Room-Temperature and High-Temperature Tensile Mechanical Properties of TA15 Titanium Alloy and TiB Whisker-Reinforced TA15 Matrix Composites Fabricated by Vacuum Hot-Pressing Sintering

Abstract

:1. Introduction

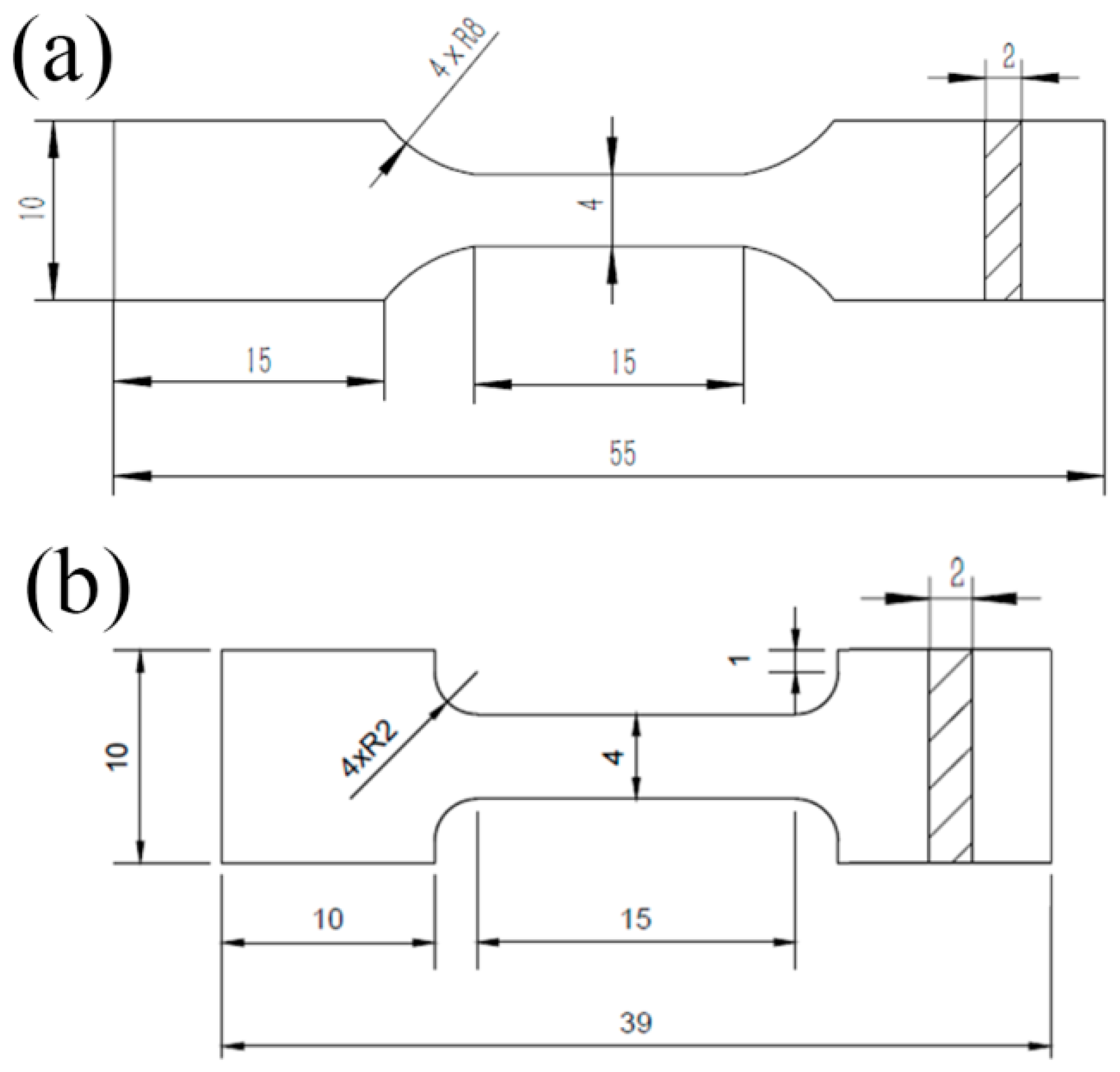

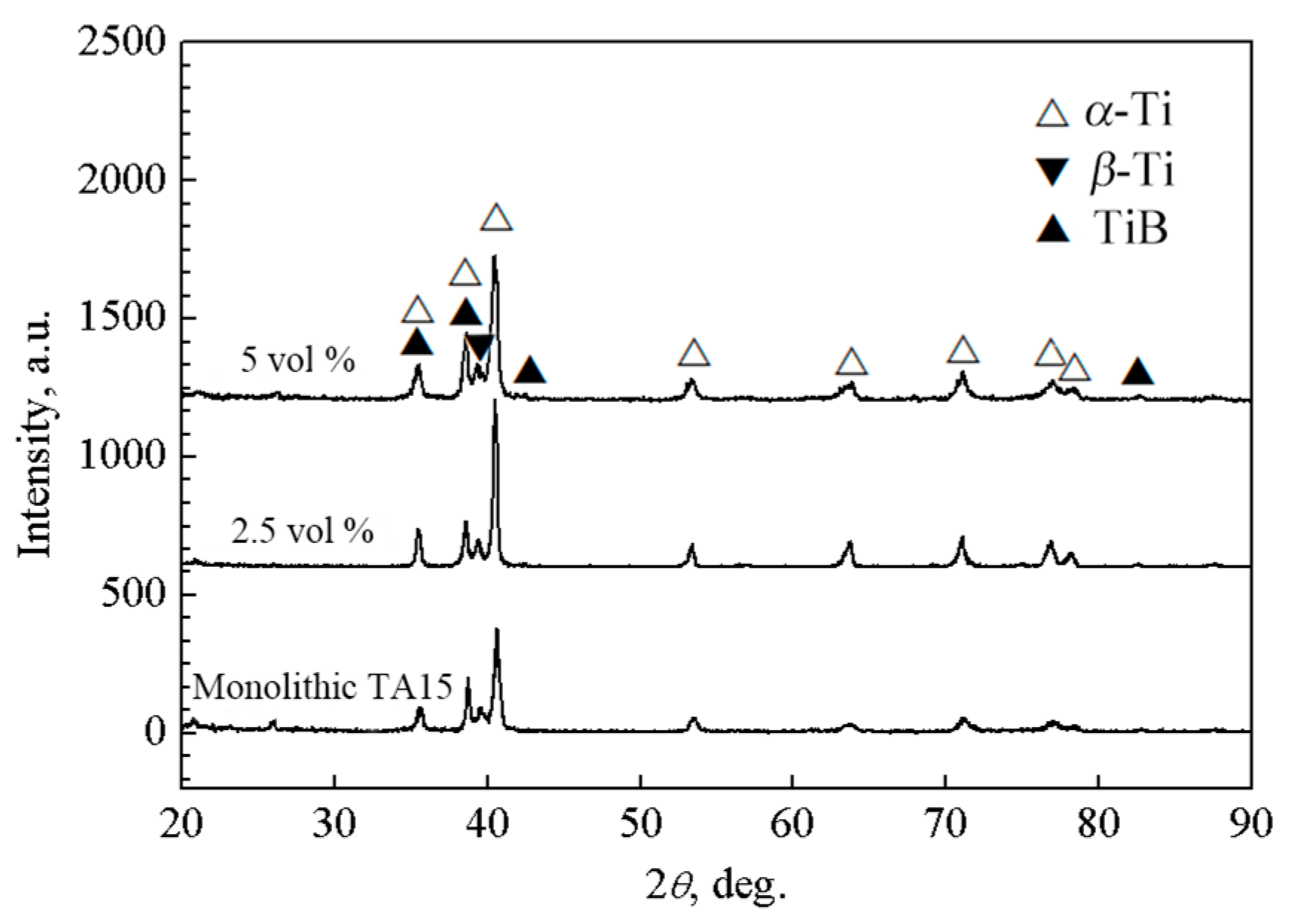

2. Experimental Procedures

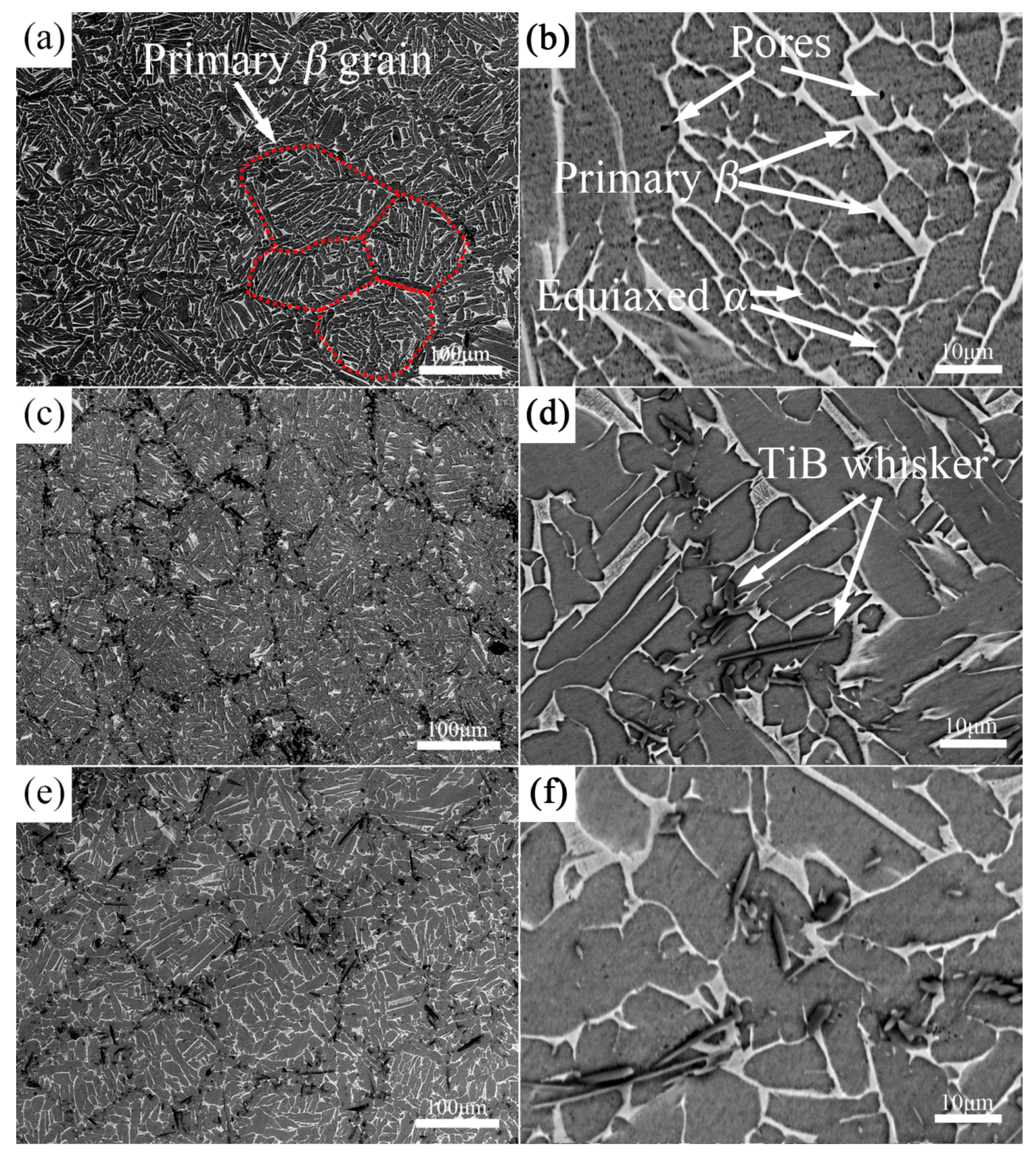

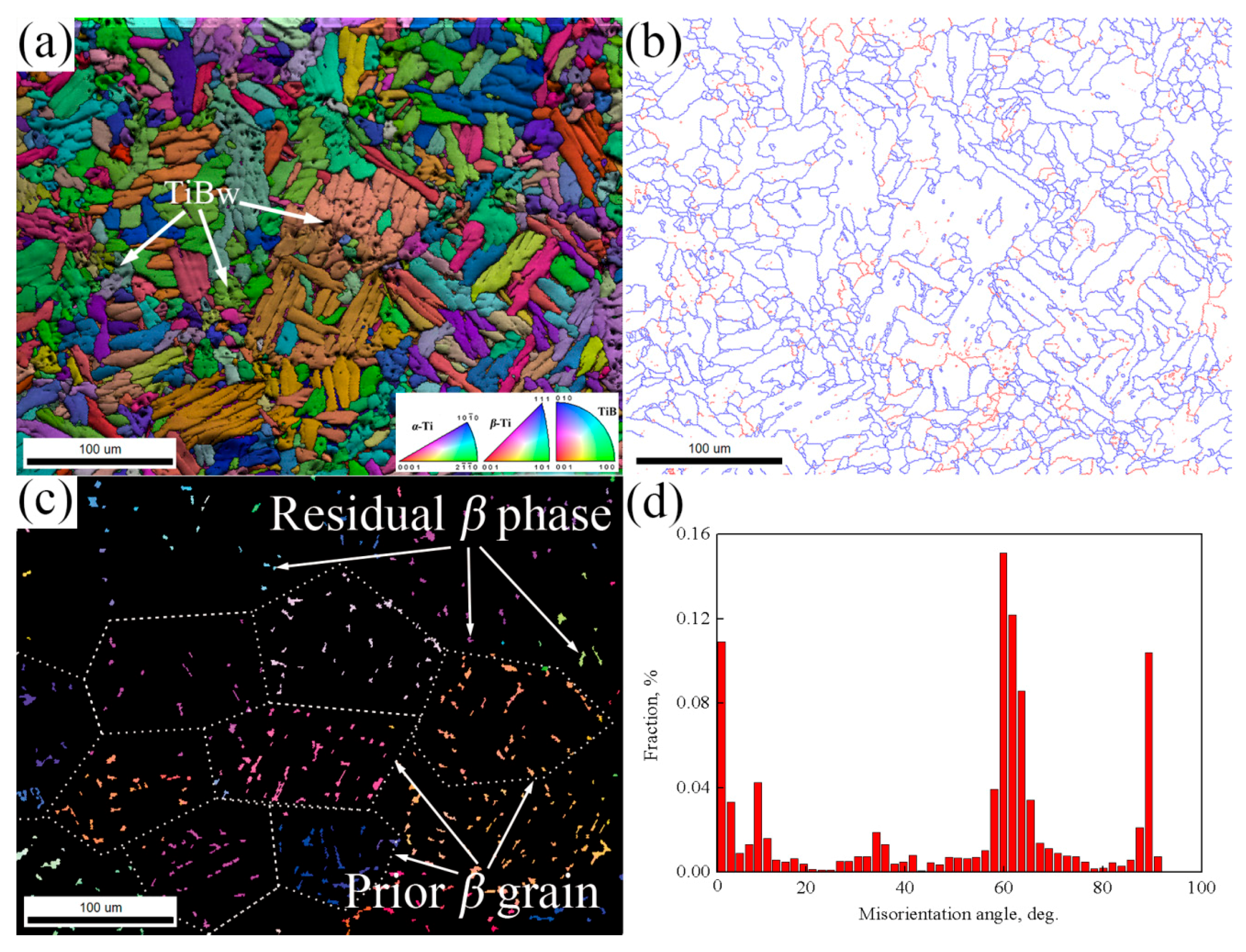

3. Results and Discussions.

4. Conclusions

- (1)

- Conditions of 1200 °C and 25 MPa are the reasonable sintering parameters in order to fabricate monolithic TA15 alloy and TA15 matrix composites by vacuum hot-pressing sintering.

- (2)

- There are no significant differences in the microstructure of monolithic TA15 alloy and TiBw/TA15 composites. The matrix exhibits a typical Widmanstätten microstructure, and the size of the primary β grain is consistent with the size of spherical TA15 titanium metallic powders. This result shows that, in the as-sintered TA15 alloy (TiBw/TA15 composites) fabricated by vacuum hot-pressing sintering using large-sized spherical TA15 titanium metallic powders (and fine TiB2 powders), the grain boundary of the primary β grain/interface of the spherical TA15 titanium metallic powders or the impurities on the surface of spherical TA15 powders is the key factor in limiting the grain coarsening of the primary β grain.

- (3)

- After sintering, the matrix of the composites consists of not only a coarse α + β lamellar microstructure, but also a small amount of equiaxed α phase. The equiaxed α distribution coincides with the distribution of TiB whiskers, and both distribute in the primary β grain boundary. This result indicates the TiBw are beneficial to the formation of equiaxed α grains.

- (4)

- When phase transformation occurs during the cooling process, the β→α is oriented according to the Burgers relationship, the number fraction of the α/α boundary angle inherited from the same parent β grain is consistent with the theoretical calculation.

