Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and Its Impact on End Products

Abstract

:1. Introduction

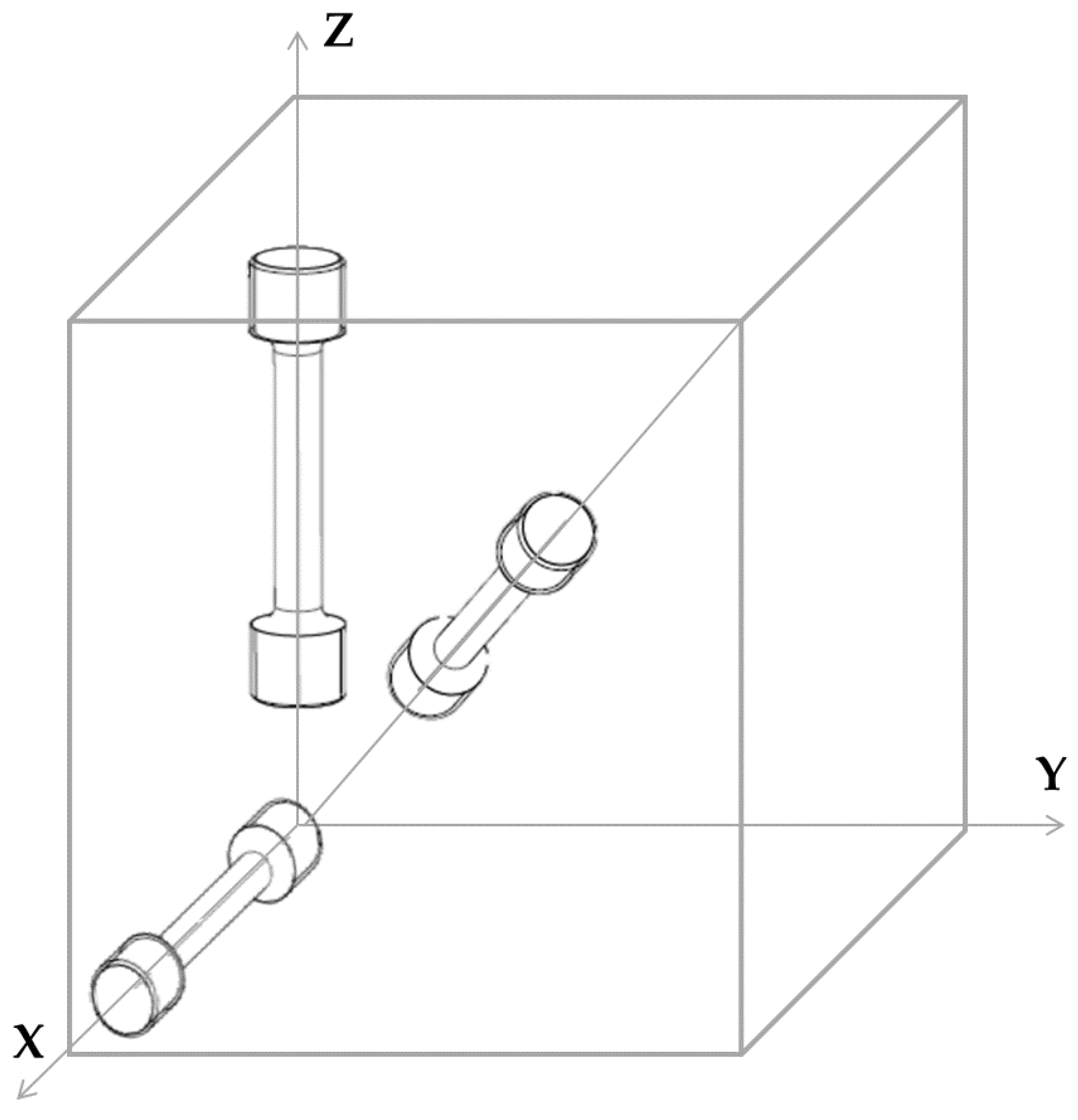

2. Materials and Methods

