Evaluation and Optimization of a Traditional North-Light Roof on Industrial Plant Energy Consumption

Abstract

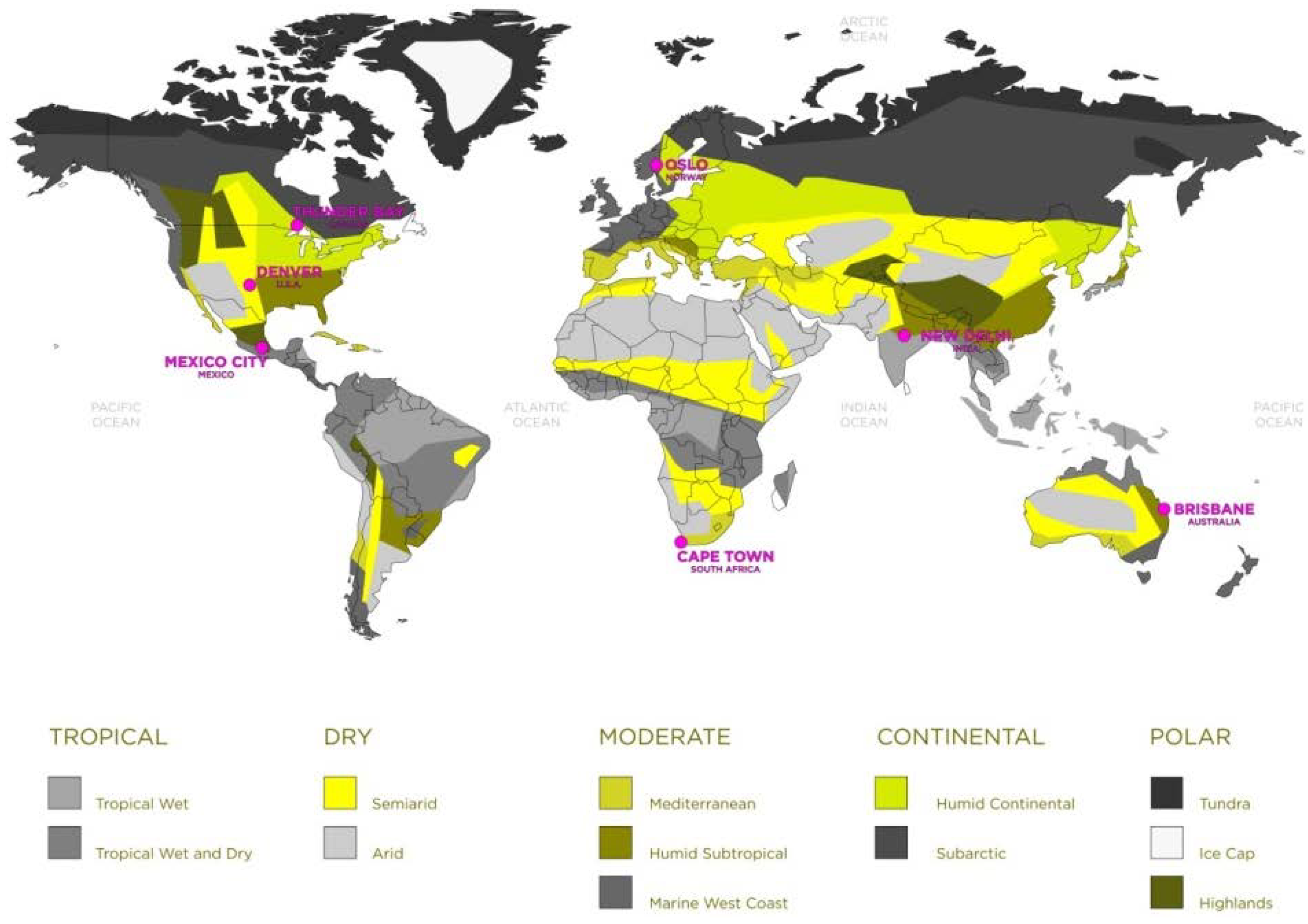

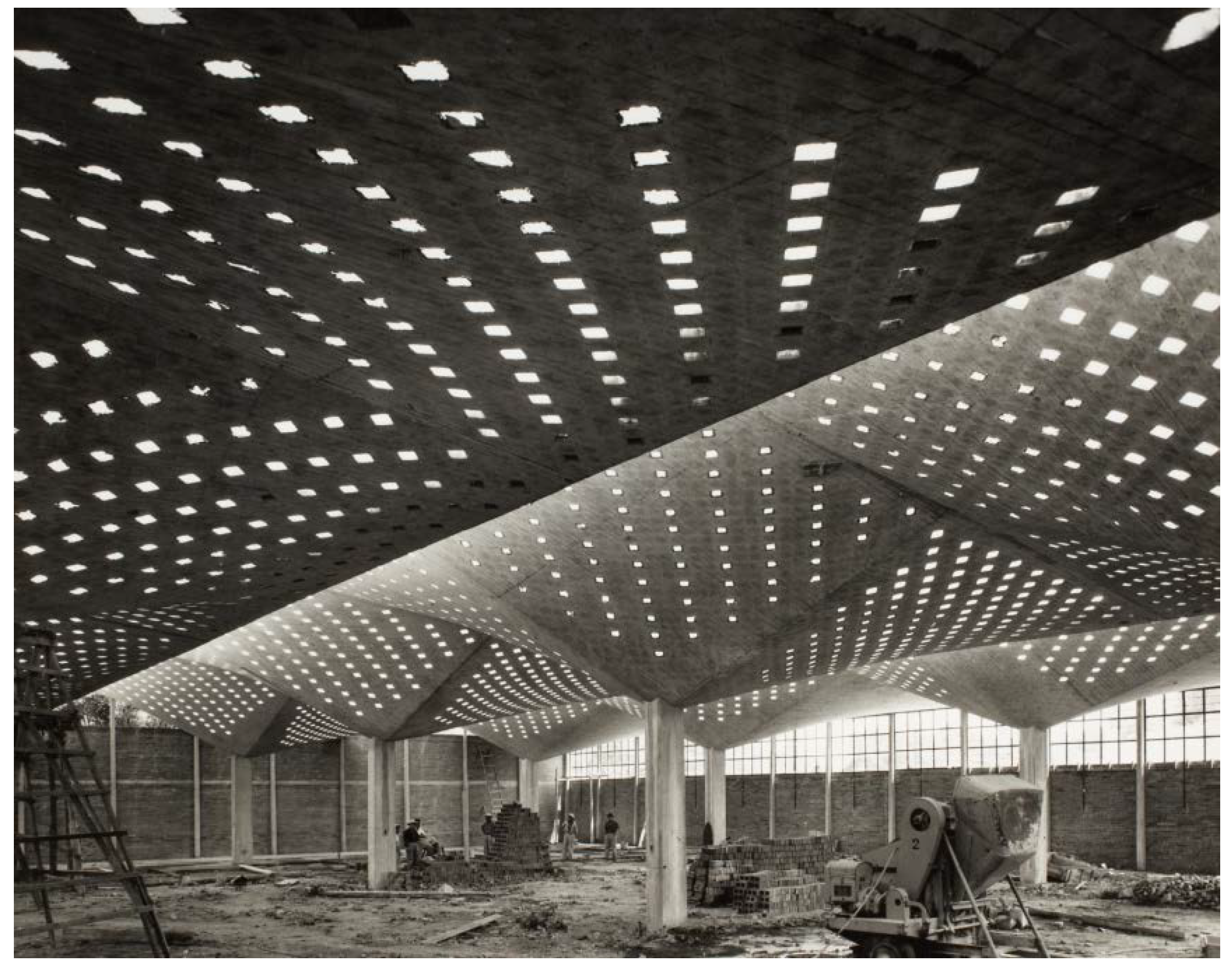

