1. Introduction

In order to fulfill the objectives of a 20% reduction of national gross fuel consumption and a 10% reduction of total emission of mean pollutants during 2005 to 2010 [

1], the efficiency improvement of coal-fired power plants, still contributing over 83% of China total power generation [

2], became the first priority and called for a structure adjustment of the electricity generation industry in China.

In 2006, the coal-fired power plants less than 100 MW in China reached a total installed capacity as high as 125 GW with the annual coal consumption and SO

2 emission more than 400 and 5.4 million tons, respectively [

3]. The pursues for higher efficiency, more economic benefits and lower pollutant emissions lead to the gradual phase-out of the small-scale backward power plants, which are replaced by advanced supercritical and ultra-supercritical ones with higher steam parameters [

4].

In order to safely use higher temperature steam over 600 °C, more demanding requirements, especially in terms of advanced materials with higher allowed temperature and pressure, higher resistance to steam oxidation corrosion, better welding performance and larger heat conduction coefficient, largely increase the associated capital and maintenance costs of both boiler and turbine. It is apparent that the research on new material is the key factor for the development of supercritical and ultra-supercritical technologies. With lots of pioneer plant practices, the ferrite/martensite steels, mainly P91, P92, E991 and P122, have been the primary choices for high temperature materials for live steam pipelines; the austenitic steels such as HR3C and SUPER304H are commonly used for the high temperature heat surfaces [

5]; Ni-based forging steel is currently selected as the material of rotary blades of high pressure turbine stages. In 2009, compared with the price of high temperature steel of subcritical power plants ranging from $15,000~18,000/ton, the specific cost of the four ferrite/martensite steels for supercritical and ultra-supercritical technologies is within the range of $20,000~30,000/ton [

6]. The investment distribution of newly built modern power plants may be different from the subcritical ones and, therefore, has some influences on the cost formation process.

The exergoeconomic analysis is a powerful tool for evaluation and optimization of various energy systems by calculating the cost rates of each material and energy stream, and the component-related exergoeconomic variables. The term exergoeconomic was first introduced by Tsatsaronis [

7] as an accurate and unambiguous characterization of a combination of economics and the exergy concept, and this methodology was greatly developed and applied with the contribution of many researchers including Valero and Lazano [

8,

9], Frangopoulos [

9,

10], von Spakovsky [

11], Lazzaretto [

12,

13], Tsatsaronis [

14,

15,

16,

17,

18,

19,

20] and some co-work [

21,

22,

23]

etc. Recently, there were also many applications of exergoeconomics for improving various power plants. Ahmadi

et al., performed comprehensive exergy, exergoeconomic and exergoenvironmental impact analysis and multi-objective optimization to a cogeneration plant system [

24], combined cycle power plants [

25], a gas turbine power plant [

26], with exact expressions of cost functions of each component and the cost expenditure due to pollutant and greenhouse gas emissions. Petrakopoulou [

27] conducted the exergoeconomic and exergoenvironmental analysis on a newly-proposed chemical looping power plant and also combined an iterative optimization to reduce the cost and environmental impacts. Shamsi [

28] optimized the steam pressure levels in a total site using thermoeconomic method and reached a total cost reduction of up to 8%.

