The Effect of Thickness of Resorbable Bacterial Cellulose Membrane on Guided Bone Regeneration

Abstract

:1. Introduction

2. Results

2.1. Thickness Measurement

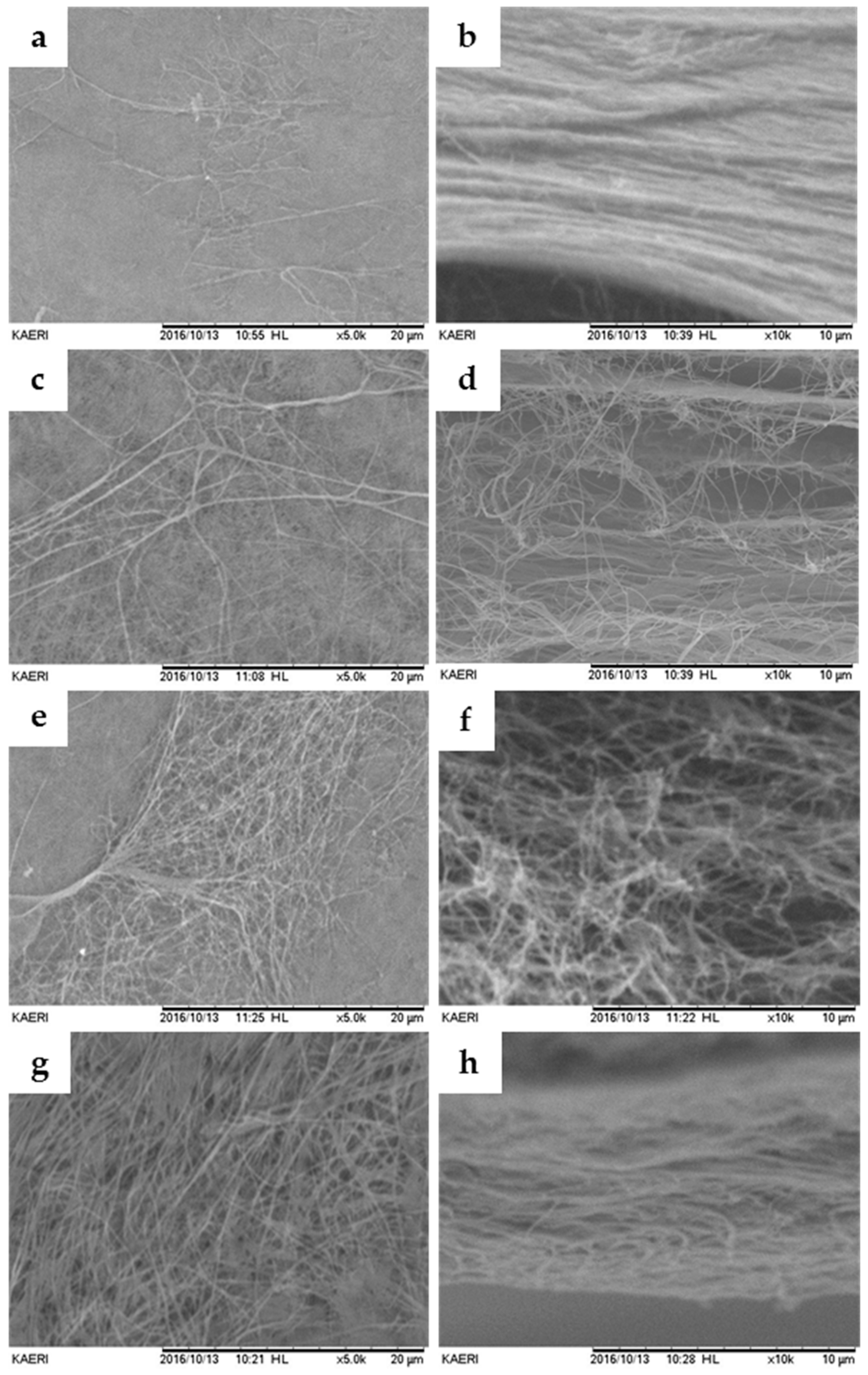

2.2. Scanning Electron Microscopy (SEM)

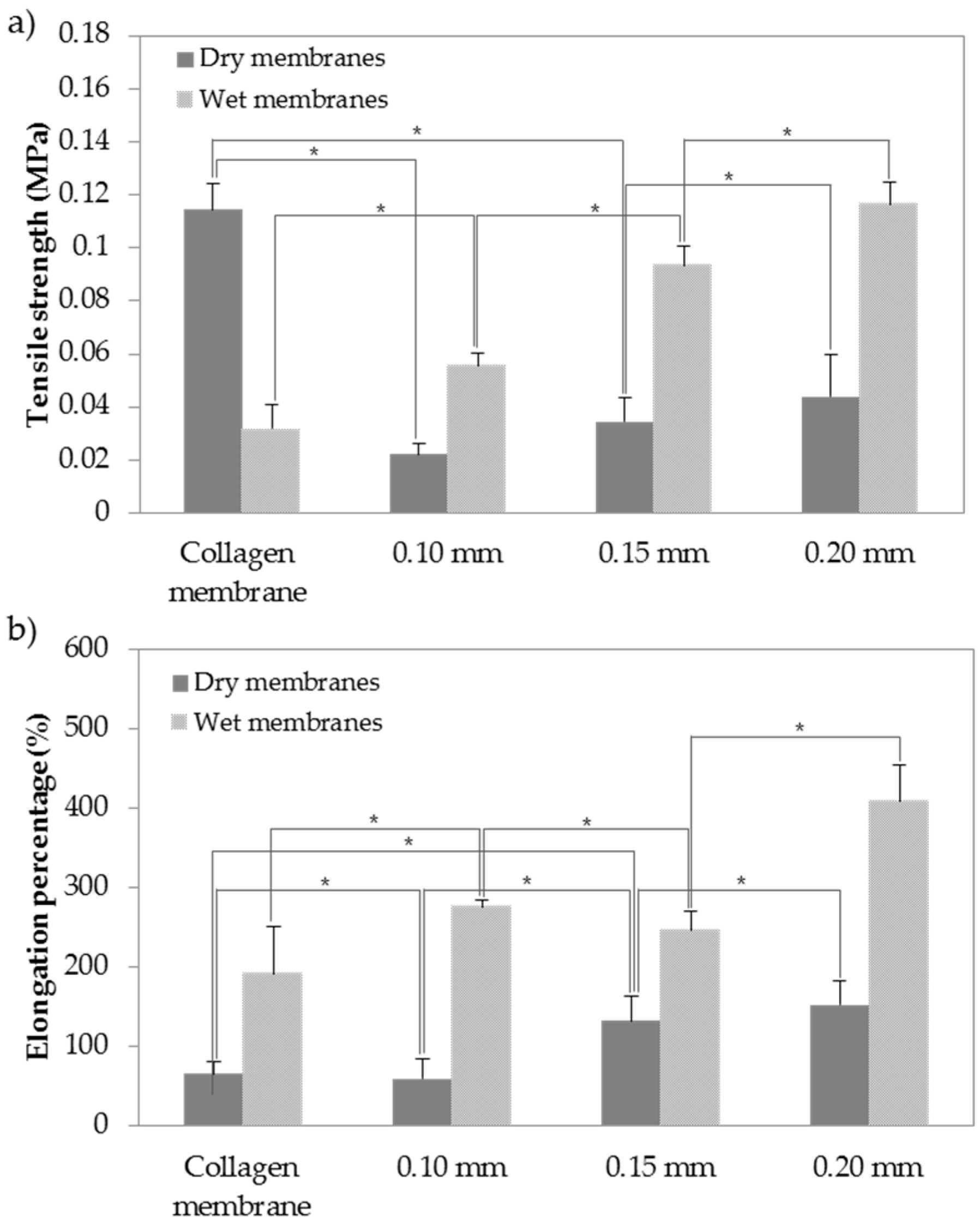

2.3. Mechanical Test of Membranes

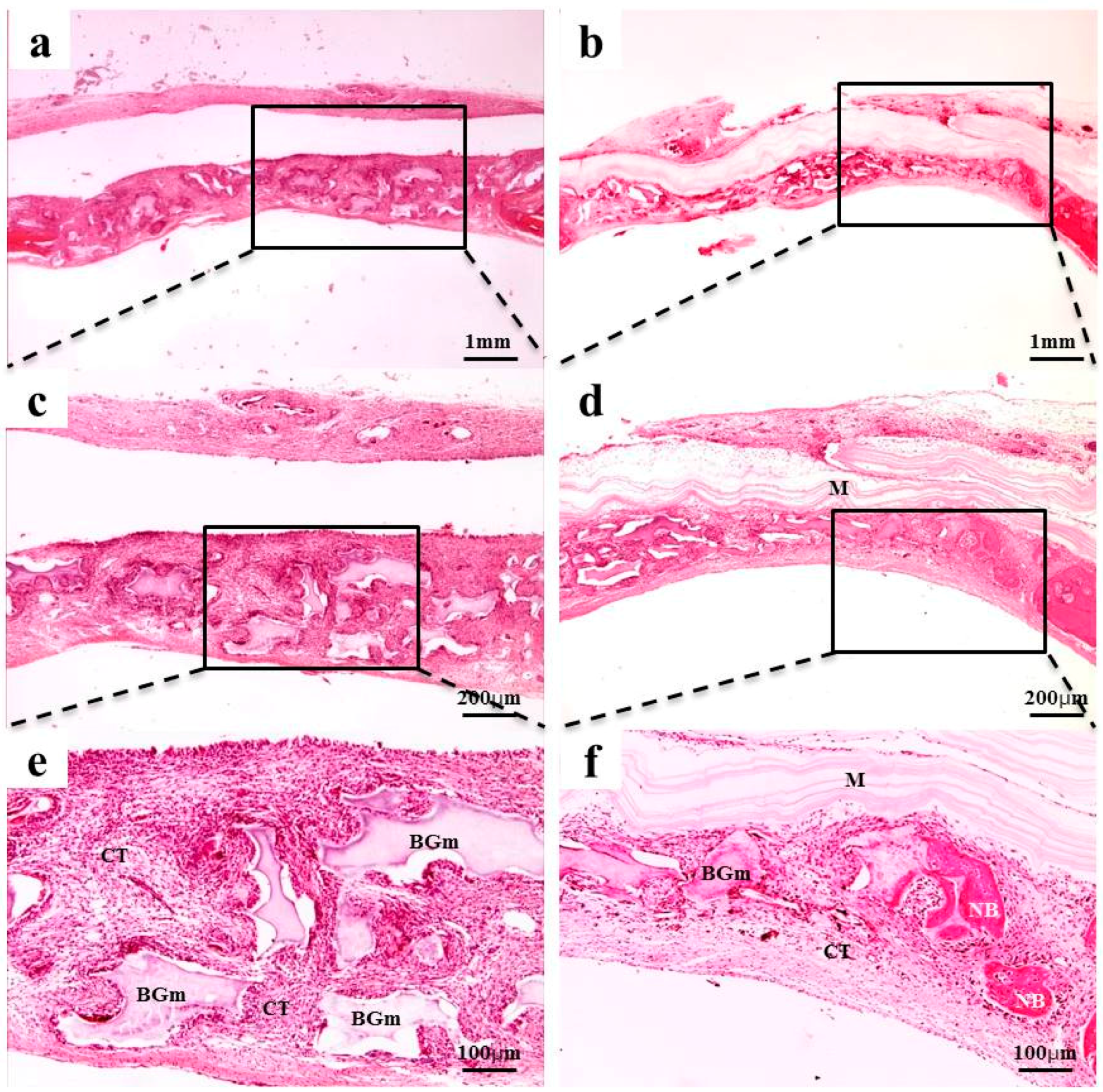

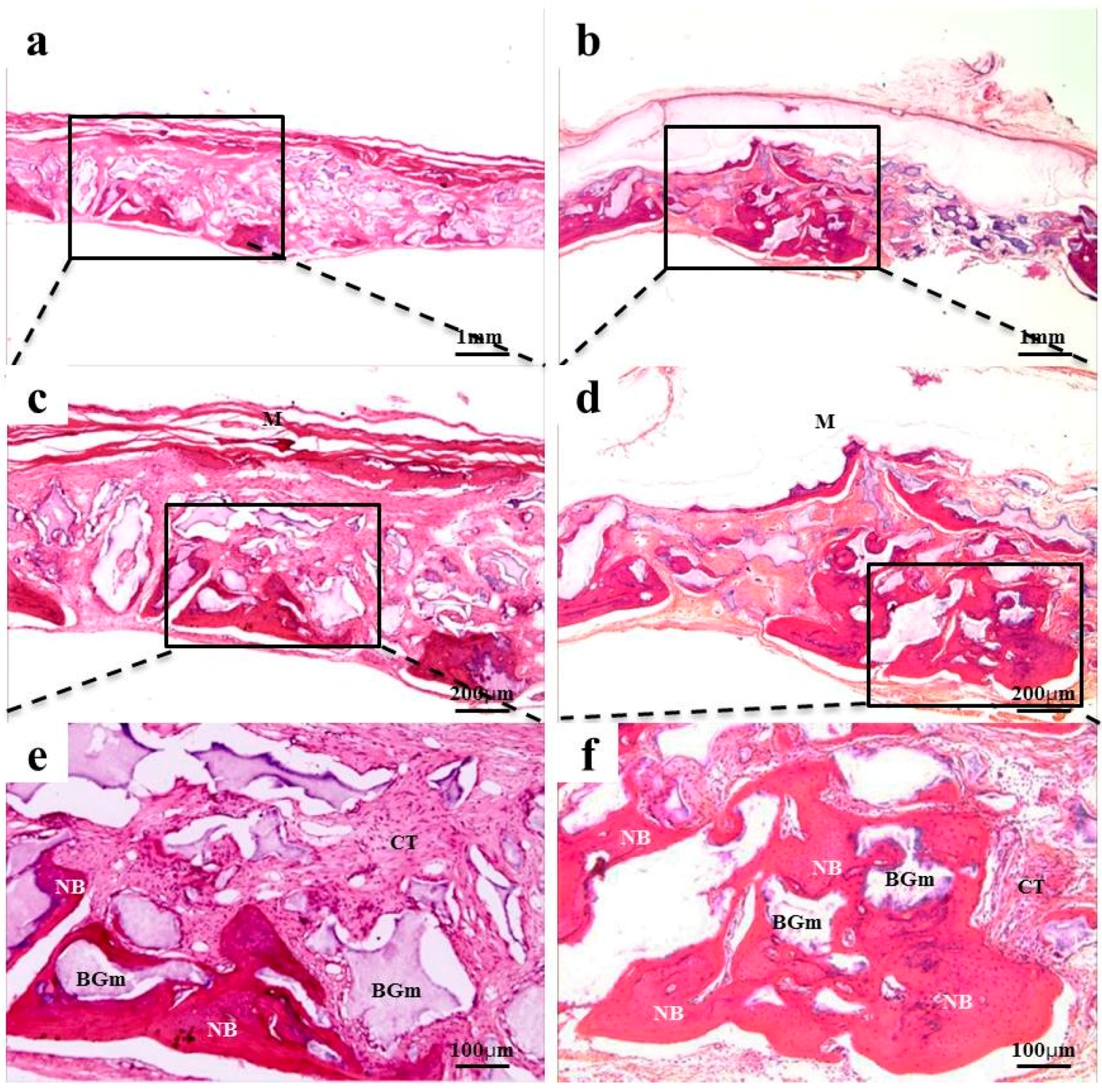

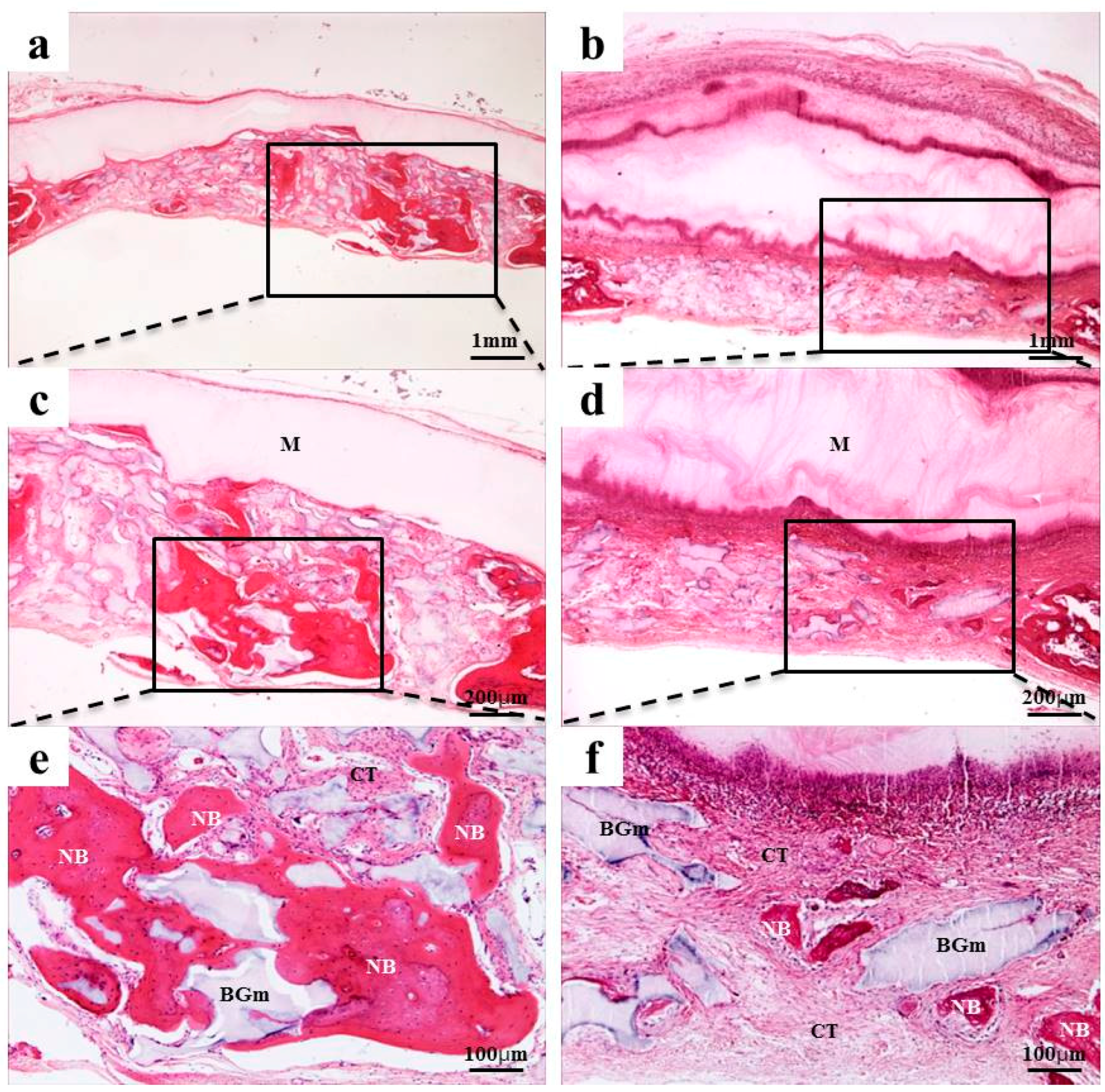

