Challenges and Barriers of Wireless Charging Technologies for Electric Vehicles

Abstract

:1. Introduction

2. Benefits of Wireless Charging over Wired Charging

2.1. Restrictions: Maximize the Upgrading Costs for Wireless Charging Technologies

2.2. Chance: Increasing the Government Funding for Wireless Charging Technology

2.3. Challenge: Minimizing Efficiency Loss

3. EV Conductive Charging Method

- Capacitive Wireless Charging System (CWCS);

- Permanent Magnetic Gear Wireless Charging System (PMWC);

- Inductive Wireless Charging System (IWC); and

- Resonant Inductive Wireless Charging System (RIWC).

3.1. Capacitive Wireless Power Transmission Method

3.2. Magnetic Gear Wireless Power Transmission Method

3.3. Inductive Power Transmission Method

3.4. Resonant Inductive Wireless Charging System (RIWC)

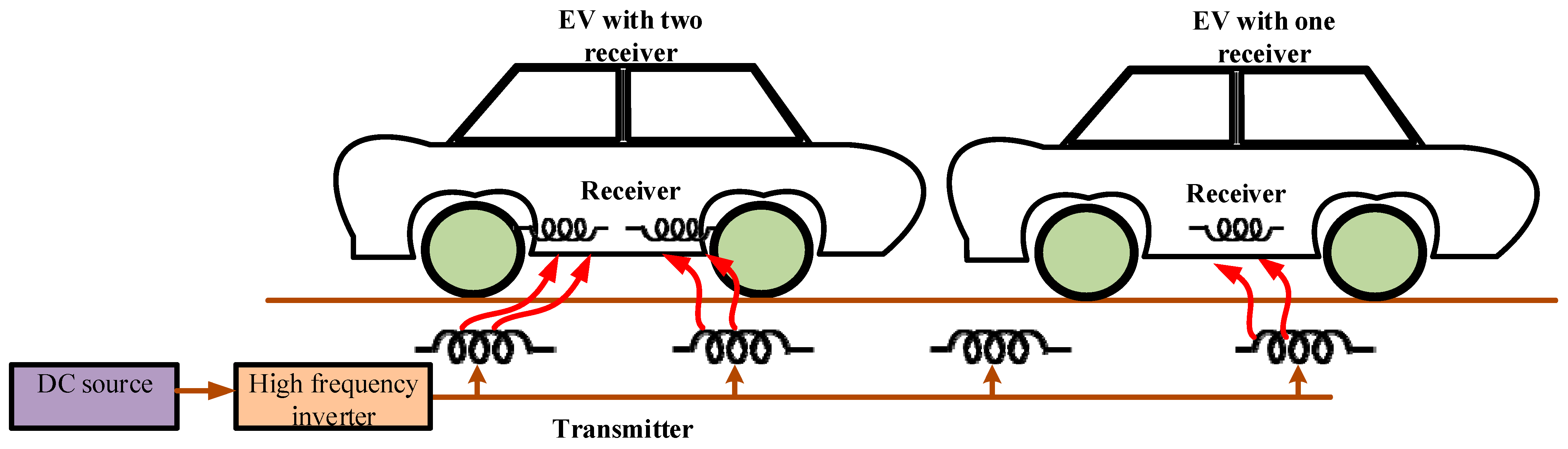

4. Static and Dynamic Wireless Charging

- Static Wireless Charging;

- Dynamic Wireless Charging.

4.1. Static Wireless Charging Method

Wireless Charging Types and Charging Methods

4.2. Dynamic Wireless Charging Method

5. Standards for Wireless Electric Vehicle Charging

- SAE. J1772 standard described the EV/PHEV conductive system of charge couplers.

- SAE. J2847/6 standard described the communication transmission between wireless EV Chargers and wirelessly-charged vehicles.

- SAE. J1773 standard described the EV inductive method of coupled charging.

- SAE. J2836/6 standard described the usage of a wireless charging system of communication for PEVs.

- UL subject 2750 described the investigation’s general plan for WEVCS.

- IEC. 61980-1 Cor.1 Ed.1.0 described the general configuration of the EV WPT system.

- IEC. 62827-2 Ed.1.0 described the WPT-Management: Multiple Varieties of Management of Device Control.

- IEC. 63028 Ed.1.0 described the WPT-Air fuel alliance resonant baseline system requirements.

5.1. EV Wireless Charging: Implementations and Standards

5.2. Companies Working to Develop and Improving WCS

- The Evatran Group developed plug-less charging for first-generation wireless electric vehicles such the Nissan Leaf, Chevrolet Volt, Tesla Model S, and Audi i3.

- Recently, WiTricity Corporation worked with Honda Motor Co. Ltd., Nissan, GM, Hyundai, and Furukawa Electric to create WCS for sedans and SUVs.

- Qualcomm Halo produced WCS for passenger, sport, and race cars, and Witricity Corporation obtained Qualcomm Halo.

- Hevo Power has been manufacturing WCS for a passenger automobile.

- Bombardier Primove manufactured WCS for vehicles ranging from rider automobiles to SUVs.

- Siemens and BMW have been manufacturing WCS for rider automobiles.

- Momentum Dynamic manufactured WCS for corporate and commercial fleet buses.

- Conductix-Wampfler manufactured WCS for buses and industrial fleets.

5.3. Challenges Faced by WEVCS

- Maintaining EMC, EMI, and frequencies according to standards is necessary for human health and safety. Table 6 shows the various challenges faced by WEVCS.

6. EV-Based Vehicle-to-Grid (V2G)

6.1. Applications for EV Wireless Charging: LOD and FOD

- System variables

- Efficiency of power loss

- Actual temperature

- Image from wave-based detection

- Thermal ultrasonic radar

- Field-based laser light detection

- Resistance inductance capacitance

6.2. LOD Detection Prototype Implementation

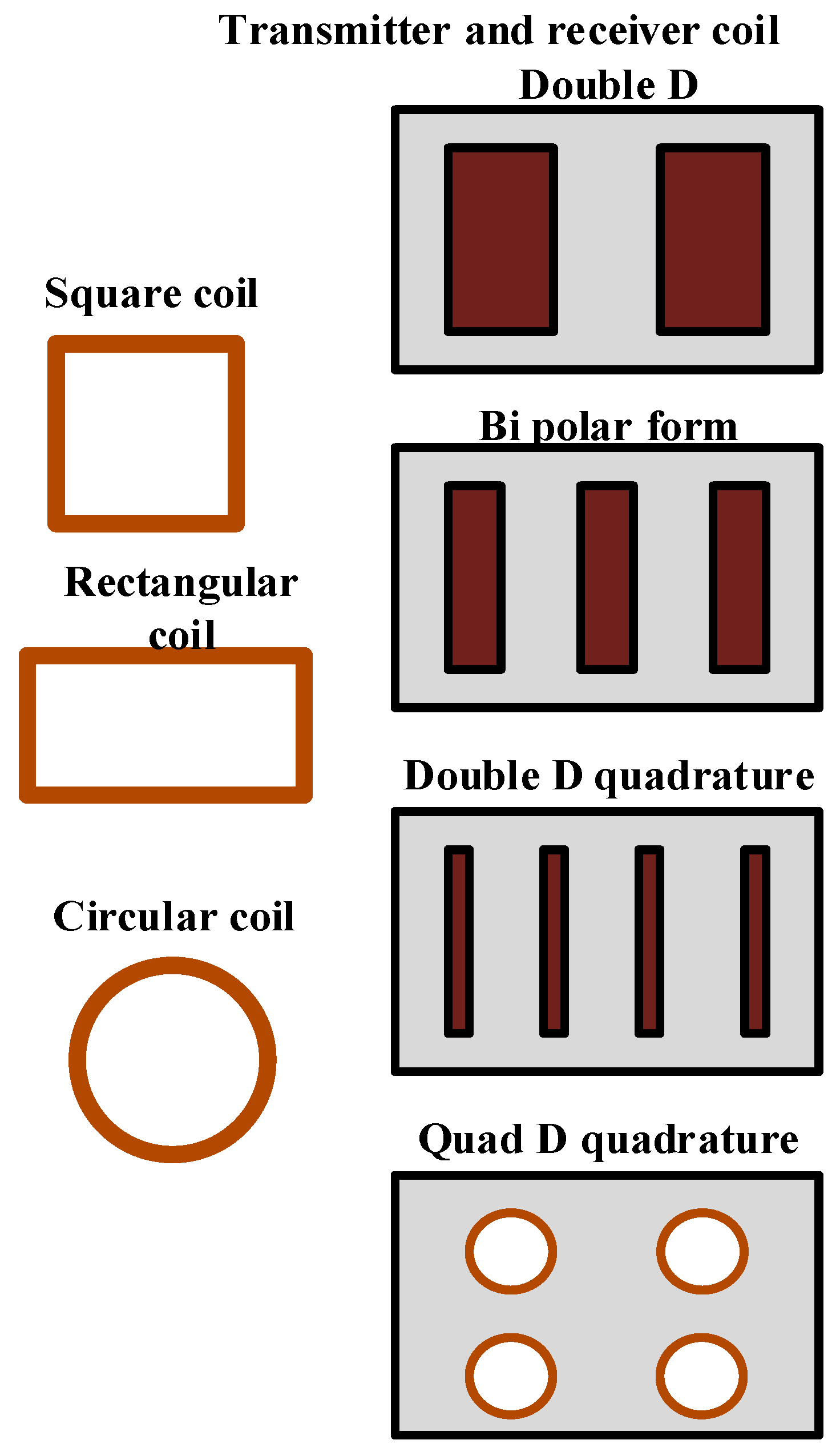

7. Quadruple Power Pad Coil Analysis for Wireless EV Charging

7.1. Background

7.2. Analysis of the QPP Configuration

7.3. Misalignment Prevention for Wireless Charging Technology of Electric Vehicles: Design, Development, and Implementation