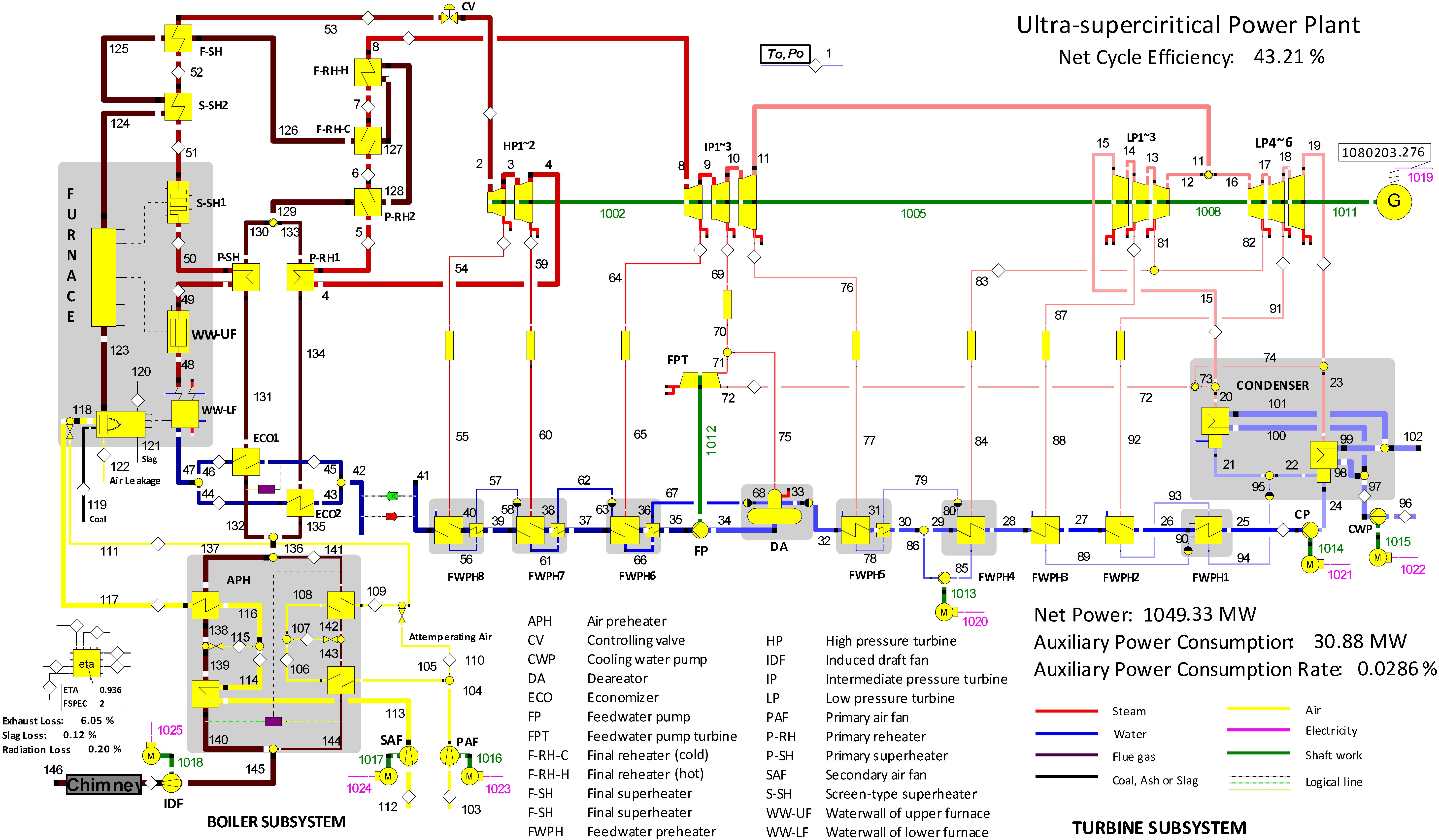

Although the exergoeconomic analysis has been widely applied for analysis and optimization of power plants, seldom focuses on the modern ultra-supercritical large-scale coal-fired power plants, where the insights into the exergoeconomic performances of the subcomponents of the once-through boiler are needed. In this paper, an existing ultra-supercritical power plant designed in 2006, constructed in 2008 and operated in 2010, was modeled and analyzed from the exergoeconomic viewpoint by using the

SPECO method [

22]. In this regard, the specific objectives of this paper are as follows:

To model the thermodynamic performance of the whole power plant and to obtain the basic information for cost estimation of the power plant.

To perform detailed thermodynamic calculation for the design of boiler.

To combine the standard design method of boiler with the corresponding economic analysis and to generate an equivalent approach to estimate boiler cost as the so-called cost function.

