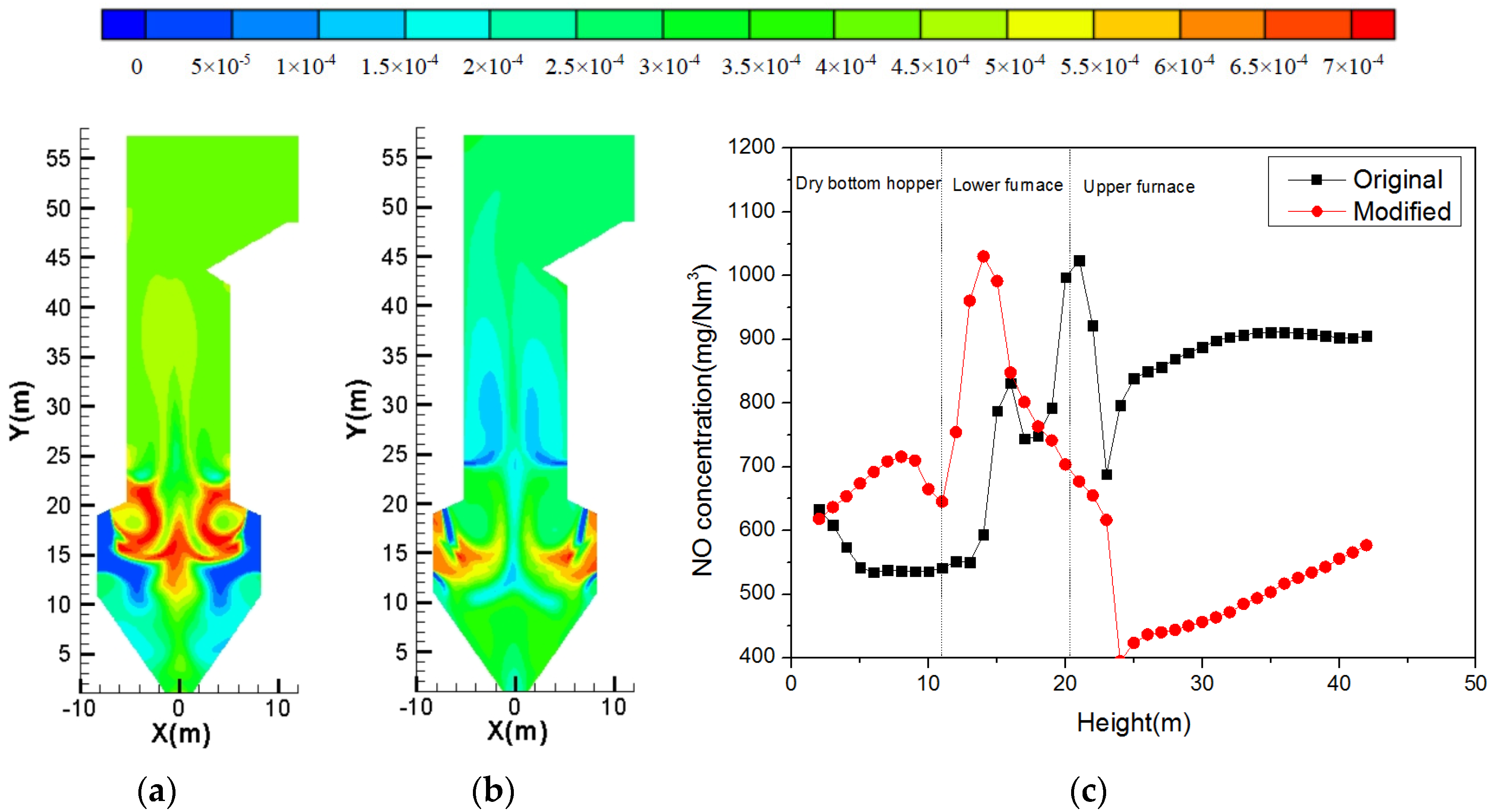

3.2. Simulation on New Combustion System

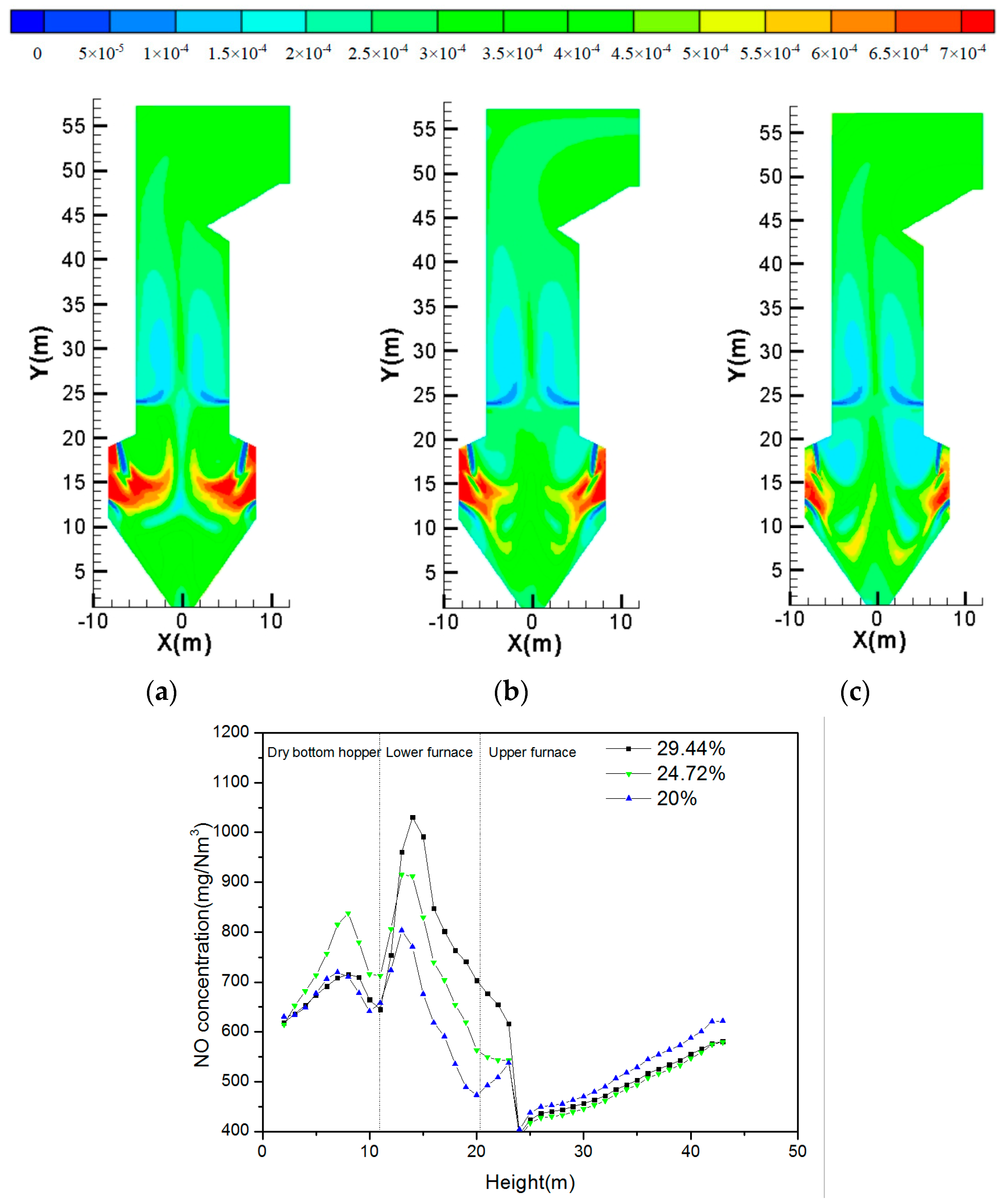

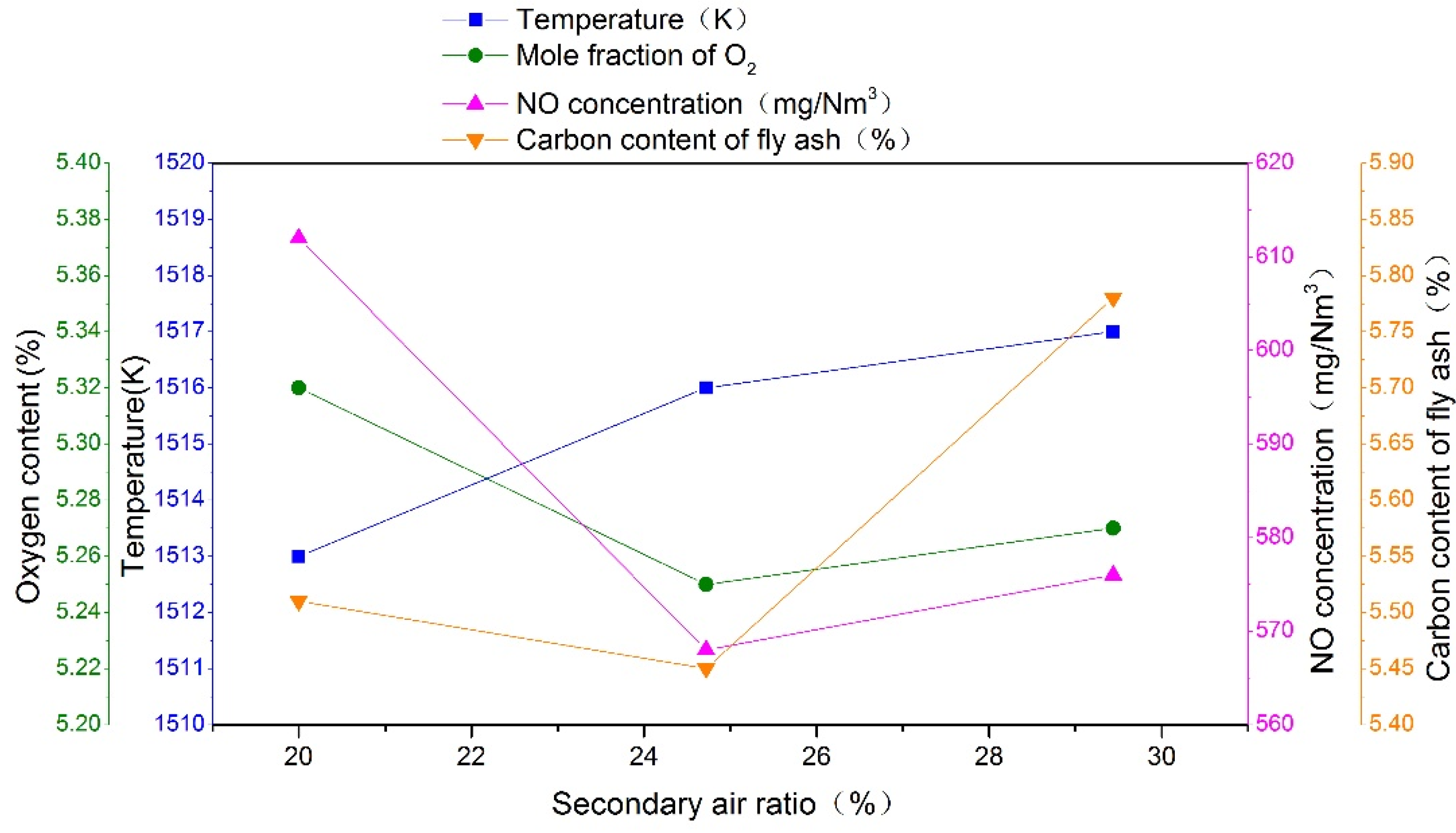