7.4. Analysis of Wireless Power Transfer Efficiency Caused by EV Static Wireless Charging Misalignment

7.5. Two Receiver Coils Were Used in a Novel Wireless Charging System Employed in Electric Vehicles

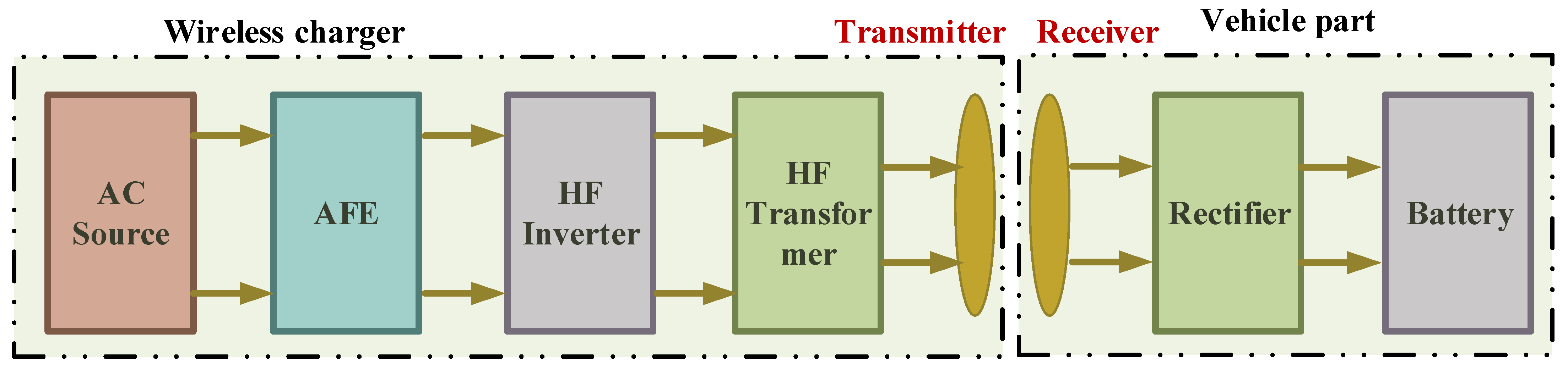

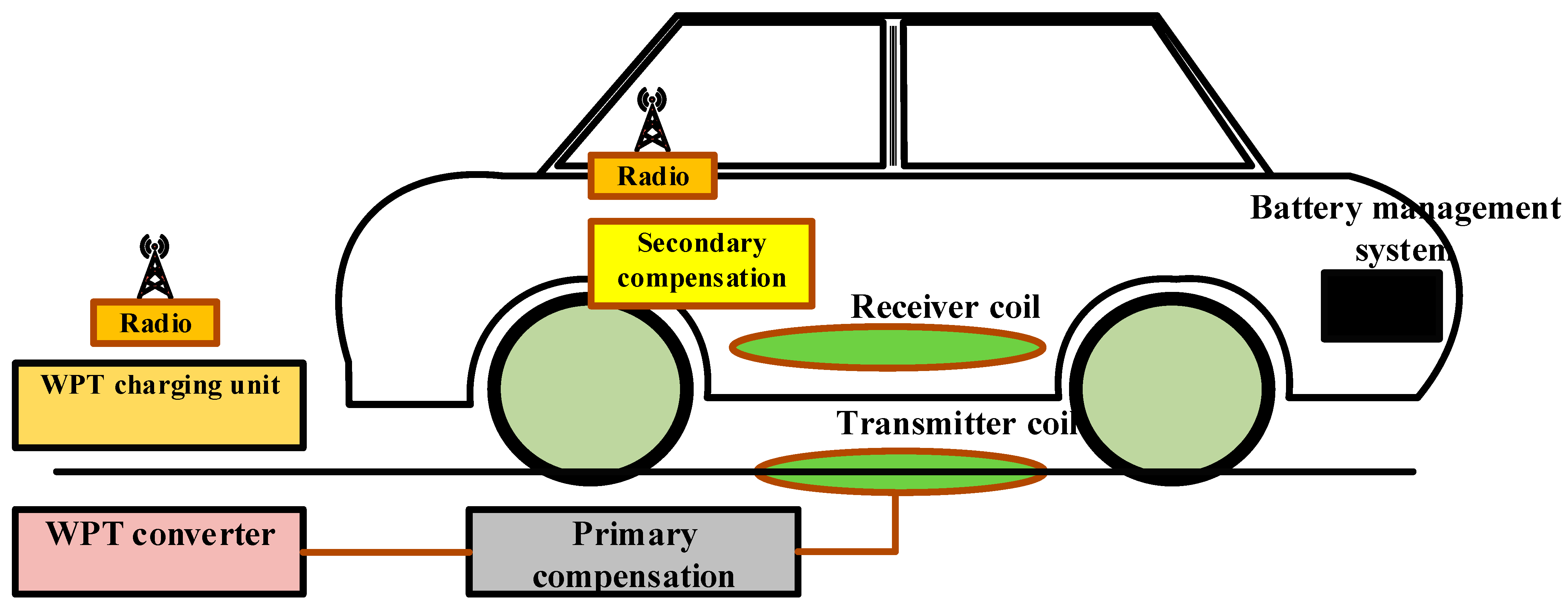

8. Wireless Charging System—Composition

8.1. Topologies for Compensation

- decreased reactive power;

- the feasibility of operating with a gentle duty cycle;

- avoidance of bifurcation and segmentation;

- the creation of a system able to tolerate severe misalignment; and

- to achieve optimum efficiency, bifurcation tolerance, a compact design, and cost reduction.

8.2. Mono-Resonant Compensation Networks

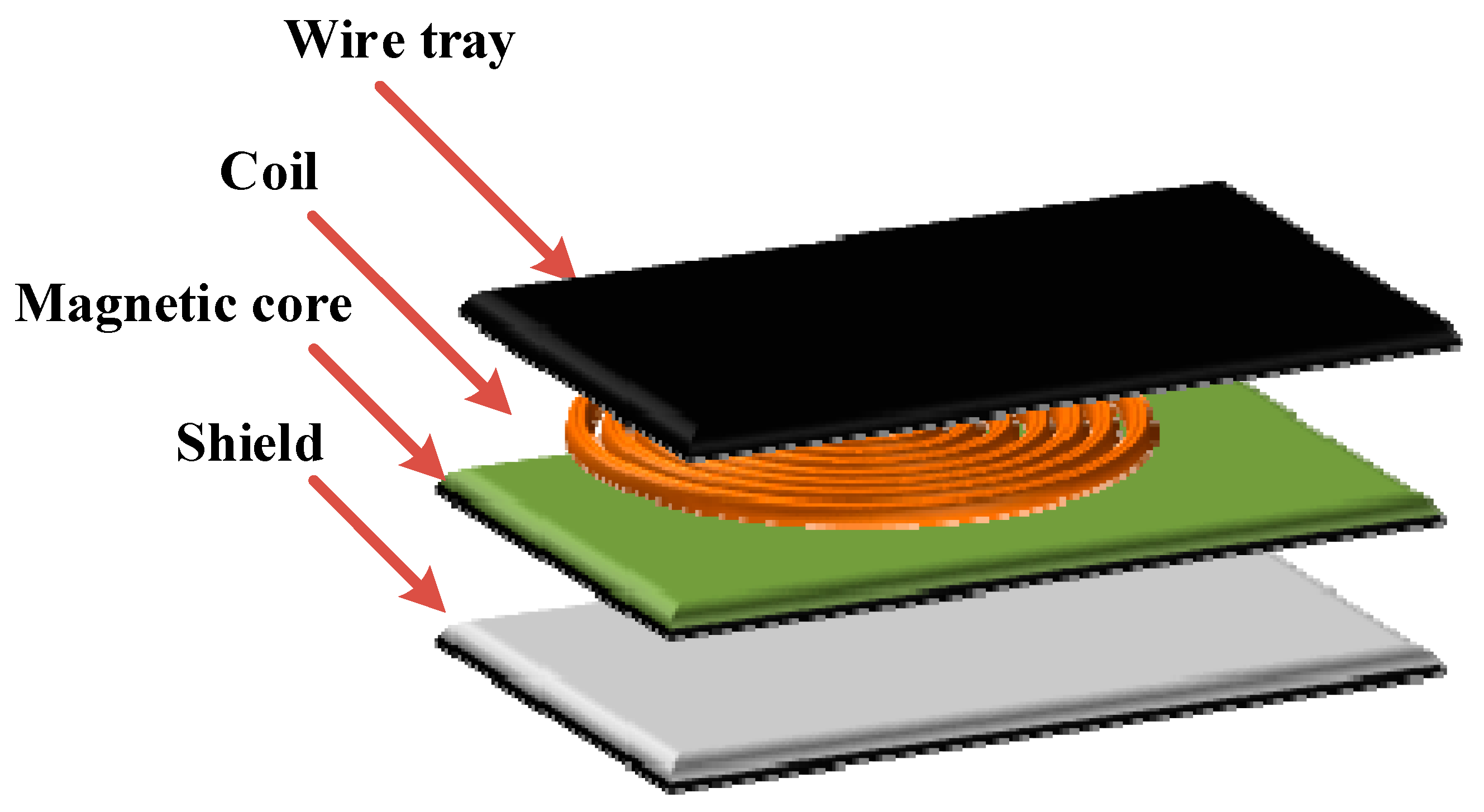

8.3. Coil Design

8.4. Batteries and Electric Vehicles

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dai, J.; Ludois, D.C. A Survey of Wireless Power Transfer and a Critical Comparison of Inductive and Capacitive Coupling fo r Small Gap Applications. IEEE Trans. Power Electron. 2015, 30, 6017–6029. [Google Scholar] [CrossRef]

- Miller, J.M.; Onar, O.C.; Chinthavali, M. Primary-Side Power Flow Control of Wireless Power Transfer for Electric Vehicle Charging. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 147–162. [Google Scholar] [CrossRef]

- Qiu, C.; Chau, K.T.; Liu, C.; Chan, C.C. Overview of wireless power transfer for electric vehicle charging. Electr. Veh. Symp. Exhib. 2013, 7, 1–9. [Google Scholar]

- Choi, S.Y.; Gu, B.W.; Jeong, S.Y.; Rim, C.T. Advances in wireless power transfer systems for roadway-powered electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 18–36. [Google Scholar] [CrossRef]

- Mi, C.C.; Buja, G.; Choi, S.Y.; Rim, C.T. Modern Advances in Wireless Power Transfer Systems for Roadway Powered Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6533–6545. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Zhao, H.; Zhu, L.; Shuai, C.; Chen, Z. Wireless Power Transfer by Electric Field Resonance and its Application in Dynamic Charging. IEEE Trans. Ind. Electron. 2016, 63, 6602–6612. [Google Scholar] [CrossRef]

- Choi, S.; Huh, J.; Lee, W.Y.; Lee, S.W.; Rim, C.T. New cross-segmented power supply rails for roadway-powered electric vehicles. IEEE Trans. Power Electron. 2013, 28, 5832–5841. [Google Scholar] [CrossRef]

- Bosshard, R.; Kolar, J.W. Multi-Objective Optimization of 50 kW/85 kHz IPT System for Public Transport. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1370–1382. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.; Boys, J. A new IPT magnetic coupler for electric vehicle charging systems. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 2487–2492. [Google Scholar]

- Budhia, M.; Boys, J.T.; Covic, G.A.; Huang, C.Y. Development of a single-sided flux magnetic coupler for electric vehicle IPT charging systems. IEEE Trans. Ind. Electron. 2013, 60, 318–328. [Google Scholar] [CrossRef]

- Nagendra, G.R.; Covic, G.A.; Boys, J.T. Determining the physical size of inductive couplers for IPT EV systems. In Proceedings of the Conference Proceedings-IEEE Applied Power Electronics Conference and Exposition-APEC, Fort Worth, TX, USA, 16–20 March 2014; pp. 3443–3450. [Google Scholar]

- Wireless Power Consortium Products. Available online: https://www.wirelesspowerconsortium.com/products (accessed on 10 May 2019).

- Wireless Chargers Archives-Qi Wireless Charging. Available online: http://www.qiwireless.com/category/wirelesschargers (accessed on 10 May 2019).

- Barnard, J.M.; Ferreira, J.A.; Van Wyk, J.D. Sliding transformers for linear contactless power delivery. IEEE Trans. Ind. Electron. 1997, 44, 774–779. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C. A high efficiency 3.3 kW loosely-coupled wireless power transfer system without magnetic material. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition, ECCE 2015, Montreal, QC, Canada, 20–24 September 2015; pp. 2282–2286. [Google Scholar]

- Wu, H.H.; Gilchrist, A.; Sealy, K.D.; Bronson, D. A high efficiency 5 kW inductive charger for EVs using dual side control. IEEE Trans. Ind. Inform. 2012, 8, 585–595. [Google Scholar] [CrossRef] [Green Version]

- Li, W. High Efficiency Wireless Power Transmission at Low Frequency Using Permanent Magnet Coupling. Master’s Thesis, University of British Columbia (Vancouver), Kelowna, BC, Canada, 2009. [Google Scholar]

- Ahmad, A.; Alam, M.S.; Chaban, R.C. Efficiency enhancement of wireless charging for Electric vehicles through reduction of coil misalignment. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; pp. 21–26. [Google Scholar]

- Mizuno, T.; Yachi, S.; Kamiya, A.; Yamamoto, D. Improvement in efficiency of wireless power transfer of magnetic resonant coupling using magneto plated wire. IEEE Trans. Magn. 2011, 47, 4445–4448. [Google Scholar] [CrossRef] [Green Version]

- Sakamoto, H.; Harada, K.; Washimiya, S.; Takehara, K.; Matsuo, Y.; Nakao, F. Large air gap coupler for inductive charger. IEEE Trans. Magn. 1999, 35 Pt 2, 3526–3528. [Google Scholar] [CrossRef]

- Takanashi, H.; Sato, Y.; Kaneko, Y.; Abe, S.; Yasuda, T. A large air gap 3 kW wireless power transfer system for electric vehicles. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; pp. 269–274. [Google Scholar]

- Duan, C.; Jiang, C.; Taylor, A.; Bai, K. Design of a zero-voltage-switching large air-gap wireless charger with low electric stress for electric vehicles. IET Power Electron. 2013, 6, 1742–1750. [Google Scholar] [CrossRef]

- Narayanamoorthi, R. Cross Interference Free Dual Frequency Wireless Power Transfer Using Frequency Bifurcation for Dynamic Biomedical Implants. IEEE Trans. Electromagn. Compat. 2021, 63, 286–293. [Google Scholar] [CrossRef]

- Kurs, A.; Karalis, A.; Moffatt, R.; Joannopoulos, J.D.; Fisher, P.; Soljacic, M. Wireless power transfer via strongly coupled magnetic resonances. Science 2007, 317, 83–86. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhao, Z.; Chen, K. Frequency decrease analysis of resonant wireless power transfer. IEEE Trans. Power Electron. 2014, 29, 1058–1063. [Google Scholar] [CrossRef]

- Villa, J.L.; Sallán, J.; Osorio, J.F.S.; Llombart, A. High-misalignment tolerant compensation topology for ICPT systems. IEEE Trans. Ind. Electron. 2012, 59, 945–951. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A Double-Sided LCC Compensation Network and Its Tuning Method for Wireless Power Transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Yvkoff, L. Will DC Fast Charging Harm Electric Car Batteries? 2010. Available online: https://www.cnet.com/roadshow/news/will-dc-fast-charging-harm-electric-car-batteries/ (accessed on 15 May 2019).

