Pore-Scale Simulation and Sensitivity Analysis of Apparent Gas Permeability in Shale Matrix

Abstract

:1. Introduction

2. Shale Matrix Pore Network Model

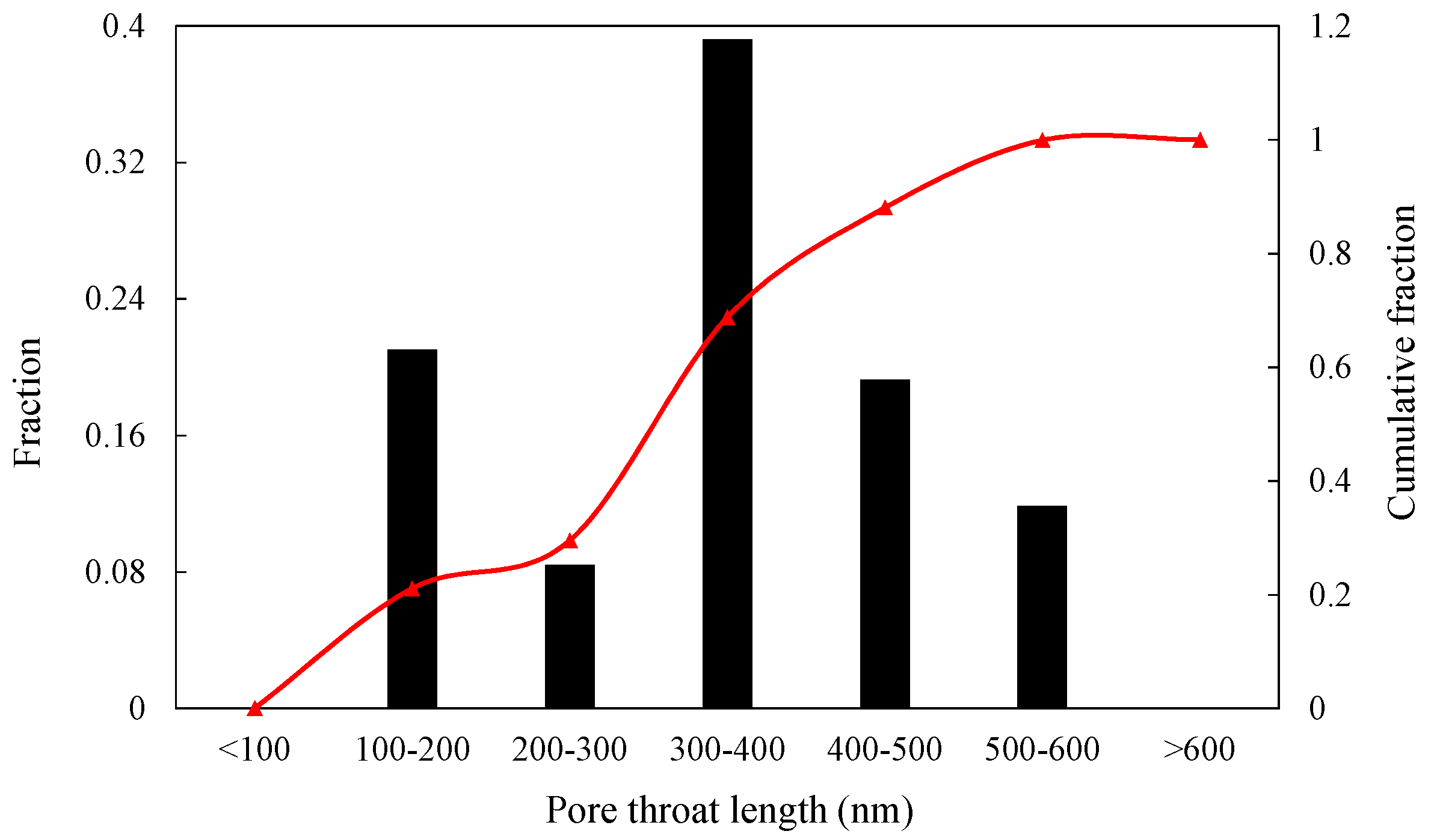

2.1. Petro-Physical Property

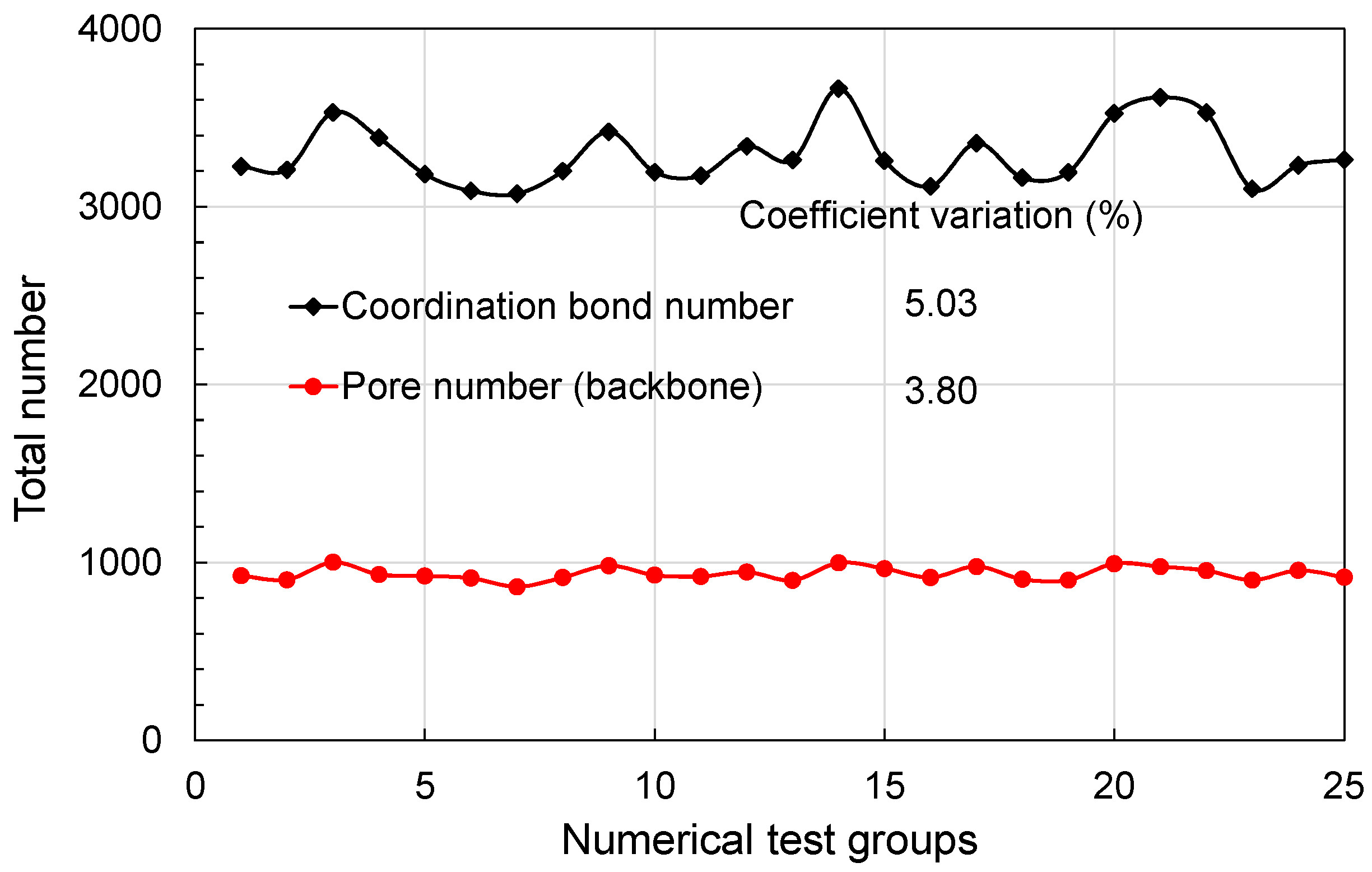

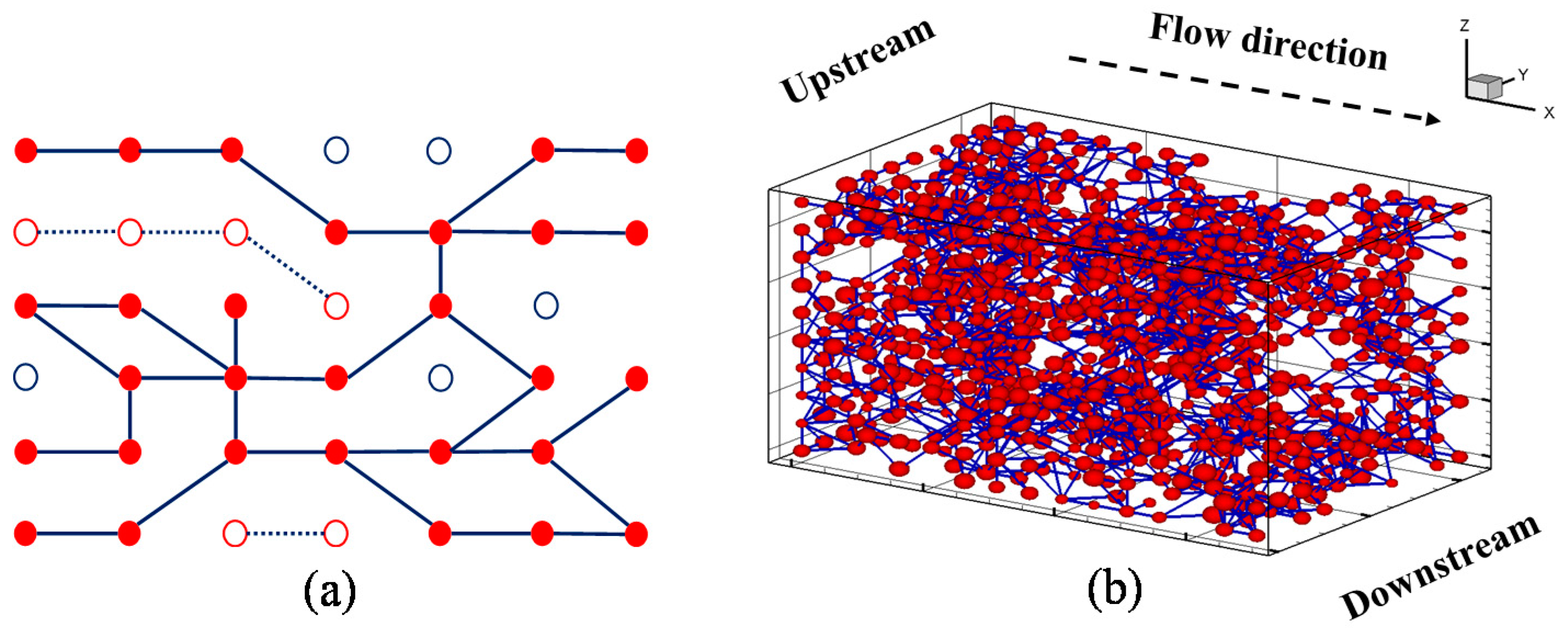