2.1. Tensile Properties

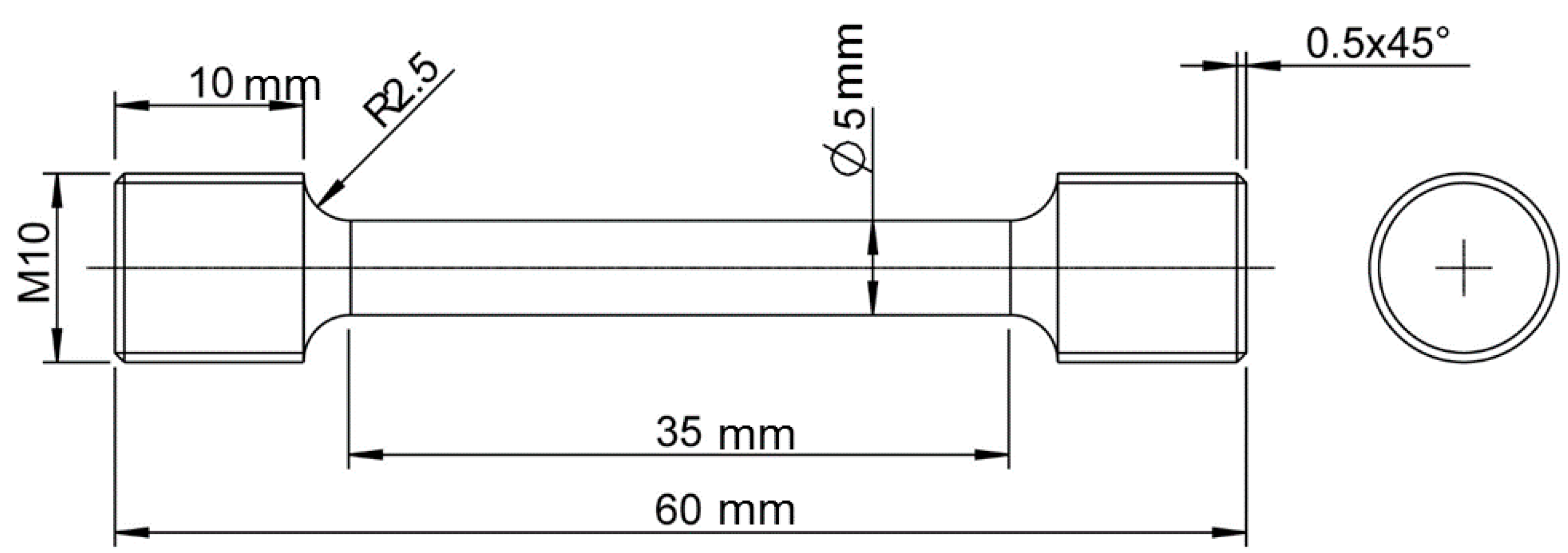

2.2. Defect Analysis

2.3. Microstructure