Crystallographic Characterization on Polycrystalline Ni-Mn-Ga Alloys with Strong Preferred Orientation

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

3.1. Thermo-Mechanical Treatment of Directionally Solidified Alloys

3.1.1. Austenite to 7M Martensite Transformation

3.1.2. Austenite to 5M Martensite Transformation

3.2. Orientation Inheritance from Austenite to 7M Martensite in Melt-Spun Ribbons

3.3. Preferential Orientation and Variant Distribution of Thin Film

3.3.1. Global Microstructure and Texture of Thin Film

3.3.2. 7M Variants Distribution in the Thin Film

3.3.3. NM Variants Distribution in the Thin Film

4. Conclusions

- (1)

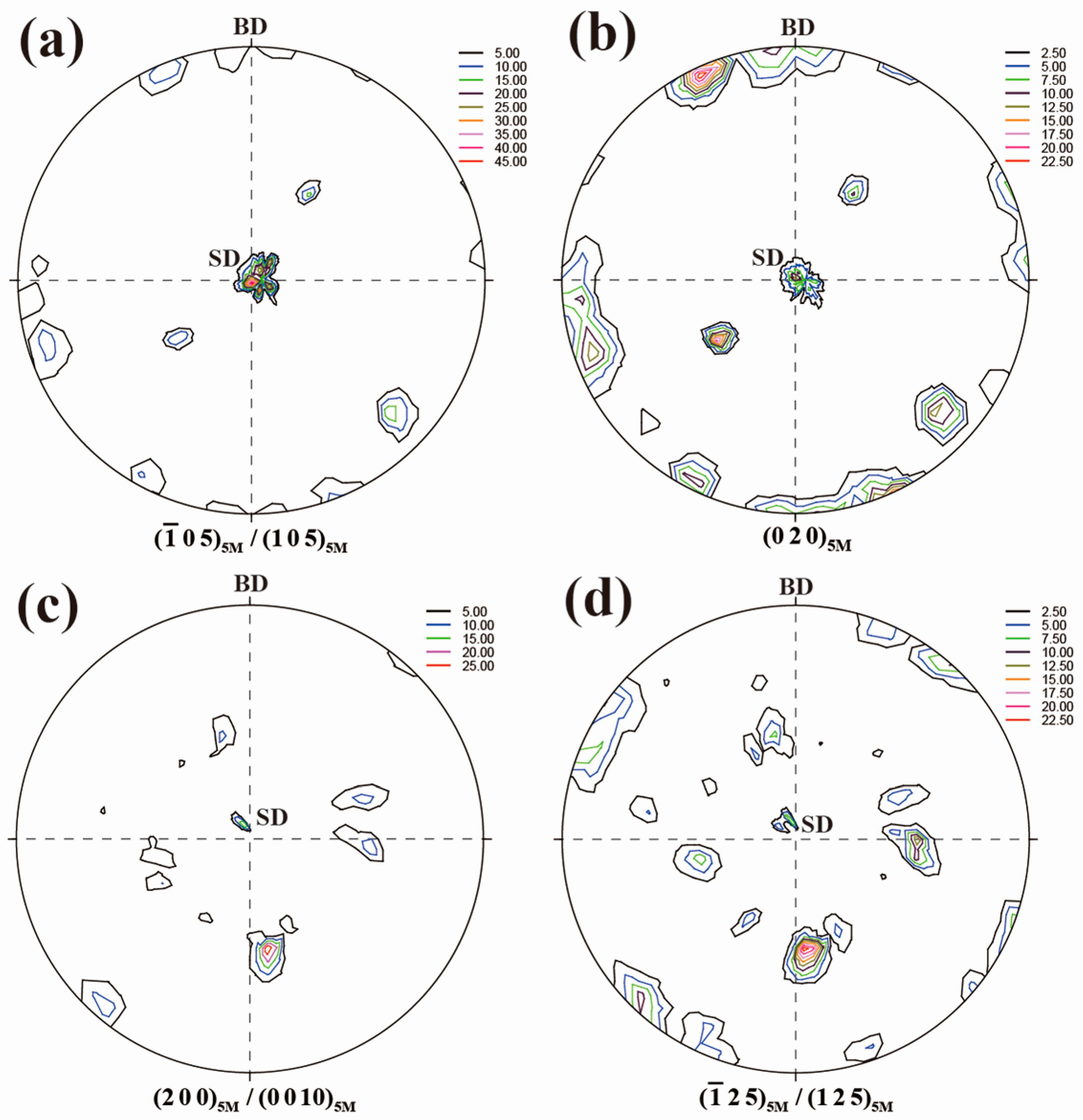

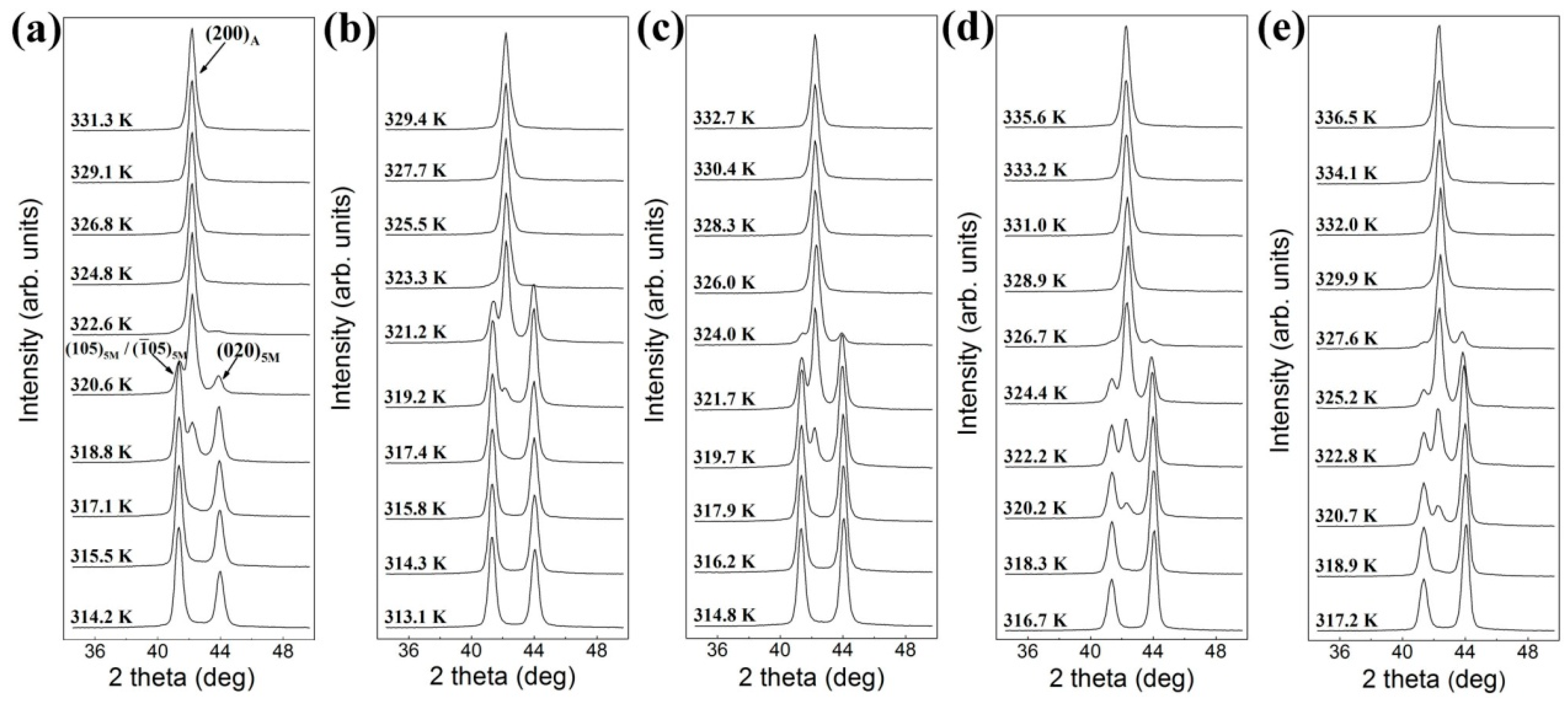

- The influence of uniaxial compression on martensitic transformation in directionally solidified Ni50Mn30Ga20 and Ni50Mn28.5Ga21.5 polycrystalline alloys was studied by neutron diffraction. It was shown that the distribution of martensite variants can be tuned through cyclic thermo-mechanical