Influence of Fine Metal Particles on Surface Discharge Characteristics of Outdoor Insulators

Abstract

:1. Introduction

2. Experimental Setup

3. Data Processing Method

4. Results and Discussion

4.1. Process of Surface Flashover on a Polymer Insulator in the Presence of Fine Metal Particles

4.2. Effects of Fine-Particle Size on Surface Discharge

4.3. Effects of Fine-Particle Amounts on Surface Discharge

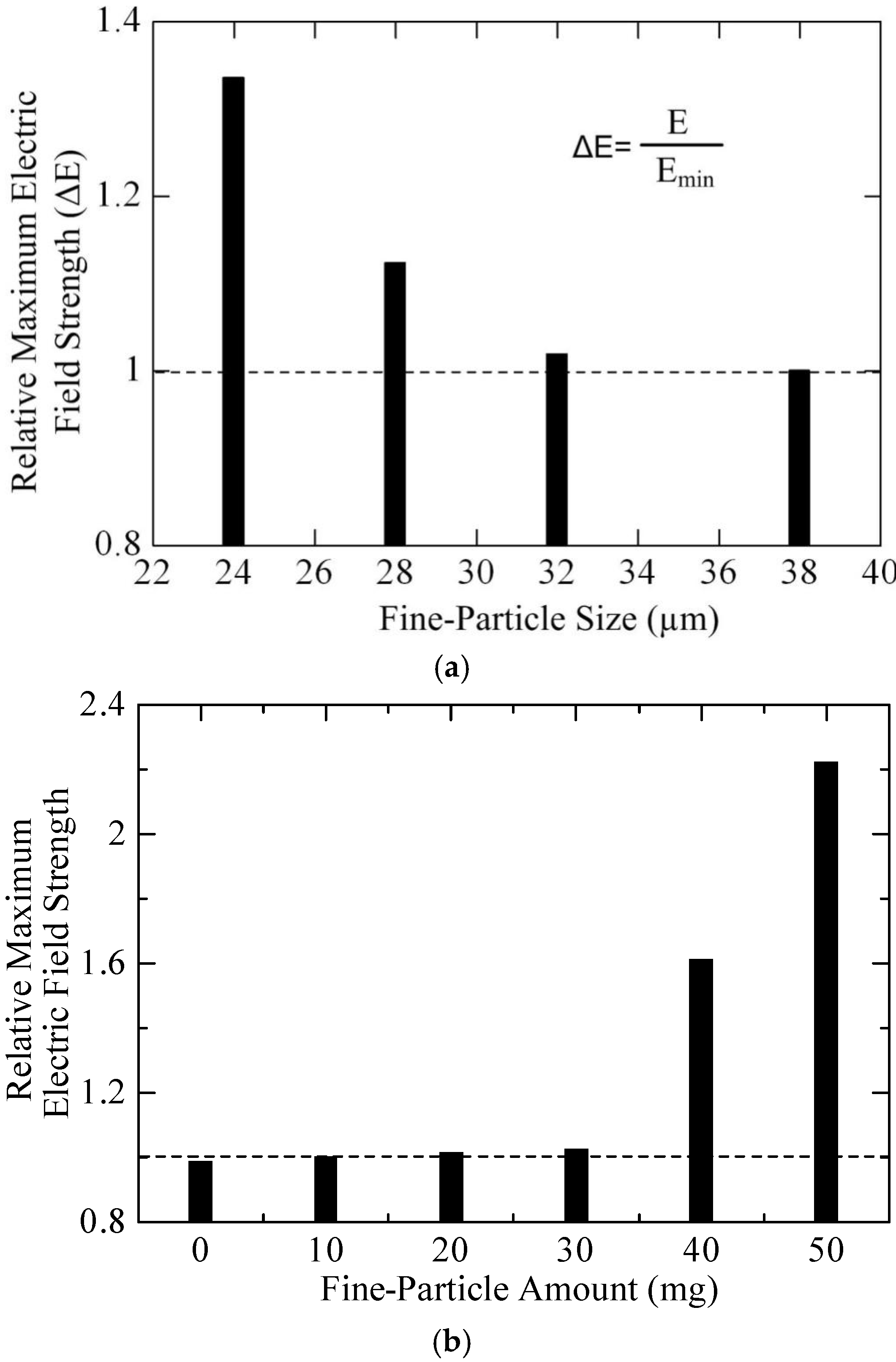

4.4. Electric Field Analysis of Insulator Surface Affected by Fine Metal Particles

5. Conclusions

- (1)

- Fine metal particles on the insulator surface under AC voltage conditions show simultaneous behaviors of erratic horizontal movement and vertical lift-off, which cause distortion and intensification of electric stresses inducing surface discharges under a rather low voltage.