To identify the cost-formation process, evaluate each component and provide some useful information for the future design improvement.

4. Results and Discussion

Table 7 presents the results of the exergetic and exergoeconomic analysis for two conditions: with and without

Zk. Comparisons of the cost rates associated to each component enable us to understand how the cost structure or cost formation process changes after adding the capital, operation and maintenance investments.

The exergetic analysis reveals the location, magnitude and sources of exergy destruction. Chemical reaction and heat transfer process are always the largest sources of entropy generation in energy systems. It is shown that the exergy destruction in furnace has far larger exergy destruction than any other components, resulting in the lowest exergetic efficiency of 62.8%. The performance of other heat exchangers in boiler improves greatly with the decrease of average temperature difference for the heat transfer between the hot and cold fluids. The turbine stages except ones working within the range of wet steam have higher exergy efficiency (generally over 90%) than heat exchangers. The exergetic performances of regenerative feedwater preheaters improve with the increase of feedwater temperature level. The exergetic efficiency of the last preheater reaches as high as 96.4%. It should be noted that the exergetic efficiencies of air preheater, the first and second feedwater preheaters are far less than those of other heat exchangers, due to the low temperature level of their cold fluids. In addition, the auxiliary components, mainly pumps and fans here, are regarded to have relative high efficiency around 85%.

It is very clear from the exergoeconomic analysis with

Zk = 0 that the specific costs of the flue gases remain unchanged due to the

F principles for boiler sub-components and the specific cost of the intermediate product accumulates gradually among the components towards the final product. Due to this accumulation, the distribution of hidden costs caused by the exergy destructions among different components tends to be quite different from that of their exergy destructions. The exergy destruction within boiler components excluding the furnace reaches as high as 150 MW which is almost two times more than that of turbine itself (82 MW); however, their hidden cost rates are proven to be almost the same with $2,180/h and $2,045/h for boiler and turbine, respectively. It indicates that the economic importance of exergy destruction within a component depends highly on its relative position of the component with respect to fuel and product streams of the overall system [

27].

The sum indicates the cost importance of different components and the improvement of design should be initially focused on the components with higher . From this point of view, the once-through boiler, among which almost all the sub-components, especially the furnace, have very large , and the components HP1, IP1 and LP6 of the turbine are the keys for improving initial design of the power plant.

Table 7.

Results of the exergetic and exergoeconomic analysis for selected components of the reference power plant.

Table 7.

Results of the exergetic and exergoeconomic analysis for selected components of the reference power plant.

| Name | Exergy Balance | | |

|---|

| | | yD | εk | cf | cp | r | | cf | cp | | | | r | f |

|---|

| MW | MW | MW | % | % | $/GJ | $/GJ | - | $/h | $/GJ | $/GJ | $/h | $/h | $/h | - | - |

|---|

| | Boiler Body | FUR | 944.2 | 2542.0 | 1597 | 37.33 | 62.86 | 4.080 | 6.491 | 0.59 | 13,869 | 4.143 | 6.872 | 1,4082 | 1,615.3 | 15,697 | 0.66 | 0.10 |

| Boiler Subsystem | S-SH2 | 22.0 | 108.5 | 86.5 | 0.87 | 79.70 | 4.018 | 5.041 | 0.26 | 318.7 | 4.018 | 7.728 | 318.7 | 836.7 | 1,155.4 | 0.92 | 0.72 |

| F-SH | 16.7 | 102.4 | 85.7 | 0.66 | 83.72 | 4.018 | 4.800 | 0.19 | 241.1 | 4.018 | 8.592 | 241.1 | 1,169.8 | 1,410.9 | 1.14 | 0.83 |

| F-RH-C | 16.9 | 97.0 | 80.1 | 0.67 | 82.60 | 4.018 | 4.865 | 0.21 | 244.1 | 4.018 | 8.614 | 244.1 | 1,081.0 | 1,325.0 | 1.14 | 0.82 |