:1. Introduction: Socio-Industrial Context of Energy-Efficient Plant Design

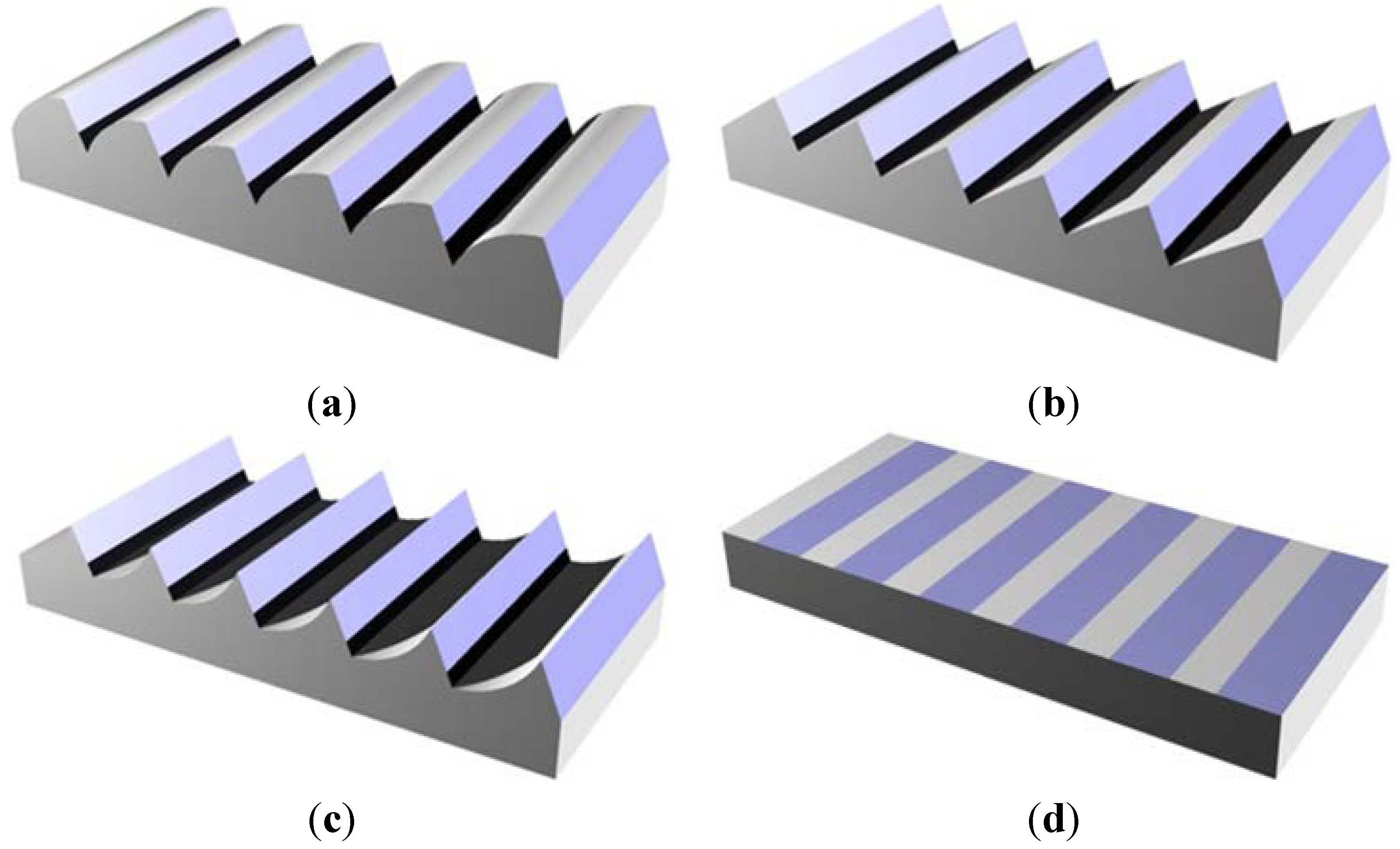

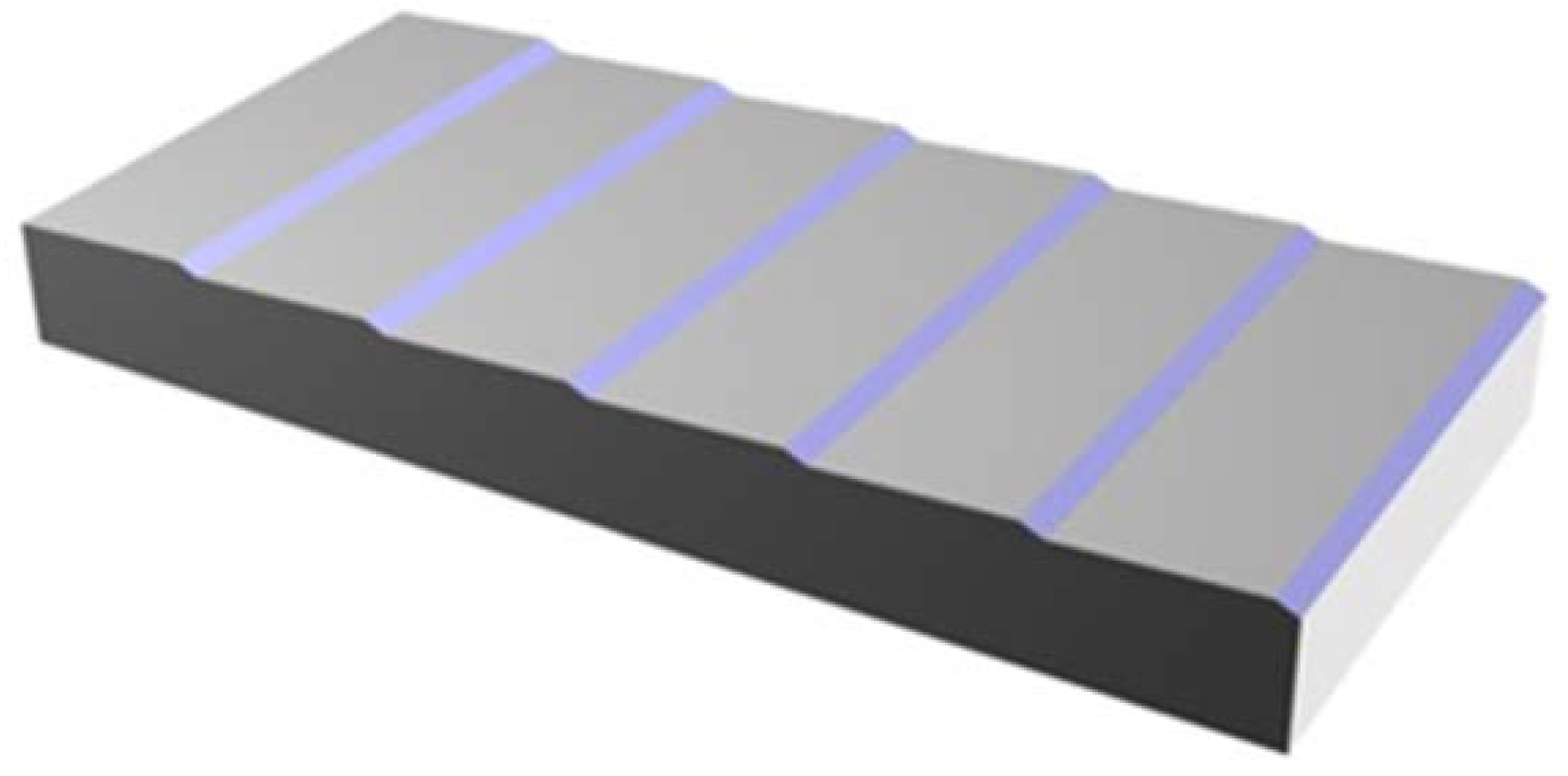

2. Context and Relevance of the North-Light Roof in Industrial Plant Buildings