treatments. For the Ni50Mn30Ga20 alloy with <0 0 1>A preferential orientation parallel to the solidification direction, a strong <0 1 0>7M preferential orientation of 7M martensite along the loading direction (//solidification direction) was induced by the external compression during martensitic transformation. In addition, it was found that the selection of preferential variants induced by thermo-mechanical treatments was strongly dependent on the austenite orientation and the direction of external load, which was evidenced in Ni50Mn28.5Ga21.5 polycrystalline alloys with <0 0 1>A and <1 1 0>A parallel to the solidification direction. For the austenite with the orientation of <0 0 1>A//SD, the compressive load applied along solidification direction favored the formation of variants with {1 0 5}5M/{−1 0 5}5M//SD (LD) and {0 2 0}5M⊥SD (LD). On the other hand, the formation of the variants with {2 0 0}5M/{0 0 10}5M//SD (//LD) and {1 2 5}5M/{−1 2 5}5M⊥SD (LD) was favored under the condition of LD//<1 1 0>A. The preferred orientation of the martensite variants formed under the external compression applied during the martensitic transformation should be attributed to the accommodation between the anisotropic lattice distortion in the martensitic transformation and the external constraint.

- (2)

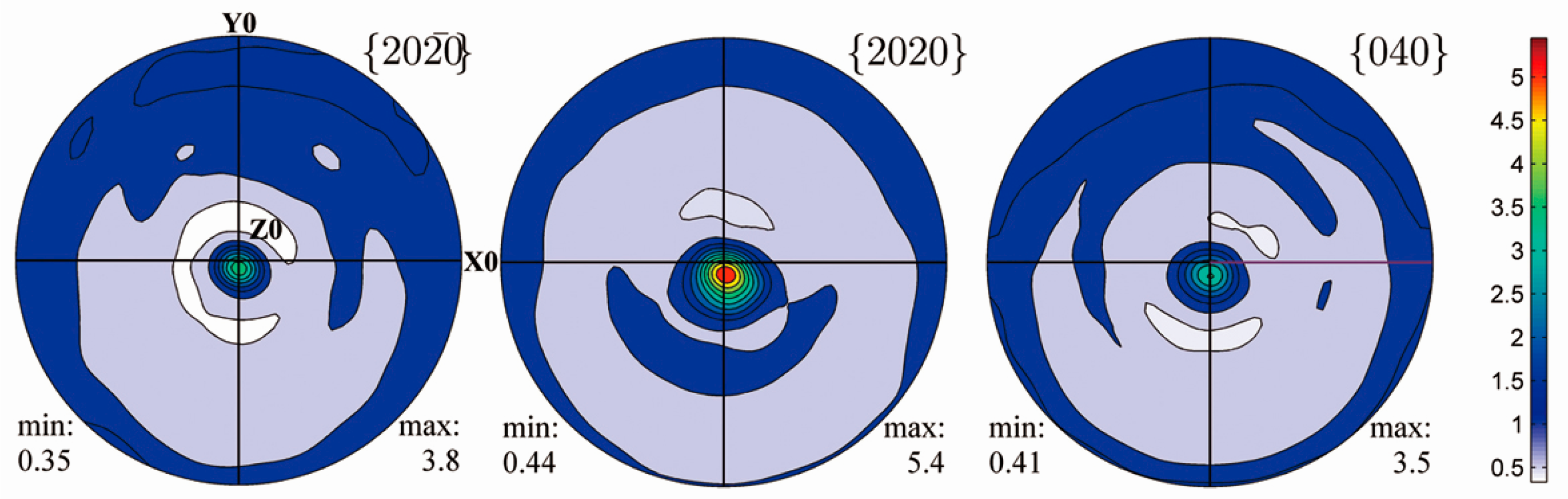

- The preferred orientation distribution for the austenite in Ni53Mn22Ga25ribbons and the 7M martensite in Ni51Mn27Ga22 ribbons was studied based on EBSD and XRD. It was found that the austenite forms a preferred orientation with {4 0 0}A parallel to ribbon plane, whereas the 7M martensite develops the preferred orientation with {2 0 −20}7M, {2 0 20}7M, and {0 4 0}7M crystallographic planes parallel to the ribbon plane. The preferred orientation distribution for austenite and 7M martensite was well correlated and the preferred orientation in ribbons can be inherited after the martensitic transformation. Such texture inheritance is attributed to the intrinsic orientation relationship between austenite and 7M martensite.