- (5)

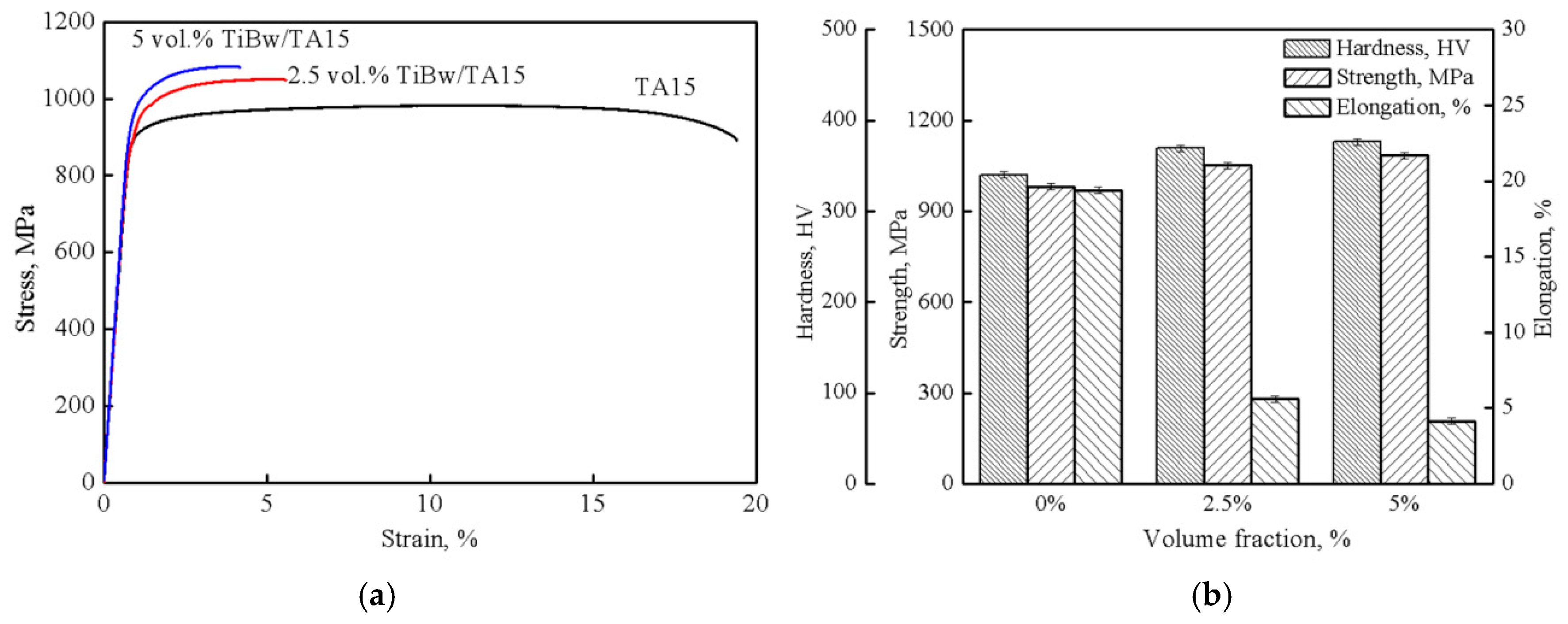

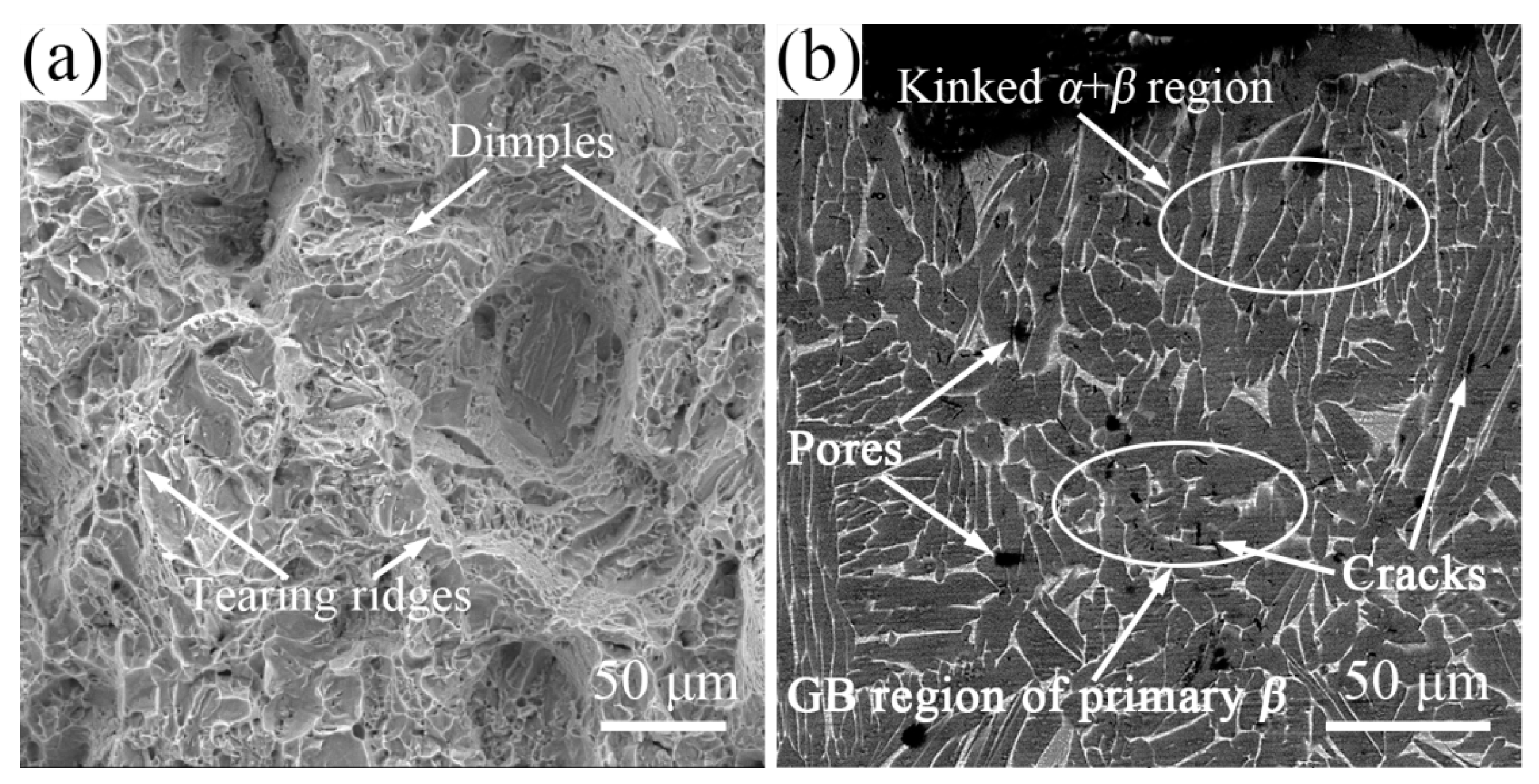

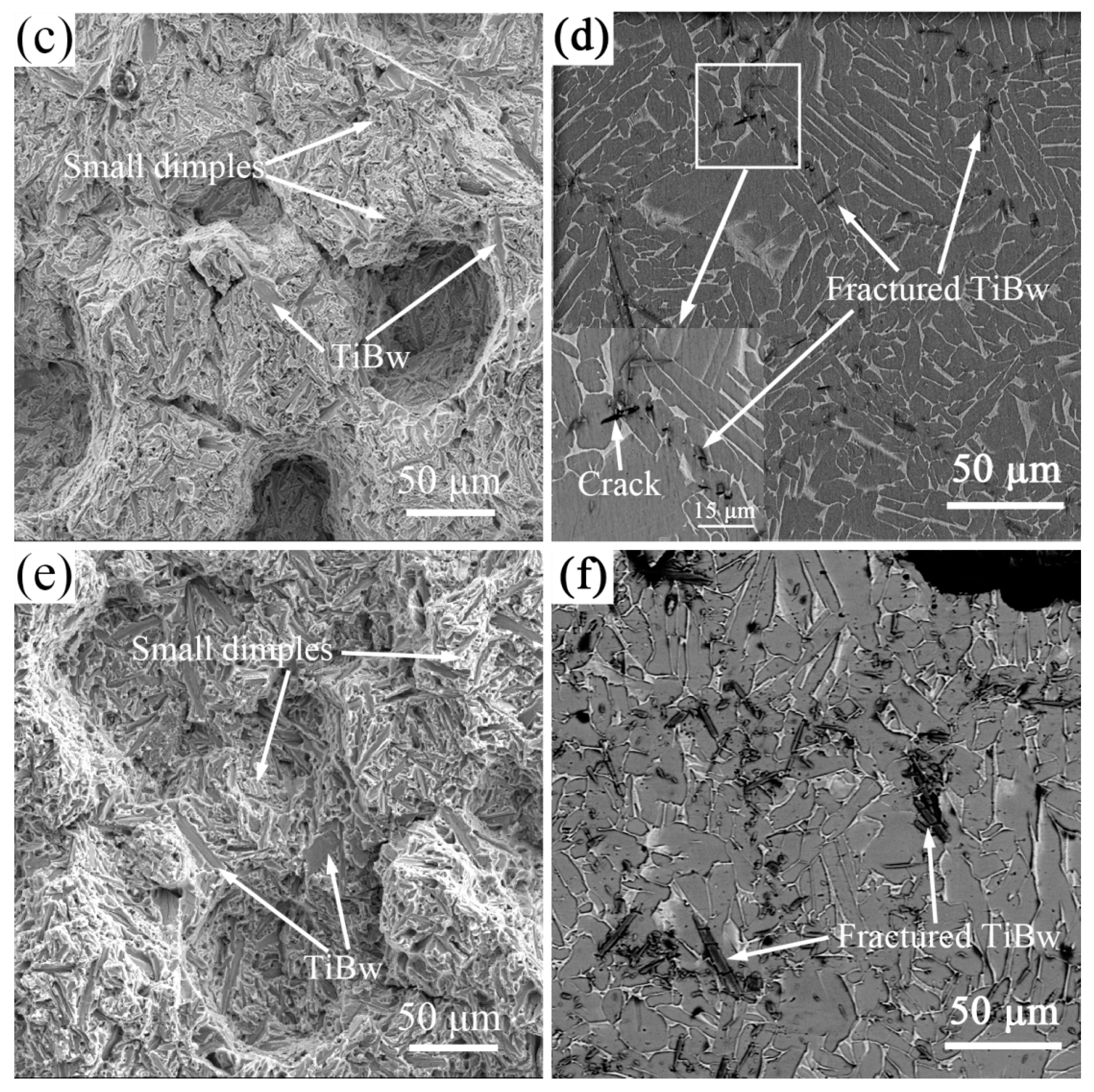

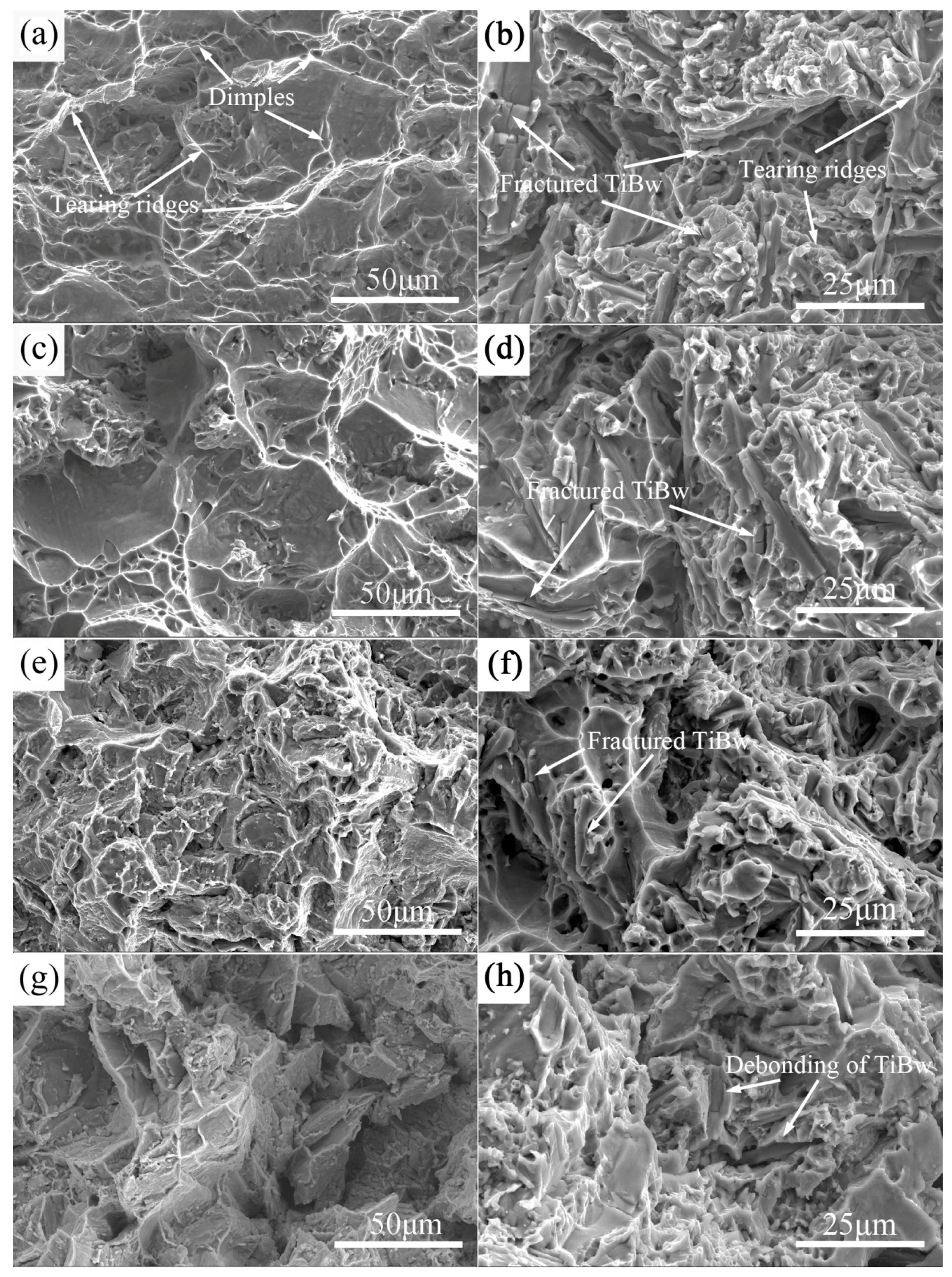

- With increasing volume fractions of TiBw reinforcement, the tensile strength of TiBw/TA15 composites increases and the ductility continues decreasing. The fracture mechanism was changed to a mixture of brittle fracture and ductile failure (composites) from ductile failure (monolithic TA15 alloy).

- (6)