2.2. Pore Connectivity

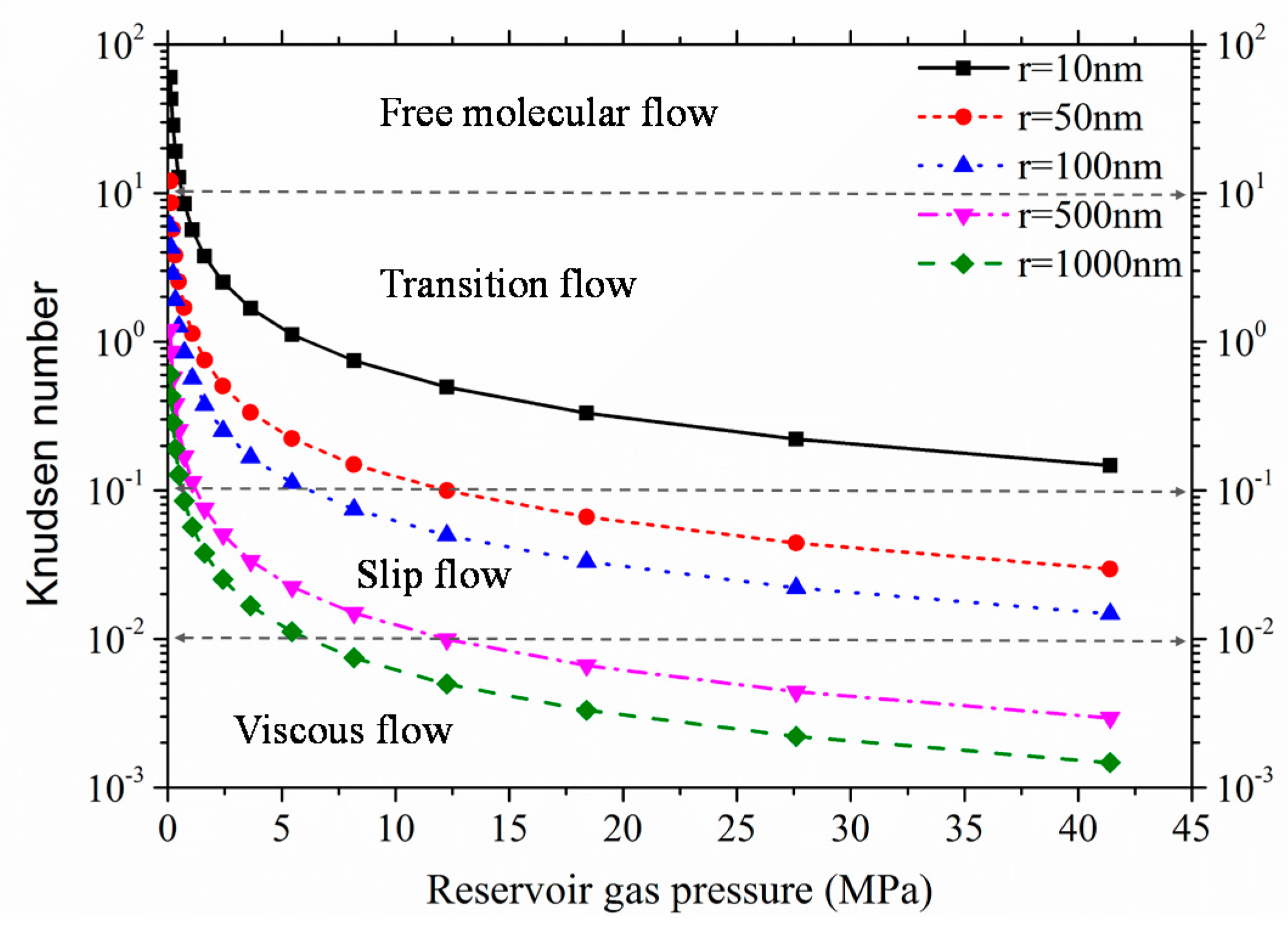

2.3. Pore-Scale Gas Flow Models

3. Results and Discussion

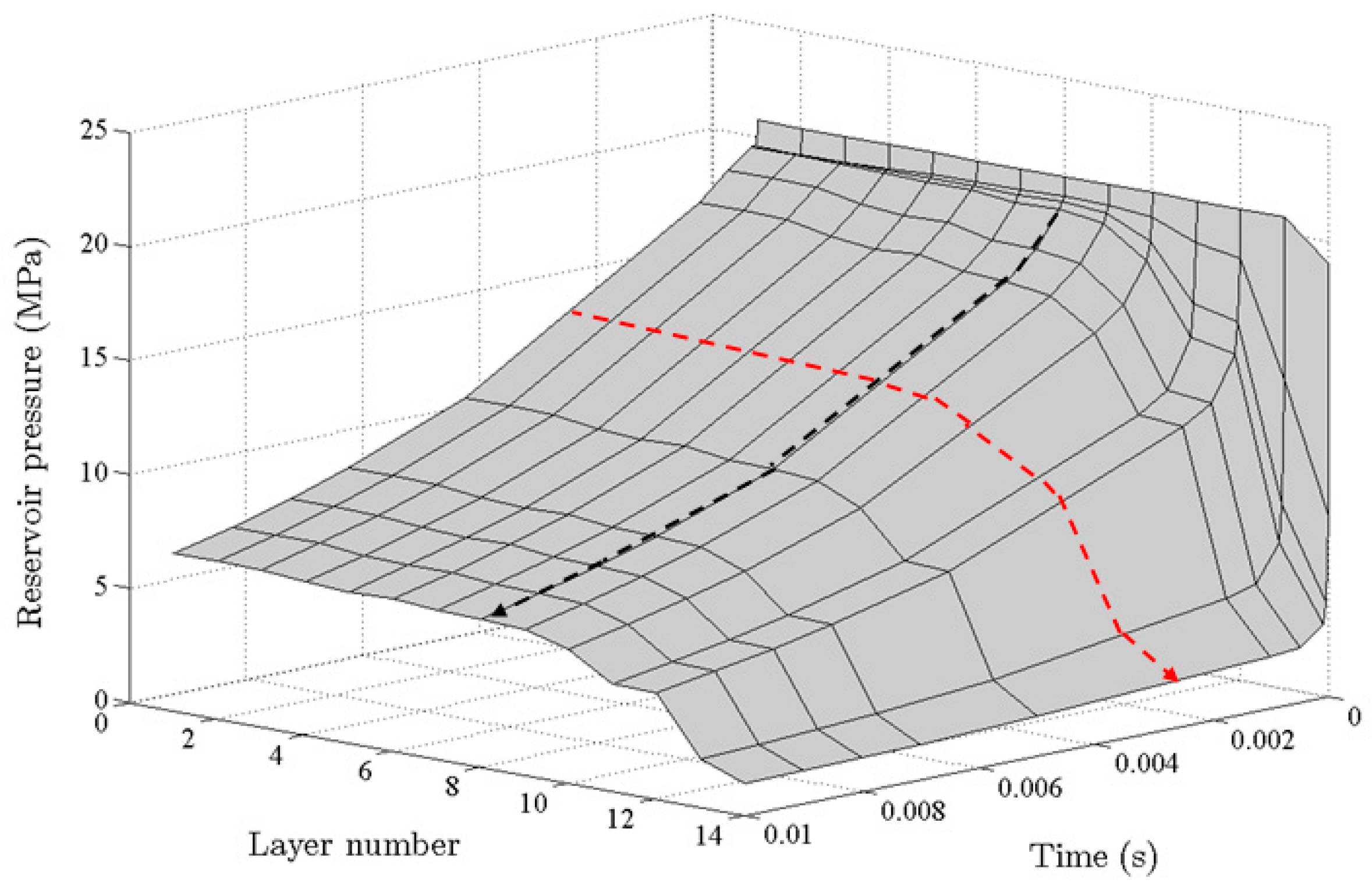

3.1. Nano-Scale Shale Matrix Gas Flow

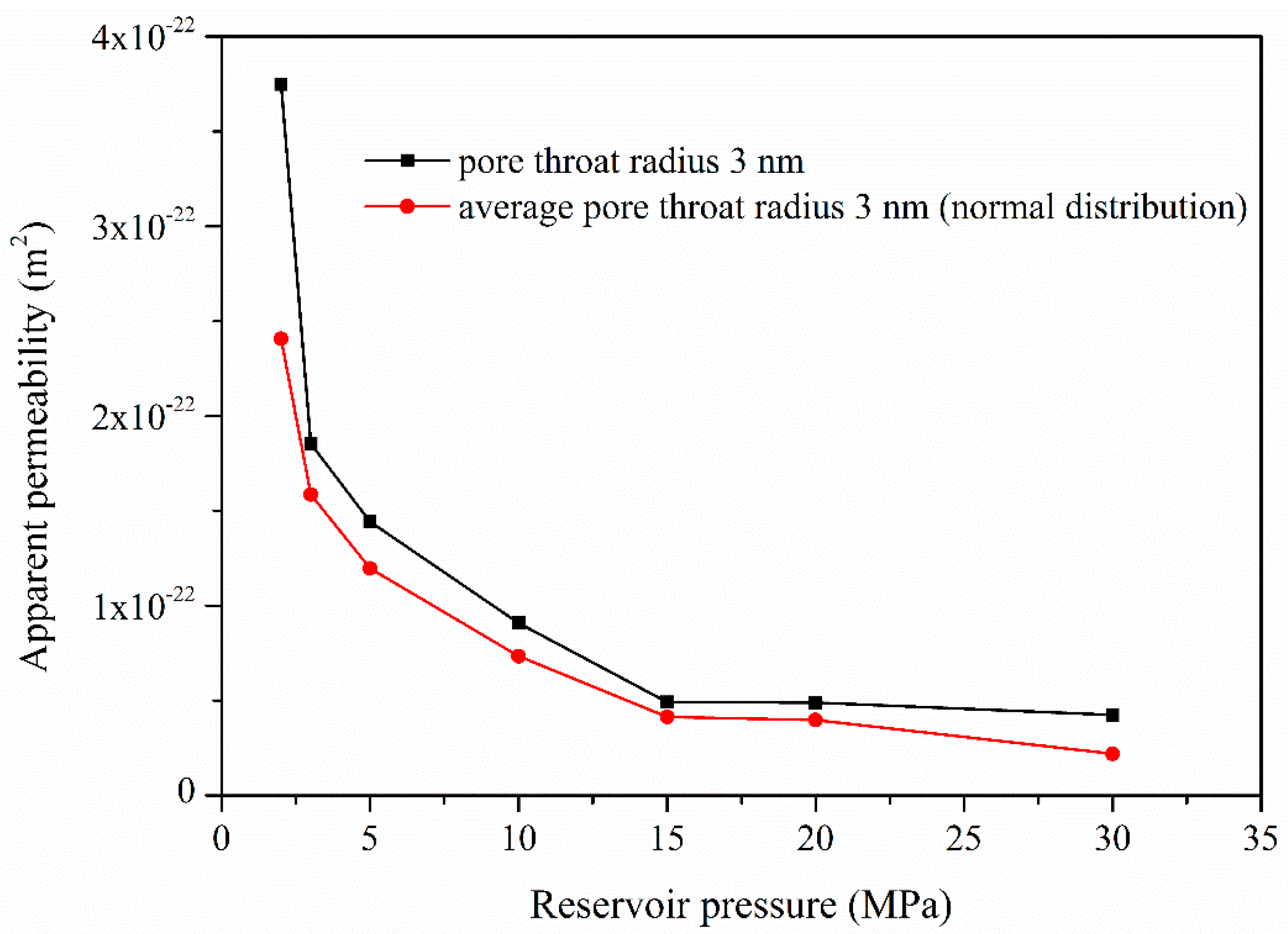

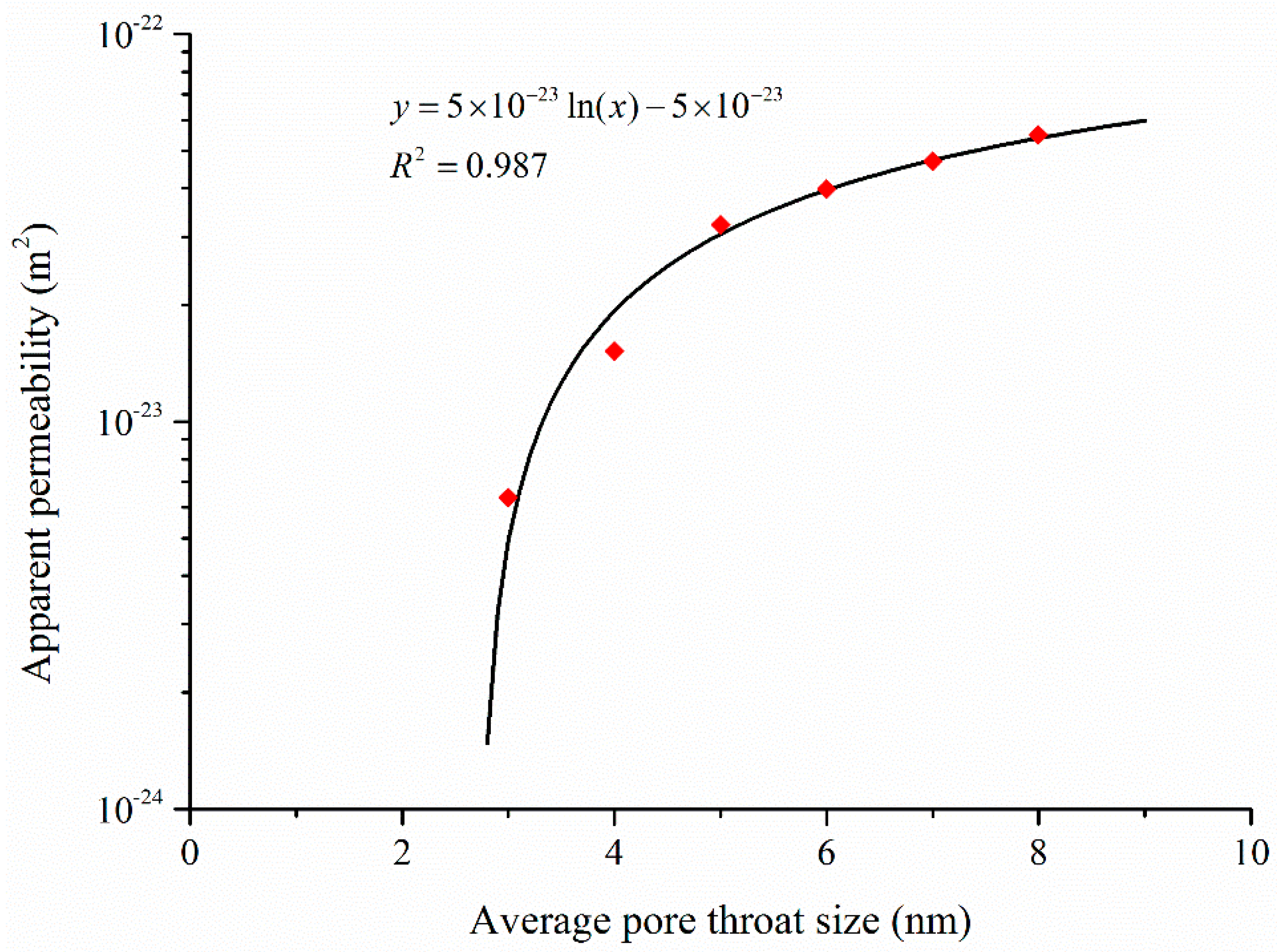