- A Simple Guide to DC Fast Charging. Available online: http://www.fleetcarma.com/dcfast-charging-guide/ (accessed on 15 May 2019).

- Lukic, S.; Pantic, Z. Cutting the Cord: Static and Dynamic Inductive Wireless Charging of Electric Vehicles. IEEE Electrif. Mag. 2013, 1, 57–64. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Review of Charging Power Levels and Infrastructure for Plug-In Electric and Hybrid Vehicles and Commentary on Unidirectional Charging. IEEE Int. Electr. Veh. Conf. IEVC 2012, 28, 2151–2169. [Google Scholar]

- Khaligh, A.; Dusmez, S. Comprehensive topological analysis of conductive and inductive charging solutions for plug-in electric vehicles. IEEE Trans. Veh. Technol. 2012, 61, 3475–3489. [Google Scholar] [CrossRef]

- J1772: SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Chapter 2 53 Coupler-SAE International. Available online: http://standards.sae.org/j1772_201602/ (accessed on 16 May 2019).

- Ahmad, F.; Alam, M.S.; Asaad, M. Developments in xEVs charging infrastructure and energy management system for smart microgrids including xEVs. Sustain. Cities Soc. 2017, 35, 552–564. [Google Scholar] [CrossRef]

- Porsche Panamera S E-Hybrid PluginCars.com. Available online: http://www.plugincars.com/porsche-panamera-s-e-hybrid (accessed on 15 May 2019).

- 2017 Audi A3 Sportback e-tron®|Audi USA. Available online: https://www.audiusa.com/models/audi-a3-sportback-e-tron/2017 (accessed on 20 May 2019).

- Specs|Cadillac ELR Forum. Available online: http://www.myelr.com/cadillac-elrspecs (accessed on 20 May 2019).

- Chevrolet Pressroom-United States-Spark EV. Available online: http://media.chevrolet.com/media/us/en/chevrolet/vehicles/spark-ev/2016.tab1.html (accessed on 20 May 2019).

- 2017 Ford® C-MAX Energi SE Plug-In Hybrid|Model Highlights|Ford.com. Available online: https://www.ford.com/cars/c-max/2017/models/c-max-energi-se/ (accessed on 21 May 2019).

- Mercedes S550 Plug-in Hybrid|PluginCars.com. Available online: http://www.plugincars.com/mercedes-s550-plug-hybrid (accessed on 21 May 2019).

- Mercedes-Benz C350 Plug-In Hybrid-EVBox. Available online: http://www.evbox.com/go-electric/electric-cars/mercedes-benz/mercedes-benz-c350-plug-in-hybrid/ (accessed on 21 May 2019).

- Smart Electric Drive|PluginCars.com. Available online: http://www.plugincars.com/smart-ed (accessed on 22 May 2019).

- The Toyota Prius Plug-in Hybrid|PluginCars.com. Available online: http://plugincars.com/toyota-prius-plugin-hybrid (accessed on 30 May 2019).

- Specifications|i-MiEV|MITSUBISHI MOTORS. Available online: http://www.mitsubishi-motors.com/en/showroom/i-miev/specifications/ (accessed on 30 May 2019).

- Nissan LEAF Will Include Fast Charge Capability and Emergency Charging Cable at Launch-Gas 2. Available online: http://gas2.org/2010/05/27/nissan-leaf-will-includefast-charge-capability-and-emergency-charging-cable-at-launch/ (accessed on 30 May 2019).

- Review and Pictures of Porsche Cayenne S E-Hybrid|PluginCars.com. Available online: http://www.plugincars.com/porsche-cayenne-s-e-hybrid (accessed on 30 May 2019).

- 2017 Volkswagen e-Golf Specifications. Available online: http://www.neftinvw.com/blog/2017-volkswagen-e-golf-specifications/ (accessed on 30 May 2019).

- Specs | Ford Focus Electric Forum, My Focus Electric. Available online: http://www.myfocuselectric.com/specs/ (accessed on 30 May 2019).

- Fiat 500e|PluginCars.com. Available online: http://www.plugincars.com/fiat-500e (accessed on 5 June 2019).

- 2017 Kia Soul EV Specifications. Available online: http://www.kiamedia.com/us/en/models/soul-ev/2017/specifications (accessed on 5 June 2019).

- Honda Accord Plug-in Hybrid|PluginCars.com. Chapter 2 54. Available online: http://www.plugincars.com/honda-accord-plug-hybrid (accessed on 5 June 2019).

- “Chevrolet Spark EV|PluginCars.com”. Available online: https://www.ford.com/cars/cmax/2017/models/c-max-energi-se/ (accessed on 5 June 2019).

- 2017 BMW i3 (94 Ah) Release Date, Price and Specs-Roadshow. Available online: https://www.cnet.com/roadshow/auto/2017-bmw-i3/preview/ (accessed on 5 June 2019).

- Hui, S.Y. Technology for Portable Electronic Products and Qi. Proc. IEEE 2013, 101, 1290–1301. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Liu, C.; Lee, C.H.T.; Shan, Z. Cost-effectiveness comparison of coupler designs of wireless power transfer for electric vehicle dynamic charging. Energies 2016, 9, 906. [Google Scholar] [CrossRef] [Green Version]

- Transfer, P. SAgE Singapore Scholarships Dynamic Charging for Electric Vehicles (EV) by Wireless; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- Bhattacharya, S.; Tan, Y.K. Design of static wireless charging coils for integration into electric vehicle. In Proceedings of the 2012 IEEE Third International Conference on Sustainable Energy Technologies (ICSET), Kathmandu, Nepal, 24–27 September 2012; pp. 146–151. [Google Scholar]

- Miller, J.M.; Jones, P.T.; Li, J.M.; Onar, O.C. ORNL experience and challenges facing dynamic wireless power charging of EV’s. IEEE Circuits Syst. Mag. 2015, 15, 40–53. [Google Scholar] [CrossRef]

- Moschoyiannis, S.; Maglaras, L.; Jiang, J.; Topalis, F.; Maglaras, A. Dynamic wireless charging of electric vehicles on the move with Mobile Energy Disseminators. Int. J. Adv. Comput. Sci. Appl. 2015, 6, 239–251. [Google Scholar]

- Laccone, F.; Malomo, L.; Froli, M.; Cignoni, P.; Pietroni, N. Automatic Design of Cable-Tensioned Glass Shells. Comput. Graph. Forum 2020, 39, 260–273. [Google Scholar] [CrossRef]

- Jang, Y.J.; Jeong, S.; Lee, M.S. Initial energy logistics cost analysis for stationary, quasi-dynamic, and dynamic wireless charging public transportation systems. Energies 2016, 9, 483. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, A.A.S.; Lashway, C.R.; Mohammed, O. Modeling and Feasibility Analysis of Quasi-dynamic WPT System for EV Applications. IEEE Trans. Transp. Electrif. 2017, 3, 343–353. [Google Scholar] [CrossRef]

- Ojika, S.; Miura, Y.; Ise, T. Evaluation of Inductive Contactless Power Transfer Outlet with Coaxial Coreless Transformer. Electr. Eng. Jpn. 2016, 195, 57–67, (English Transl. Denki Gakkai Ronbunshi). [Google Scholar] [CrossRef]

- Esteban, B.; Sid-Ahmed, M.; Kar, N.C. A Comparative Study of Power Supply Architectures in Wireless EV Charging Systems. IEEE Trans. Power Electron. 2015, 30, 6408–6422. [Google Scholar] [CrossRef]

- SLi; Mi, C.C. Wireless power transfer for electric vehicle applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 4–17. [Google Scholar]

- Chao, Y.-H.; Shieh, J.-J. Series-parallel loosely coupling power supply with primary-side control. In Proceedings of the 2012 IEEE Third International Conference on Sustainable Energy Technologies (ICSET), Kathmandu, Nepal, 24–27 September 2012; pp. 352–356. [Google Scholar]

- Park, C.; Lim, S.; Shin, J.; Lee, C.-Y. How much hydrogen should be supplied in the transportation market? Focusing on hydrogen fuel cell vehicle demand in South Korea: Hydrogen demand and fuel cell vehicles in South Korea. Technol. Forecast. Soc. Change 2022, 181, 121750. [Google Scholar] [CrossRef]

- Huh, J.; Lee, S.W.; Lee, W.Y.; Cho, G.H.; Rim, C.T. Narrow-width inductive power transfer system for online electrical vehicles. IEEE Trans. Power Electron. 2011, 26, 3666–3679. [Google Scholar] [CrossRef]

- Kashani, S.A.; Soleimani, A.; Khosravi, A.; Mirsalim, M. State-of-the-Art Research on Wireless Charging of Electric Vehicles Using Solar Energy. Energies 2023, 16, 282. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, B.S.; Lee, J.H.; Lee, S.H.; Park, C.B.; Jung, S.M.; Lee, S.G.; Yi, K.P.; Baek, J. Development of 1-MW Inductive Power Transfer System for a High-Speed Train. IEEE Trans. Ind. Electron. 2015, 62, 6242–6250. [Google Scholar] [CrossRef]

- Julio, A. Ruiz ITS systems developing in Malaga. 2nd Congress EU Core Net Cities, 2014. Available online: https://intellias.com/intellias-opens-its-first-spanish-officein-malaga/ (accessed on 19 February 2023).

- INTIS-Integrated Infrastructure Solutions. Available online: http://www.intis.de/intis/downloads_e.html (accessed on 7 June 2019).

- Umenei, A.E. Understanding Low Frequency Non-Radiative Power Transfer. WHITEPAPER-Fult. Innov. LLC.; Wirel. Power Consortium …, no. June 2011. Available online: https://www.semanticscholar.org/paper/UNDERSTANDING-LOW-FREqUENCY-NON-RADIATIVE-POWER-Umenei/777695524c40f6d352130a71b047ea611d0ee86a (accessed on 30 December 2022).

- Sazonov, E.; Neuman, M.R. Wearable Sensors: Fundamentals, Implementation and Applications; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Sun, T.; Xie, X.; Wang, Z. Wireless Power Transfer for Medical Microsystems; Springer: New York, NY, USA, 2013. [Google Scholar]

- Chabalko, M.J.; Besnoff, J.; Ricketts, D.S. Magnetic Field Enhancement in Wireless Power with Metamaterials and Magnetic Resonant Couplers. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 452–455. [Google Scholar] [CrossRef]

- Agbinya, J.I. Wireless Power Transfer; River Publishers: Aalborg, Denmark, 2012; Chapter 4; p. 119. [Google Scholar]

- Dashora, H.K.; Bertoluzzo, M.; Buja, G. Reflexive properties for different pick-up circuit topologies in a distributed IPT track. In Proceedings of the 2015 IEEE International Conference on Industrial Informatics, INDIN 2015, Cambridge, UK, 22–24 July 2015; pp. 69–75. [Google Scholar]

- Kazmierkowski, M.P.; Moradewicz, A.J. Unplugged but connected: Review of contactless energy transfer systems. IEEE Ind. Electron. Mag. 2012, 6, 47–55. [Google Scholar] [CrossRef]

- Maxwell, J.C. Summary for Policymakers. Treatise Electr. Magn. 1954, 53, 1–30. [Google Scholar]

- Ampere’s Law-Reference Notes. Available online: http://notes.tyrocity.com/ampereslaw/ (accessed on 10 June 2019).

- Lopez-Ramos, A.; Menendez, J.R.; Pique, C. Conditions for the Validity of Faraday’s Law of Induction and Their Experimental Confirmation. Eur. J. Phys. 2008, 29, 1069–1076. [Google Scholar] [CrossRef] [Green Version]

- Justin, A. Biot-Savart Law. Int. J. Res. 2015, 2, 2348–6848. [Google Scholar]

- Maxwell, J. A Dynamical Theory of the Electromagnetic Field. Proc. R. Soc. 1863, 459–512. [Google Scholar]

- Lu, X.; Wang, P.; Niyato, D.; Kim, D.I.; Han, Z. Wireless Charging Technologies: Fundamentals, Standards, and Network Applications. IEEE Commun. Surv. Tutor. 2016, 18, 1413–1452. [Google Scholar] [CrossRef] [Green Version]

- Leblanc, M.; Hutin, M. Transformer System for Electric Railways. U.S. Patent 527,857, 1894. [Google Scholar]

- Wireless Transmission of Energy. Available online: https://teslaresearch.jimdo.com/wireless-transmission-of-energy-1/ (accessed on 10 June 2019).