3.3. The Air Distribution of F-Layer and Arch

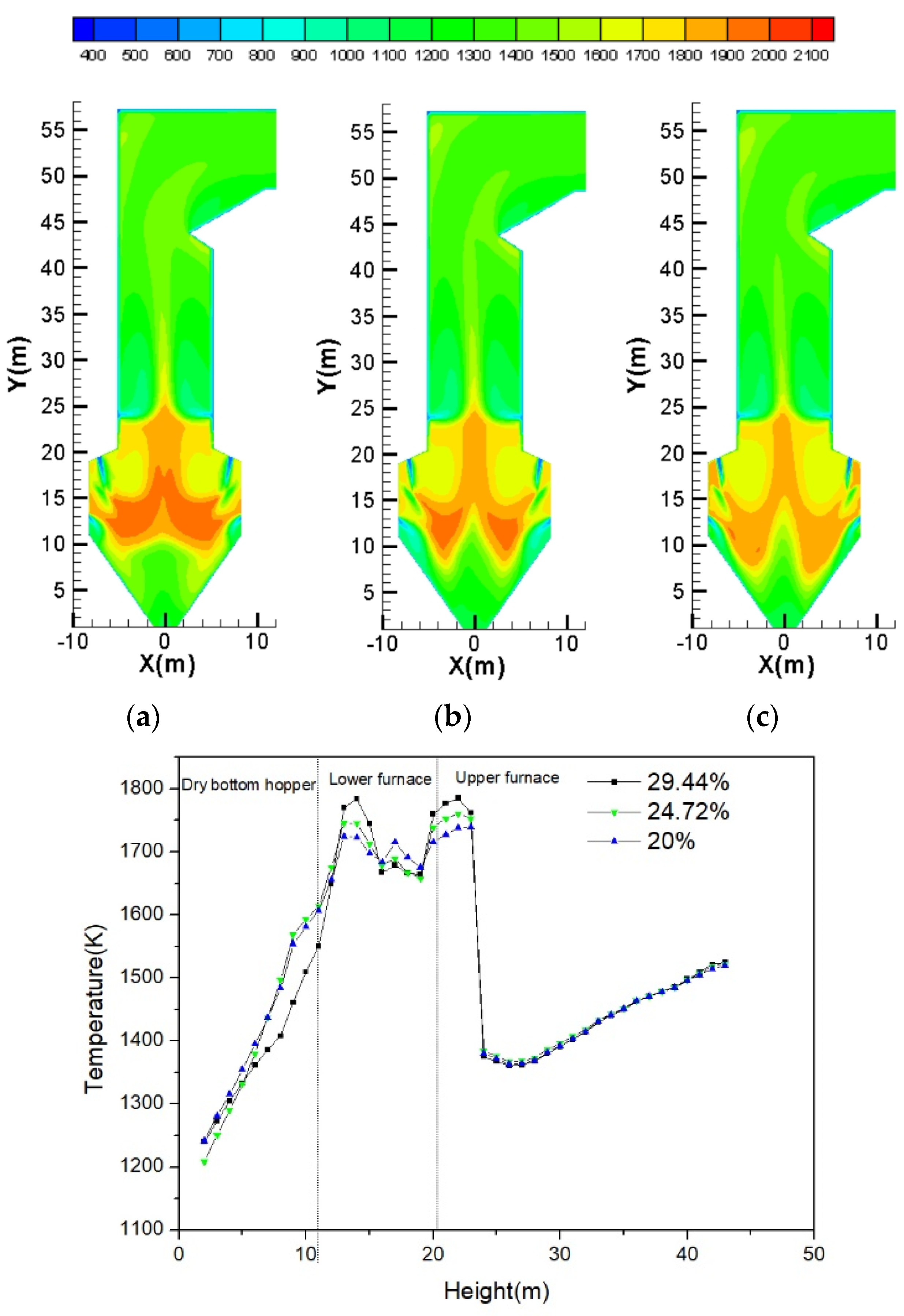

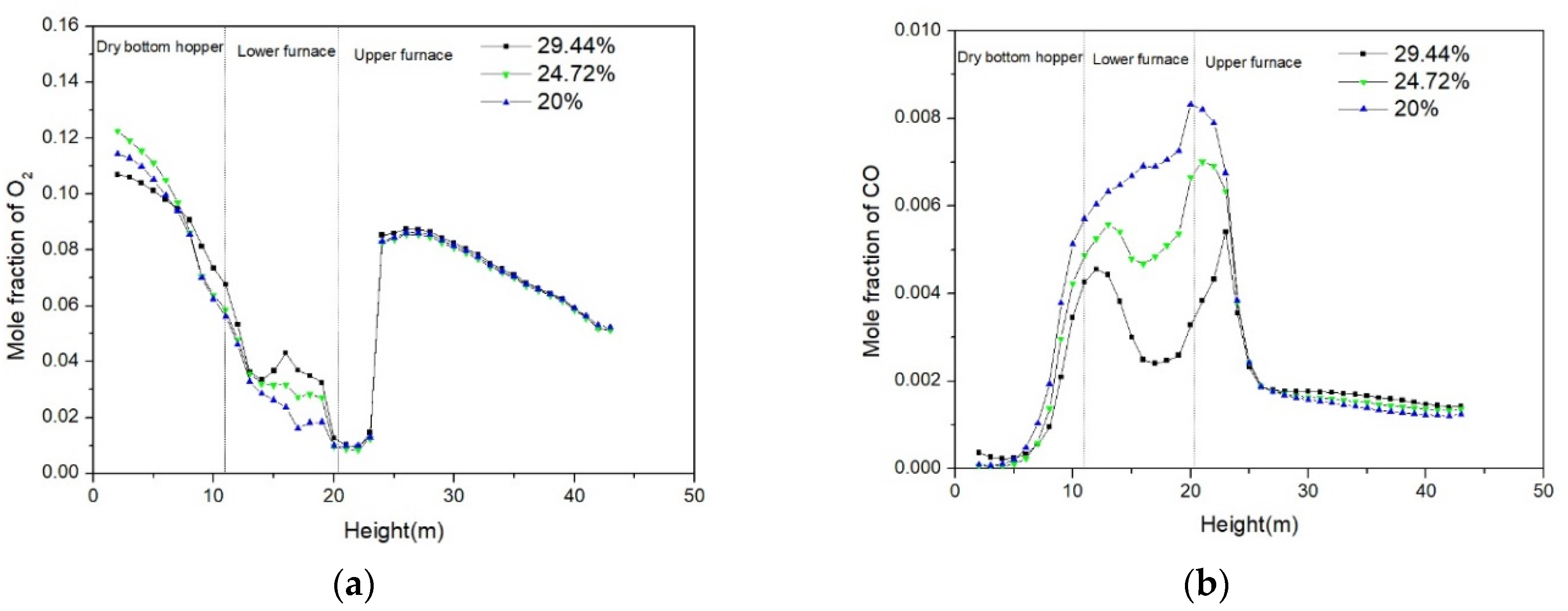

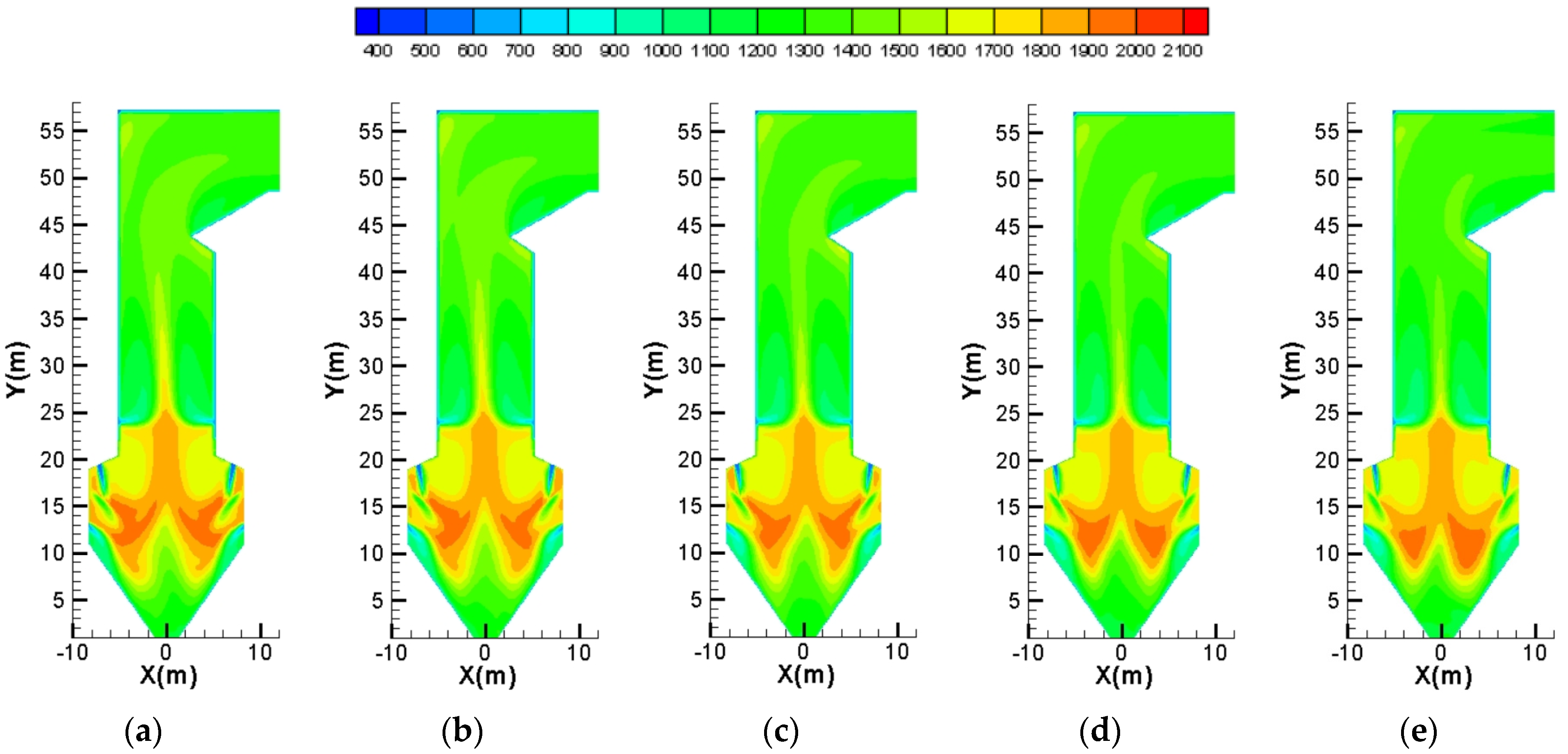