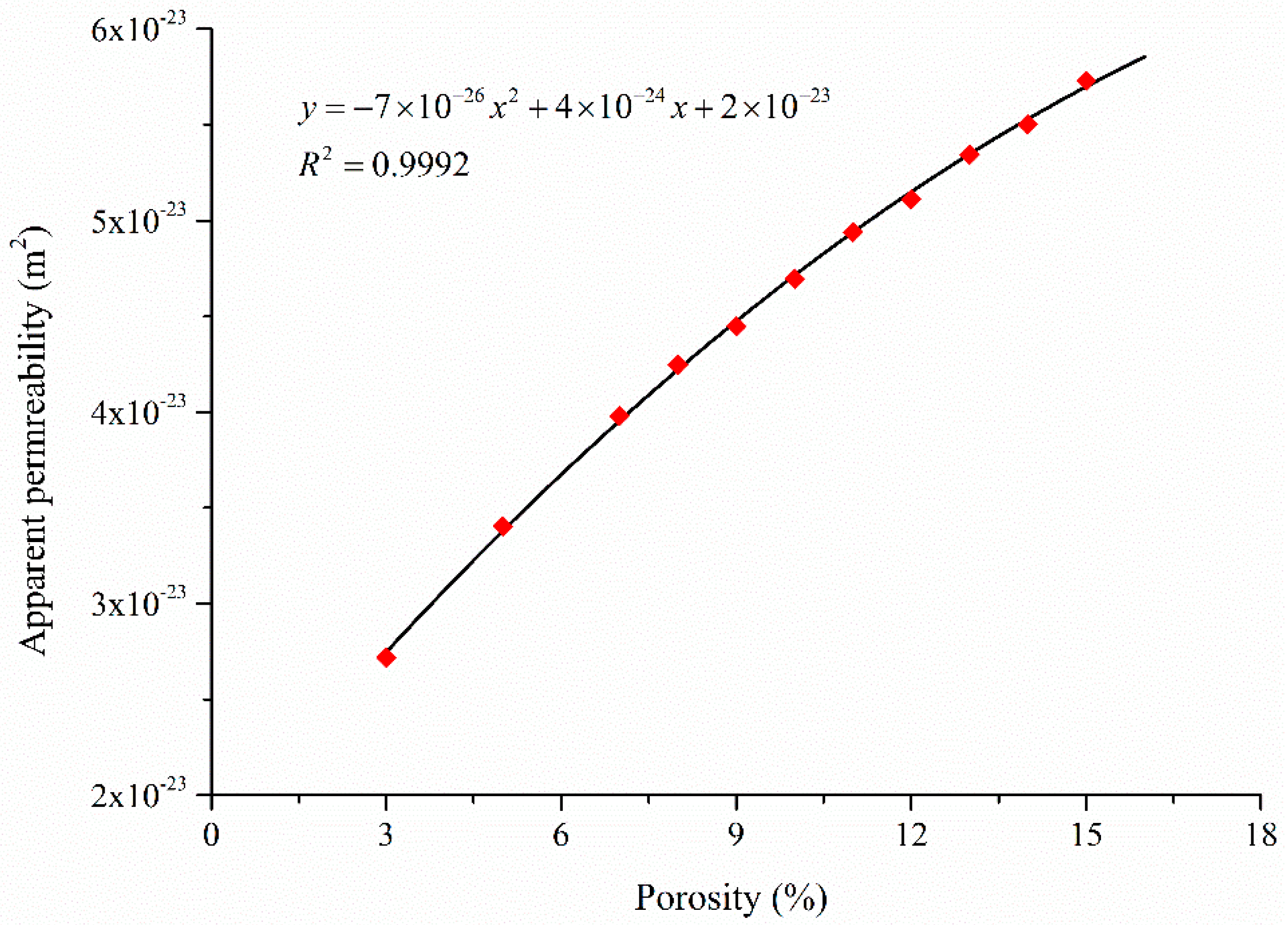

3.2. Apparent Permeability of Shale Matrix

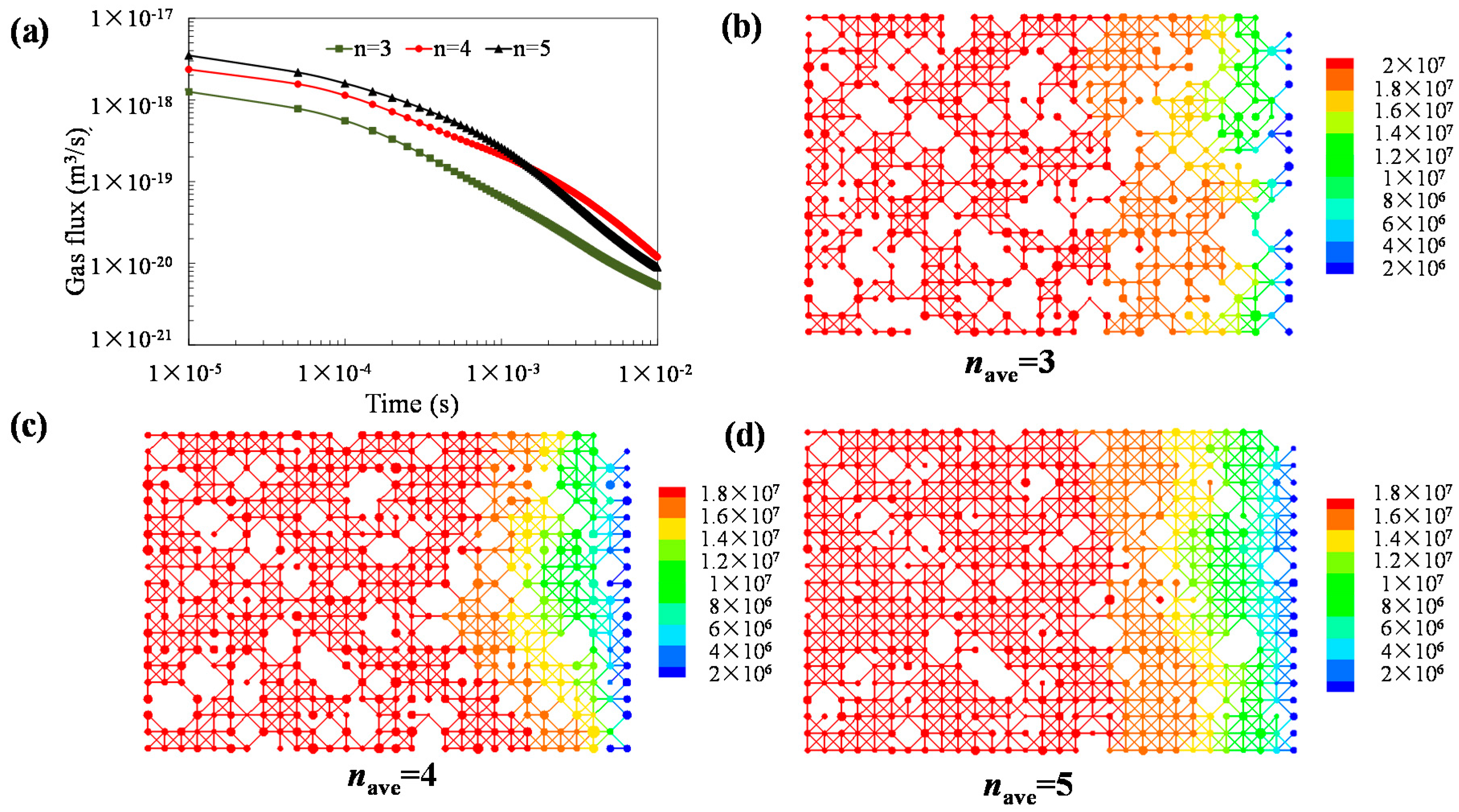

3.3. Connectivity in Tight Formations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Soeder, D.J. Porosity and permeability of Eastern Devonian gas shale. SPE Form. Eval. 1988, 3, 116–124. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Renault, P. The effect of spatially correlated blocking up of some bonds or nodes of a network on the percolation threshold. Transp. Porous Media 1991, 6, 451–468. [Google Scholar] [CrossRef]

- Curtis, M.E.; Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Microstructural investigation of gas shales in two and three dimensions using nanometer-scale resolution imaging. AAPG Bull. 2012, 96, 665–677. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar]

- Firouzi, M.; Rupp, E.C.; Liu, C.W.; Wilcox, J. Molecular simulation and experimental characterization of the nanoporous structures of coal and gas shale. Int. J. Coal Geol. 2014, 121, 123–128. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Mehmani, A.; Prodanović, M.; Javadpour, F. Multiscale, Multiphysics Network Modeling of Shale Matrix Gas Flows. Transp. Porous Media 2013, 99, 377–390. [Google Scholar] [CrossRef]