- JBolger, G.; Kirsten, F.A.; Ng, L.S. Inductive power coupling for an electric highway system. In Proceedings of the 28th IEEE Vehicular Technology Conference, Denver, CO, USA, 22–24 March 1978; pp. 137–144. [Google Scholar]

- Zell, C.E.; Bolger, J.G. Development of an engineering prototype of a roadway powered electric transit vehicle system: A public/private sector program. In Proceedings of the 32nd IEEE Vehicular Technology Conference, San Diego, CA, USA, 23–26 March 1982; Volume 32, pp. 35–38. [Google Scholar]

- California PATH Program Roadway Powered Electric Vehicle Project Track Construction And Testing Program Phase 3D. Traffic, 1994. Available online: https://escholarship.org/uc/item/1jr98590Accessed (accessed on 20 December 2022).

- Shinohara, N. Wireless power transmission progress for electric vehicle in Japan. IEEE Radio Wirel. Symp. RWS 2013, 109–111. Available online: https://onlinelibrary.wiley.com/doi/10.1002/tee.22340 (accessed on 20 December 2022).

- Nikitin, P.V.; Rao, K.V.S.; Lazar, S. An Overview of Near Field UHF RFID. In Proceedings of the 2007 IEEE International Conference on RFID, Grapevine, TX, USA, 26–28 March 2007; pp. 167–174. [Google Scholar]

- Power Supply-Is There Any Difference between Induction and Resonant Wireless Energy Transfer-Electrical Engineering Stack Exchange. Available online: https://electronics.stackexchange.com/questions/25176/is-there-any-difference-betweeninduction-and-resonant-wireless-energy-trans (accessed on 15 June 2019).

- Jung, G.; Jeon, S.; Cho, D.; Member, S. Design and Implementation of Shaped MagneticResonance-Based Wireless Power Transfer System for Roadway-Powered Moving Electric Vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar]

- Seungyoung, A.; Joungho, K. Magnetic field design for high efficient and low EMF wireless power transfer in on-line electric vehicle. In Proceedings of the 5th European Conference on Antennas and Propagation (EUCAP), Rome, Italy, 11–15 April 2011; pp. 3979–3982. [Google Scholar]

- Nam, P.S.; Dong, H.C. The On-Line Electric Vehicle: Wireless Electric Ground Transportation Systems; Springer: Berlin, Germany, 2017. [Google Scholar]

- Hori, Y. Novel EV society based on motor/capacitor/wireless; Application of electric motor, supercapacitors, and wireless power transfer to enhance operation of future vehicles. In Proceedings of the 2012 IEEE MTT-S International Microwave Workshop Series on Innovative Wireless Power Transmission: Technologies, Systems, and Applications, Kyoto, Japan, 10–11 May 2012; pp. 3–8. [Google Scholar]

- Imura, T.; Okabe, H.; Uchida, T.; Hori, Y. Study on open and short end helical antennas with capacitor in series of wireless power transfer using magnetic resonant couplings. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Porto, Portugal, 3–5 November 2009; pp. 3848–3853. [Google Scholar]

- Covic, G.A.; Boys, J.T.; Budhia, M.; Huang, C. Electric vehicles—Personal transportation for the future. World Electr. Veh. J. 2010, 4, 693–704. [Google Scholar] [CrossRef] [Green Version]

- Garnica, J.; Chinga, R.A.; Lin, J. Wireless Power Transmission: From Far Field to Near Field. Proc. IEEE 2013, 101, 1321–1331. [Google Scholar] [CrossRef]

- Matsumoto, H. Research on solar power satellites and microwave power transmission in Japan. IEEE Microw. Mag. 2002, 3, 36–45. [Google Scholar] [CrossRef]

- Shinohara, N.; Kubo, Y. Wireless Charging for Electric Vehicle with Microwaves. In Proceedings of the 2013 3rd International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 29–30 October 2013. [Google Scholar]

- Brown, W.C. The History of Power Transmission by Radio Waves. IEEE Trans. Microw. Theory Tech. 1984, 32, 1230–1242. [Google Scholar] [CrossRef] [Green Version]

- Range, S. Beam Efficiency of Wireless Power Transmission via Radio Waves from Short Range to Long Range. J. Electromagn. Eng. Sci. 2010, 10, 4–10. [Google Scholar] [CrossRef]

- Kapranov, V.V.; Matsak, I.S.; Tugaenko, V.Y.; Blank, A.V.; Suhareva, N.A. Atmospheric turbulence effects on the performance of the laser wireless power transfer system. In Free-Space Laser Communication and Atmospheric Propagation XXIX; SPIE: San Francisco, CA, USA, 2017; p. 100961E. [Google Scholar]

- Dickinson, R.M.M. Performance of a High-Power, 2.388-GHz Receiving Array in Wireless Power Transmission Over 1.54 km. In MTT-S International Microwave Symposium Digest; IEEE: Piscataway, NJ, USA, 1976; Volume 76, pp. 139–141. [Google Scholar]

- Shinohara, N. Wireless charging system of electric vehicle with GaNSchottky diodes. In Proceedings of the IMS2011 Workshop WFA “Wireless Power Transmission”, Baltimore, MD, USA, 10 June 2011; p. CD-ROM. [Google Scholar]

- Tritschler, J.; Reichert, S.; Goeldi, B. A practical investigation of a high power, bidirectional charging system for electric vehicles. In Proceedings of the 16th European Conference on Power Electronics and Applications, Lappeenranta, Finland, 26–28 August 2014; pp. 1–7. [Google Scholar]

- Triviño, A.; González-González, J.M.; Aguado, J.A. Wireless Power Transfer Technologies Applied to Electric Vehicles: A Review. Energies 2021, 14, 1547. [Google Scholar] [CrossRef]

- Wireless Electric Vehicle Charging Technology|Halo & Power Transfer|Qualcomm. Available online: https://www.qualcomm.com/solutions/automotive/wevc (accessed on 15 June 2019).

- R. Schuylenbergh, Koeranadvan; Puers, Inductive Powering: Basic Theory and Application to Biomedical System, no. 1. 2014. Available online: https://link.springer.com/book/10.1007/978-90-481-2412-1 (accessed on 19 February 2023).

- Kamineni, A.; Covic, G.A.; Boys, J.T. Analysis of Coplanar Intermediate Coil Structures in Inductive Power Transfer Systems. IEEE Trans. Power Electron. 2015, 30, 6141–6154. [Google Scholar] [CrossRef]

- Nguyen, T.-D.D.; Li, S.; Li, W.; Mi, C.C. Feasibility study on bipolar pads for efficient wireless power chargers. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition-APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; pp. 1676–1682. [Google Scholar]

- Zhang, W.; Wong, S.-C.; Tse, C.K.; Chen, Q. An Optimized Track Length in Roadway Inductive Power Transfer Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 598–608. [Google Scholar] [CrossRef]

- Zhang, Z.; Chau, K.T. Homogeneous Wireless Power Transfer for Move-and-Charge. IEEE Trans. Power Electron. 2015, 30, 6213–6220. [Google Scholar] [CrossRef]

- Li, W.; Zhao, H.; Li, S.; Deng, J.; Kan, T.; Mi, C.C. Integrated LCC Compensation Topology for Wireless Charger in Electric and Plug-in Electric Vehicles. IEEE Trans. Ind. Electron. 2015, 62, 4215–4225. [Google Scholar] [CrossRef]

- Chen, L.; Liu, S.; Zhou, Y.C.; Cui, T.J. An optimizable circuit structure for highefficiency wireless power transfer. IEEE Trans. Ind. Electron. 2013, 60, 339–349. [Google Scholar] [CrossRef]

- Bertoluzzo, M.; Buja, G.; Dashora, H.K. Lumped Track Layout Design for Dynamic Wireless Charging of Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6631–6640. [Google Scholar]

- Venkatesan, M.; Rajamanickam, N.; Vishnuram, P.; Bajaj, M.; Blazek, V.; Prokop, L.; Misak, S. A Review of Compensation Topologies and Control Techniques of Bidirectional Wireless Power Transfer Systems for Electric Vehicle Applications. Energies 2022, 15, 7816. [Google Scholar] [CrossRef]

- Zaheer, A.; Hao, H.; Covic, G.A.; Kacprzak, D. Investigation of multiple decoupled coil primary pad topologies in lumped IPT systems for interoperable electric vehicle charging. IEEE Trans. Power Electron. 2015, 30, 1937–1955. [Google Scholar] [CrossRef]

- Bertoluzzo, M.; Di Barba, P.; Forzan, M.; Mognaschi, M.E.; Sieni, E. Optimization of Compensation Network for a Wireless Power Transfer System in Dynamic Conditions: A Circuit Analysis Approach. Algorithms 2022, 15, 261. [Google Scholar] [CrossRef]

- Ongayo, D.; Hanif, M. Comparison of Circular and Rectangular Coil Transformer Parameters for Wireless Power Transfer Based on Finite. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference (COBEP/SPEC), Fortaleza, Brazil, 29 February 2016. [Google Scholar]

- Mahmud, M.H.; Elmahmoud, W.; Barzegaran, M.R.; Brake, N. Efficient Wireless Power Charging of Electric Vehicle by Modifying the Magnetic Characteristics of the Transmitting Medium. IEEE Trans. Magn. 2017, 63, 6631–6640. [Google Scholar] [CrossRef]

- Sekiya, N.; Monjugawa, Y. A Novel REBCO Wire Structure That Improves Coil Quality Factor in MHz Range and its Effect on Wireless Power Transfer Systems. IEEE Trans. Appl. Supercond. 2017, 27, 1–5. [Google Scholar] [CrossRef]

- Yilmaz, T.; Hasan, N.; Zane, R.; Pantic, Z. FbifMulti-Objective Optimization of Circular Magnetic Couplers for Wireless Power Transfer Applications. IEEE Trans. Magn. 2017, 53, 1–12. [Google Scholar] [CrossRef]

- Boys, J.T.; Covic, G.A. Inductive Power Transfer Systems (IPT) Fact Sheet: No. 1-Basic Concepts. Available online: http://www.qualcomm.com/media/documents/ (accessed on 16 February 2019).

- Hwang, K.; Cho, J.; Kim, D.; Park, J.; Kwon, J.H.; Kwak, S.I.; Park, H.H.; Ahn, S. An autonomous coil alignment system for the dynamic wireless charging of electric vehicles to minimize lateral misalignment. Energies 2017, 10, 315. [Google Scholar] [CrossRef]

- Liu, N.; Habetler, T.G. Design of a Universal Inductive Charger for Multiple Electric Vehicle Models. IEEE Trans. Power Electron. 2015, 30, 6378–6390. [Google Scholar] [CrossRef]

- Vaka, R.; Keshri, R.K. Review on Contactless Power Transfer for Electric Vehicle Charging. Energies 2017, 10, 636. [Google Scholar] [CrossRef] [Green Version]

- Ni, W.; Collings, I.B.; Wang, X.; Liu, R.P.; Kajan, A.; Hedley, M.; Abolhasan, M. Radio alignment for inductive charging of electric vehicles. IEEE Trans. Ind. Informatics 2015, 11, 427–440. [Google Scholar] [CrossRef]

- Ko, Y.D.; Jang, Y.J. The Optimal System Design of the Online Electric Vehicle Utilizing Wireless Power Transmission Technology. Intell. Transp. Syst. IEEE Trans. 2013, 14, 1255–1265. [Google Scholar] [CrossRef]

- Choi, S.Y.; Huh, J.; Lee, W.Y.; Rim, C.T. Asymmetric coil sets for wireless stationary EV chargers with large lateral tolerance by dominant field analysis. IEEE Trans. Power Electron. 2014, 29, 6406–6420. [Google Scholar] [CrossRef]

- Choi, S.Y.; Jeong, S.Y.; Gu, B.W.; Lim, G.C.; Rim, C.T. Ultraslim S-Type Power Supply Rails for Roadway-Powered Electric Vehicles. IEEE Trans. Power Electron. 2015, 30, 6456–6468. [Google Scholar] [CrossRef]

- ORNL Surges Forward with 20-Kilowatt Wireless Charging for Vehicles|ORNL. 2016. Available online: https://www.ornl.gov/news/ornl-surges-forward-20-kilowatt-wirelesscharging-vehicles (accessed on 15 June 2019).