Characterization

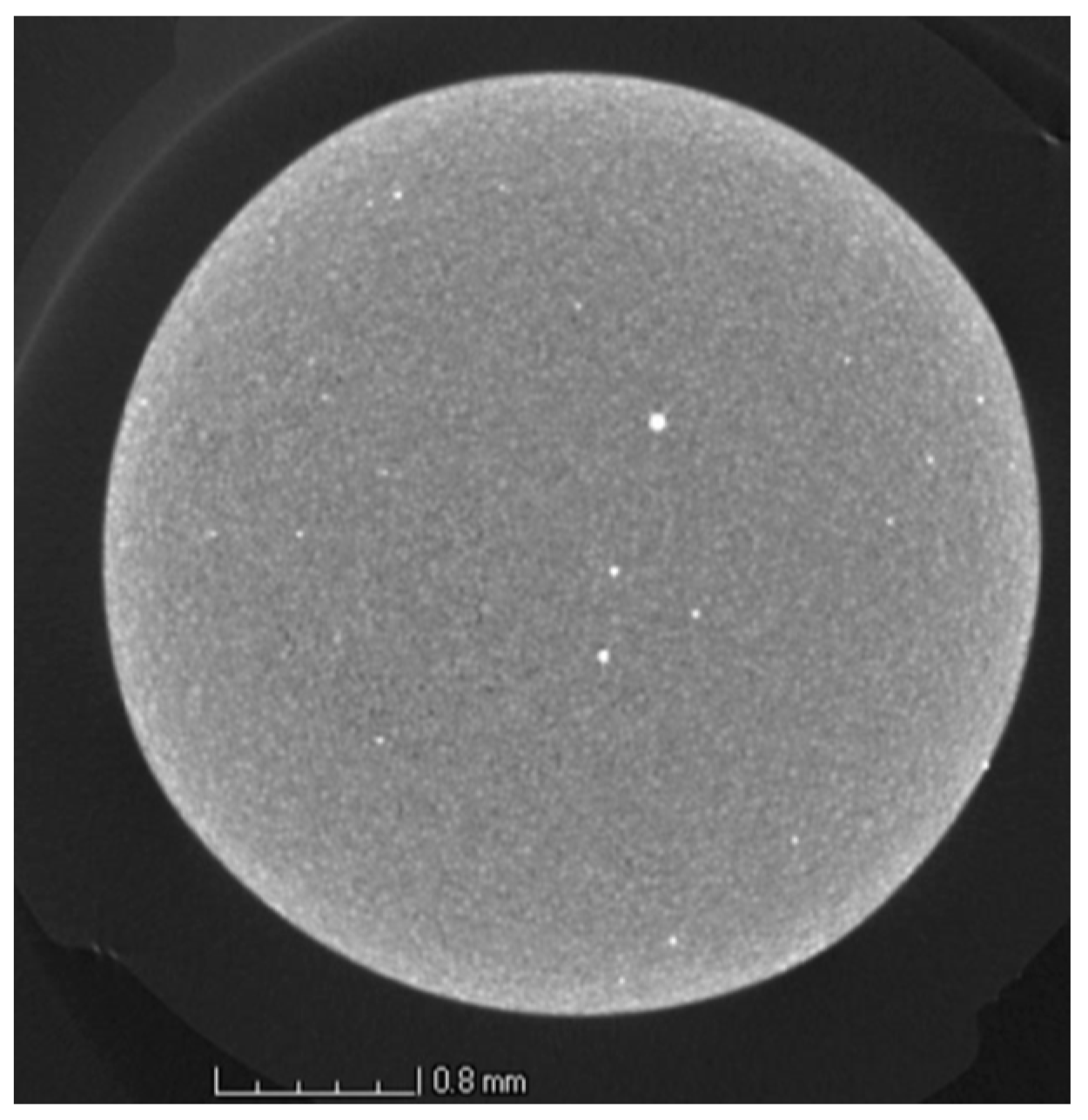

2.4. Powder Investigation