3. Plant Building Energy Consumption Simulation

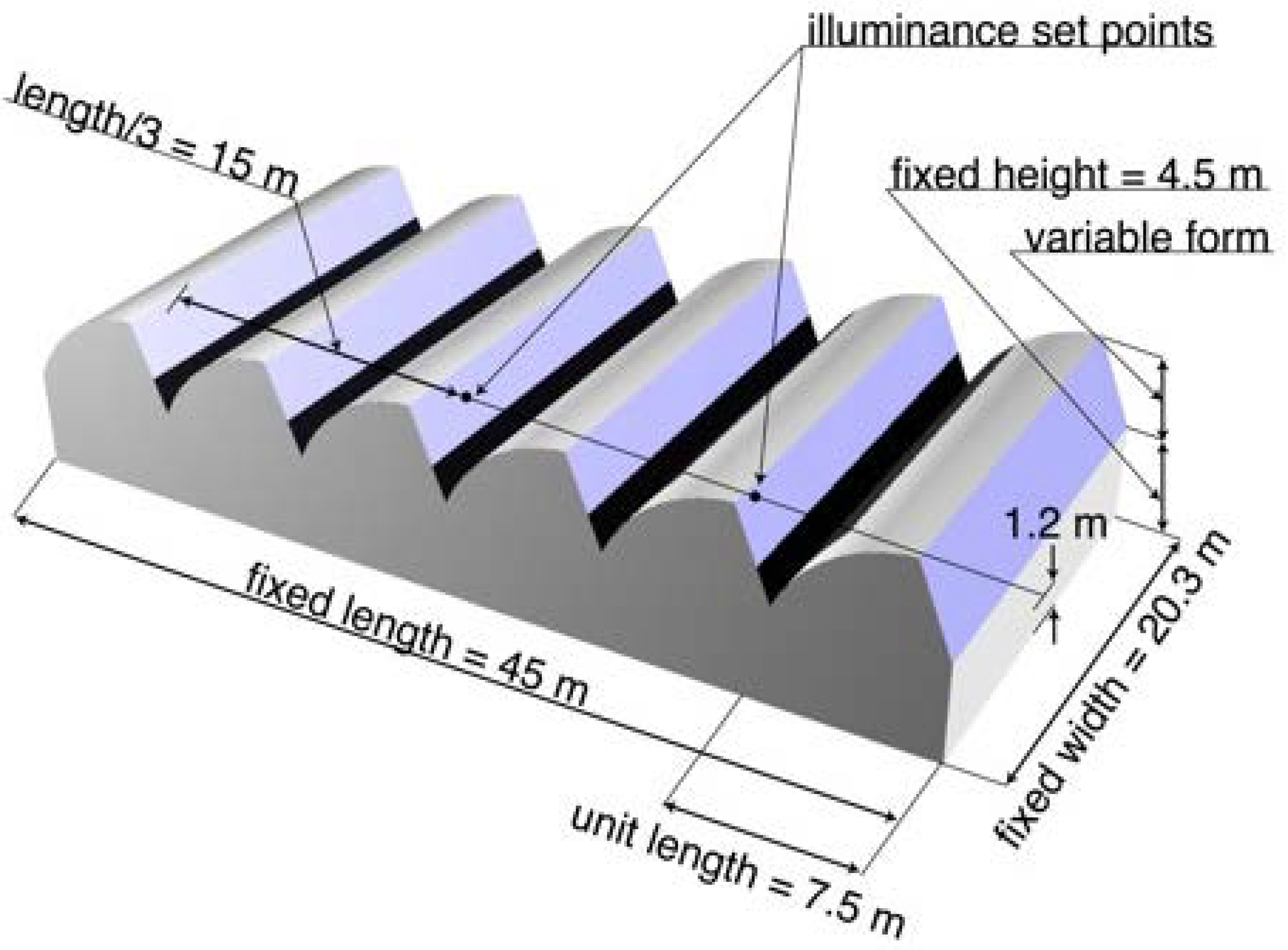

3.1. EnergyPlus Simulation Model

| Element | Layer 1 | Layer 2 | Layer 3 |

|---|---|---|---|

| Floor | 150 cm soil | 10 cm concrete | - |

| Wall | 1 cm concrete 1–4 dry block | 11 cm concrete cinder block | 1 cm gypsum plaster |

| Window | 6 mm low emissivity glass | 3 mm air gap | 6 mm low emissivity glass |