| F-RH-H | 6.5 | 32.9 | 26.3 | 0.26 | 80.18 | 4.018 | 5.012 | 0.25 | 94.2 | 4.018 | 10.490 | 94.2 | 519.5 | 613.7 | 1.61 | 0.85 |

| P-RH2 | 8.7 | 32.7 | 24.0 | 0.34 | 73.45 | 4.018 | 5.470 | 0.36 | 125.5 | 4.018 | 8.409 | 125.5 | 254.1 | 379.6 | 1.09 | 0.67 |

| P-SH | 19.1 | 118.2 | 99.1 | 0.76 | 83.84 | 4.018 | 4.792 | 0.19 | 276.2 | 4.018 | 9.295 | 276.2 | 1,605.7 | 1,881.9 | 1.31 | 0.85 |

| ECON1 | 15.3 | 124.8 | 109.5 | 0.60 | 87.76 | 4.018 | 4.578 | 0.14 | 220.9 | 4.018 | 7.192 | 220.9 | 1,030.4 | 1,251.2 | 0.79 | 0.82 |

| P-RH1 | 4.5 | 37.5 | 33.1 | 0.18 | 88.10 | 4.018 | 4.561 | 0.14 | 64.6 | 4.018 | 15.379 | 64.6 | 1,288.2 | 1,352.8 | 2.83 | 0.95 |

| ECON2 | 7.6 | 48.6 | 41.0 | 0.30 | 84.28 | 4.018 | 4.767 | 0.19 | 110.6 | 4.018 | 14.662 | 110.6 | 1,460.4 | 1,571.0 | 2.65 | 0.93 |

| APH | 33.5 | 116.1 | 82.5 | 1.33 | 71.11 | 4.018 | 5.651 | 0.41 | 485.1 | 4.018 | 6.397 | 485.1 | 221.7 | 706.7 | 0.59 | 0.31 |

| PAF | 0.5 | 2.9 | 2.5 | 0.02 | 84.30 | 8.360 | 9.917 | 0.19 | 13.8 | 12.873 | 30.234 | 21.3 | 132.9 | 154.2 | 1.35 | 0.86 |

| SAF | 0.5 | 3.4 | 2.9 | 0.02 | 84.50 | 8.360 | 9.894 | 0.18 | 16.1 | 12.873 | 26.340 | 24.7 | 116.3 | 141.1 | 1.05 | 0.83 |

| IDF | 1.6 | 11.2 | 9.6 | 0.06 | 86.02 | 8.360 | 9.718 | 0.16 | 47.0 | 12.873 | 20.653 | 72.3 | 196.6 | 268.9 | 0.60 | 0.73 |

| Turbine Subsystem | Turbine Body | HP1 | 17.2 | 276.1 | 258.8 | 0.68 | 93.76 | 8.185 | 8.729 | 0.07 | 507.7 | 10.875 | 12.182 | 674.6 | 542.9 | 1,217.4 | 0.12 | 0.45 |

| HP2 | 2.2 | 59.6 | 57.3 | 0.09 | 96.29 | 8.185 | 8.500 | 0.04 | 65.1 | 10.875 | 11.877 | 86.5 | 120.3 | 206.7 | 0.09 | 0.58 |

| IP1 | 9.4 | 200.6 | 191.2 | 0.37 | 95.31 | 7.513 | 7.882 | 0.05 | 254.4 | 10.511 | 11.902 | 355.9 | 601.5 | 957.4 | 0.13 | 0.63 |

| IP2 | 6.1 | 143.5 | 137.3 | 0.24 | 95.72 | 7.513 | 7.848 | 0.05 | 165.9 | 10.511 | 11.854 | 232.1 | 432.0 | 664.2 | 0.13 | 0.65 |

| IP3 | 4.0 | 99.4 | 95.4 | 0.16 | 95.96 | 7.513 | 7.829 | 0.04 | 108.6 | 10.511 | 11.827 | 151.9 | 300.1 | 452.0 | 0.13 | 0.66 |