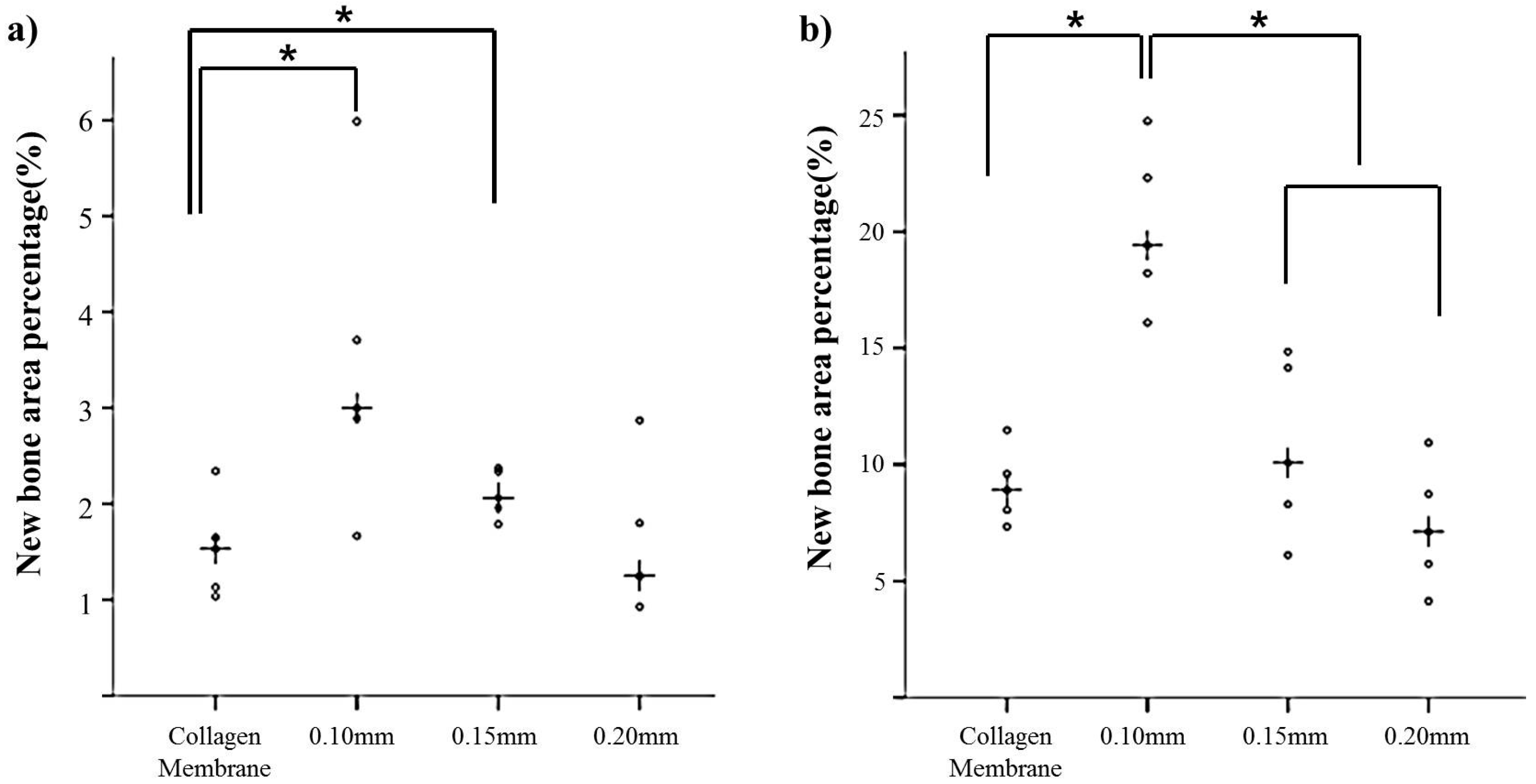

2.4. Histological Findings

3. Discussion

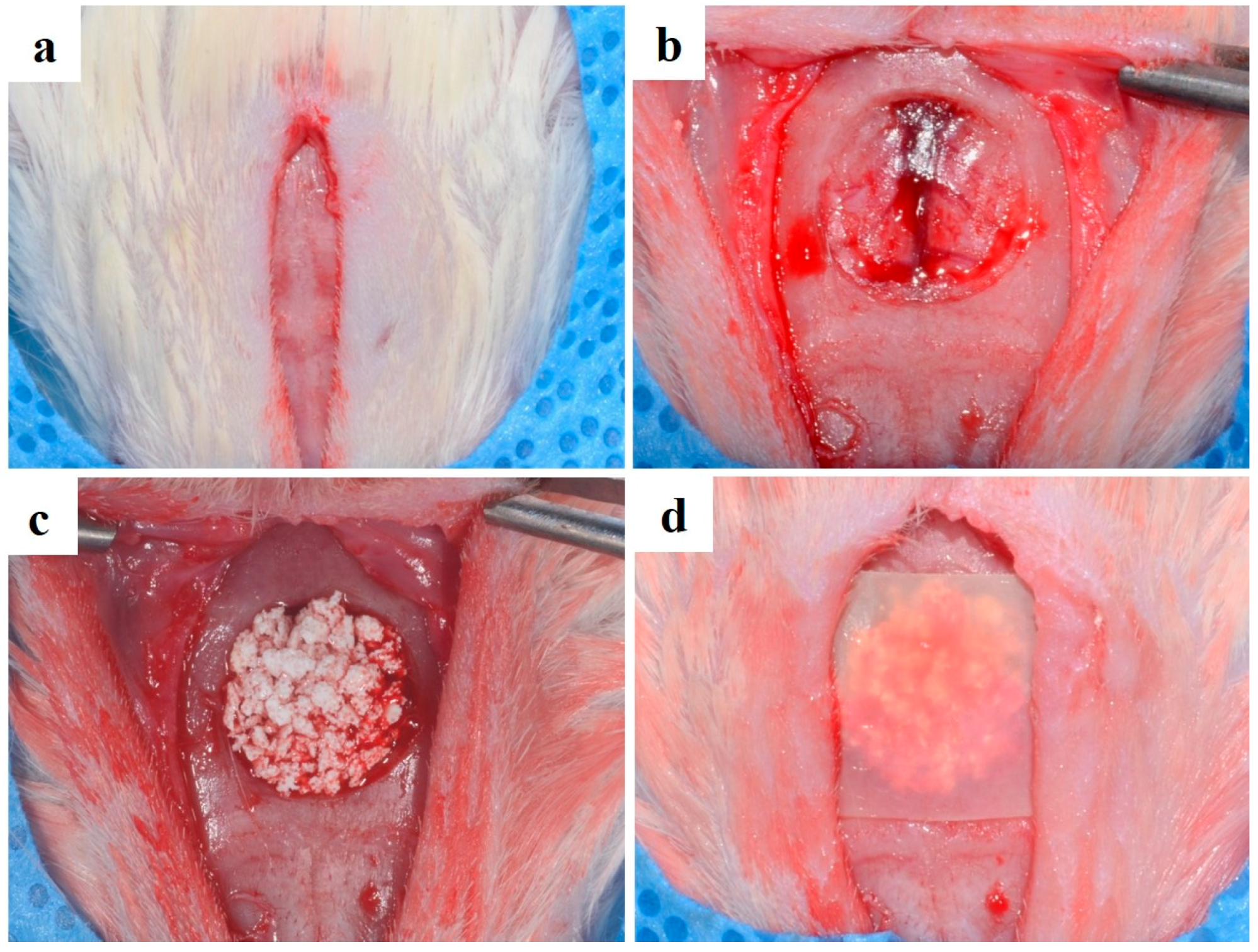

4. Materials and Methods

4.1. Preparation of Bacterial Cellulose Membrane

4.2. Thickness Measurement

4.3. Mechanical Properties

4.4. Experiment Animals

4.5. Surgical Procedures

4.6. Histomorphometric Analysis

4.7. Statistical Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ueyama, Y.; Ishikawa, K.; Mano, T.; Koyama, T.; Nagatsuka, H.; Suzuki, K.; Ryoke, K. Usefulness