- (3)

- Epitaxially grown thin films with nominal composition Ni50Mn30Ga20 and thickness of 1.5 μm were prepared on MgO(1 0 0) substrate with a Cr buffer layer by DC magnetron sputtering. Based on EBSD measurements, it was revealed that the coarse plates in the top layer of the film are of the NM martensite, whereas the fine plates in the film interior are of the 7M martensite. For both 7M and NM martensite, the plate-like microstructures are composed of two distinct kinds of plate groups with low or high relative contrast. For 7M martensite, {2 0 −20}7M, {2 0 20}7M and {0 4 0}7M are nearly parallel to the substrate surface, whereas for the NM martensite, {0 0 4}NM and {2 2 0}NM tends to be parallel to the substrate surface. EBSD measurements show that one plate group of 7M martensite consists of four twin-related variants. In the low relative contrast zone, the majority of variants are in Type-I twin relation, whereas for the high relative contrast zone, the majority of variants are in Type-II twin relation. The selection of twinning type is a consequence of external constraint from the rigid substrate and the twinning type with less shear deformation in the film normal direction is favored. For NM martensite, one plate group of NM martensite also consists of 4 martensite plates, but each plate is composed of two twin related variants with one thicker than the other. The in-plate major and minor variants are distributed symmetrically to the inter-plate interfaces in low relative contrast zones, but asymmetrically distributed in high relative contrast zones. The difference in the orientation combination of the in-plate variants accounts for the topological differences observed for the two relative contrast zones.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Murray, S.J.; Marioni, M.; Allen, S.M.; O’Handley, R.C.; Lograsso, T.A. 6% magnetic-field-induced strain by twin-boundary motion in ferromagnetic Ni-Mn-Ga. Appl. Phys. Lett. 2000, 77, 886–888. [Google Scholar] [CrossRef]

- Sozinov, A.; Likhachev, A.A.; Lanska, N.; Ullakko, K. Giant magnetic field induced strain in NiMnGa seven-layered martensitic phase. Appl. Phys. Lett. 2002, 80, 1746–1748. [Google Scholar] [CrossRef]

- Mullner, P.; Chernenko, V.A.; Kostorz, G. Large cyclic magnetic-field-induced deformation in orthorhombic (14M) Ni-Mn-Ga martensite. J. Appl. Phys. 2004, 95, 1531–1536. [Google Scholar] [CrossRef]

- Jiang, C.B.; Wang, J.M.; Xu, H.B. Temperature dependence of the giant magnetostrain in a NiMnGa magnetic shape memory alloy. Appl. Phys. Lett. 2005, 86, 252508. [Google Scholar] [CrossRef]

- Sozinov, A.; Lanska, N.; Soroka, A.; Zou, W. 12% magnetic field-induced strain in Ni-Mn-Ga-based non-modulated martensite. Appl. Phys. Lett. 2013, 102, 021902. [Google Scholar] [CrossRef]

- Pagounis, E.; Chulist, R.; Szczerba, M.J.; Laufenberg, M. Over 7% magnetic field-induced strain in a Ni-Mn-Ga five-layered martensite. Appl. Phys. Lett. 2014, 105, 052405. [Google Scholar] [CrossRef]

- Pagounis, E.; Szczerba, M.J.; Chulist, R.; Laufenberg, M. Large magnetic field-induced work output in a NiMnGa seven-layered modulated martensite. Appl. Phys. Lett. 2015, 107, 152407. [Google Scholar] [CrossRef]

- Planes, A.; Mañosa, L.; Acet, M. Magnetocaloric effect in ferromagnetic Heusler shape-memory alloys. J. Phys. Condens. Matter 2009, 21, 233201. [Google Scholar] [CrossRef] [PubMed]

- Dunand, D.C.; Müllner, P. Size Effects on Magnetic Actuation in Ni-Mn-Ga Shape-Memory Alloys. Adv. Mater. 2011, 23, 216–232. [Google Scholar] [CrossRef] [PubMed]

- O’Handley, R.C. Model for strain and magnetization in magnetic shape-memory alloys. J. Appl. Phys. 1998, 83, 3263–3270. [Google Scholar] [CrossRef]