- Mehmani, A.; Prodanović, M. The application of sorption hysteresis in nano-petrophysics using multiscale multiphysics network models. Int. J. Coal Geol. 2014, 128, 96–108. [Google Scholar] [CrossRef]

- Raoof, A.; Hassanizadeh, S.M. A New Method for Generating Pore-Network Models of Porous Media. Transp. Porous Media 2010, 81, 391–407. [Google Scholar] [CrossRef]

- Dewers, T.A.; Heath, J.; Duranti, R. Three-dimensional pore networks and transport properties of a shale gas formation determined from focused ion beam serial imaging. Int. J. Oil Gas Coal Technol. 2012, 5, 229–248. [Google Scholar] [CrossRef]

- Oren, P.E.; Bakke, S. Process Based Reconstruction of Sandstones and Prediction of Transport Properties. Transp. Porous Media 2002, 46, 311–343. [Google Scholar] [CrossRef]

- Arns, J.Y.; Robins, V.; Shepperd, A.P.; Sok, R.M.; Pinczewski, W.V.; Knackstedt, M.A. Effect of network topology on relative permeability. Transp. Porous Media 2004, 55, 21–46. [Google Scholar] [CrossRef]

- Hu, Q.H.; Ewing, R.P.; Dultz, S. Low pore connectivity in natural rock. J. Contam. Hydrol. 2012, 133, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Javadpour, F. Nanoscale Gas Flow in Shale Gas Sediments. J. Can. Pet. 2007, 46, 55–61. [Google Scholar] [CrossRef]

- Ziarani, A.S.; Aguilera, R. Knudsen’s Permeability Correction for Tight Porous Media. Transp. Porous Media 2011, 91, 239–260. [Google Scholar] [CrossRef]

- Freeman, C.M.; Moridis, G.J.; Blasingame, T.A. A Numerical Study of Microscale Flow Behavior in Tight Gas and Shale Gas Reservoir Systems. Transp. Porous Media 2011, 90, 253–268. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, S.J.; Cheng, L.S.; Xu, W.J.; Liu, H.J.; Yang, Y.; Xue, Y.C. Effect of flow mechanism with multi-nonlinearity on production of shale gas. J. Nat. Gas Sci. Eng. 2015, 24, 291–301. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and Apparent Permeability of Gas Flow in Mudrocks. J. Can. Pet. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Shi, J.T.; Zhang, L.; Li, Y.; Yu, W.; He, X.N.; Liu, N.; Li, X.F.; Wang, T. Diffusion and Flow Mechanisms of Shale Gas through Matrix Pores and Gas Production Forecasting. SPE 2013, 167226, 1–19. [Google Scholar]

- Song, H.Q.; Yu, M.X.; Zhu, W.Y.; Zhang, Y.; Jiang, S.X. Dynamic Characteristics of Gas Transport in Nanoporous Media. Chin. Phys. Lett. 2013, 30, 014701. [Google Scholar] [CrossRef]

- Hildenbrand, A.A.; Ghanizadeh, A.; Kross, B.M. Transport properties of unconventional gas systems. Mar. Pet. Geol. 2012, 31, 90–99. [Google Scholar] [CrossRef]

- Zhang, P.W.; Hu, L.M.; Wen, Q.B.; Meegoda, J.N. A multi-flow regimes model for simulating gas transport in shale matrix. Geotech. Lett. 2015, 5, 231–235. [Google Scholar] [CrossRef]

- Sakhaee-Pour, A.; Bryant, S.L. Gas permeability of shale. SPE Reserv. Eval. Eng. 2012, 401–409. [Google Scholar] [CrossRef]

- Zhang, L.; Li, D.; Lu, D.; Zhang, T. A new formulation of apparent permeability for gas transport in shale. J. Nat. Gas Sci. Eng. 2015, 23, 221–226. [Google Scholar] [CrossRef]

- Wasaki, A.; Akkutlu, I.Y. Permeability of organic-rich shale. SPE 2015, 170830, 1–15. [Google Scholar] [CrossRef]

- Riewchotisakul, S.; Akkutlu, I.Y. Adsorption enhanced transport of hydrocarbons in organic nanopores. SPE 2016, 175107, 1–17. [Google Scholar] [CrossRef]

- Kou, R.; Alafnan, S.F.K.; Akkutlu, I.Y. Multi-scale analysis of gas transport mechanisms in kerogen. Transp. Porous Media 2016. [Google Scholar] [CrossRef]

- Song, W.H.; Yao, J.; Li, Y.; Sun, H.; Zhang, L.; Yang, Y.F.; Zhao, J.L.; Sui, H.G. Apparent gas permeability in an organic-rich shale reservoir. Fuel 2016, 181, 973–984. [Google Scholar] [CrossRef]

- Ghassemi, A.; Pak, A. Numerical study of factors influencing relative permeabilities of two immiscible fluids flowing through porous media using lattice Boltzmann method. J. Petr. Sci. Eng. 2011, 77, 135–145. [Google Scholar] [CrossRef]

- Schaap, M.G.; Porter, M.L.; Christensen, B.S.B.; Wildenschild, D. Comparison of pressure-saturation characteristics derived from computed tomography and lattice Boltzmann simulations. Water Resour. Res. 2007, 43, 1–15. [Google Scholar] [CrossRef]

- Joekar-Niasar, V.; Hassanizadeh, S.M.; Dahle, H.K. Non-equilibrium effects in capillarity and interfacial area in two-phase flow: Dynamic pore network modelling. J. Fluid Mech. 2010, 655, 38–71. [Google Scholar] [CrossRef]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef]

- Ma, J.S.; Sanchez, J.P.; Wu, K.J.; Couples, G.D.; Jiang, Z.Y. A pore network model for simulating non-ideal gas flow in micro- and nano-porous materials. Fuel 2014, 116, 498–508. [Google Scholar] [CrossRef]