as guided bone regeneration membrane of the alginate membrane. Biomaterials 2002, 23, 2027–2033. [Google Scholar] [CrossRef]

- Hämmerle, C.H.; Jung, R.E.; Yaman, D.; Lang, N.P. Ridge augmentation by applying bioresorbable membranes and deproteinized bovine bone mineral: A report of twelve consecutive cases. Clin. Oral Implants Res. 2008, 19, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Proussaefs, P.; Lozada, J. The use of resorbable collagen membrane in conjunction with autogenous bone graft and inorganic bovine mineral for buccal/labial alveolar ridge augmentation: A pilot study. J. Prosthet. Dent. 2003, 90, 530–538. [Google Scholar] [CrossRef]

- Simion, M.; Trisi, P.; Piattelli, A. Vertical ridge augmentation using a membrane technique associated with osseointegrated implants. Int. J. Periodontics Restor. Dent. 1994, 14, 497–511. [Google Scholar]

- Dahlin, C.; Linde, A.; Gottlow, J.; Nyman, S. Healing of bone defects by guided tissue regeneration. Plast. Reconstr. Surg. 1988, 81, 672–676. [Google Scholar] [CrossRef] [PubMed]

- Dahlin, C.; Sennerby, L.; Lekholm, U.; Linde, A.; Nyman, S. Generation of new bone around titanium implants using a membrane techinque: An experimental study inrabbits. Int. J. Oral. Maxillofac. Implant. 1989, 4, 19–25. [Google Scholar]

- Scantlebury, T.V. 1982–1992: A decade of technology development for guided tissue regeneration. J. Periodontol. 1993, 64, 1129–1137. [Google Scholar] [CrossRef] [PubMed]

- Sculean, A.; Nikolidakis, D.; Schwarz, F. Regeneration of periodontaltissues: Combinations of barrier membranes and grafting materials - biological foundation and preclinical evidence: A systematic review. J. Clin. Periodontol. 2008, 35, 106–116. [Google Scholar] [CrossRef] [PubMed]