- Wu, G.H.; Yu, C.H.; Meng, L.Q.; Chen, J.L.; Yang, F.M.; Qi, S.R.; Zhan, W.S.; Wang, Z.; Zheng, Y.F.; Zhao, L.C. Giant magnetic-field-induced strains in Heusler alloy NiMnGa with modified composition. Appl. Phys. Lett. 1999, 75, 2990–2992. [Google Scholar] [CrossRef]

- James, R.D.; Tickle, R.; Wuttig, M. Large field-induced strains in ferromagnetic shape memory materials. Mater. Sci. Eng. A 1999, 273–275, 320–325. [Google Scholar] [CrossRef]

- Gaitzsch, U.; Pötschke, M.; Roth, S.; Rellinghaus, B.; Schultz, L. A 1% magnetostrain in polycrystalline 5M Ni-Mn-Ga. Acta Mater. 2009, 57, 365–370. [Google Scholar] [CrossRef]

- Jin, X.; Marioni, M.; Bono, D.; Allen, S.M.; O’Handley, R.C.; Hsu, T.Y. Empirical mapping of Ni-Mn-Ga properties with composition and valence electron concentration. J. Appl. Phys. 2002, 91, 8222–8222. [Google Scholar] [CrossRef]

- Pons, J.; Chernenko, V.A.; Santamarta, R.; Cesari, E. Crystal structure of martensitic phases in Ni-Mn-Ga shape memory alloys. Acta Mater. 2000, 48, 3027–3038. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Wang, Y.D.; Zuo, L. New approach into twin interfaces of modulated martensite. J. Appl. Cryst. 2010, 43, 617–622. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Twin relationships of 5M modulated martensite in Ni-Mn-Ga alloy. Acta Mater. 2011, 59, 3390–3397. [Google Scholar] [CrossRef]

- Glavatskyy, I.; Glavatska, N.; Urubkov, I.; Hoffman, J.U.; Bourdarot, F. Crystal and magnetic structure temperature evolution in Ni-Mn-Ga magnetic shape memory martensite. Mater. Sci. Eng. A 2008, 481–482, 298–301. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Evidence for a monoclinic incommensurate superstructure in modulated martensite. Acta Mater. 2012, 60, 6982–6990. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Pareti, L.; Paoluzi, A.; Calestani, G. Commensurate and incommensurate “5M” modulated crystal structures in Ni-Mn-Ga martensitic phases. Acta Mater. 2007, 55, 5237–5245. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Villa, E.; Paoluzi, A.; Calestani, G.; Chernenko, V.; Besseghini, S.; Ritter, C.; Passaretti, F. Crystal structure of 7M modulated Ni-Mn-Ga martensitic phase. Acta Mater. 2008, 56, 4529–4535. [Google Scholar] [CrossRef]

- Han, M.; Bennett, J.C.; Gharghouri, M.A.; Chen, J.; Hyatt, C.V. Understanding modulated twin transition at the atomic level. Acta Mater. 2007, 55, 1731–1740. [Google Scholar] [CrossRef]

- Jiang, C.B.; Muhammad, Y.; Deng, L.F.; Wu, W.; Xu, H.B. Composition dependence on the martensitic structures of the Mn-rich NiMnGa alloys. Acta Mater. 2004, 52, 2779–2785. [Google Scholar] [CrossRef]

- Cong, D.Y.; Zetterström, P.; Wang, Y.D.; Delaplane, R.; Reng, R.L.; Zhao, X.; Zuo, L. Crystal structure and phase transformation in Ni53Mn25Ga22 shape memory alloy from 20 K to 473 K. Appl. Phys. Lett. 2005, 87, 111906. [Google Scholar] [CrossRef]

- Seguí, C.; Chernenko, V.A.; Pons, J.; Cesari, E.; Khovailo, V.; Takagi, T. Low-temperature-induced intermartensitic phase transformations in Ni-Mn-Ga single crystal. Acta Mater. 2005, 53, 111–120. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Composition-dependent ground state of martensite in Ni-Mn-Ga alloys. Acta Mater. 2013, 61, 3858–3865. [Google Scholar] [CrossRef]

- Li, Z.B.; Yang, B.; Zhang, Y.D.; Esling, C.; Zou, N.F.; Zhao, X.; Zuo, L. Crystallographic insights into the intermartensitic transformation in Ni-Mn-Ga alloys. Acta Mater. 2014, 74, 9–17. [Google Scholar] [CrossRef]