- Zhang, P.W.; Hu, L.M.; Meegoda, J.N.; Gao, S.Y. Micro/Nano-pore Network Analysis of Gas Flow in Shale Matrix. Sci. Rep. 2015, 5, 13501. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.Y.; Hu, Q.H. Estimating permeability using median pore throat radius obtained from mercury intrusion porosimetry. J. Geophys. Eng. 2013, 10, 025014. [Google Scholar] [CrossRef]

- Wan, Y.; Pan, Z.J.; Tang, S.H.; Connell, L.D.; Down, D.D.; Camilleri, M. An experimental investigation of diffusivity and porosity anisotropy of a Chinese gas shale. J. Nat. Gas Sci. Eng. 2015, 23, 70–79. [Google Scholar] [CrossRef]

- Haughey, D.P.; Beveridge, G.G. Local voidage variation in a randomly packed bed of equal-sized spheres. Chem. Eng. Sci. 1966, 21, 905–916. [Google Scholar] [CrossRef]

- Vega, B.; Dutta, A.; Kovscek, A.R. CT Imaging of Low-Permeability, Dual-Porosity Systems Using High X-ray Contrast Gas. Transp. Porous Media 2014, 101, 81–97. [Google Scholar] [CrossRef]

- Gao, S.Y.; Meegoda, J.N.; Hu, L.M. Two methods for pore network of porous media. Int. J. Numer. Anal. Methods Geomech. 2012, 36, 1954–1970. [Google Scholar] [CrossRef]

- Gao, S.Y.; Meegoda, J.N.; Hu, L.M. A dynamic two-phase flow model for air sparging. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 1801–1821. [Google Scholar] [CrossRef]

- Gao, S.Y.; Meegoda, J.N.; Hu, L.M. Simulation of dynamic two-phase flow during multistep air sparging. Transp. Porous Media 2013, 96, 173–192. [Google Scholar] [CrossRef]

- Civan, F. Effective Correlation of Apparent Gas Permeability in Tight Porous Media. Transp. Porous Media 2010, 82, 375–384. [Google Scholar] [CrossRef]

- Florence, F.A.; Rushing, J.A.; Newsham, K.E.; Blasingame, T.A. Improved Permeability Prediction Relations for Low Permeability Sands. SPE Int. 2007, 107954, 1–18. [Google Scholar]

- Cui, X.; Bustin, R.M.; Brezovski, R.; Nasssichuk, B.; Glover, K.; Pathi, V. A new method to simultaneously measure in situ permeability. CSUG/SPE 2010, 138148, 1–8. [Google Scholar]

- Gensterblum, Y.; Ghanizadeh, A.; Krooss, B.M. Gas permeability measurements on Australian subbituminous coals: Fluid dynamic and poroelastic aspects. J. Nat. Gas Sci. Eng. 2014, 19, 202–214. [Google Scholar] [CrossRef]

- Brown, G.P.; DiNardo, A.; Cheng, G.K.; Sherwood, T.K. The Flow of Gases in Pipes at Low Pressures. J. Appl. Phys. 1946, 17, 802–813. [Google Scholar] [CrossRef]

| Mehmani et al. (2013, 2014) | Ma et al. (2014) | Chen et al. (2015) | Present Model | |

|---|---|---|---|---|

| Simulation Method | Pore Network Model | Pore Network Model | LBM (Lattice Boltzmann Method) | Pore Network Model |

| Constructing pore-scale model | Extract pore network from Finney pack of spheres by Delaunay tessellation method. Finney pack is a dense random pack of identical spheres. | A realistic 3D pore network model of gas shale, and it was constructed from high-resolution 2D grey-scale images. The resolution is 15 nm. | Reconstructed 3D nanoscale porous structures of shale by Markov chain Monte Carlo (MCMC) method based on SEM images of shale samples. | It is a mathematical model, and the pore size and pore throat size distributions are generated based on shale statistic data. |

| Porosity | Initial porosity is relatively high, shrink some pores and pore throats radii until reaching the porosity of 10% for shale. | 2.9%. | Four samples: 19.1%, 22.6%, 26.8%, 17.6%, respectively. | The porosity is 7% assumed in this work according to typical shale data but can be varied based on shale formation. This pore network model is porosity-determined, and it is flexible. Coordination bond length can be calculated by porosity. |

| Coordination number | Single scale network: average number is 4. Dual scale network (series and parallel). | Less than 3. | Connected with neighboring 18 cells (D3Q19 lattice model). | Average coordination number is 3, and it ranges from 0 to 26. |

| Connectivity | A fraction of the removed throats (fr) defined according to the whole pore network model percolation. | Low connectivity. | High connectivity (four samples: 98.0%, 99.1%, 99.7%, and 99.8%). | Each bond has the existing probability, and reduction factor determines the status of the bond open or block. |

| Klinkenberg (1941) | |

| Brown et al. (1946) | |

| Beskok and Karniadakis (1999) | |

| Florence et al. (2007) | |

| Civan (2009) | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Hu, L.; Meegoda, J.N. Pore-Scale Simulation and Sensitivity Analysis of Apparent Gas Permeability in Shale Matrix. Materials 2017, 10, 104. https://doi.org/10.3390/ma10020104

Zhang P, Hu L, Meegoda JN. Pore-Scale Simulation and Sensitivity Analysis of Apparent Gas Permeability in Shale Matrix. Materials. 2017; 10(2):104. https://doi.org/10.3390/ma10020104

Chicago/Turabian StyleZhang, Pengwei, Liming Hu, and Jay N. Meegoda. 2017. "Pore-Scale Simulation and Sensitivity Analysis of Apparent Gas Permeability in Shale Matrix" Materials 10, no. 2: 104. https://doi.org/10.3390/ma10020104

APA StyleZhang, P., Hu, L., & Meegoda, J. N. (2017). Pore-Scale Simulation and Sensitivity Analysis of Apparent Gas Permeability in Shale Matrix. Materials, 10(2), 104. https://doi.org/10.3390/ma10020104