- Behring, J.; Junker, R.; Walboomers, X.F.; Chessnut, B.; Jansen, J.A. Toward guided tissue and bone regeneration: Morphology, attachment, proliferation, and migration of cells cultured on collagen barrier membranes. A systematic review. Odontology 2008, 96, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Kasaj, A.; Reichert, C.; Götz, H.; Röhrig, B.; Smeets, R.; Willershausen, B. In vitro evaluation of various bioabsorbable and nonresorbable barrier membranes for guided tissue regeneration. Head Face Med. 2008, 4, 22. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Kerns, D.G. Mechanisms of guided bone regeneration: A review. Open Dent. J. 2014, 8, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Rakhmatia, Y.D.; Ayukawa, Y.; Furuhashi, A.; Koyano, K. Current barrier membranes: Titanium mesh and other membranes for guided bone regeneration in dental applications. J. Prosthodont. Res. 2013, 57, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Dahlin, C.; Andersson, L.; Linde, A. Bone augmentation at fenestrated implants by an osteopromotive membrane technique: A controlled clinical study. Clin. Oral Implants Res. 1991, 2, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Buser, D.; Dula, K.; Belser, U.; Hirt, H.P.; Berthold, H. Localized ridge augmentation using guided bone regeneration. 1. Surgical procedure in the maxilla. Int. J. Periodontics Restor. Dent. 1993, 13, 29–45. [Google Scholar]

- Parodi, R.; Carusi, G.; Santarelli, G.; Nanni, F. Implant placement in large edentulous ridges expanded by GBR using a bioresorbable collagen membrane. Int. J. Periodontics Restor. Dent. 1998, 18, 266–275. [Google Scholar]

- Hammerle, C.H.; Lang, N.P. Single stage surgery combining transmucosal implant placement with guided bone regeneration and bioresorbable materials. Clin. Oral Implants Res. 2001, 12, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Postlethwaite, A.E.; Seyer, J.M.; Kang, A.H. Chemotactic attraction of human fibroblasts to type I, II, and III collagens and collagen-derived peptides. Proc. Natl. Acad. Sci. USA 1978, 75, 871–875. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.H.; Huh, J.B.; Park, J.Y.; Jeon, Y.C.; Kang, S.S.; Kim, J.Y.; Rhie, J.W.; Cho, D.W. Fabrication of blended polycaprolactone/poly (lactic-co-glycolic acid)/β-tricalcium phosphate thinmembrane using solid freeform fabrication technology forguided bone regeneration. Tissue Eng. Part A 2013, 19, 317–328. [Google Scholar] [CrossRef] [PubMed]

- Koyama, M.; Helbert, W.; Imai, T.; Sugiyama, J.; Henrissat, B. Parallel-up structure evidences the molecular directionality during biosynthesis of bacterial cellulose. Proc. Natl. Acad. Sci. USA 1997, 94, 9091–9095. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A new family of nature-based materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef] [PubMed]

- Nathan, P.; Paul, G. Bacterial cellulose-based materials and medical devices: Current state and perspectives. Appl. Microbiol. Biot. 2011, 91, 1277–1286. [Google Scholar]

- Iguchi, M.; Yamanaka, S.; Budhiono, A. Bacterial cellulose—A masterpiece of nature’s arts. J. Mater. Sci. 2000, 35, 261–270. [Google Scholar] [CrossRef]

- Rajwade, J.M.; Paknikar, K.M.; Kumbhar, J.V. Applications of bacterial cellulose and its composites in biomedicine. Appl. Microbiol. Biot. 2015, 99, 2491–2511. [Google Scholar] [CrossRef] [PubMed]

- Yaser, D. Nanostructured biomaterials and biocomposites from bacterial cellulose nanofibers. J. Nanosci. Nanotechnol. 2009, 9, 5105–5122. [Google Scholar]

- Lee, S.H.; Lim, Y.M.; Jeong, S.I.; An, S.J.; Kang, S.S.; Jeong, C.M.; Huh, J.B. The effect of bacterial cellulose membrane compared with collagen membrane on guided bone regeneration. J. Adv. Prosthodont. 2015, 7, 484–495. [Google Scholar] [CrossRef] [PubMed]

- Pretzel, D.; Linss, S.; Ahrem, H.; Endres, M.; Kaps, C.; Klemm, D.; Kinne, R.W. A novel in vitro bovine cartilage punch model for assessing the regeneration of focal cartilage defects with biocompatible bacterial nanocellulose. Arthritis Res. Ther. 2013, 15. [Google Scholar] [CrossRef] [PubMed]

- Clasen, C.; Sultanova, B.; Wilhelms, T.; Heisig, P.; Kulicke, W.M. Effects of different drying processes on the material properties of bacterial cellulose membranes. Macromol. Symp. 2006, 244, 48–58. [Google Scholar] [CrossRef]

- Iglhaut, J.; Aukhil, I.; Simpson, D.M.; Johnston, M.C.; Koch, G. Progenitor cell kinetics during guided tissue regeneration in experimental periodontal wounds. J. Periodontal Res. 1988, 23, 107–117. [Google Scholar] [CrossRef] [PubMed]