| Roof | 6 mm asphalt cover | 15 cm concrete | 1 cm gypsum plaster |

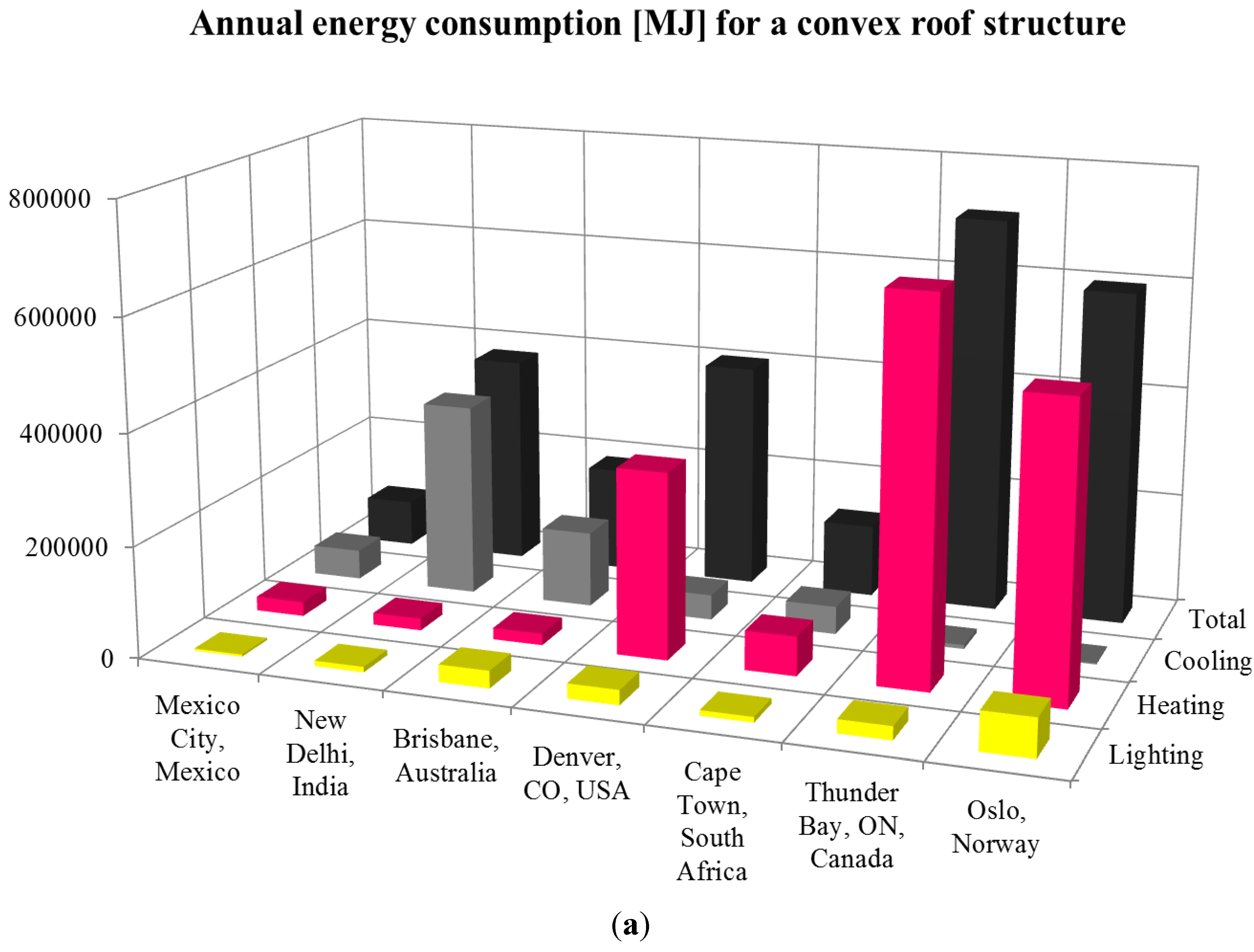

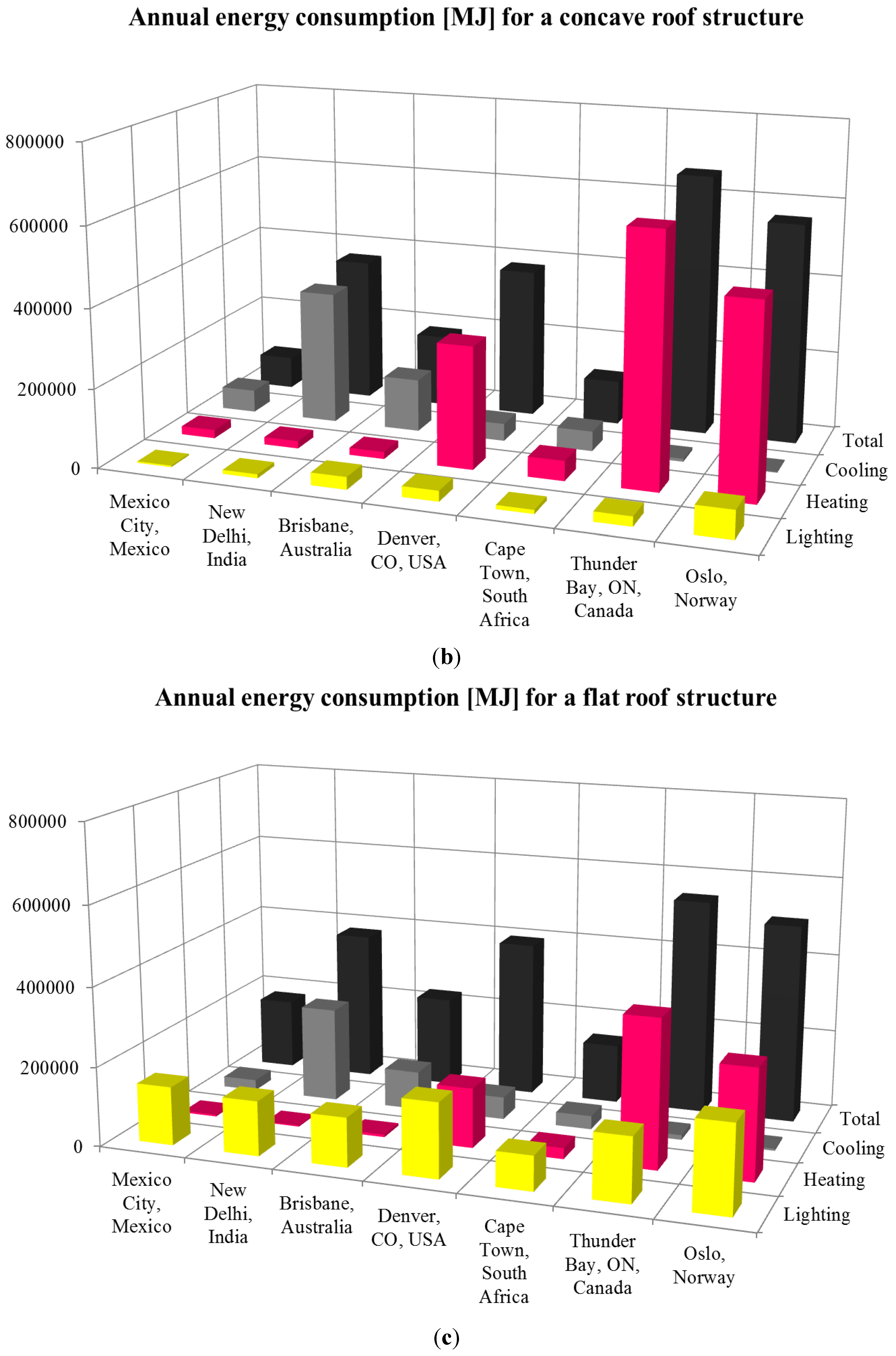

3.2. Simulation Results and Discussion

| City | Convex roof | Concave roof | Flat roof | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lighting | Heating | Cooling | Total | Lighting | Heating | Cooling | Total | Lighting | Heating | Cooling | Total | |

| Mexico City | 3,728 | 25,907 | 53,738 | 83,373 | 3,867 | 21,367 | 57,149 | 82,383 | 147,629 | 4,342 | 26,991 | 178,962 |

| New Delhi | 9,684 | 21,636 | 348,336 | 379,656 | 9,989 | 18,908 | 337,630 | 366,527 | 138,040 | 2,724 | 239,394 | 380,158 |