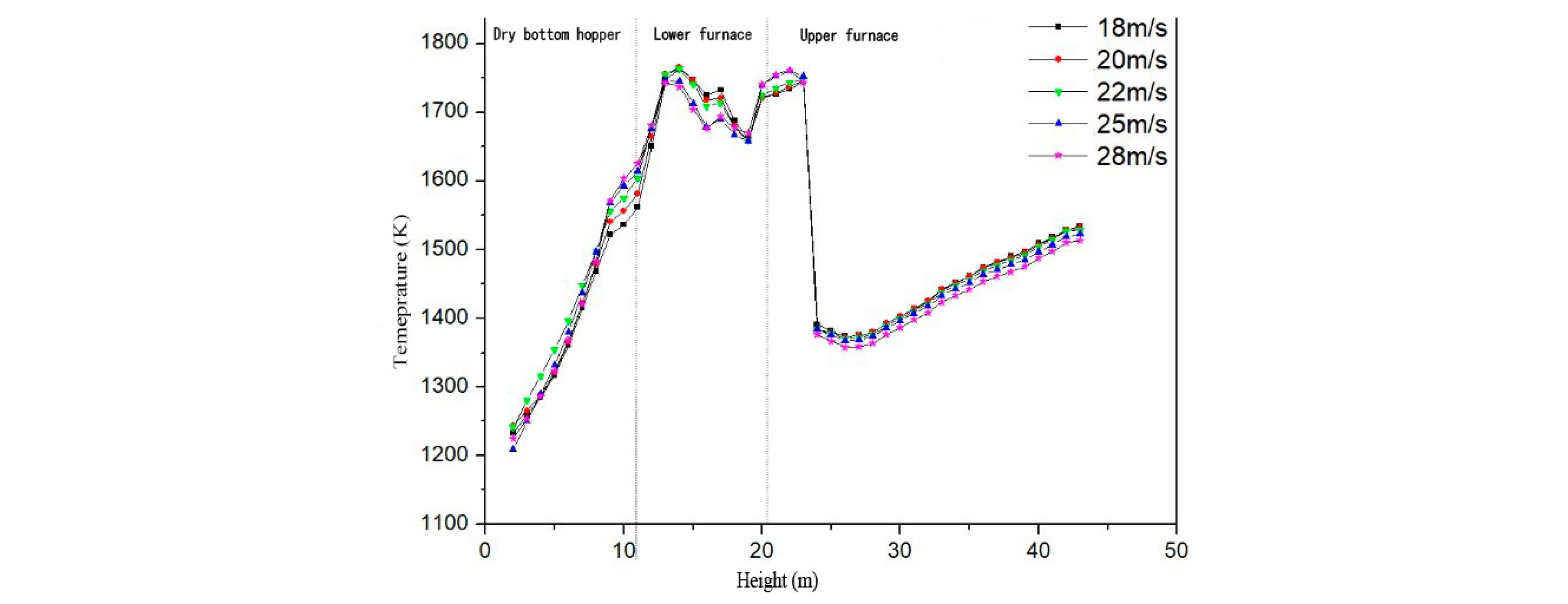

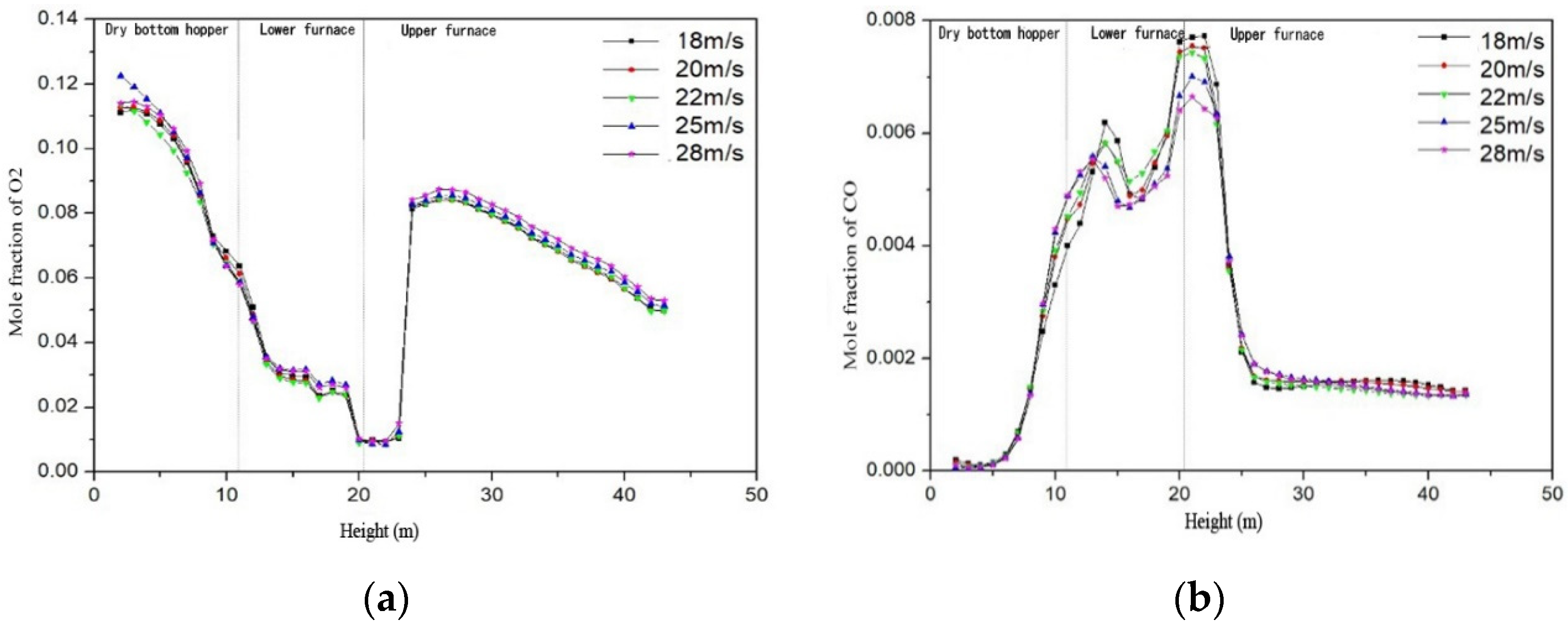

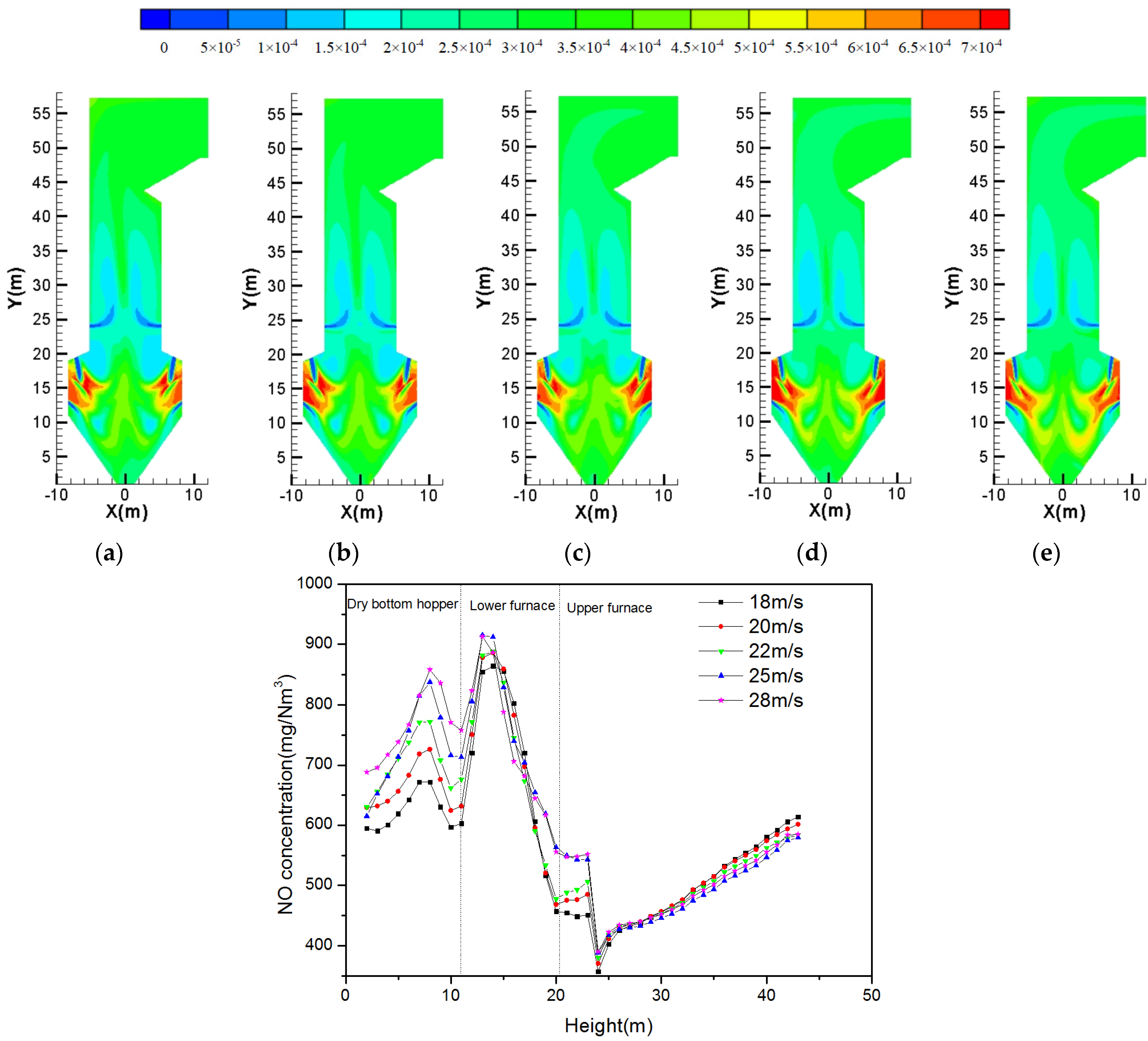

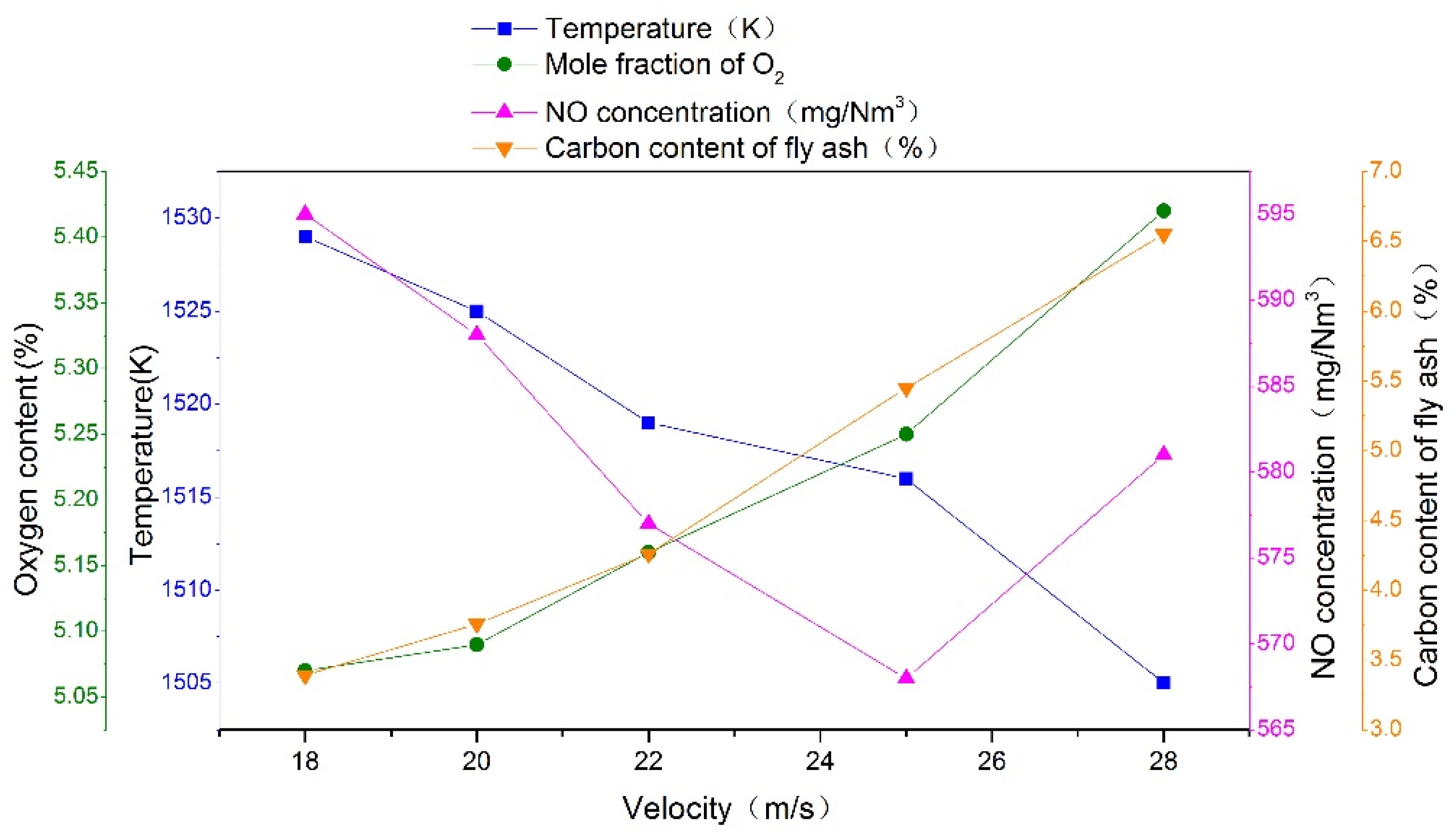

3.4. The Influence of Velocity of Arch Airflow

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pui, D.Y.H.; Chen, S.-C.; Zuo, Z. PM 2.5 in China: Measurements, sources, visibility and health effects, and mitigation. Particuology 2014, 13, 1–26. [Google Scholar] [CrossRef]

- Kuang, M.; Li, Z.; Liu, C.; Zhu, Q.; Zhang, Y.; Wang, Y. Evaluation of overfire air behavior for a down-fired 350 MWe utility boiler with multiple injection and multiple staging. Appl. Therm. Eng. 2012, 48, 164–175. [Google Scholar] [CrossRef]