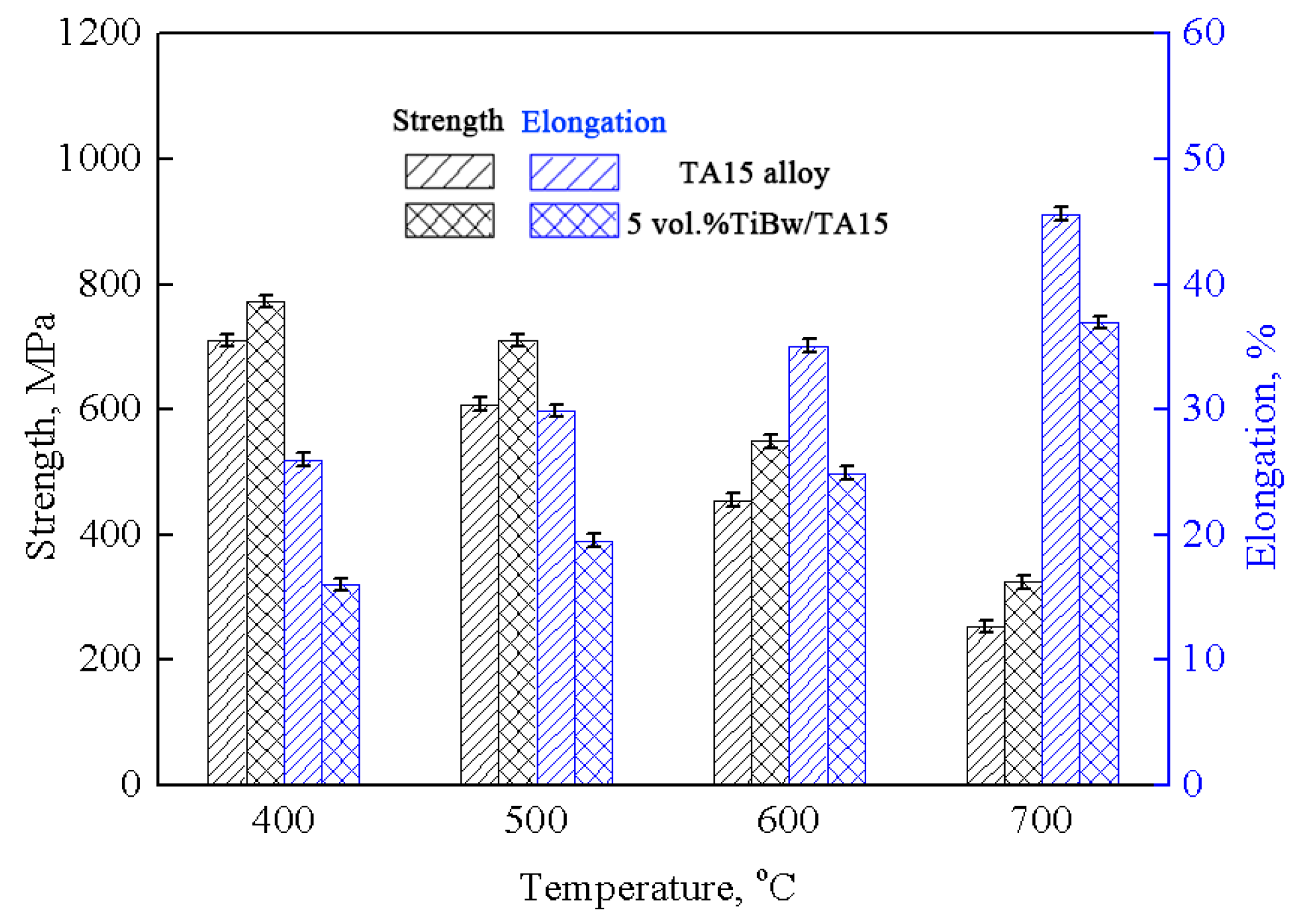

- TiBw can effectively improve the high-temperature strength of the composites. For 5 vol % TiBw/TA15 composites, there is an increasing damage of interface debonding with the stretching temperature. The fracture mechanism of the composites is dominated by TiB whisker fracturing or debonding followed by ductile fracture of the matrix in the whole temperature range of 400 °C to 700 °C. However, there is no fractured TiBw in the composites when the tensile temperature exceeds 700 °C.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, L.J.; Geng, L.; Peng, H.; Zhang, X.J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture. Scr. Mater. 2011, 64, 844–847. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Imayev, V.; Gaisin, R.; Gaisina, E.; Imayev, R.; Fecht, H.J.; Pyczak, F. Effect of hot forging on microstructure and tensile properties of Ti–TiB based composites produced by casting. Mater. Sci. Eng. A 2014, 609, 34–41. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.W. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Schuh, C.; Dunand, D.C. Whisker alignment of Ti–6Al–4V/TiB composites during deformation by transformation superplasticity. Int. J. Plast. 2011, 17, 317–340. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, W.; Zhang, D.; Wu, R.; Bian, Y.; Fang, P. In situ technique for synthesizing (TiB + TiC)/Ti composites. Scr. Mater. 1999, 41, 39–46. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R 2011, 29, 49–113. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Qin, J.N.; Zhang, Z.W.; Chen, Y.F.; Lu, W.J.; Zhang, D. Effect of β heat treatment temperature on microstructure and mechanical properties of in situ titanium matrix composites. Mater. Des. 2010, 31, 4269–4273. [Google Scholar] [CrossRef]

- Zhang, C.J.; Kong, F.T.; Xiao, S.L.; Niu, H.Z.; Xu, L.J.; Chen, Y.Y. Evolution of microstructural characteristic and tensile properties during preparation of TiB/Ti composite sheet. Mater. Des. 2012, 36, 505–510. [Google Scholar] [CrossRef]

- Wang, M.M.; Lu, W.J.; Qin, J.N.; Ma, F.C.; Lu, J.Q.; Zhang, D. Effect of volume fraction of reinforcement on room temperature tensile property of in situ (TiB + TiC)/Ti matrix composites. Mater. Des. 2006, 27, 494–498. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Rosenberger. Processing and properties of titanium–titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Gambone, M.L.; Rosenberger, A.H. Creep of SiC/Ti-1100 composite in a vacuum environment. Acta Mater. 1999, 47, 1723–1734. [Google Scholar] [CrossRef]