| Brisbane | 31,276 | 20,932 | 135,881 | 188,089 | 31,740 | 18,040 | 134,266 | 184,046 | 124,139 | 6,383 | 97,739 | 228,261 |

| Denver | 26,672 | 333,879 | 45,103 | 405,654 | 26,831 | 309,293 | 44,332 | 380,456 | 188,303 | 150,742 | 56,856 | 395,901 |

| Cape Town | 9,678 | 70,557 | 50,069 | 130,304 | 10,135 | 62,968 | 50,652 | 111,439 | 87,446 | 27,823 | 34,137 | 149,406 |

| Thunder Bay | 24,246 | 679,906 | 7,158 | 711,310 | 24,659 | 631,272 | 7,418 | 663,349 | 161,397 | 372,398 | 11,868 | 545,663 |

| Oslo | 69,022 | 527,487 | 2,130 | 598,639 | 70,236 | 487,471 | 2,346 | 560,053 | 220,519 | 277,297 | 5,002 | 502,818 |

3.2.1. Negative Effect of North-Light Roof on Building Energy Consumption

3.2.2. Positive Effect of North-Light Roof on Building Energy Consumption

4. Optimization of Building Energy Consumption for a Plant with a North-Light Roof

4.1. Problem Description

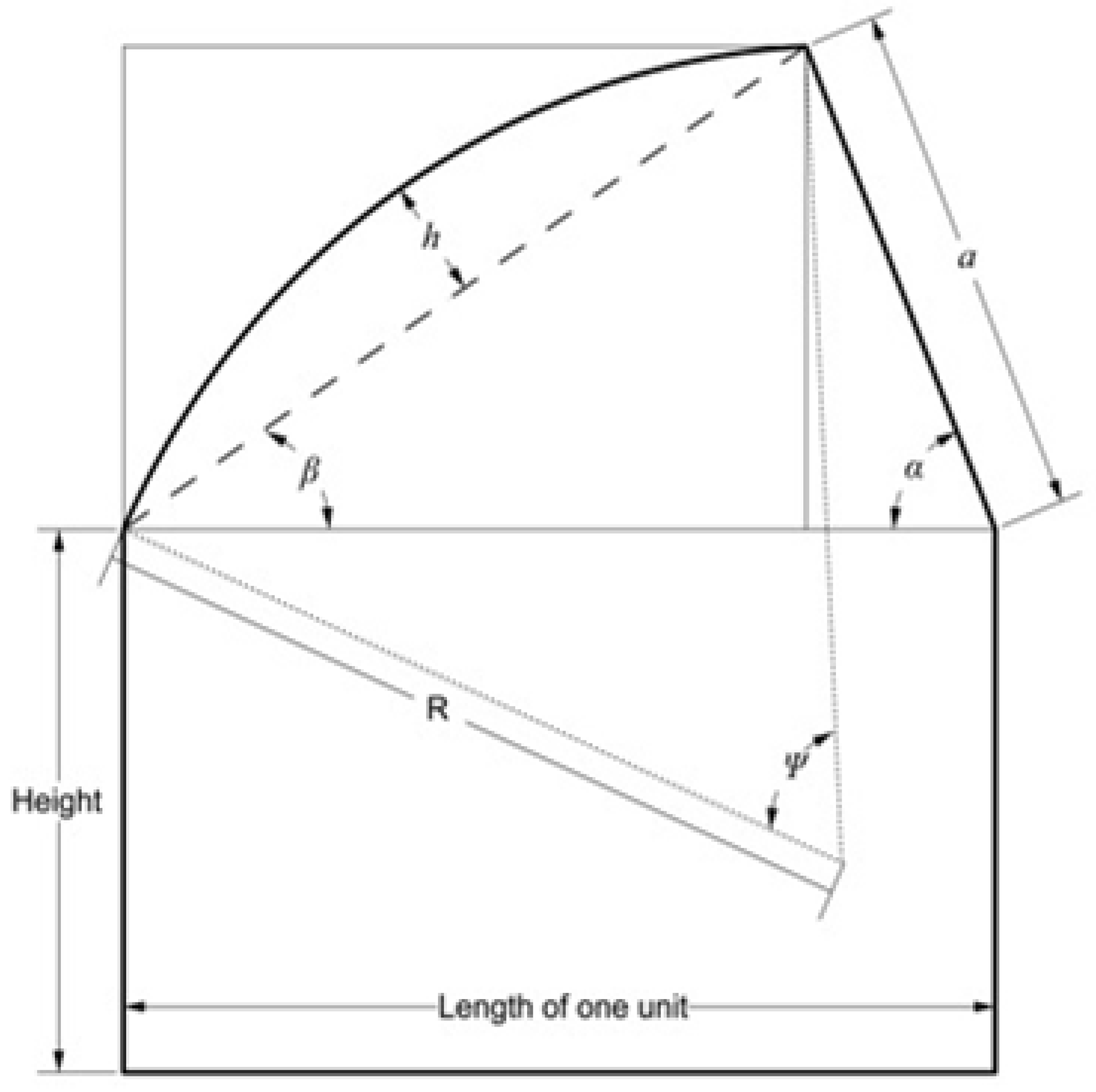

4.2. Roof Shape Optimization Problem

- 3.

- 4.

- and

4.3. Roof Shape Problem Analysis

4.4. Roof Shape Problem Solution

- Step 1. Sampling: Randomly and uniformly sample designs ( in this study);

- Step 2. Simulate the sample’s environmental performance with the crude simulation model.

- 2-1. For each of the sample designs, simulate its building energy consumption using the crude model. The crude model is based on simulation in EnergyPlus using a time step of one hour, the maximum allowable time step.