| LP1 | 3.3 | 55.9 | 52.5 | 0.13 | 94.04 | 7.513 | 7.989 | 0.06 | 90.1 | 10.511 | 12.342 | 126.0 | 220.3 | 346.4 | 0.17 | 0.64 |

| LP2 | 4.3 | 62.9 | 58.6 | 0.17 | 93.17 | 7.513 | 8.063 | 0.07 | 116.2 | 10.511 | 12.446 | 162.6 | 246.0 | 408.6 | 0.18 | 0.60 |

| LP3 | 14.0 | 87.0 | 73.0 | 0.55 | 83.95 | 7.513 | 8.950 | 0.19 | 377.6 | 10.511 | 13.686 | 528.3 | 306.3 | 834.6 | 0.30 | 0.37 |

| LP4 | 3.3 | 55.9 | 52.5 | 0.13 | 94.04 | 7.513 | 7.989 | 0.06 | 90.1 | 10.511 | 12.342 | 126.0 | 220.3 | 346.4 | 0.17 | 0.64 |

| LP5 | 7.8 | 101.8 | 94.0 | 0.31 | 92.30 | 7.513 | 8.140 | 0.08 | 212.0 | 10.511 | 12.553 | 296.6 | 394.2 | 690.7 | 0.19 | 0.57 |

| LP6 | 10.6 | 51.3 | 40.8 | 0.42 | 79.39 | 7.513 | 9.464 | 0.26 | 286.2 | 10.511 | 14.405 | 400.4 | 170.9 | 571.3 | 0.37 | 0.30 |

| COND | 39.3 | - | - | 1.55 | - | 9.900 | - | | 1,399.1 | 13.851 | - | 1,957.4 | 1,370.9 | 3,328.3 | - | 0.41 |

| Regeneration System | FWPH1 | 0.586 | 0.962 | 0.377 | 0.023 | 39.13 | 7.513 | 19.200 | 1.56 | 15.8 | 10.511 | 27.668 | 22.2 | 1.1 | 23.3 | 1.63 | 0.05 |

| FWPH2 | 2.6 | 8.1 | 5.5 | 0.10 | 68.26 | 7.513 | 11.007 | 0.47 | 69.6 | 10.511 | 15.682 | 97.3 | 5.6 | 103.0 | 0.49 | 0.06 |

| FWPH3 | 2.0 | 10.7 | 8.8 | 0.08 | 81.70 | 7.513 | 9.195 | 0.22 | 53.1 | 10.511 | 13.014 | 74.4 | 4.7 | 79.1 | 0.24 | 0.06 |

| FWPH4 | 4.5 | 25.9 | 21.4 | 0.18 | 82.62 | 7.513 | 9.093 | 0.21 | 121.7 | 10.511 | 12.787 | 170.3 | 5.1 | 175.3 | 0.22 | 0.03 |

| FWPH5 | 3.6 | 30.5 | 26.9 | 0.14 | 88.06 | 7.513 | 8.532 | 0.14 | 98.5 | 10.511 | 11.992 | 137.8 | 5.3 | 143.2 | 0.14 | 0.04 |

| DA | 3.1 | 29.7 | 26.6 | 0.12 | 89.56 | 7.583 | 8.467 | 0.12 | 84.7 | 10.549 | 12.645 | 117.8 | 83.1 | 200.9 | 0.20 | 0.41 |

| FWPH6 | 4.5 | 47.8 | 43.2 | 0.18 | 90.51 | 7.629 | 8.428 | 0.11 | 124.5 | 10.574 | 12.860 | 172.5 | 183.4 | 355.9 | 0.22 | 0.52 |

| FWPH7 | 7.1 | 107.4 | 100.3 | 0.28 | 93.35 | 8.185 | 8.768 | 0.07 | 210.5 | 10.875 | 12.315 | 279.7 | 240.1 | 519.8 | 0.13 | 0.46 |