3. Results and Discussion

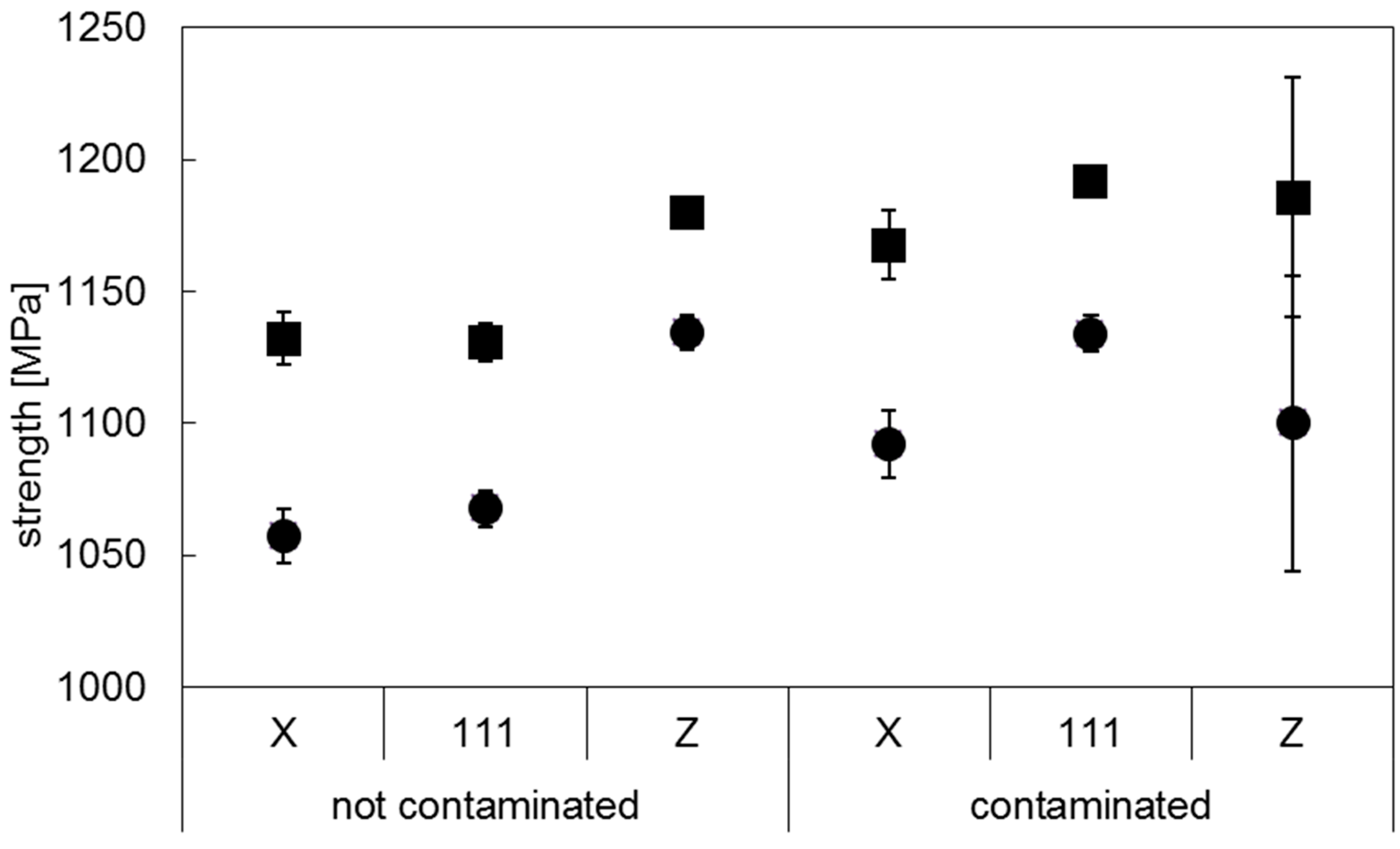

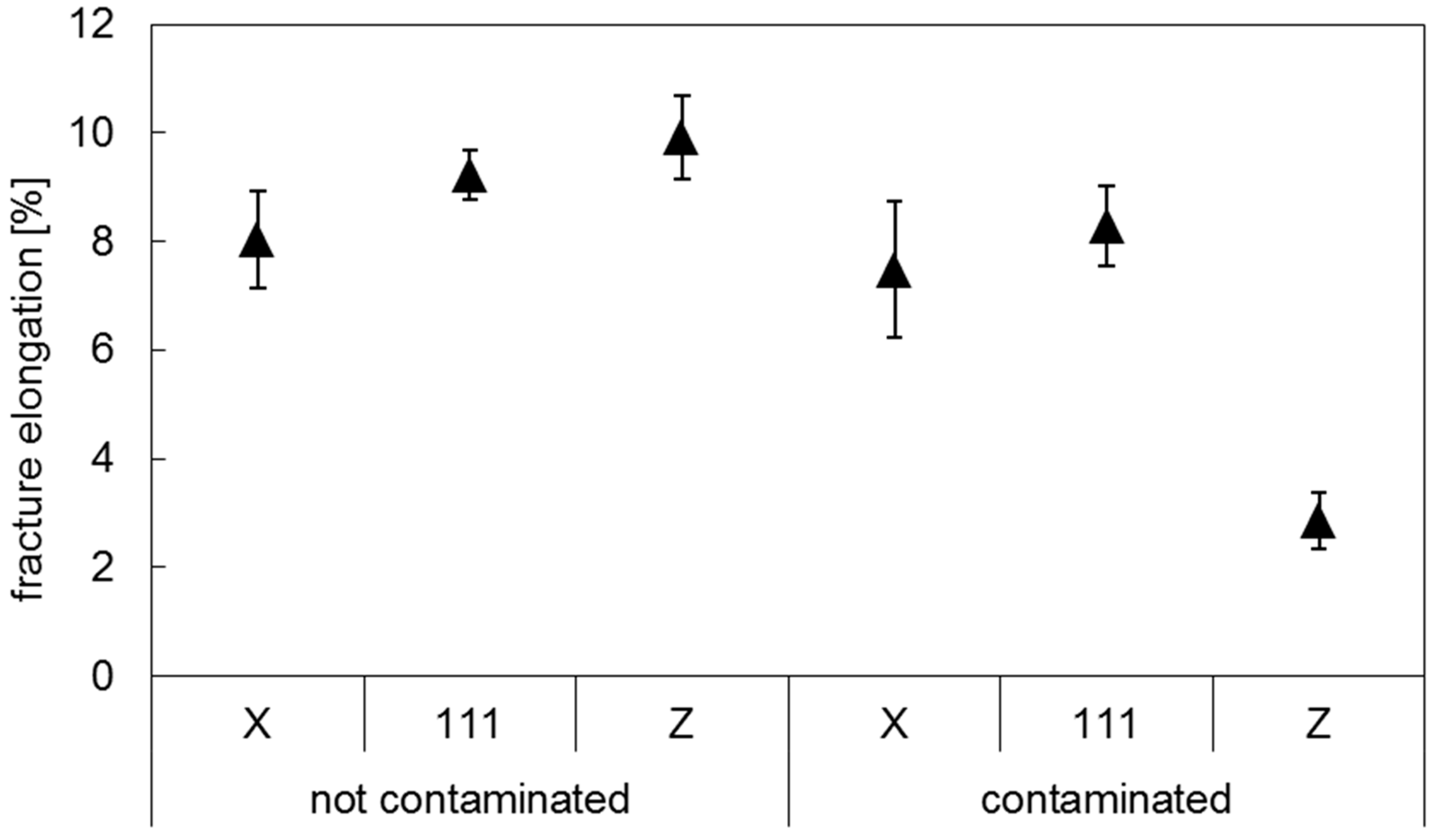