- Wang, W.H.; Liu, Z.H.; Zhang, J.; Chen, J.L.; Wu, G.H.; Zhan, W.S.; Chin, T.S.; Wen, G.H.; Zhang, X.X. Thermoelastic intermartensitic transformation and its internal stress dependency in Ni52Mn24Ga24 single crystals. Phys. Rev. B 2002, 66, 052411. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Seguí, C.; Cesari, E.; Pons, J.; Kokorin, V.V. Sequence of martensitic transformations in Ni-Mn-Ga alloys. Phys. Rev. B 1998, 57, 2659–2662. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Pons, J.; Segui, C.; Cesari, E. Premartensitic phenomena and other phase transformations in Ni-Mn-Ga alloys studied by dynamical mechanical analysis and electron diffraction. Acta Mater. 2002, 50, 53–60. [Google Scholar] [CrossRef]

- Brokmeier, H.G.; Gan, W.M.; Randau, C.; Voeller, M.; Rebelo-Kornmeier, J.; Hofmann, M. Texture analysis at neutron diffractometer STRESS-SPEC. Nucl. Instrum. Methods Phys. Res. A 2011, 642, 87–92. [Google Scholar] [CrossRef]

- Hoelzel, M.; Gan, W.M.; Hofmann, M.; Randau, C.; Seidl, G.; Jüttner, P.; Schmahl, W.W. Rotatable multifunctional load frames for neutron diffractometers at FRM II-design, specifications and applications. Nucl. Instrum. Methods Phys. Res. A 2013, 711, 101–105. [Google Scholar] [CrossRef]

- Wang, Y.D.; Brown, D.W.; Choo, H.; Liaw, P.K.; Cong, D.Y.; Benson, M.L.; Zuo, L. Experimental evidence of stress-field-induced selection of variants in Ni-Mn-Ga ferromagnetic shape-memory alloys. Phys. Rev. B 2007, 75, 174404. [Google Scholar] [CrossRef]

- Straka, L.; Heczko, O.; Hanninen, H. Activation of magnetic shape memory effect in Ni-Mn-Ga alloys by mechanical and magnetic treatment. Acta Mater. 2008, 56, 5492–5499. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Gan, W.M.; Zou, N.F.; Zhao, X.; Zuo, L. In-situ neutron diffraction study of martensitic variant redistribution in polycrystalline Ni-Mn-Ga alloy under cyclic thermo-mechanical treatment. Appl. Phys. Lett. 2014, 105, 021907. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Determination of the orientation relationship between austenite and incommensurate 7M modulated martensite in Ni-Mn-Ga alloys. Acta Mater. 2011, 59, 2762–2772. [Google Scholar] [CrossRef]

- Li, Z.B.; Zou, N.F.; Yang, B.; Gan, W.M.; Hou, L.; Li, X.; Zhang, Y.D.; Esling, C.; Hofmann, M.; Zhao, X.; et al. Effect of compressive load on the martensitic transformation from austenite to 5M martensite in a polycrystalline Ni-Mn-Ga alloy studied by in-situ neutron diffraction. J. Alloys Compd. 2016, 666, 1–9. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Determination of the orientation relationship between austenite and 5M modulated martensite in Ni-Mn-Ga alloys. J. Appl. Cryst. 2011, 44, 1222–1226. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Sanchez-Valdes, C.F.; Sanchez Llamazares, J.L.; Esling, C.; Zhao, X.; Zuo, L. Giant magnetocaloric effect in melt-spun Ni-Mn-Ga ribbons with magneto-multistructural transformation. Appl. Phys. Lett. 2014, 104, 044101. [Google Scholar] [CrossRef]

- Li, Z.B.; Sanchez Llamazares, J.L.; Sanchez-Valdes, C.F.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Microstructure and magnetocaloric effect of melt-spun Ni52Mn26Ga22 ribbon. Appl. Phys. Lett. 2012, 100, 174102. [Google Scholar] [CrossRef]

- Hernando, B.; Sanchez Llamazares, J.L.; Prida, V.M.; Baldomir, D.; Serantes, D.; Ilyn, M.; González, J. Magnetocaloric effect in preferentially textured Mn50Ni40In10 melt spun ribbons. Appl. Phys. Lett. 2009, 94, 222502. [Google Scholar] [CrossRef]