- Wu, H.H.; Masquelier, M.P. An overview of a 50kW inductive charging system for electric buses. In Proceedings of the 2015 IEEE Transportation Electrification Conference and Expo, ITEC 2015, Dearborn, MI, USA, 14–17 June 2015. [Google Scholar]

- Fisher, T.M.; Farley, K.B.; Gao, Y.; Bai, H.; Tse, Z.T.H. Electric vehicle wireless charging technology: A state-of-the-art review of magnetic coupling systems. Wirel. Power Transf. 2014, 1, 87–96. [Google Scholar] [CrossRef]

- Bojarski, M.; Asa, E.; Colak, K.; Czarkowski, D. A 25 kW industrial prototype wireless electric vehicle charger. In Proceedings of the Conference Proceedings-IEEE Applied Power Electronics Conference and Exposition-APEC, Long Beach, CA, USA, 20–24 March 2016; Volume 2016, pp. 1756–1761. [Google Scholar]

- Bojarski, M.; Asa, E.; Colak, K.; Czarkowski, D. Analysis and Control of Multiphase Chapter 2 59 Inductively Coupled Resonant Converter for Wireless Electric Vehicle Charger Applications. IEEE Trans. Transp. Electrif. 2017, 3, 312–320. [Google Scholar] [CrossRef]

- Bosshard, R. Multi-Objective Optimization of Inductive Power Transfer Systems for EV Charging; ETH Zurich: Zürich, Switzerland, 2015. [Google Scholar]

- “Charging Electric Buses Quickly and Efficiently: Bus Stops Fitted with Modular Components Make “Charge & Go” Simple to Implement. 2013. Available online: http://www.conductix.us/en/news/2013-05-29/charging-electric-buses-quickly-andefficiently-bus-stops-fitted-modular-components-make-charge-go (accessed on 15 June 2019).

- Sato, F.; Morita, J.; Takura, T.; Sato, T.; Matsuki, H. Research on Highly Efficient Contactless Power Station System using Meander Coil for Moving Electric Vehicle Model. J. Magn. Soc. Jpn. 2012, 36, 249–252. [Google Scholar] [CrossRef] [Green Version]

- Chigira, M.; Nagatsuka, Y.; Kaneko, Y.; Abe, S.; Yasuda, T.; Suzuki, A. Small-size lightweight transformer with new core structure for contactless electric vehicle power transfer system. In Proceedings of the IEEE Energy Conversion Congress and Exposition: Energy Conversion Innovation for a Clean Energy Future, ECCE 2011, Proceedings, Phoenix, AZ, USA, 17–22 September 2011; pp. 260–266. [Google Scholar]

- Yang, Y.; Cui, J.; Cui, X. Design and Analysis of Magnetic Coils for Optimizing the Coupling Coefficient in an Electric Vehicle Wireless Power Transfer System. Energies 2020, 13, 4143. [Google Scholar] [CrossRef]

- Horiuchi, T.; Kawashima, K. Study on Planar Antennas for Wireless Power Transmission of Electric Vehicles. IEEJ. Trans. Ind. Appl. 2010, 130, 1371–1377. [Google Scholar] [CrossRef]

- Laccone, F.; Malomo, L.; Pérez, J.; Pietroni, N.; Ponchio, F.; Bickel, B.; Cignoni, P. A bending-active twisted-arch plywood structure: Computational design and fabrication of the FlexMaps Pavilion. SN Appl. Sci. 2020, 2, 1505. [Google Scholar] [CrossRef]

- Developments in Wireless Power Transfer Standards and Regulations|IEEE Standards University. Available online: http://www.standardsuniversity.org/e-magazine/june2016/selected-developments-wireless-power-transfer-standards-regulations/ (accessed on 13 June 2019).

- Alam, M.M.; Mekhilef, S.; Bassi, H.; Rawa, M.J.H. Analysis of LC-LC2 Compensated Inductive Power Transfer for High Efficiency and Load Independent Voltage Gain. Energies 2018, 11, 2883. [Google Scholar] [CrossRef] [Green Version]

- Cho, J.-H.; Lee, B.-H.; Kim, Y.-J. Maximizing Transfer Efficiency with an Adaptive Wireless Power Transfer System for Variable Load Applications. Energies 2021, 14, 1417. [Google Scholar] [CrossRef]

- Elliott, G.A.J.; Covic, G.A.; Kacprzak, D.; Boys, J.T. A new concept: Asymmetrical pick-ups for inductively coupled power transfer monorail systems. IEEE Trans. Magn. 2006, 42, 3389–3391. [Google Scholar] [CrossRef]

- Keeling, N.A.; Covic, G.A.; Boys, J.T. A unity-power-factor IPT pickup for highpower appl5ications. IEEE Trans. Ind. Electron. 2010, 57, 744–751. [Google Scholar] [CrossRef]

- Green, A.W. 10 kHz inductively coupled power transfer-concept and control. In Proceedings of the 5th International Conference on Power Electronics and Variable-Speed Drives, London, UK, 26–28 October 1994; pp. 694–699. [Google Scholar]

- Okasili, I.; Elkhateb, A.; Littler, T. A Review of Wireless Power Transfer Systems for Electric Vehicle Battery Charging with a Focus on Inductive Coupling. Electronics 2022, 11, 1355. [Google Scholar] [CrossRef]

- Zhang, W.; Member, S.; Mi, C.C. Compensation Topologies of High-Power Wireless Chapter 2 60 Power Transfer Systems. IEEE Trans. Veh. Technol. 2016, 65, 4768–4778. [Google Scholar] [CrossRef]

- Tho, H.N.; Zhang, C.; Zhang, J.; Lee, S.B.; Jang, I.G. Layout Optimization of the Receiver Coils for Transfer Systems. IEEE J. Emerg. Sel. Top. POWER Electron. 2017, 5, 1311–1321. [Google Scholar]

- Throngnumchai, K.; Kai, T.; Minagawa, Y. A study on receiver circuit topology of a cordless battery charger for electric vehicles. In Proceedings of the IEEE Energy Conversion Congress and Exposition: Energy Conversion Innovation for a Clean Energy Future, ECCE 2011, Proceedings, Phoenix, AZ, USA, 17–22 September 2011; pp. 843–850. [Google Scholar]

- IEC 61980-1:2015|IEC Webstore. Available online: https://webstore.iec.ch/publication/22951 (accessed on 15 June 2019).

- IEC 61980-1:2015/COR1:2017|IEC Webstore. Available online: https://webstore.iec.ch/publication/59640 (accessed on 10 June 2019).

- IEC 61980-1-Electric Vehicle Wireless Power Transfer (WPT) Systems-Part 1: General Requirements|Engineering360. Available online: http://standards.globalspec.com/std/10072168/iec-61980-1 (accessed on 15 February 2019).

- Annarelli, A.; Nonino, F.; Palombi, P. Understanding the management of cyber resilient systems. Comput. Ind. Eng. 2020, 149, 106829. [Google Scholar] [CrossRef]

- Wireless Power Transfer for Light-Duty Plug-in/Electric Vehicles and Alignment Methodology. Available online: https://www.sae.org/standards/content/j2954_202010/ (accessed on 17 June 2019).

- J1773A: SAE Electric Vehicle Inductively Coupled Charging-SAE International. Available online: http://standards.sae.org/j1773_201406/ (accessed on 17 June 2019).

- J2847/6: Communication between Wireless Charged Vehicles and Wireless EV Chargers-SAE International. Available online: http://standards.sae.org/j2847/6_201508/ (accessed on 11 June 2019).

- J2931/6: Signaling Communication for Wirelessly Charged Electric Vehicles-SAE International. Available online: http://standards.sae.org/j2931/6_201508/ (accessed on 15 February 2019).

- Charging Stations|Industries|UL. Available online: http://industries.ul.com/energy/e-mobility/charging-stations (accessed on 17 February 2019).

- Jeong, S.; Jang, Y.J.; Kum, D. Economic Analysis of the Dynamic Charging Electric Vehicle. IEEE Trans. Power Electron. 2015, 30, 6368–6377. [Google Scholar] [CrossRef]

- Giler, E. WiTricity. Available online: https://www.ted.com/talks/eric_giler_demos_wireless_electricity (accessed on 10 February 2019).

- ICNIRP. Available online: http://www.icnirp.org/ (accessed on 17 June 2019).

- Mazzeo, D.; Matera, N.; Oliveti, G. Interaction Between a Wind-PV-Battery-Heat Pump Trigeneration System and Office Building Electric Energy Demand Including Vehicle Charging. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Nguyen, H.N.T.; Zhang, C.; Mahmud, A. Optimal Coordination of G2V and V2G to Support Power Grids With High Penetration of Renewable Energy. IEEE Trans. Transp. Electrif. 2015, 1, 188–195. [Google Scholar] [CrossRef]

- Tho, H.N.; Zhang, C.; Zhang, J. Dynamic Demand Control of Electric Vehicles to Support Power Grid with High Penetration Level of Renewable Energy. IEEE Trans. Transp. Electrif. 2016, 2, 66–75. [Google Scholar]

- Wei, W.; Liu, F.; Mei, S.; Hou, Y. Robust energy and reserve dispatch under variable renewable generation. IEEE Trans. Smart Grid 2015, 6, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Jain, P.; Jain, T. Impacts of G2V and V2G power on electricity demand profile. In Proceedings of the 2014 IEEE International Electric Vehicle Conference, IEVC 2014, Florence, Italy, 17–19 December 2014. [Google Scholar]

- Huang, X.; Qiang, H.; Huang, Z.; Sun, Y.; Li, J. The interaction research of smart grid and EV based wireless charging. In Proceedings of the 2013 IEEE Vehicle Power and Propulsion Conference (VPPC), Beijing, China, 15–18 October 2013; pp. 354–358. [Google Scholar]

- Brooks, A.N. Final Report Grid Regulation Ancillary Service. Regulation 2002, 1, 61. [Google Scholar]

- Arif, S.M.; Lie, T.T.; Seet, B.C.; Ayyadi, S.; Jensen, K. Review of Electric Vehicle Technologies, Charging Methods, Standards and Optimization Techniques. Electronics 2021, 10, 1910. [Google Scholar] [CrossRef]

- Song, K.; Lan, Y.; Zhang, X.; Jiang, J.; Sun, C.; Yang, G.; Yang, F.; Lan, H. A Review on Interoperability of Wireless Charging Systems for Electric Vehicles. Energies 2023, 16, 1653. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Kwak, H.G.; Jang, G.C.; Choi, S.Y.; Rim, C.T. Dual-Purpose Nonoverlapping Coil Sets as Metal Object and Vehicle Position Detections for Wireless Stationary EV Chargers. IEEE Trans. Power Electron. 2018, 33, 7387–7397. [Google Scholar] [CrossRef]

- Kuyvenhoven, N.; Dean, C.; Melton, J.; Schwannecke, J.; Umenei, A.E. Development of a foreign object detection and analysis method for wireless power systems. In Proceedings of the ISPCE 2011–2011 IEEE Symposium on Product Compliance Engineering, Proceedings, San Diego, CA, USA, 10–12 October 2011. [Google Scholar]

- Fukuda, S.; Nakano, H.; Murayama, Y.; Murakami, T.; Kozakai, O.; Fujimaki, K. A novel metal detector using the quality factor of the secondary coil for wireless power transfer systems. In Proceedings of the 2012 IEEE MTT-S International Microwave Workshop Series on Innovative Wireless Power Transmission: Technologies, Systems, and Applications, IMWSIWPT 2012-Proceedings, Kyoto, Japan, 10–11 May 2012. [Google Scholar]

- Kato, T.; Ninomiya, Y.; Masaki, I. An Obstacle Detection Method by Fusion of Radar and Motion Stereo. IEEE Trans. Intell. Transp. Syst. 2002, 3, 182–188. [Google Scholar] [CrossRef]

- Xu, Q.; Ning, H.; Chen, W. Video-based foreign object debris detection. In Proceedings of the 2009 IEEE International Workshop on Imaging Systems and Techniques, IST 2009-Proceedings, Shenzhen, China, 11–12 May 2009. [Google Scholar]

- Futatsumori, S.; Morioka, K.; Kohmura, A.; Yonemoto, N. Design and measurement of W-band offset stepped parabolic reflector antennas for airport surface foreign object debris detection radar systems. In Proceedings of the 2014 International Workshop on Antenna Technology: Small Antennas, Novel EM Structures and Materials, and Applications, iWAT 2014, Sydney, Australia, 4–6 March 2014. [Google Scholar]

- Laccone, F.; Malomo, L.; Pérez, J.; Pietroni, N.; Ponchio, F.; Bickel, B.; Cignoni, P. FlexMaps Pavilion: A twisted arc made of mesostructured flat flexible panels. In Proceedings of the IASS Symposium 2019—60th Anniversary Symposium of the International Association for Shell and Spatial Structures, 2019; Structural Membranes 2019—9th International Conference on Textile Composites and Inflatable Structures, FORM and FORCE, Barcelona, Spain, 7–10 October 2019; pp. 509–515. [Google Scholar]

- Ahmad, A.; Alam, M.S.; Varshney, Y.; Khan, R.H. A state of the Art review on Wireless Power Transfer a step towards sustainable mobility. In Proceedings of the 2017 14th IEEE India Council International Conference (INDICON), Roorkee, India, 15–17 December 2017; pp. 1–6. [Google Scholar]

- M. S. P Wireless charging 2020–interoperable and standardized Technological and standardization challenges Status and goals of standardization International projects and timeline Activities and status of project STILLE Project goals, structure and activities. 2017; pp. 1–13.