- Zhang, W.C.; Wang, M.M.; Chen, W.Z.; Feng, Y.J.; Yu, Y. Preparation of TiBw/Ti–6Al–4V composite with an inhomogeneous reinforced structure by a canned hot extrusion process. J. Alloys Compd. 2016, 669, 79–90. [Google Scholar] [CrossRef]

- Huang, L.J.; Yang, F.Y.; Hua, H.T.; Rong, X.D.; Geng, L.; Wu, L.Z. TiB whiskers reinforced high temperature titanium Ti60 alloy composites with novel network microstructure. Mater. Des. 2013, 51, 421–490. [Google Scholar] [CrossRef]

- Koo, M.Y.; Park, J.S.; Park, M.K.; Kim, K.T.; Hong, S.H. Effect of aspect ratios of in situ formed TiB whiskers on the mechanical properties of TiBw/Ti–6Al–4V composites. Scr. Mater. 2012, 66, 487–490. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.C.; Dong, W.Q.; Yang, J.L.; Feng, Y.J. Effects of pre-sintering on microstructure and properties of TiBw/Ti6Al4V composites fabricated by hot extrusion with steel cup. Mater. Sci. Eng. A 2015, 638, 38–45. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.C.; Dong, W.Q.; Han, X.Z.; Pei, C.L.; Jiao, X.Y.; Feng, Y.J. Research on heat treatment of TiBw/Ti6Al4V composites tubes. Mater. Des. 2015, 73, 1–9. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Wang, B.; Wu, L.Z. Effects of volume fraction on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with novel network microstructure. Mater Des. 2013, 45, 532–538. [Google Scholar] [CrossRef]

- Lu, H.Y.; Zhang, D.L.; Gabbitas, B.; Yang, F.; Matthews, S. Synthesis of a TiBw/Ti6Al4V composite by powder compact extrusion using a blended powder mixture. J. Alloys Compd. 2014, 606, 262–268. [Google Scholar] [CrossRef]

- Lu, W.J.; Zhang, D.; Zhang, X.N.; Wu, R.J.; Sakata, T.; Mori, H. Microstructure and tensile properties of in situ (TiB + TiC)/Ti6242 (TiB:TiC = 1:1) composites prepared by common casting technique. Mater. Sci. Eng. A 2001, 311, 142–150. [Google Scholar] [CrossRef]

- Sun, Z.C.; Wang, X.Q.; Zhang, J.; Yang, H. Prediction and control of equiaxed α in near-β forging of TA15 Ti-alloy based on BP neural network: For purpose of tri-modal microstructure. Mater. Sci. Eng. A 2014, 591, 18–25. [Google Scholar] [CrossRef]

- Zhu, S.; Yang, H.; Guo, L.G.; Fan, X.G. Effect of cooling rate on microstructure evolution during α/β heat treatment of TA15 titanium alloy. Mater. Charact. 2012, 70, 101–110. [Google Scholar] [CrossRef]