- Li, S.; Chen, Z.; He, E.; Jiang, B.; Li, Z.; Wang, Q. Combustion characteristics and NO x formation of a retrofitted low-volatile coal-fired 330 MW utility boiler under various loads with deep-air-staging. Appl. Therm. Eng. 2017, 110, 223–233. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, R.; Yang, F.; Cheng, F. Numerical simulation on optimization of structure and operating parameters of a novel lean coal decoupling burner. Chin. J. Chem. Eng. 2020, 28, 2890–2899. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, H.; Zhou, H.; Lei, L.; Duan, X. Improving the Performance of a 300 MW Down-Fired Pulverized-Coal Utility Boiler by Inclining Downward the F-Layer Secondary Air. Energy Fuels 2010, 24, 4857–4865. [Google Scholar] [CrossRef]

- Kuang, M.; Li, Z. Review of gas/particle flow, coal combustion, and NOx emission characteristics within down-fired boilers. Energy 2014, 69, 144–178. [Google Scholar] [CrossRef]

- Song, M.; Zeng, L.; Yang, X.; Chen, Z.; Li, Z. Influence of the mass ratio of pulverized-coal in fuel-rich flow to that in fuel-lean flow on the gas/particle flow and particle distribution characteristics in a 600 MWe down-fired boiler. Exp. Therm. Fluid Sci. 2018, 91, 363–373. [Google Scholar] [CrossRef]

- Ma, L.; Fang, Q.; Lv, D.; Zhang, C.; Chen, Y.; Chen, G.; Duan, X.; Wang, X. Reducing NOx Emissions for a 600 MWe Down-Fired Pulverized-Coal Utility Boiler by Applying a Novel Combustion System. Environ. Sci. Technol. 2015, 49, 13040–13049. [Google Scholar] [CrossRef]

- Ma, L.; Fang, Q.; Tan, P.; Zhang, C.; Chen, G.; Lv, D.; Duan, X.; Chen, Y. Effect of the separated overfire air location on the combustion optimization and NO reduction of a 600 MW FW down-fired utility boiler with a novel combustion system. Appl. Energy 2016, 180, 104–115. [Google Scholar] [CrossRef]

- Ma, L.; Yu, S.; Fang, Q.; Zhang, C.; Chen, G. Effect of separated over-fire air angle on combustion and NOx emissions in a down-fired utility boiler with a novel combustion system. Process Saf. Environ. Prot. 2020, 138, 57–66. [Google Scholar] [CrossRef]

- Chen, T.; Zhou, Y.; Wang, B.; Deng, W.; Song, Z.; Li, W.; Yang, W.; Sun, L. Investigations on combustion optimization and NOX reduction of a 600-MWe down-fired boiler: Influence of rearrangement of tertiary air and jet angle of secondary air and separated over-fire air. J. Clean. Prod. 2020, 277, 124310. [Google Scholar] [CrossRef]

- Li, X.; Zeng, L.; Liu, H.; Du, H.; Yang, X.; Han, H.; Liu, W.; Zhang, S.; Song, M.; Chen, Z.; et al. Numerical simulation study on the influences of the secondary-tertiary air proportion on the airflow mixing effects and pulverized coal combustion characteristics in a 300-MW down-fired boiler. Process Saf. Environ. Prot. 2019, 130, 326–343. [Google Scholar] [CrossRef]

- Liu, G.; Chen, Z.; Li, Z.; Li, G.; Zong, Q. Numerical simulations of flow, combustion characteristics, and NO x emission for down-fired boiler with different arch-supplied over-fire air ratios. Appl. Therm. Eng. 2015, 75, 1034–1045. [Google Scholar] [CrossRef]

- Ren, F.; Li, Z.; Zeng, L.; Chen, Z.; Zhu, Q. Numerical Simulation of Flow, Combustion, and NOxEmission Characteristics in a 300 MW Down-Fired Boiler with Different OFA Ratios. Numer. Heat Transf. Part A Appl. 2012, 62, 231–249. [Google Scholar] [CrossRef]

- Song, M.; Zeng, L.; Li, X.; Liu, Y.; Chen, Z.; Li, Z. Effects of tertiary air damper opening on flow, combustion and hopper near-wall temperature of a 600 MWe down-fired boiler with improved multiple-injection multiple-staging technology. J. Energy Inst. 2018, 91, 573–583. [Google Scholar] [CrossRef]

- Song, M.; Zeng, L.; Zhao, Y.; Pei, J.; Li, Z. Secondary air distribution in a 600 MWe multi-injection multi-staging down-fired boiler: A comprehensive study. J. Energy Inst. 2020, 93, 1250–1260. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Han, H.; Tu, Y.; Liu, G.; Zeng, L.; Li, Z. Detailed gas/particle flow characteristics of an improved down-fired boiler with respect to a critical factor affecting coal burnout: Vent-air inclination angle. Energy 2019, 182, 570–584. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Han, H.; Zeng, L.; Li, Z. Experimental characterization of anthracite combustion and NO emission for a 300-MWe down-fired boiler with a novel combustion system: Influence of primary and vent air distributions. Appl. Energy 2019, 238, 1551–1562. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Li, L.; Zeng, L.; Li, Z. Achievement in ultra-low-load combustion stability for an anthracite- and down-fired boiler after applying novel swirl burners: From laboratory experiments to industrial applications. Energy 2020, 192, 116623. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Fang, Q.; Musa, A.A.B.; Wei, Y.; Luo, Z.; Zhou, H. Numerical Simulation of Multifuel Combustion in a 200 MW Tangentially Fired Utility Boiler. Energy Fuels 2011, 26, 313–323. [Google Scholar] [CrossRef]

- Truelove, J.S. Three-dimensional radiation in absorbing-emitting-scattering media using the discrete-ordinates approximation. J. Quant. Spectrosc. Radiat. Transf. 1988, 39, 27–31. [Google Scholar] [CrossRef]

- Kobayashi, H.; Howard, J.B.; Sarofim, A.F. Coal devolatilization at high temperatures. Symp. Int. Combust. 1977, 16, 411–425. [Google Scholar] [CrossRef]

- Sivathanu, Y.R.; Faeth, G.M. Generalized state relationships for scalar properties in nonpremixed hydrocarbon/air flames. Combust. Flame 1990, 82, 211–230. [Google Scholar] [CrossRef]