- Xue, Z.; Candemir, S.; Antani, S.; Long, L.R.; Jaeger, S.; Demner-Fushman, D.; Thoma, G.R. Foreign object detection in chest X-rays. In Proceedings of the 2015 IEEE International Conference on Bioinformatics and Biomedicine, BIBM 2015, Washington, DC, USA, 9–12 November 2015. [Google Scholar]

- Jang, G.C.; Jeong, S.Y.; Kwak, H.G.; Rim, C.T. Metal object detection circuit with non-overlapped coils for wireless EV chargers. In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference, SPEC 2016, Auckland, New Zealand, 5–8 December 2016. [Google Scholar]

- ICNIRP. Guidelines for limiting exposure to time-varying electric and magnetic fields (1 Hz to 100 kHz). Int. Comm. NON-IONIZING Radiat. Prot.-Health Phys. 2010. [Google Scholar]

- IEEE Std C95.1-2005 (Revision IEEE Std C95.1-1991); IEEE Standard for Safety Levels With Respect to Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz. IEEE: Piscataway, NJ, USA, 2005.

- Ziegelberger, G. ICNIRP statement on the, guidelines for limiting exposure to timevarying electric, magnetic, and electromagnetic fields (UP to 300 GHz). Health Phys. 2009, 97, 257–258. [Google Scholar]

- Poguntke, T.; Schumann, P.; Ochs, K. Radar-based living object protection for inductive charging of electric vehicles using two-dimensional signal processing. Wirel. Power Transf. 2017, 4, 88–97. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Chiang, C. Foreign Metal Detection by Coil Impedance for EV Wireless Charging System. In Proceedings of the 28th International Electric Vehicle Symposium and Exhibition 2015, Goyang, Republic of Korea, 3–6 May 2015; pp. 1–4. [Google Scholar]

- Shahjalal, M.; Shams, T.; Tasnim, M.N.; Ahmed, M.R.; Ahsan, M.; Haider, J. A Critical Review on Charging Technologies of Electric Vehicles. Energies 2022, 15, 8239. [Google Scholar] [CrossRef]

- Amjad, M.; Farooq-i-Azam, M.; Ni, Q.; Dong, M.; Ansari, E.A. Wireless charging systems for electric vehicles. Renew. Sustain. Energy Rev. 2022, 167, 112730. [Google Scholar] [CrossRef]

- Savari, G.F.; Sathik, M.J.; Raman, L.A.; El-Shahat, A.; Hasanien, H.M.; Almakhles, D.; Aleem, S.H.A.; Omar, A.I. Assessment of charging technologies, infrastructure and charging station recommendation schemes of electric vehicles: A review. Ain Shams Eng. J. 2023, 14, 101938. [Google Scholar] [CrossRef]

- Alam, M.S.; Ahmad, A.; Khan, Z.A.; Rafat, Y.; Chabaan, R.C.; Khan, I.; Al-Shariff, S.M. A Bibliographical Review of Electrical Vehicles (xEVs) Standards. SAE Int. J. Altern. Powertrains 2018, 7, 63–98. [Google Scholar] [CrossRef]

- Ahmad, A.; Alam, M.S. Magnetic Analysis of Copper Coil Power Pad with Ferrite Core for Wireless Charging Application. Trans. Electr. Electron. Matererials 2019, 20, 165–173. [Google Scholar] [CrossRef]

- ElGhanam, E.; Hassan, M.; Osman, A.; Kabalan, H. Design and Performance Analysis of Misalignment Tolerant Charging Coils for Wireless Electric Vehicle Charging Systems. World Electr. Veh. J. 2021, 12, 89. [Google Scholar] [CrossRef]

- Mwasilu, F.; Justo, J.J.; Kim, E.K.; Do, T.D.; Jung, J.W. Electric vehicles and smart grid interaction: A review on vehicle to grid and renewable energy sources integration. Renew. Sustain. Energy Rev. 2014, 34, 501–516. [Google Scholar] [CrossRef]

- Khan, W.; Ahmad, A.; Ahmad, F.; SaadAlam, M. A Comprehensive Review of Fast Charging Infrastructure for Electric Vehicles. Smart Sci. 2018, 6, 256–270. [Google Scholar] [CrossRef]

- Debbou, M.; Colet, F. Inductive wireless power transfer for electric vehicle dynamic charging. In Proceedings of the IEEE PELS Workshop on Emerging Technologies: Wireless Power, WoW 2016, Knoxville, TN, USA, 4–6 October 2016; pp. 118–122. [Google Scholar]

- Kim, K.R.; Kim, D.H.; Kim, H.J. Magnetic resonance wireless power transmission using a LLC resonant circuit for a locomotion robot’s battery charging. In Proceedings of the Intelligent Robotics and Applications: 6th International Conference, ICIRA 2013, Busan, South Korea, 25–28 September 2013. [Google Scholar]

- Uddin, M.K.; Ramasamy, G.; Mekhilef, S.; Ramar, K.; Lau, Y.C. A review on highfrequency resonant inverter technologies for wireless power transfer using magnetic resonance coupling. In Proceedings of the 2014 IEEE Conference Energy Conversion, CENCON 2014, Johor Bahru, Malaysia, 13–14 October 2014; pp. 412–417. [Google Scholar]

- Mou, X.; Gladwin, D.T.; Zhao, R.; Sun, H. Survey on magnetic resonant coupling wireless power transfer technology for electric vehicle charging. IET Power Electron. 2019, 12, 3005–3020. [Google Scholar] [CrossRef] [Green Version]

- Mousa, A.G.E.; Abdel Aleem, S.H.E.; Ibrahim, A.M. Mathematical Analysis of Maximum Power Points and Currents Based Maximum Power Point Tracking in Solar Photovoltaic System: A Solar Powered Water Pump Application. Int. Rev. Electr. Eng. 2016, 11, 97. [Google Scholar] [CrossRef]

- Asna, M.; Shareef, H.; Achikkulath, P.; Mokhlis, H.; Errouissi, R.; Wahyudie, A. Analysis of an Optimal Planning Model for Electric Vehicle Fast-Charging Stations in Al Ain City, United Arab Emirates. IEEE Access 2021, 9, 73678–73694. [Google Scholar] [CrossRef]

- Mohamed, N.; Aymen, F.; Issam, Z.; Bajaj, M.; Ghoneim, S.S.M. The Impact of Coil Position and Number on Wireless System Performance for Electric Vehicle Recharging. Sensors 2021, 21, 4343. [Google Scholar] [CrossRef]

- Ma, G.; Kamaruddin, M.H.; Kang, H.S.; Goh, P.S.; Kim, M.H.; Lee, K.Q.; Ng, C.Y. Watertight integrity of underwater robotic vehicles by self-healing mechanism. Ain. Shams Eng. J. 2021, 12, 1995–2007. [Google Scholar] [CrossRef]

- Younes, Z.; Alhamrouni, I.; Mekhilef, S.; Reyasudin, M. A memory-based gravitational search algorithm for solving economic dispatch problem in micro-grid. Ain. Shams Eng. J. 2021, 12, 1985–1994. [Google Scholar] [CrossRef]

- Hussien, A.M.; Hasanien, H.M.; Mekhamer, S.F. Sunflower optimization algorithmbased optimal PI control for enhancing the performance of an autonomous operation of a microgrid. Ain. Shams Eng. J. 2021, 12, 1883–1893. [Google Scholar] [CrossRef]

- Sobhy, M.A.; Abdelaziz, A.Y.; Hasanien, H.M.; Ezzat, M. Marine predators algorithm for load frequency control of modern interconnected power systems including renewable energy sources and energy storage units. Ain. Shams Eng. J. 2021, 12, 3843–3857. [Google Scholar] [CrossRef]

- Savari, G.F.; Krishnasamy, V.; Sathik, J.; Ali, Z.M.; Abdel Aleem, S.H.E. Internet of Things based real-time electric vehicle load forecasting and charging station recommendation. ISA Trans. 2020, 97, 431–447. [Google Scholar] [CrossRef]

- Mostafa, M.H.; Aleem, S.H.E.A.; Ali, S.G.; Abdelaziz, A.Y.; Ribeiro, P.F.; Ali, Z.M. Robust energy management and economic analysis of microgrids considering different battery characteristics. IEEE Access 2020, 8, 54751–54775. [Google Scholar] [CrossRef]

- Kawasan, M.; Zobaa, A.F.; Hasanien, H.M.; Aleem, S.H.A.; Ali, Z.M. Towards accurate calculation of supercapacitor electrical variables in constant power applications using new analytical closed-form expressions. J. Energy Storage 2021, 42, 102998. [Google Scholar]

- Rawa, M.; Abusorrah, A.; Bassi, H.; Mekhilef, S.; Ali, Z.M.; Aleem, S.H.A.; Hasanien, H.M.; Omar, A.I. Economical-technical-environmental operation of power networks with windsolar-hydropower generation using analytic hierarchy process and improved grey wolf algorithm. Ain. Shams Eng. J. 2021, 12, 2717–2734. [Google Scholar] [CrossRef]

- Erdogan, A.; Kizilkan, O.; Colpan, C.O. Thermodynamic performance assessment of solar based closed brayton cycle for different supercritical fluids. In Proceedings of the 2019 4th International Conference on Smart and Sustainable Technologies (SpliTech), Split, Croatia, 18–21 June 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Jahangir, H.; Tayarani, H.; Ahmadian, A.; Golkar, M.A.; Miret, J.; Tayarani, M.; Gao, H.O. Charging demand of Plug-in Electric Vehicles: Forecasting travel behavior based on a novel Rough Artificial Neural Network approach. J. Clean Prod. 2019, 229, 1029–1044. [Google Scholar] [CrossRef]

- Majhi, R.C.; Ranjitkar, P.; Sheng, M. Assessment of dynamic wireless charging based electric road system: A case study of Auckland motorway. Sustain. Cities Soc. 2022, 84, 104039. [Google Scholar] [CrossRef]

- Sudimac, B.; Ugrinović, A.; Jurčević, M. The application of photovoltaic systems in sacred buildings for the purpose of electric power production: The case study of the Cathedral of St. Michael Archangel Belgrade. Sustainability 2020, 12, 1408. [Google Scholar] [CrossRef] [Green Version]

- Ji, B.; Song, X.; Cao, W.; Pickert, V.; Hu, Y.; Mackersie, J.W.; Pierce, G. In situ diagnostics and prognostics of solder fatigue in IGBT modules for electric vehicle drives. IEEE Trans. Power Electron. 2015, 30, 1535–1543. [Google Scholar] [CrossRef]

- Triviño-Cabrera, A.; Ochoa, M.; Fernández, D.; Aguado, J.A. Independent primaryside controller applied to wireless chargers for electric vehicles. In Proceedings of the 2014 IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014. [Google Scholar] [CrossRef] [Green Version]

- Castilla, M.; Miret, J.; Matas, J.; de Vicuña, L.G.; Guerrero, J.M. Control design guidelines for single-phase grid-connected photovoltaic inverters with damped resonant harmonic compensators. IEEE Trans. Ind. Electron. 2009, 56, 4492–4501. [Google Scholar] [CrossRef]

- Gandoman, F.H.; Van Mierlo, J.; Ahmadi, A.; Abdel Aleem, S.H.E.; Chauhan, K. Safety and reliability evaluation for electric vehicles in modern power system networks. Distrib. Energy Resour. Microgrids 2019, 389–404. [Google Scholar] [CrossRef]

- Sharaf, A.M.; Omar, N.; Gandoman, F.H.; Zobaa, A.F.; Abdel Aleem, S.H.E. Electric and Hybrid Vehicle Drives and Smart Grid Interfacing. Adv. Renew. Energies Power Technol. 2018, 2, 413–439. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, J.; Bhattacharyya, S. Application of graphene and graphene-based materials in clean energy-related devices Minghui. Arch. Thermodyn 2012, 33, 23–40. [Google Scholar] [CrossRef]

- Naoui, M.; Flah, A.; Ben hamed, M. Inductive charger efficiency under internal and external parameters variation for an electric vehicle in motion. Int. J. Powertrains 2019, 8, 343–358. [Google Scholar] [CrossRef]

- Guerrero, J.M.; de Vicuna, L.G.; Matas, J.; Castilla, M.; Miret, J. A wireless controller to enhance dynamic performance of parallel inverters in distributed generation systems. IEEE Trans. Power Electron. 2004, 19, 1205–1213. [Google Scholar] [CrossRef]

- Rosu, S.G. A Dynamic Wireless Charging System for Electric Vehicles Based on DC/AC Converters with SiC MOSFET-IGBT Switches and Resonant Gate-Drive. In Proceedings of the IECON 2016-42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4465–4470. [Google Scholar]