3.1. Mechanical Properties

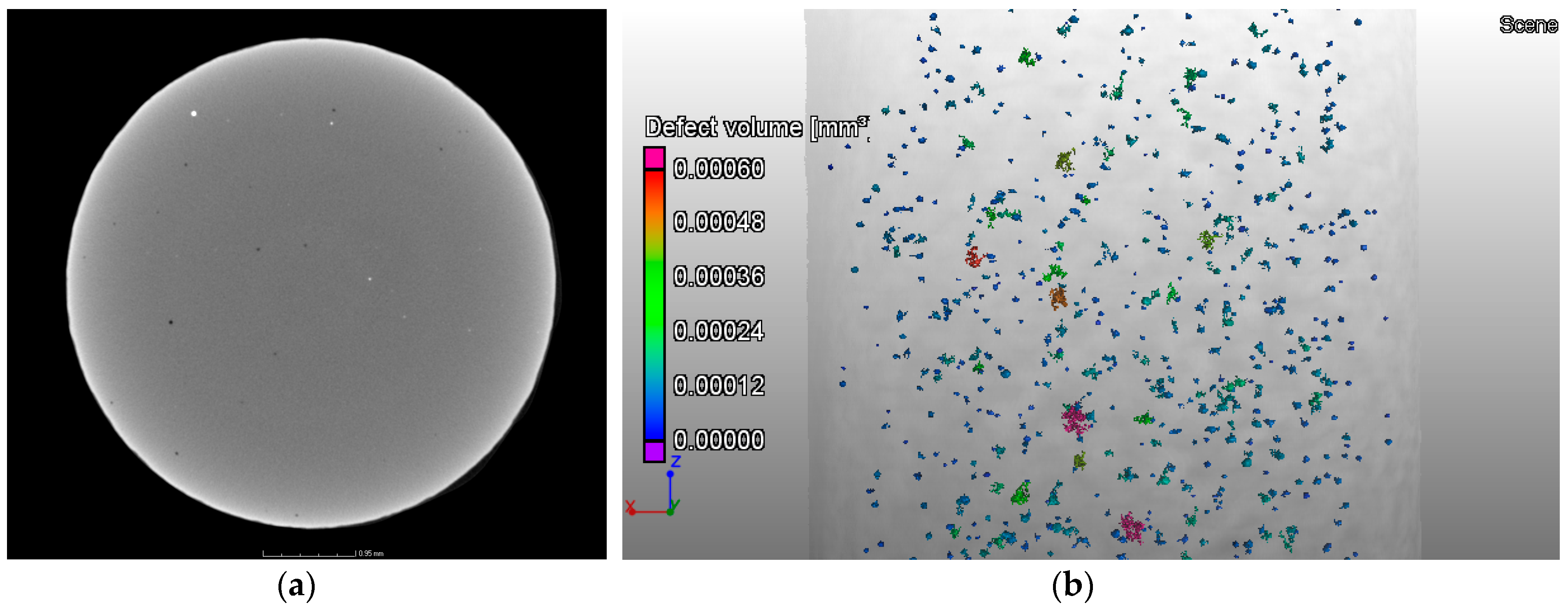

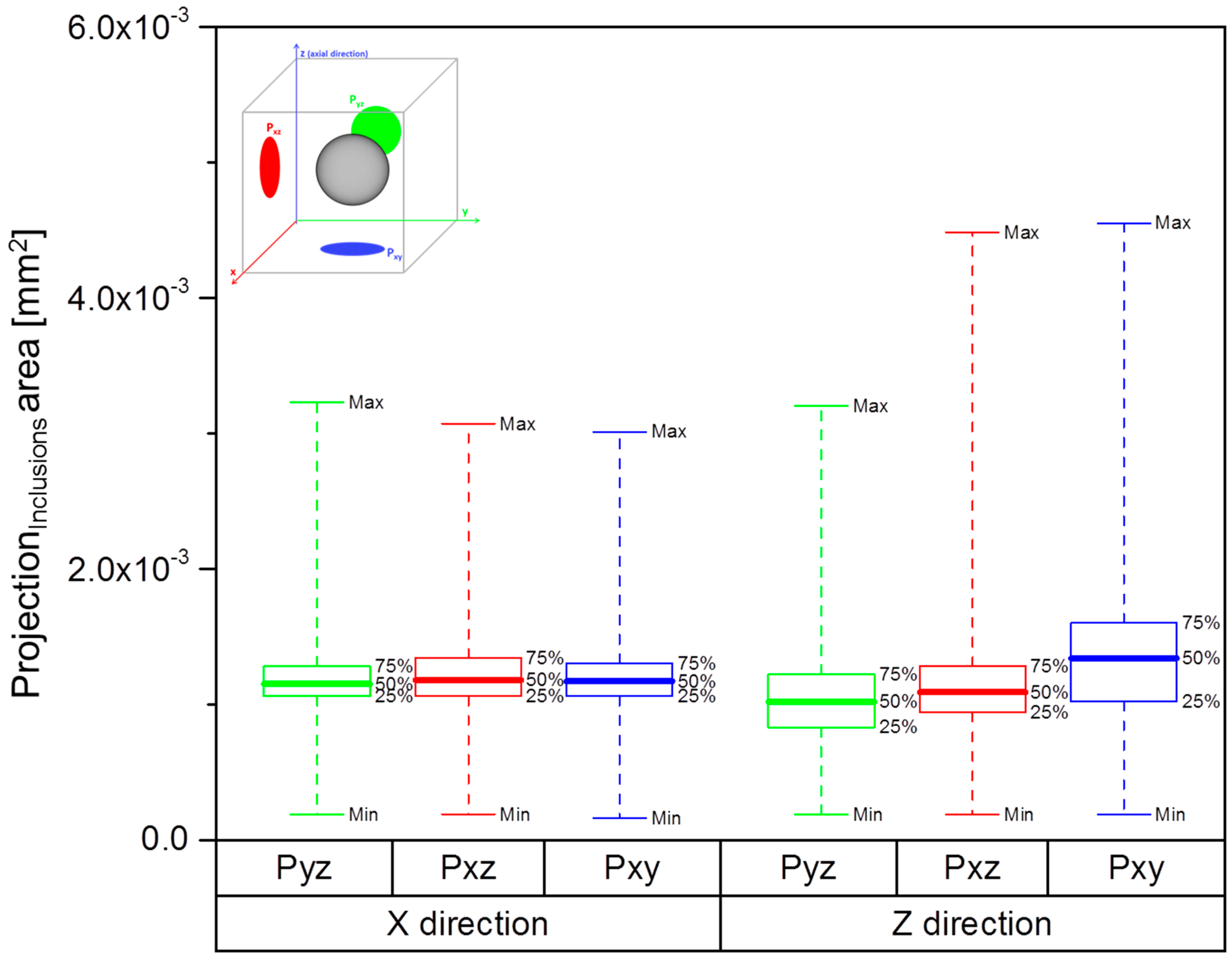