- Karring, T.; Nyman, S.; Lindhe, J.; Sirirat, M. Potentials for root resorption during periodontalwound healing. J. Clin. Periodontol. 1984, 11, 41–52. [Google Scholar] [CrossRef] [PubMed]

- Fleisher, N.; Waal, H.D.; Bloom, A. Regeneration of lost attachment apparatus in the dog using vicryl absorbable mesh (Polyglactin 910). Int. J. Periodontics Res. Dent. 1988, 8, 45–55. [Google Scholar]

- Meurant, G. Physical Forces and the Mammalian Cell; Academic Press: New York, NY, USA, 2012. [Google Scholar]

- Steinberg, A.D.; LeBreton, G.; Willey, R. Extravascular clot formation and platelet activation on variously treated root surfaces. J. Periodontol. 1986, 57, 516–522. [Google Scholar] [CrossRef] [PubMed]

- Rasmusson, L.; Sennerby, L.; Lundgren, D.; Nyman, S. Morphological and dimensional changes after barrier removal in bone formed beyond the skeletal borders at titanium implants: A kinetic study in the rabbit tibia. Clin. Oral Implant Res. 1997, 8, 103–116. [Google Scholar] [CrossRef]

- Wang, H.L.; MacNeil, R.L.; Shieh, A.T.; O’Neal, R.B. Utilization of a resorbable collagenmembrane in repairing gingival recession defects. Pract. Periodontics Aesthet. Dent. 1996, 8, 441–448. [Google Scholar] [PubMed]

- Minabe, M. A critical review of the biologicrationale for guided tissue regeneration. J. Periodontol. 1991, 62, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.J.; Shin, Y.M.; Kim, S.E.; Jeong, S.I.; Jeong, J.O.; Park, J.S.; Gwon, H.J.; Seo, D.E.; Nho, Y.C.; Kang, S.S.; et al. Characterization of hydroxyapatite-coated bacterial cellulose scaffold for bone tissue engineering. Biotechnol. Bioprocess Eng. 2015, 20, 948–955. [Google Scholar] [CrossRef]

- Helenius, G.; Bäckdahl, H.; Bodin, A.; Nannmark, U.; Gatenholm, P.; Risberg, B. In vivo biocompatibility of bacterial cellulose. J. Biomed. Mater. Res. A 2006, 76, 431–438. [Google Scholar] [CrossRef] [PubMed]

- Yamanaka, S.; Watanabe, K.; Kitamura, N.; Iguchi, M.; Mitsuhashi, S.; Nishi, Y.; Uryu, M. The structure and mechanical properties of sheets prepared from bacterial cellulose. J. Mater. Sci. 1989, 24, 3141–3145. [Google Scholar] [CrossRef]

- Linde, A.; Thoren, C.; Dahlin, C.; Sandberg, E. Creation of new bone by an osteopromotive membrane technique. An experimental study in rats. J. Oral Maxillofac. Surg. 1993, 51, 892–897. [Google Scholar] [CrossRef]

| Variable | Group (n) | Mean ± SD | Median | p-Value |

|---|---|---|---|---|

| 2 weeks ** | Collagen (5) | 1.54 ± 0.52 | 1.53 | 0.003 |

| 0.10 mm (5) | 3.45 ± 1.60 | 3.00 | ||

| 0.15 mm (5) | 2.10 ± 0.25 | 2.06 | ||

| 0.20 mm (5) | 1.62 ± 0.77 | 1.25 | ||

| 8 weeks *** | Collagen (5) | 9.08 ± 1.59 | 8.91 | <0.001 |

| 0.10 mm (5) | 20.16 ± 3.41 | 19.41 | ||

| 0.15 mm (5) | 10.70 ± 3.75 | 10.08 | ||

| 0.20 mm (5) | 7.33 ± 2.63 | 7.12 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-J.; An, S.-J.; Bae, E.-B.; Gwon, H.-J.; Park, J.-S.; Jeong, S.I.; Jeon, Y.-C.; Lee, S.-H.; Lim, Y.-M.; Huh, J.-B. The Effect of Thickness of Resorbable Bacterial Cellulose Membrane on Guided Bone Regeneration. Materials 2017, 10, 320. https://doi.org/10.3390/ma10030320

Lee Y-J, An S-J, Bae E-B, Gwon H-J, Park J-S, Jeong SI, Jeon Y-C, Lee S-H, Lim Y-M, Huh J-B. The Effect of Thickness of Resorbable Bacterial Cellulose Membrane on Guided Bone Regeneration. Materials. 2017; 10(3):320. https://doi.org/10.3390/ma10030320

Chicago/Turabian StyleLee, You-Jin, Sung-Jun An, Eun-Bin Bae, Hui-Jeong Gwon, Jong-Seok Park, Sung In Jeong, Young-Chan Jeon, So-Hyoun Lee, Youn-Mook Lim, and Jung-Bo Huh. 2017. "The Effect of Thickness of Resorbable Bacterial Cellulose Membrane on Guided Bone Regeneration" Materials 10, no. 3: 320. https://doi.org/10.3390/ma10030320