- Jang, Y.J.; Ko, Y.D.; Jeong, S. Optimal design of the wireless charging electric vehicle. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Bellocchi, S.; Colbertaldo, P.; Manno, M.; Nastasi, B. Assessing the effectiveness of hydrogen pathways: A techno-economic optimisation within an integrated energy system. Energy 2023, 263 Pt E, 126017. [Google Scholar] [CrossRef]

- Colak, K.; Asa, E.; Bojarski, M.; Czarkowski, D.; Onar, O.C. A Novel Phase-Shift Control of Semibridgeless Active Rectifier for Wireless Power Transfer. IEEE Trans. Power Electron. 2015, 30, 6288–6297. [Google Scholar] [CrossRef]

- Shin, Y.; Park, J.; Kim, H.; Woo, S.; Park, B.; Huh, S.; Lee, C.; Ahn, S. Design Considerations for Adding Series Inductors to Reduce Electromagnetic Field Interference in an Over-Coupled WPT System. Energies 2021, 14, 2791. [Google Scholar] [CrossRef]

- Narayanamoorthi, R. Modeling of Capacitive Resonant Wireless Power and Data Transfer to Deep Biomedical Implants. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1253–1263. [Google Scholar] [CrossRef]

- Musavi, F.; Eberle, W. Overview of wireless power transfer technologies for electric vehicle battery charging. IET Power Electron. 2014, 7, 60–66. [Google Scholar] [CrossRef]

- Haque, M.S.; Mohammad, M.; Pries, J.L.; Choi, S. Comparison of 22 kHz and 85 kHz 50 kW Wireless Charging System Using Si and SiC Switches for Electric Vehicle. In Proceedings of the 2018 IEEE 6th Workshop on Wide Bandgap Power Devices and Applications (WiPDA) 2018, Atlanta, GA, USA, 31 October 2018–2 November 2018; Volume 2018, pp. 192–198. [Google Scholar] [CrossRef]

- Mohamed, N.; Aymen, F.; Ben Hamed, M.; Lassaad, S. Analysis of battery-EV state of charge for a dynamic wireless charging system. Energy Storage 2019, 5, e117. [Google Scholar] [CrossRef] [Green Version]

- Joseph, P.K.; Devaraj, E.; Gopal, A. Overview of wireless charging and vehicletogrid integration of electric vehicles using renewable energy for sustainable transportation. IET Power Electron. 2019, 12, 627–638. [Google Scholar] [CrossRef]

- Cristofari, A. Active-set identification with complexity guarantees of an almost cyclic 2-coordinate descent method with armijo line search. SIAM J. Optim. 2022, 32, 739–764. [Google Scholar] [CrossRef]

- Corio, E.; Laccone, F.; Pietroni, N.; Cignoni, P. Conception and parametric design workflow for a timber large-spanned reversible grid shell to shelter the archaeological site of the Roman shipwrecks in Pisa. Int. J. Comp. Meth. Exp. Meas. 2017, 5, 551–561. [Google Scholar] [CrossRef]

- Moosavi, S.A.; Mortazavi, S.S.; Namadmalan, A.; Iqbal, A.; Al-Hitmi, M. Design and Sensitivity Analysis of Dynamic Wireless Chargers for Efficient Energy Transfer. IEEE Access 2021, 9, 16286–16295. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. IEEE Trans. Power. Electron. 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Ghate, K.; Dole, L. A review on magnetic resonance based wireless power transfer system for electric vehicles. In Proceedings of the 2015 International Conference on Pervasive Computing (ICPC), Pune, India, 8–10 January 2015; pp. 1–3. [Google Scholar] [CrossRef]

- Kalwar, K.A.; Aamir, M.; Mekhilef, S. Inductively coupled power transfer (ICPT) for electric vehicle charging-A review. Renew. Sustain. Energy Rev. 2015, 47, 462–475. [Google Scholar] [CrossRef] [Green Version]

- Chopra, S.; Bauer, P. Analysis and design considerations for a contactless power transfer system. INTELEC. Int. Telecommun. Energy Conf. 2011, 1–6. [Google Scholar] [CrossRef]

- García, X.D.T.; Vázquez, J.; Roncero-Sánchez, P. Design, implementation issues and performance of an inductive power transfer system for electric vehicle chargers with series-series compensation. IET Power Electron. 2015, 8, 1920–1930. [Google Scholar] [CrossRef]

- Zhao, J.; Cai, T.; Duan, S.; Feng, H.; Chen, C.; Zhang, X. A General Design Method of Primary Compensation Network for Dynamic WPT System Maintaining Stable Transmission Power. IEEE Trans. Power Electron. 2016, 31, 8343–8358. [Google Scholar] [CrossRef]

- Mollaei, M.S.M.; Jayathurathnage, P.; Tretyakov, S.A.; Simovski, C.R. High-Impedance Wireless Power Transfer Transmitter Coils for Freely Positioning Receivers. IEEE Access 2021, 9, 42994–43000. [Google Scholar] [CrossRef]

- Shi, X.; Qi, C.; Qu, M.; Ye, S.; Wang, G.; Sun, L.; Yu, Z. Effects of coil shapes on wireless power transfer via magnetic resonance coupling. J. Electromagn. Waves Appl. 2014, 28, 1316–1324. [Google Scholar] [CrossRef]

- Ahmad, A.; Alam, M.S.; Mohamed, A.A.S. Design and Interoperability Analysis of Quadruple Pad Structure for Electric Vehicle Wireless Charging Application. IEEE Trans. Transp. Electrif. 2019, 5, 934–945. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.A.; Boys, J.T. Design and optimization of circular magnetic structures for lumped inductive power transfer systems. IEEE Trans. Power Electron. 2011, 26, 3096–3108. [Google Scholar] [CrossRef]

- Member, S.; Covic, G.A.; Boys, J.T. Design and Optimisation of Magnetic Structures for Lumped Inductive Power Transfer Systems. In Proceedings of the 2009 IEEE Energy Conversion Congress and Exposition 2009, San Jose, CA, USA, 20–24 September 2009; pp. 2081–2088. [Google Scholar]

- Flah, A.; Khan, I.A.; Agarwal, A.; Sbita, L.; Simoes, M.G. Field-oriented control strategy for double-stator single-rotor and double-rotor single-stator permanent magnet machine: Design and operation. Comput. Electr. Eng. 2021, 90, 1–15. [Google Scholar] [CrossRef]

- Naoui, M.; Flah, A.; Ben Hamed, M.; Sbita, L. Review on autonomous charger for EV and HEV. In Proceedings of the 2017 International Conference on Green Energy Conversion Systems (GECS), Hammamet, Tunisia, 23–25 March 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Aymen, F.; Mahmoudi, C. A Novel Energy Optimization Approach for Electrical Vehicles in a Smart City. Energies 2019, 12, 929. [Google Scholar] [CrossRef] [Green Version]

- Rawat, T.; Niazi, K.R.; Gupta, N.; Sharma, S. Impact assessment of electric vehicle charging/discharging strategies on the operation management of grid N. Mohamed, F. Aymen, M. Alqarni et al. Ain Shams Engineering Journal 13 (2022) 101569 14 accessible and remote microgrids. Int. J. Energy Res. 2019, 43, 9034–9048. [Google Scholar] [CrossRef]

- Hwang, J.J.; Kuo, J.K.; Wu, W.; Chang, W.R.; Lin, C.H.; Wang, S.E. Lifecycle performance assessment of fuel cell/battery electric vehicles. Int. J. Hydrog. Energy 2013, 38, 3433–3446. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Han, B.-M. A Bidirectional Wireless Power Transfer EV Charger Using Self-Resonant PWM. IEEE Trans. Power Electron. 2015, 30, 1784–1787. [Google Scholar] [CrossRef]

- Shanmugam, Y.; Sathik, J.; Almakhles, D.J. A Comprehensive Review of the On-Road Wireless Charging System for E-Mobility Applications. Front. Energy Res. 2022, 10, 926270. [Google Scholar] [CrossRef]

- Xie, K.; Xu, J.; Pan, Z. Research and application of anti-offset wireless charging plant protection UAV. Electr. Eng. 2020, 102, 2529–2537. [Google Scholar] [CrossRef]

- Raju, S.; Wu, R.; Chan, M.; Yue, C.P. Modeling of mutual coupling between planar inductors in wireless power applications. IEEE Trans. Power Electron. 2014, 29, 481–490. [Google Scholar] [CrossRef]

- Mohamed, N.; Aymen, F.; Lassaad, S.; Mouna, B.H. Practical validation of the vehicle speed influence on the wireless recharge system efficiency. Int. Energy Conf. 2020, 372–376. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, K.W.E. An improved and integrated design of segmented dynamic wireless power transfer for electric vehicles. Energies 2021, 14, 1975. [Google Scholar] [CrossRef]

- Lu, F.; Member, S.; Zhang, H.; Member, S. A Dynamic Charging System With Reduced Output Power Pulsation for Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6580–6590. [Google Scholar] [CrossRef]

- Zhou, S.; Chris Mi, C. Multi-Paralleled LCC Reactive Power Compensation Networks and Their Tuning Method for Electric Vehicle Dynamic Wireless Charging. IEEE Trans. Ind. Electron. 2016, 63, 6546–6556. [Google Scholar] [CrossRef]

- Alphones, A.; Jayathurathnage, P. Review on wireless power transfer technology (invited paper). In Proceedings of the IEEE Asia Pacific Microwave Conference (APMC), Kuala Lumpur, Malaysia, 13–16 November 2017; pp. 326–329. [Google Scholar] [CrossRef]

- Salau, A.O.; Marriwala, N.; Athaee, M. Data Security in Wireless Sensor Networks: Attacks and Countermeasures. In Mobile Radio Communications and 5G Networks: Proceedings of MRCN 2020; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Bi, Z.; Kan, T.; Mi, C.C.; Zhang, Y.; Zhao, Z.; Keoleian, G.A. A review of wireless power transfer for electric vehicles: Prospects to enhance sustainable mobility. Appl. Energy 2016, 179, 413–425. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, A.; Motors, R.C.H. Comparative Analysis of Power Pad for Wireless Charging of Electric Vehicles; SAE: Warrendale, PA, USA, 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Ahmad, A.; Alam, M.S.; Rafat, Y.; Shariff, S.M.; Al-Saidan, I.S.; Chabaan, R.C. Foreign Object Debris Detection and Automatic Elimination for Autonomous Electric Vehicles Wireless Charging Application. SAE Int. J. Electrified Veh. 2020, 9, 93–110. [Google Scholar] [CrossRef]

- Shanmugam, Y.; Narayanamoorthi, R.; Vishnuram, P.; Bajaj, M.; Aboras, K.M.; Thakur, P. A Systematic Review of Dynamic Wireless Charging System for Electric Transportation. IEEE Access 2022, 10, 133617–133642. [Google Scholar] [CrossRef]

- Musavi, F.; Edington, M.; Eberle, W. Wireless power transfer: A survey of EV battery charging technologies. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; Volume 2012, pp. 1804–1810. [Google Scholar] [CrossRef]

- Vishnuram, P.; Alagarsamy, S.; Krishnasamy, V.; Bajaj, M.; Khurshaid, T.; Nauman, D.; Kamel, S. A Comprehensive Review on EV Power Converter Topologies Charger Types Infrastructure and Communication Techniques. Front. Energy Res. 2023, 11, 101. [Google Scholar] [CrossRef]

- Ashok, J.; Thirumoorthy, P. Design considerations for implementing an optimal battery management system of a wireless sensor node. Indian J. Sci. Technol. 2014, 7, 1255–1259. [Google Scholar] [CrossRef]

- Wang, G.; Sun, J. Improved Magnetic Coupling Resonance Wireless Power Transfer System. Chin. Control Conf. CCC 2020, 2020, 5317–5321. [Google Scholar] [CrossRef]

- Adaramola, B.A.; Salau, A.O.; Adetunji, F.O.; Fadodun, O.G.; Ogundipe, A.T. Adetunji Development and Performance Analysis of a GPS-GSM Guided System for Vehicle Tracking. In Proceedings of the International Conference on Computation, Automation and Knowledge Management (ICCAKM), Dubai, United Arab Emirates, 9–10 January 2020; pp. 286–290. [Google Scholar] [CrossRef]

- Khan, S.; Ahmad, A.; Ahmad, F.; Shafaati Shemami, M.; Saad Alam, M.; Khateeb, S. A Comprehensive Review on Solar Powered Electric Vehicle Charging SystemA Comprehensive Review on Solar Powered Electric Vehicle Charging System. Smart Sci. 2018, 6, 54–79. [Google Scholar] [CrossRef]

- Ahmad, A.; Khan, Z.A.; Saad Alam, M.; Khateeb, S. A Review of the Electric Vehicle Charging Techniques, Standards, Progression and Evolution of EV Technologies in Germany. Smart Sci. 2018, 6, 36–53. [Google Scholar] [CrossRef]

- Khan, S.; Shariff, S.; Ahmad, A.; Saad Alam, M. A comprehensive review on level 2 charging system for electric vehicles. Smart Sci. 2018, 6, 271–293. [Google Scholar] [CrossRef]

- Apparatus for transmitting electrical energy. IEEE Trans. Circuits Syst. I Regul. Pap. 2013, 1, 1–4.