| FWPH8 | 1.5 | 43.2 | 41.6 | 0.06 | 96.42 | 8.185 | 8.489 | 0.04 | 45.6 | 10.875 | 12.703 | 60.6 | 213.4 | 274.0 | 0.17 | 0.78 |

| FPT | 8.6 | 46.7 | 38.2 | 0.34 | 81.68 | 7.513 | 9.198 | 0.22 | 231.5 | 10.511 | 15.838 | 323.9 | 407.8 | 731.6 | 0.51 | 0.56 |

| FP | 5.4 | 38.2 | 32.8 | 0.21 | 85.88 | 9.198 | 10.711 | 0.16 | 178.4 | 15.838 | 22.285 | 307.2 | 453.3 | 760.5 | 0.41 | 0.60 |

| CP | 0.2 | 1.1 | 0.9 | 0.01 | 84.61 | 8.360 | 9.880 | 0.18 | 5.1 | 12.873 | 30.092 | 7.8 | 49.9 | 57.7 | 1.34 | 0.86 |

| CWP | 2.5 | 11.1 | 8.6 | 0.10 | 77.21 | 8.360 | 10.827 | 0.30 | 76.4 | 12.873 | 28.245 | 117.6 | 358.2 | 475.8 | 1.19 | 0.75 |

| G | 11.7 | 1111.5 | 1099.9 | 0.46 | 98.95 | 8.272 | 8.360 | 0.01 | 347.6 | 12.288 | 12.873 | 516.3 | 1,800.2 | 2,316.5 | 0.05 | 0.78 |

| Total (EL = 175MW) | 1283 | 2529 | 1070 | 50.75 | 42.31 | 3.911 | 9.244 | 1.36 | 18,069 | 3.911 | 14.512 | 18,069 | 20,293 | 38,362 | 2.71 | 0.53 |

In general, the components in boiler subsystem have much larger relative cost difference rk than other components. The heat surfaces placed in the rear flue gas duct, such as P-RH1 and ECON2, achieve the greatest r as high as 2.8, while ones surrounded by higher-temperature flue gas, such as S-SH2, F-RH, F-SH and P-SH, have relative small r ranging from 0.9 to 1.5. Moreover, this parameter of the components in turbine and regeneration system is below 0.5, mostly around 0.1~0.3. What means by this is that the add costs of exergy streams through the heat surfaces after furnace due to their capital investment are much larger than that of turbine subsystem. By comparison, reducing the construction cost of these heat surfaces while keeping or lowering the level of exergy destruction must be achieved for future boiler design.

Exergoeconomic factors can identify the major cost sources (investment cost or cost of exergy destruction) of each component. It is clear that the air preheater and the furnace have far less exergoeconomic factors than any other components in the boiler. It indicates that the capital investments of these two components should be increased to improve their thermodynamic performance and the overall performance. The extremely high exergoeconomic factors of other heating surfaces indicate that more profits and cost effectiveness can be obtained if part of heat absorbed in these surfaces can be realized by the more effective radiation heat transfer in furnace with less heating surface areas. At the same time, the surface area of the air preheater can be increased to achieve a higher air preheating temperature, which can lead to a temperature increase of the flue gas and also a more even temperature field in furnace for more fierce radiation. Both the exergy destruction and the investment cost can be properly reduced and, therefore, better performance of the boiler can be achieved.

The turbine sections generally have large exergoeconomic factors within the range from 0.7 to 0.8 with the exception of the last two parallel sections LP3 and LP6, indicating that the performance of the final stages should be improved by increasing the capital investment. For the final turbine stages working in wet steam zone, more demanding blade metallurgy and coatings can be applied to against the blade erosion caused by condensed water droplets.

In addition, the factors of feedwater preheaters are rather small, less than 0.4, especially that of the low pressure feedwater preheaters, no more than 0.03. What is meant by this is that more feedwater preheaters can be configured to enhance the overall cycle performance by approaching the ideal feedwater preheating process.