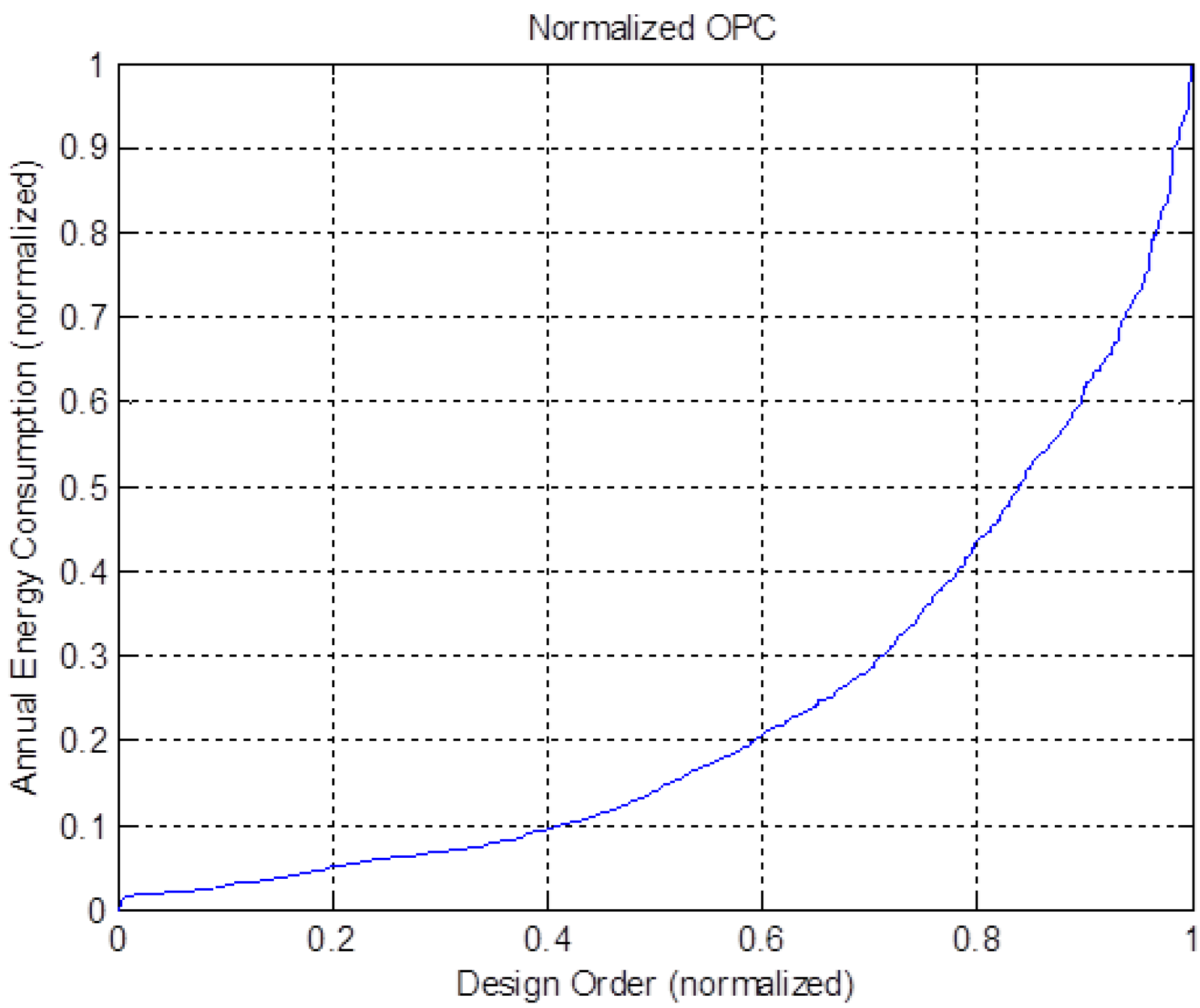

- 2-2. Estimate the normalized Ordered Performance Curve (OPC) type based on the sorted performance of the designs. OPC is defined in OO theory as a plot of performance values as a function of the order of performance.

- Step 3. Design Selection: Order the estimated performance of the designs (from lowest to high building energy consumption) and select the top designs as the selected set (horse racing selection rule). The variable s is determined according to the Universal Alignment Probability (UAP) table (defined in OO theory) and a desired acceptable level of k (also known as alignment level in OO theory, which is defined as the number of truly good enough designs in the selected set). A high noise level can be assumed since no prior knowledge is known about the noise.

- Step 4. Further distinguish between the selected sample design performances and the more accurate simulation model.

- 4-1. For each of the selected designs, simulate the building energy consumption using the more accurate EnergyPlus model using a time step of one minute, the minimum allowable time step.

- 4-2. Select the design with the best performance as the final solution.

4.5. Numerical Results for the Roof Shape Optimization

5. Conclusions

Acknowledgments

References

- Brei, M.; Johnson, K. Adapting Cities to Climate Change: Challenges for Urban Policy Innovation. Available online: http://www.feem.it/userfiles/attach/201252412465452012.05.24_Margaretha%20Breil_Katie%20Johnson_presentation.pdf (accessed on 19 December 2012).

- Markusen, J.R. Multinational firms, location and trade. World Econ. 1998, 21, 733–756. [Google Scholar] [CrossRef]

- Price, A.; Ross, M. Reducing industrial electricity costs—An automotive case study. Electr. J. 1989, 2, 40–51. [Google Scholar] [CrossRef]

- Leven, B.; Weber, C. Efficiency in Innovative Industries: Application and Benefits of Energy Indicators in the Automobile Industry. In Proceedings of American Council for an Energy-Efficient Economy: Summer Study on Energy Efficiency in Industry, Tarrytown, NY, USA, 24–27 July 2001.