- Sun, Z.C.; Mao, X.J.; Wu, H.L.; Yang, H.; Li, J.J. Tri-modal microstructure and performance of TA15 Ti-alloy under near-β forging and given subsequent solution and aging treatment. Mater. Sci. Eng. A 2016, 654, 113–123. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.Q.; Lia, A.; Wang, H.M. Microstructure and tensile properties of laser melting deposited TiC/TA15 titanium matrix composites. J. Alloys Compd. 2009, 485, 156–162. [Google Scholar] [CrossRef]

- Qi, J.Q.; Wang, H.W.; Zou, C.M.; Wei, Z.J. Influence of matrix characteristics on tensile properties of in situ synthesized TiC/TA15 composite. Mater. Sci. Eng. A. 2012, 553, 59–66. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.Q.; Lia, A.; Wang, H.M. High temperature mechanical properties of a laser melting deposited TiC/TA15 titanium matrix composite. J. Alloys Compd. 2010, 496, 189–195. [Google Scholar] [CrossRef]

- Metallic Materials-Tensile Testing at Ambient Temperature; ISO 6892; BSI: London, UK, 1998.

- Malaysia. Jabatan Standard. Metallic Materials-Tensile Testing at Elevated Temperature; ISO 783, IDT; Department of Standards Malaysia: Selangor, Malaysia, 1999.

- Huang, L.J.; Geng, L.; Peng, H.X.; Balasubramaniam, K.; Wang, G.S. Effects of sintering parameters on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with a novel network architecture. Mater. Des. 2011, 32, 3347–3353. [Google Scholar] [CrossRef]

- Hill, D.; Banerjee, R.; Huber, D.; Tiley, J.; Fraser, H.L. Formation of equiaxed alpha in TiB reinforced Ti alloy composites. Scr. Mater. 2005, 52, 387–392. [Google Scholar] [CrossRef]

- Wang, J.H.; Guo, X.L.; Qin, J.N.; Zhang, D.; Lu, W.J. Microstructure and mechanical properties of investment casted titanium matrix composites with B4C additions. Mater. Sci. Eng. A 2015, 628, 366–373. [Google Scholar] [CrossRef]

- Yue, Y.; Dai, L.Y.; Zhong, H.; Tan, C.L.; Ma, M.Z.; Zhang, X.Y.; Liu, R.P. Enhanced mechanical properties for mill-annealed Ti-20Zr-6.5Al-4V alloy with a fine equiaxed microstructure. Mater. Sci. Eng. A 2016, 678, 286–290. [Google Scholar] [CrossRef]

- Wang, B.; Huang, L.J.; Liu, B.X.; Geng, L.; Hu, H.T. Effects of deformation conditions on the microstructure and substructure evolution of TiBw/Ti60 composite with network structure. Mater. Sci. Eng. A 2015, 627, 316–325. [Google Scholar] [CrossRef]

- Wang, S.C.; Aindow, M.; Starink, M.J. Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Mater. 2003, 51, 2485–2503. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X.; Balasubramaniam, K. High temperature tensile properties of in situ TiBw/Ti6Al4V composites with a novel network reinforcement architecture. Mater. Sci. Eng. A 2012, 534, 688–692. [Google Scholar] [CrossRef]

| Al | Mo | V | Zr | Fe | Si | O | C | N | H | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| 6.62 | 1.70 | 2.25 | 1.9 | 0.04 | 0.02 | 0.15 | 0.003 | 0.007 | 0.001 | Bal. |

| Size Distribution of TA15 Powders | D10 | D50 | D90 |

|---|---|---|---|

| Diameter (μm) | 90 | 140 | 200 |

| Size Distribution of TiB2 Powders (μm) | >8 | 5~8 | 2~5 | <2 |

|---|---|---|---|---|

| Proportion (%) | 11.3 | 30.9 | 49.3 | 8.5 |

| Angle of α/α Boundary in a Parent β grain, ° (Tol ± 1°) | Theoretical Ratio, % [34] | Actual Ratio, % | Actual Misorientation Angle Ratio, % |

|---|---|---|---|

| 10 (10.53) | 9.1 | 8 | 0.04 |

| 60 (60,60.83) | 54.6 | 54 | 0.27 |

| 63 (63.26) | 18.2 | 18 | 0.09 |

| 90 (90) | 18.2 | 20 | 0.10 |

| Sample | UTS, MPa | Elongation, % |

|---|---|---|

| Vacuum hot-pressing sintering 2.5 vol % TiBw/TA15 | 1051 ± 6 | 5.6 ± 0.5 |

| Vacuum hot-pressing sintering 5 vol % TiBw/TA15 | 1085 ± 5 | 4.2 ± 0.3 |

| Laser melting deposited 5 vol % TiC/TA15 [24] | 1086 ± 45 | 4.3 ± 1.8 |

| As-cast 10 vol % TiC/TA15 [25] | 1048 ± 5 | 3.9 ± 0.6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Zhang, W.; Zeng, L.; Cui, G.; Chen, W. Room-Temperature and High-Temperature Tensile Mechanical Properties of TA15 Titanium Alloy and TiB Whisker-Reinforced TA15 Matrix Composites Fabricated by Vacuum Hot-Pressing Sintering. Materials 2017, 10, 424. https://doi.org/10.3390/ma10040424

Feng Y, Zhang W, Zeng L, Cui G, Chen W. Room-Temperature and High-Temperature Tensile Mechanical Properties of TA15 Titanium Alloy and TiB Whisker-Reinforced TA15 Matrix Composites Fabricated by Vacuum Hot-Pressing Sintering. Materials. 2017; 10(4):424. https://doi.org/10.3390/ma10040424

Chicago/Turabian StyleFeng, Yangju, Wencong Zhang, Li Zeng, Guorong Cui, and Wenzhen Chen. 2017. "Room-Temperature and High-Temperature Tensile Mechanical Properties of TA15 Titanium Alloy and TiB Whisker-Reinforced TA15 Matrix Composites Fabricated by Vacuum Hot-Pressing Sintering" Materials 10, no. 4: 424. https://doi.org/10.3390/ma10040424