- (2)

- Flashover voltage shows a decreasing tendency as particle size is reduced and particle amount is increased. An especially significant change occurs when the particle size is smaller than 28 µm, associated with a uniform distribution.

- (3)

- The fine-particle of size below 28 µm and of particle amount over 40 mg can cause the significant distortion and intensification of the electric field on the specimen surface, which is related to an easier ignition and propagation of surface discharges to flashover.

- (4)

- Light emission from surface discharges can be quantitatively analyzed as the indicator and classification index of propagation and strength of surface discharges. It shows a decreasing tendency in the discharge luminous intensity as particle size is increased and particle amount is decreased.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Douar, M.A.; Beroual, A.; Souche, X. Degradation of various polymeric materials in clean and salt fog conditions: Measurements of AC flashover voltage and assessment of surface damages. IEEE Trans. Dielectr. Electrl. Insul. 2015, 22, 391–399. [Google Scholar] [CrossRef]

- Farzaneh, M. Insulator flashover under icing conditions. IEEE Trans. Dielectr. Electrl. Insul. 2014, 21, 1997–2011. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B.X. Energy eigenvector analysis of surface discharges for evaluating the performance of polymer insulator in presence of water droplets. IEEE Trans. Dielectr. Electrl. Insul. 2014, 21, 2438–2447. [Google Scholar] [CrossRef]

- Abbasi, A.; Shayegani, A.; Niayesh, K. Contribution of design parameters of SiR insulators to their DC pollution flashover performance. IEEE Trans. Power Del. 2014, 29, 1814–1821. [Google Scholar] [CrossRef]

- Yin, F.; Farzaneh, M.; Jiang, X.L. Electrical performance of composite insulators under icing conditions. IEEE Trans. Dielectr. Electrl. Insul. 2014, 21, 2584–2593. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Wang, L.M.; Guan, Z.C.; Zhang, F.Z. Pollution flashover performance of full-scale ±800 kV converter station post insulators at high altitude area. IEEE Trans. Dielectr. Electrl. Insul. 2013, 20, 717–726. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B.X. Pattern identification of surface flashover induced by discrete water droplets on polymer insulator. IEEE Trans. Dielectr. Electrl. Insul. 2014, 21, 1972–1981. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B.X. Recurrent plot analysis of leakage current in dynamic drop test for hydrophobicity evaluation of silicone rubber insulator. IEEE Trans. Power Del. 2013, 28, 1996–2003. [Google Scholar] [CrossRef]

- Wardman, J.; Wilson, T.; Hardie, S.; Bodger, P. Influence of volcanic ash contamination on the flashover voltage of HVAC outdoor suspension insulators. IEEE Trans. Dielectr. Electrl. Insul. 2014, 21, 1189–1197. [Google Scholar] [CrossRef]

- Gouda, O.E.; El Dein, A.Z. Experimental techniques to simulate naturally polluted high voltage transmission line insulators. IEEE Trans. Dielectr. Electrl. Insul. 2014, 21, 2199–2205. [Google Scholar] [CrossRef]

- Qi, B.; Li, C.R.; Hao, Z.; Geng, B.B.; Xu, D.G.; Liu, S.Y.; Deng, C. Surface discharge initiated by immobilized metallic particles attached to gas insulated substation insulators: process and features. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 792–800. [Google Scholar] [CrossRef]

- Jiang, X.L.; Liu, Y.; Meng, Z.G.; Long, C.H.; Jin, X.; Zhang, Z.J. Effect of fog-haze on AC flashover performance of insulator. High Volt. Eng. 2014, 40, 3311–3317. [Google Scholar]

- Wang, J.; Chen, L.H.; Liu, Y.; Liang, X.D. Effect of the electric field on the contamination accumulation characteristic of the insulators. High Volt. Eng. 2011, 37, 585–593. [Google Scholar]

- Guan, Z.C.; Wang, L.M.; Yang, B.; Lai, Q.; Ding, N.; Wang, H.; Liu, W. Study on the polluted regularity of insulators quantitatively described by partial surface conductivity. In Proceedings of 2001 International Symposium on Electrical Insulating Materials (ISEIM 2001), Himeji, Japan, 19–22 November 2001; pp. 293–296.