- Liu, H.; Zhao, Q.; Cao, W.; Huang, N.; Zhao, X. Simulation Based Evaluation and Optimization for Energy Consumption of a Typical Welding Shop. In Proceedings of IEEE Conference on Automation Science and Engineering, Trieste, Italy, 24–27 August 2011.

- Galayda, J.; Yudelson, J. Inside Going Green: The little green book of corporate sustainability. 2009. Available online: http://www.naed.org/uploadedFiles/TEDGreenRoom/Resources/Glossary/Little_Green_Book_of_Corporate_Sustainability.pdf (accessed on 19 December 2012).

- Szokolay, S. Introduction to Architectural Science: The Basis of Sustainable Design; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Paroncini, M.; Calcagni, B. Comment on “Daylighting performance of sawtooth roofs of industrial buildings”. Light. Res. Technol. 2003, 35, 358–359. [Google Scholar] [CrossRef]

- Lam, D.; Li, D. Measurements of solarradiation and illuminance on vertical surfaces and daylighting applications. Renew. Energy 2000, 20, 389–404. [Google Scholar] [CrossRef]

- Kuchta, M. Daylighting in American Industrial Architecture: Three Investigations. Master Thesis, Rice University, Houston, TX, USA, 1994. [Google Scholar]

- Joedicke, J. Shell Architecture; Karl Kramer: Stuttgart, Germany, 1963. [Google Scholar]

- Munce, J.F. Industrial Architecture: An Analysis of International Building Practice; F.W. Dodge Corporation: New York, NY, USA, 1960. [Google Scholar]

- Heras, M.; Jimenez, M.; San Isidro, M.; Zarzalejo, L.; Perez, M. Energetic analysis of a passive solar design, incorporated ina a courtyard after refurbishment, using an innovative cover component based on a sawtooth roof concept. Solar Energy 2005, 78, 85–96. [Google Scholar] [CrossRef]

- Asdrubali, F. Daylighting performance of sawtooth roofs of industrial buildings. Light. Res. Technol. 2003, 35, 343–359. [Google Scholar] [CrossRef]

- Tsangrassoulis, A.; Santamouris, M. A method to estimate the daylight efficiency of round skylights. Energy Build. 2000, 32, 41–45. [Google Scholar] [CrossRef]

- U.S. Department of Energy. EnergyPlus Energy Simulation Software. Available online: http://apps1.eere.energy.gov/buildings/energyplus/ (accessed on 19 December 2012).

- Drury, J. Metric Handbook; Architectural Press: Oxford, UK, 1999. [Google Scholar]

- U.S. Department of Energy. Policies for A/C and Heating Temperature Set-Points in Municipal Facilities. Available online: http://www.eereblogs.energy.gov/tap/post/QA-Policies-for-AC-and-Heating-Temperature-Set-points-in-Municipal-Facilities.aspx (accessed on 19 December 2012).

- Fu, M. Optimization for simulation: Theory versus practice. J. Comput. 2002, 14, 192–215. [Google Scholar]

- Wright, J.; Loosemore, H. The Multi-Criterion Optimization of Building Thermal Design and Control. In Proceedings of 17th International Building Performance Simulation Association Conference, Rio de Janeiro, Brazil, 13–15 August 2001.

- Wright, J.; Loosemore, H.; Farmani, R. Optimization of building thermal design and control by multi-criterion genetic algorithm. Energy Build. 2002, 34, 959–972. [Google Scholar] [CrossRef]

- Caldas, L.; Norford, L. Genetic algorithms for optimization of building envelopes and the design and control of HVAC systems. J. Solar Energy Eng. 2003, 125, 343–352. [Google Scholar] [CrossRef]

- Tuhus-Durow, D.; Krarti, M. Genetic algorithm based approach to optimize building envelope design for residential buildings. Build. Environ. 2010, 45, 1574–1584. [Google Scholar] [CrossRef]

- Wanga, W.; Zmeureanu, R.; Rivard, H. Applying multi-objective genetic algorithms in green building design optimization. Build. Environ. 2005, 40, 1512–1525. [Google Scholar] [CrossRef]

- Palonen, M.; Hasan, A.; Siren, K. A Genetic Algorithm for Optimzation of Building Envelope and HVAC System Parameters. In Proceedings of 11th International Building Performance Simulation Association Conference, Glasgow, Scotland, 27–30 July 2009.

- Wetter, M.; Wright, J. A comparison of deterministic and probalistic optimization algorithms for non smooth simulation-based optimization. Build. Environ. 2004, 39, 989–999. [Google Scholar] [CrossRef]

- Ho, Y.; Zhao, Q.; Jia, Q. Ordinal Optimization: Soft Optimization for Hard Problems; Springer: New York, NY, USA, 2007. [Google Scholar]

- Moyrera Garlock, M.; Billington, D. Felix Candela: Engineer, Builder, Structural Artist; Yale University Press: New Haven, CT, USA, 2008. [Google Scholar]

© 2013 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Adriaenssens, S.; Liu, H.; Wahed, M.; Zhao, Q. Evaluation and Optimization of a Traditional North-Light Roof on Industrial Plant Energy Consumption. Energies 2013, 6, 1944-1960. https://doi.org/10.3390/en6041944

Adriaenssens S, Liu H, Wahed M, Zhao Q. Evaluation and Optimization of a Traditional North-Light Roof on Industrial Plant Energy Consumption. Energies. 2013; 6(4):1944-1960. https://doi.org/10.3390/en6041944

Chicago/Turabian StyleAdriaenssens, Sigrid, Hao Liu, Mariam Wahed, and Qianchuan Zhao. 2013. "Evaluation and Optimization of a Traditional North-Light Roof on Industrial Plant Energy Consumption" Energies 6, no. 4: 1944-1960. https://doi.org/10.3390/en6041944