- Liu, J.; Woodcock, T.G.; Scheerbaum, N.; Gutfleisch, O. Influence of annealing on magnetic field-induced structural transformation and magnetocaloric effect in Ni-Mn-In-Co ribbons. Acta Mater. 2009, 57, 4911–4920. [Google Scholar] [CrossRef]

- Sanchez Llamazares, J.L.; Sanchez, T.; Santos, J.D.; Pérez, M.J.; Sanchez, M.L.; Hernando, B.; Escoda, L.; Suñol, J.J.; Varga, R. Martensitic phase transformation in rapidly solidified Mn50Ni40In10 alloy ribbons. Appl. Phys. Lett. 2008, 92, 012513. [Google Scholar] [CrossRef]

- Sanchez Llamazares, J.L.; Hernando, B.; García, C.; González, J.; Escoda, L.; Suñol, J.J. Martensitic transformation in Ni50.4Mn34.9In14.7 melt spun ribbons. J. Phys. D Appl. Phys. 2009, 42, 045002. [Google Scholar] [CrossRef]

- Liu, J.; Scheerbaum, N.; Hinz, D.; Gutfleisch, O. Magnetostructural transformation in Ni-Mn-In-Co ribbons. Appl. Phys. Lett. 2008, 92, 162509. [Google Scholar] [CrossRef]

- Rama Rao, N.V.; Gopalan, R.; Manivel Raja, M.; AroutChelvane, J.; Majumdar, B.; Chandrasekaran, V. Magneto-structural transformation studies in melt-spun Ni-Mn-Ga ribbons. Scr. Mater. 2007, 56, 405–408. [Google Scholar] [CrossRef]

- Czaja, P.; Maziarz, W.; Przewoźnik, J.; Kapusta, C.; Hawelek, L.; Chrobak, A.; Drzymała, P.; Fitta, M.; Kolano-Burian, A. Magnetocaloric properties and exchange bias effect in Al for Sn substituted Ni48Mn39.5Sn12.5 Heusler alloy ribbons. J. Magn. Magn. Mater. 2014, 358–359, 142–148. [Google Scholar] [CrossRef]

- Bruno, N.M.; Yegin, C.; Karaman, I.; Chen, J.H.; Ross, J.H., Jr.; Liu, J.; Li, J. The effect of heat treatments on Ni43Mn42Co4Sn11 meta-magnetic shape memory alloys for magnetic refrigeration. Acta Mater. 2014, 74, 66–84. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Zheng, Q.; Zheng, X.; Li, M.; Du, J.; Yan, A. Enhanced magnetic refrigeration properties in Mn-rich Ni-Mn-Sn ribbons by optimal annealing. Sci. Rep. 2015, 5, 11010. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.H.; Chen, J.L.; Hu, H.N.; Zhang, M.; Dai, X.F.; Zhu, Z.Y.; Liu, G.D.; Wu, G.H.; Meng, F.B.; Li, Y.X. The influence of heat treatment on the magnetic and phase transformation properties of quaternary Heusler alloy Ni50Mn8Fe17Ga25 ribbons. Scr. Mater. 2004, 51, 1011–1015. [Google Scholar] [CrossRef]

- Li, Z.B.; Jiang, Y.W.; Li, Z.Z.; Yang, Y.Q.; Yang, B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Texture inheritance from austenite to 7M martensite in Ni-Mn-Ga melt-spun ribbons. Results Phys. 2016, 6, 428–433. [Google Scholar] [CrossRef]

- Ranzieri, P.; Fabbrici, S.; Nasi, L.; Righi, L.; Casoli, F.; Chernenko, V.A.; Villa, E.; Albertini, F. Epitaxial Ni-Mn-Ga/MgO(100) thin films ranging in thickness from 10 to 100nm. Acta Mater. 2013, 61, 263–272. [Google Scholar] [CrossRef]

- Jakob, A.M.; Hennes, M.; Müller, M.; Spemann, D.; Mayr, S.G. Coupling of micromagnetic and structural properties across the martensite and Curie temperatures in miniaturized Ni-Mn-Ga ferromagnetic shape memory alloys. Adv. Funct. Mater. 2013, 23, 4694–4702. [Google Scholar] [CrossRef]