- Casale, E.P.; Que, W.G.; Sebo, S.A. Distribution of salt contamination in the course of fog chamber tests of polymer insulators. In Proceedings of 2002 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Quintana Roo, Mexico, 20–24 October 2002; pp. 359–362.

- Li, Y.; Wang, J.; Liang, X.D.; Liu, Y.Y. Adhesion force measurement of electrical insulating materials by atomic force microscopy. In Proceedings of Power Engineering and Automation Conference (PEAM), Wuhan, China, 18–20 September 2012; pp. 1–5.

- Zhong, Y.; Peng, Z.R.; Liu, P.; Wu, X.Q. The influence of charged sand particles on the external insulation performance of composite insulators in sandstorm condition. In Proceedings of 8th International Conference on Properties and Applications of Dielectric Materials, Bali, Indonesia, June 2006; pp. 542–545.

- Wang, B.; Liang, X.D.; Zhang, Y.B.; Luo, B.; Li, Z.Y.; Zhou, Y.X. Natural pollution test of composite and porcelain insulators under AC and DC stress. High Volt. Eng. 2009, 35, 2322–2328. [Google Scholar]

- Wang, B.; Chen, H.J.; Chen, W. A preliminary discussion on accumulated contamination regular pattern on composite insulators. Hebei Electric Power. 2003, 22, 30–32. [Google Scholar]

- Tang, C.Y.; Liang, X.D. A brief introduction to service performance and natural contamination test on abroad DC polymeric insulators. Power System Technology. 1999, 23, 50–53. [Google Scholar]

- Deng, H.M.; He, Z.H.; Xu, Y.H.; Ma, J.; Li, J. Effects of haze environment on discharge path under lightning impulses. High Volt. Eng. 2009, 35, 2669–2673. [Google Scholar]

- Wang, L.M.; Liu, D.; Chen, F.L.; Mei, H.W.; Lu, M. Simulation method and testing apparatus of fog-haze. High Volt. Eng. 2014, 40, 3297–3304. [Google Scholar]

- Liu, Y.Y.; Li, Y.; Wang, J.; Liang, X.D. Adhesion force and long-range attractive force between contamination particles and insulator surface. High Volt. Eng. 2014, 40, 1010–1016. [Google Scholar]

- El-Zohri, E.H.; Abdel-Salam, M.; Shafey, H.M. Mathematical modeling of flashover mechanism due to deposition of fire-produced soot particles on suspension insulators of a HVTL. Electric Power Syst. Res. 2013, 95, 232–246. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B.X.; Du, D.M. Pattern analysis on dielectric breakdown characteristics of biodegradable polyethylene film under nonuniform electric field. Int. Trans. Electr. Energy Syst. 2013, 23, 72–82. [Google Scholar] [CrossRef]

- Du, B.X.; Liu, Y. Pattern analysis of discharge characteristics for hydrophobicity evaluation of polymer insulator. IEEE Trans. Dielectr. Electrl. Insul. 2011, 18, 114–121. [Google Scholar] [CrossRef]

- Hao, L.; Lewin, P.L.; Hunter, J.A.; Swaffield, D.J.; Contin, A.; Walton, C.; Michel, M. Discrimination of multiple PD sources using wavelet decomposition and principal component analysis. IEEE Trans. Dielectr. Electrl. Insul. 2011, 18, 1702–1711. [Google Scholar] [CrossRef]

- Carraz, F.; Rain, P.; Tobazéon, R. Particle-initiated breakdown in a quasi-uniform field in transformer oil. IEEE Trans. Dielectr. Electrl. Insul. 1995, 2, 1052–1063. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xia, B.; Du, B.; Farzaneh, M. Influence of Fine Metal Particles on Surface Discharge Characteristics of Outdoor Insulators. Energies 2016, 9, 87. https://doi.org/10.3390/en9020087

Liu Y, Xia B, Du B, Farzaneh M. Influence of Fine Metal Particles on Surface Discharge Characteristics of Outdoor Insulators. Energies. 2016; 9(2):87. https://doi.org/10.3390/en9020087

Chicago/Turabian StyleLiu, Yong, Bowen Xia, Boxue Du, and Masoud Farzaneh. 2016. "Influence of Fine Metal Particles on Surface Discharge Characteristics of Outdoor Insulators" Energies 9, no. 2: 87. https://doi.org/10.3390/en9020087