- Baum, M.M.; Street, P.J. Predicting the Combustion Behaviour of Coal Particles. Combust. Sci. Technol. 1971, 3, 231–243. [Google Scholar] [CrossRef]

- Field, M.A. Rate of combustion of size-graded fractions of char from a low-rank coal between 1 200 °K and 2 000 °K. Combust. Flame 1969, 13, 237–252. [Google Scholar] [CrossRef]

- Ma, L.; Gharebaghi, M.; Porter, R.; Pourkashanian, M.; Jones, J.M.; Williams, A. Modelling methods for co-fired pulverised fuel furnaces. Fuel 2009, 88, 2448–2454. [Google Scholar] [CrossRef]

- De Soete, G.G. Overall reaction rates of NO and N2 formation from fuel nitrogen. Symp. Int. Combust. 1975, 15, 1093–1102. [Google Scholar] [CrossRef]

- Ma, L.; Fang, Q.; Yin, C.; Zhong, L.; Zhang, C.; Chen, G. More efficient and environmentally friendly combustion of low-rank coal in a down-fired boiler by a simple but effective optimization of staged-air windbox. Fuel Process. Technol. 2019, 194, 106118. [Google Scholar] [CrossRef]

- Zha, Q.; Li, D.; Wang, C.a.; Che, D. Numerical evaluation of heat transfer and NO x emissions under deep-air-staging conditions within a 600 MW e tangentially fired pulverized-coal boiler. Appl. Therm. Eng. 2017, 116, 170–181. [Google Scholar] [CrossRef]

- Li, D.; Lv, Q.; Feng, Y.; Wang, C.a.; Liu, X.; Chen, K.; Xu, K.; Zhong, J.; Che, D. Effects of Coal Blending and Operating Conditions on Combustion and NO x Emission Characteristics in a Tangentially-fired Utility Boiler. Energy Procedia 2017, 105, 4015–4020. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Wang, J.; Zeng, L.; Zhang, X.; Li, X.; Li, Z. Effects of secondary air distribution in primary combustion zone on combustion and NO emissions of a large-scale down-fired boiler with air staging. Energy 2018, 165, 399–410. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y. Numerical optimization of the influence of multiple deep air-staged combustion on the NOx emission in an opposed firing utility boiler using lean coal. Fuel 2020, 269, 116996. [Google Scholar] [CrossRef]

- Choi, M.; Park, Y.; Li, X.; Kim, K.; Sung, Y.; Hwang, T.; Choi, G. Numerical evaluation of pulverized coal swirling flames and NOx emissions in a coal-fired boiler: Effects of co- and counter-swirling flames and coal injection modes. Energy 2021, 217, 119439. [Google Scholar] [CrossRef]

- Tan, P.; Tian, D.; Fang, Q.; Ma, L.; Zhang, C.; Chen, G.; Zhong, L.; Zhang, H. Effects of burner tilt angle on the combustion and NOX emission characteristics of a 700 MWe deep-air-staged tangentially pulverized-coal-fired boiler. Fuel 2017, 196, 314–324. [Google Scholar] [CrossRef]

| Mixed Air | C-Layer | D-Layer | E-Layer | F-Layer | Tertiary Overfired Air | Leakage | |

|---|---|---|---|---|---|---|---|

| Temperature (K) | 556 | 630 | 630 | 630 | 630 | 543 | |

| Ratio (%) | 23.9 | 5 | 4.6 | 6.9 | 34.5 | 20.1 | 5 |

| Velocity (m s−1) | 23.8 | 40 | 14.3 | 14.3 | 14.3 | 26.5 |

| Mixed Air | E-Layer | Tertiary Air | F-Layer | SOFA | Air Leak | |

|---|---|---|---|---|---|---|

| Temperature (K) | 582 | 630 | 393 | 630 | 630 | |

| Ratio (%) | 36.9 | 5.9 | 7.4 | 14.8 | 30 | 5 |

| Speed (m s−1) | 25 | 30 | 25 | 30 | 30 |

| Proximate Analysis (wt.%) | Elemental Analysis (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Moisturear | Volatile Matterdaf | Fixed Carbondaf | Ashar | Car | Har | Nar | Sar | Oar * |

| 7.9 | 20 | 80 | 26.9 | 55.0 | 2.2 | 2.0 | 4.0 | 2.0 |

| Temperature (K) | NOx (mg Nm−3, 6% O2) | Carbon Content in Fly Ash | |

|---|---|---|---|

| Experimental | 1530 | 900–1000 | 2–3 |

| Simulation | 1609 | 906 | 2.5 |

| Condition | Secondary Air on Arch | Mixed Air | F-Layer | E-Layer | Tertiary Air | SOFA | Air Leak |

|---|---|---|---|---|---|---|---|

| Case-A | 29.5 | 36.9 | 14.8 | 5.9 | 7.4 | 30 | 5 |

| Case-B | 24.7 | 32.2 | 19.5 | 5.9 | 7.4 | 30 | 5 |

| Case-C | 20.0 | 27.4 | 24.3 | 5.9 | 7.4 | 30 | 5 |

| Secondary Air on the Arch | Temperature (K) | Oxygen Fraction (mol.%) | NO (mg Nm−3) | Carbon Content in Fly Ash (%) |

|---|---|---|---|---|

| 20% | 1513 | 5.3 | 612 | 5.5 |

| 24.7% | 1516 | 5.2 | 568 | 5.5 |

| 29.5% | 1517 | 5.3 | 576 | 5.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Wang, S.; Wei, Z.; Yu, J. Retrofit of a 600 MW Down-Fired Pulverized-Coal Furnace for Low NOx Emission. Energies 2023, 16, 6837. https://doi.org/10.3390/en16196837

Liu T, Wang S, Wei Z, Yu J. Retrofit of a 600 MW Down-Fired Pulverized-Coal Furnace for Low NOx Emission. Energies. 2023; 16(19):6837. https://doi.org/10.3390/en16196837

Chicago/Turabian StyleLiu, Tao, Sheng Wang, Ziming Wei, and Jie Yu. 2023. "Retrofit of a 600 MW Down-Fired Pulverized-Coal Furnace for Low NOx Emission" Energies 16, no. 19: 6837. https://doi.org/10.3390/en16196837