- Yeduru, S.R.; Backen, A.; Fähler, S.; Schultz, L.; Kohl, M. Transformation behaviour of freestanding epitaxial Ni-Mn-Ga films. J. Alloys Compd. 2013, 577, S353–S357. [Google Scholar] [CrossRef]

- Jakob, A.M.; Müller, M.; Rauschenbach, B.; Mayr, S.G. Nanoscale mechanical surface properties of single crystalline martensitic Ni-Mn-Ga ferromagnetic shape memory alloys. New J. Phys. 2012, 14, 033029. [Google Scholar] [CrossRef]

- Tillier, J.; Bourgault, D.; Odier, P.; Ortega, L.; Pairis, S.; Fruchart, O.; Caillault, N.; Carbone, L. Tuning macro-twinned domain sizes and the b-variants content of the adaptive 14-modulated martensite in epitaxial Ni-Mn-Ga films by co-sputtering. Acta Mater. 2011, 59, 75–81. [Google Scholar] [CrossRef]

- Yeduru, S.R.; Backen, A.; Kübel, C.; Wang, D.; Scherer, T.; Fähler, S.; Schultz, L.; Kohl, M. Microstructure of free-standing epitaxial Ni-Mn-Ga films before and after variant reorientation. Scr. Mater. 2012, 66, 566–569. [Google Scholar] [CrossRef]

- Buschbeck, J.; Niemann, R.; Heczko, O.; Thomas, M.; Schultz, L.; Fähler, S. In situ studies of the martensitic transformation in epitaxial Ni-Mn-Ga films. Acta Mater. 2009, 57, 2516–2526. [Google Scholar] [CrossRef]

- Thomas, M.; Heczko, O.; Buschbeck, J.; Rößler, U.K.; McCord, J.; Scheerbaum, N.; Schultz, L.; Fähler, S. Magnetically induced reorientation of martensite variants in constrained epitaxial Ni-Mn-Ga films grown on MgO(001). New J. Phys. 2008, 10, 023040. [Google Scholar] [CrossRef]

- Kaufmann, S.; Rößler, U.K.; Heczko, O.; Wuttig, M.; Buschbeck, J.; Schultz, L.; Fähler, S. Adaptive modulations of martensites. Phys. Rev. Lett. 2010, 104, 145702. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Zhang, Y.D.; Li, Z.B.; Qin, G.W.; Zhao, X.; Esling, C.; Zuo, L. Insight into variant selection of seven-layer modulated martensite in Ni-Mn-Ga thin films grown on MgO(001) substrate. Acta Mater. 2015, 93, 205–217. [Google Scholar] [CrossRef]

- Yang, B.; Li, Z.B.; Zhang, Y.D.; Qin, G.W.; Esling, C.; Perroud, O.; Zhao, X.; Zuo, L. Microstructural features and orientation correlations of non-modulated martensite in Ni-Mn-Ga epitaxial thin films. Acta Mater. 2013, 61, 6809–6820. [Google Scholar] [CrossRef]

- Ranzieri, P.; Campanini, M.; Fabbrici, S.; Nasi, L.; Casoli, F.; Cabassi, R.; Buffagni, E.; Grillo, V.; Magén, C.; Celegato, F.; et al. Achieving giant magnetically induced reorientation of martensitic variants in magnetic shape-memory Ni-Mn-Ga films by microstructure engineering. Adv. Mater. 2015, 27, 4760–4766. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yang, B.; Zou, N.; Zhang, Y.; Esling, C.; Gan, W.; Zhao, X.; Zuo, L. Crystallographic Characterization on Polycrystalline Ni-Mn-Ga Alloys with Strong Preferred Orientation. Materials 2017, 10, 463. https://doi.org/10.3390/ma10050463

Li Z, Yang B, Zou N, Zhang Y, Esling C, Gan W, Zhao X, Zuo L. Crystallographic Characterization on Polycrystalline Ni-Mn-Ga Alloys with Strong Preferred Orientation. Materials. 2017; 10(5):463. https://doi.org/10.3390/ma10050463

Chicago/Turabian StyleLi, Zongbin, Bo Yang, Naifu Zou, Yudong Zhang, Claude Esling, Weimin Gan, Xiang Zhao, and Liang Zuo. 2017. "Crystallographic Characterization on Polycrystalline Ni-Mn-Ga Alloys with Strong Preferred Orientation" Materials 10, no. 5: 463. https://doi.org/10.3390/ma10050463