- Huang, R.; Zhang, B.; Qiu, D.; Zhang, Y. Frequency splitting phenomena of magnetic resonant coupling wireless power transfer. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Xu, H.; Wang, C.; Xia, D.; Liu, Y. Design of magnetic coupler for wireless power transfer. Energies 2019, 15, 3000. [Google Scholar] [CrossRef] [Green Version]

- Pinto, R.; Lopresto, V.; Genovese, A. A numerical study for the design of a new DD coil prototype for dynamic wireless charging of electric vehicles. IET Conf. Publ. 2018, 2018, 2–6. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H. Research on the wireless power transmission system based on coupled magnetic resonances. In Proceedings of the 2011 International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011; pp. 2255–2258. [Google Scholar] [CrossRef]

- Dashora, H.K.; Buja, G.; Bertoluzzo, M.; Pinto, R.; Lopresto, V. Analysis and design of DD coupler for dynamic wireless charging of electric vehicles. J. Electromagn. Waves Appl. 2018, 32, 170–189. [Google Scholar] [CrossRef]

- Ichikawa, K.; Bondar, H. Power Transfer System. 2012, pp. 255–259. Available online: https://www.google.ch/patents/US20120299392 (accessed on 27 December 2022).

- Joy, E.R.; Kushwaha, B.K.; Rituraj, G.; Kumar, P. Analysis and comparison of four compensation topologies of contactless power transfer system. In Proceedings of the 2015 4th International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, United Arab Emirates, 24–26 November 2015. [Google Scholar] [CrossRef]

- Campbell, S. Oak Ridge National Laboratory Wireless Charging of Electric Vehicles–CRADA Report; Oak Ridge National Lab.(ORNL): Oak Ridge, TN, USA, 2016. [Google Scholar]

- Chen, Q.; Wong, S.C.; Tse, C.K.; Ruan, X. Analysis, design, and control of a transcutaneous power regulator for artificial hearts. IEEE Trans. Biomed. Circuits Syst. 2009, 3, 23–31. [Google Scholar] [CrossRef]

- Mazzeo, D.; Matera, N.; De Luca, R.; Musmanno, R. A smart algorithm to optimally manage the charging strategy of the Home to Vehicle (H2V) and Vehicle to Home (V2H) technologies in an off-grid home powered by renewable sources. Energy Syst. 2022, 1–38. [Google Scholar] [CrossRef]

- Di Tommaso, A.O.; Genduso, F.; Miceli, R. A small power transmission prototype for electric vehicle wireless battery charge applications. In Proceedings of the 2012 International Conference on Renewable Energy Research and Applications (ICRERA), Nagasaki, Japan, 11–14 November 2012. [Google Scholar] [CrossRef]

- Phaebua, K.; Lertwiriyaprapa, T.; Phongcharoenpanich, C. Study of a repeater Tx antenna concept of a portable device wireless battery charging system. In Proceedings of the The 20th Asia-Pacific Conference on Communication (APCC2014), Pattaya, Thailand, 1–3 October 2014; Volume 2015, pp. 442–445. [Google Scholar] [CrossRef]

- Berger, A.; Agostinelli, M.; Vesti, S.; Oliver, J.A.; Cobos, J.A.; Huemer, M. A Wireless Charging System Applying Phase-Shift and Amplitude Control to Maximize Efficiency and Extractable Power. IEEE Trans. Power Electron. 2015, 30, 6338–6348. [Google Scholar] [CrossRef]

- Cristofari, A.; De Santis, M.; Lucidi, S.; Rinaldi, F. Minimization over the ℓ1 -ball using an active-set non-monotone projected gradient. Comput. Optim. Appl. 2022, 83, 693–721. [Google Scholar] [CrossRef]

- Laccone, F.; Malomo, L.; Pietroni, N.; Cignoni, P.; Schork, T. Integrated computational framework for the design and fabrication of bending-active structures made from flat sheet material. Structures 2021, 34, 979–994, ISSN 2352-0124. [Google Scholar] [CrossRef]

- Redder, D.A.G.; Brown, A.D.; Skinner, J.A. A contactless electrical energy transmission system. IEEE Trans. Ind. Electron. 1999, 46, 23–30. [Google Scholar] [CrossRef]

- Lee, S.; Huh, J.; Park, C.; Choi, N.S.; Cho, G.H.; Rim, C.T. OnLine Electric Vehicle using inductive power transfer system. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 1598–1601. [Google Scholar] [CrossRef]

- Rahulkumar, J.; Narayanamoorthi, R.; Vishnuram, P.; Bajaj, M.; Blazek, V.; Prokop, L.; Misak, S. An Empirical Survey on Wireless Inductive Power Pad and Resonant Magnetic Field Coupling for In-Motion EV Charging System. IEEE Access 2023, 11, 4660–4693. [Google Scholar] [CrossRef]

- Nagatsuka, Y.; Ehara, N.; Kaneko, Y.; Abe, S.; Yasuda, T. Compact contactless power transfer system for electric vehicles. In Proceedings of the The 2010 International Power Electronics Conference-ECCE ASIA-IPEC, Sapporo, Japan, 21–24 June 2010; Volume 2010, pp. 807–813. [Google Scholar] [CrossRef]

- Ullah, R.; Khan, S.; Khan, N.A.; Tahir, M.; Ahmad, N. Effect of replacement of soybean meal by silkworm meal on growth performance, apparent metabolizable energy and nutrient digestibility in broilers at day 28 post hatch. J. Anim. Plant Sci. 2018, 28, 1239–1246. [Google Scholar]

- Wang, C.S.; Stielau, O.H.; Covic, G.A. Design considerations for a contactless electric vehicle battery charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1314. [Google Scholar] [CrossRef]

- Covic, G.A.; Member, S.; Boys, J.T. Modern Trends in Inductive Power Transfer for Transportation Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 28–41. [Google Scholar] [CrossRef]

- Pinuela, M.; Yates, D.C.; Lucyszyn, S.; Mitcheson, P.D. Maximizing DC-to-load efficiency for inductive power transfer. IEEE Trans. Power Electron. 2013, 28, 2437–2447. [Google Scholar] [CrossRef] [Green Version]

- Alam, B.; Nusrat, M.; Sarwer, Z.; Zaid, M.; Sarwar, A. A General Review of the Recently Proposed Asymmetrical Multilevel Inverter Topologies. In Innovations in Cyber Physical Systems: Select Proceedings of ICICPS 2020; Springer: Berlin, Germany, 2021; Zaid, M. [Google Scholar]

- Zhang, W.; Wong, S.C.; Chi, K.T.; Chen, Q. Analysis and Comparison of Secondary Series- and Parallel-Compensated Inductive Power Transfer Systems Operating for Optimal Efficiency and LoadIndependent Voltage-Transfer Ratio. IEEE Trans. Power Electron. 2013, 29, 2979–2990. [Google Scholar] [CrossRef]

- Pantic, Z.; Bai, S.; Lukic, S.M. ZCS LCC-compensated resonant inverter for inductive-power-transfer application. IEEE Trans. Ind. Electron. 2011, 58, 3500–3510. [Google Scholar] [CrossRef]

- Fu, M.; Tang, Z.; Ma, C. Analysis and Optimized Design of Compensation Capacitors for a Megahertz WPT System Using Full-Bridge Rectifier. IEEE Trans. Ind. Inform. 2019, 15, 95–104. [Google Scholar] [CrossRef]

- Vishnuram, P.; Nastasi, B. Wireless Chargers for Electric Vehicle: A Systematic Review on Converter Topologies, Environmental Assessment, and Review Policy. Energies 2023, 16, 1731. [Google Scholar] [CrossRef]

- Jamal, N.; Saat, S.; Yusmarnita, Y.; Zaid, T.; Isa, M.S.M.; Isa, A.A.M. Investigations on capacitor compensation topologies effects of different inductive coupling links configurations. Int. J. Power Electron. Drive Syst. 2015, 6, 274–281. [Google Scholar] [CrossRef] [Green Version]

- Shevchenko, V.; Husev, O.; Strzelecki, R.; Pakhaliuk, B.; Poliakov, N.; Strzelecka, N. Compensation topologies in IPT systems: Standards, requirements, classification, analysis, comparison and application. IEEE Access 2020, 7, 120559–120580. [Google Scholar] [CrossRef]

- Li, J.; Kang, J.; Tian, C.; Tian, D.; Xie, T. Study on Wireless Power Transfer Technology with Series-Series Type of Magnetic Coupling Resonance Model. DEStech Trans. Comput. Sci. Eng. 2017, 225–232. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, A.; Wang, H. Structure analysis of magnetic coupling resonant for wireless power transmission system. Futur. Energy Environ. Mater. II 2015, 1, 63–70. [Google Scholar] [CrossRef]

- Wang, C.S.; Covic, G.A.; Stielau, O.H. General stability criterions for zero phase angle controlled loosely coupled inductive power transfer systems. In Proceedings of the IECON’01. 27th Annual Conference of the IEEE Industrial Electronics Society (Cat. No.37243), Denver, CO, USA, 29 November 2001–2 December 2001; Volume 2, pp. 1049–1054. [Google Scholar] [CrossRef]

- Bosshard, R.; Kolar, J.W.; Mühlethaler, J.; Stevanović, I.; Wunsch, B.; Canales, F. Modeling and η-α-pareto optimization of inductive power transfer coils for electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 50–64. [Google Scholar] [CrossRef]

- Froli, M.; Laccone, F. Experimental static and dynamic tests on a large-scale free-form Voronoi grid shell mock-up in comparison with finite-element method results. Int. J. Adv. Struct. Eng. 2017, 9, 293–308. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, A.A.S.; Shaier, A.A.; Metwally, H.; Selem, S.I. Interoperability of the Universal WPT3 Transmitter with Different Receivers for Electric Vehicle Inductive Charger Interoperability of the universal WPT3 transmitter with different receivers for electric vehicle inductive charger. eTransportation 2021, 6, 100084. [Google Scholar] [CrossRef]

- Zhang, Z. Energy Systems for Electric and Hybrid Vehicles. In Energy Cryptography for Wireless Charging of Electric Vehicles; The Institution of Engineering and Technology: London, UK, 2016; pp. 319–417. [Google Scholar]

- Ahmad, A.; Alam, M.S.; Chabaan, R. A Comprehensive Review of Wireless Charging Technologies for Electric Vehicles. IEEE Trans. Transp. Electrif. 2017, 4, 38–63. [Google Scholar] [CrossRef]

- Li, Y.; Lin, T.; Mai, R.; Huang, L.; He, Z. Compact DoubleSided Decoupled Coils-Based WPT Systems for High-Power Applications: Analysis, Design, and Experimental Verification. IEEE Trans. Transp. Electrif. 2017, 4, 64–75. [Google Scholar] [CrossRef]

- Electric Vehicle Wireless Power Transfer (WPT) Systems–Part 3: Specific Requirements for the Magnetic Field Wireless Power Transfer Systems. 2019. Available online: https://webstore.iec.ch/publication/27435 (accessed on 18 March 2019).

- Electric Vehicle Wireless Power Transfer (WPT) Systems–Part 2: Specific Requirements for Communication between Electric Road Vehicle (EV) and Infrastructure. 2019. Available online: https://webstore.iec.ch/publication/31050 (accessed on 18 March 2021).

- Standard IEC 61980-1; Electric Vehicle Wireless Power Transfer (WPT) Systems—Part I: Gen_eral Requirements|Engineering360. International Standard IEC: Geneva, Switzerland, 2015.

- IEC—TC 69 Dashboard > Documents: Working Documents, Other Documents, Support Documents. 2017. Available online: http://www.iec.ch/dyn/www/f?p=103:30:0::::FSP%0A_ORG_ID,FSP_LANG_ID:1255,2 (accessed on 13 March 2021).

- Electrically Propelled Road Vehicles? Magnetic Field Wireless Power Transfer? Safety and Interoperability Requirements. 2020. Available online: https://www.iso.org/standard/73547.html (accessed on 18 March 2021).

- Electrically Propelled Road Vehicles? Magnetic Field Wireless Power Transfer? Safety and Interoperability Requirements. 2017. Available online: https://www.iso.org/standard/64700.html (accessed on 18 March 2021).

- Use Cases for Wireless Charging Communication for Plug-in Electric Vehicles. 2013. Available online: https://www.sae.org/standards/content/j2836/6_201305/ (accessed on 18 March 2021).