3.2. Defect Distribution Analysis

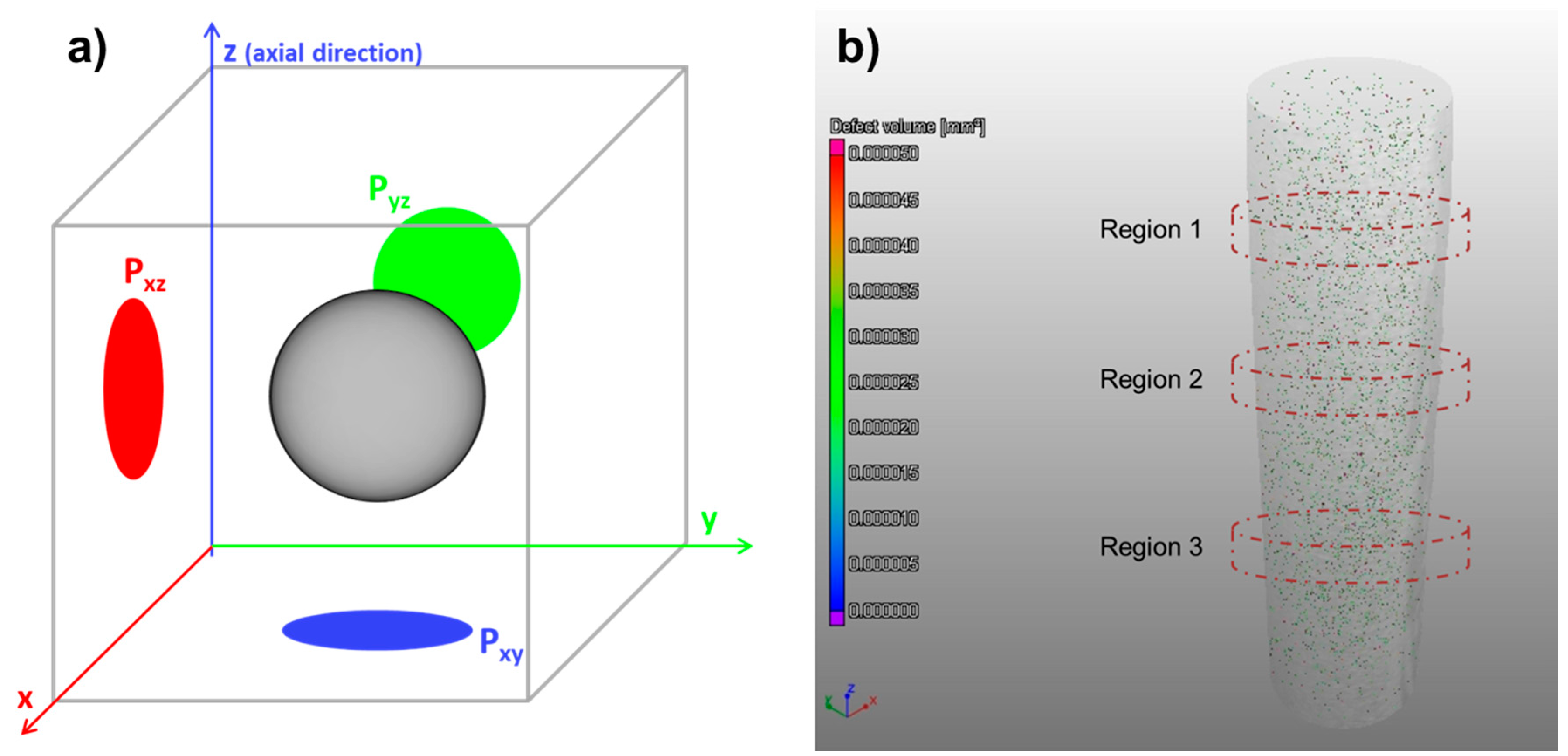

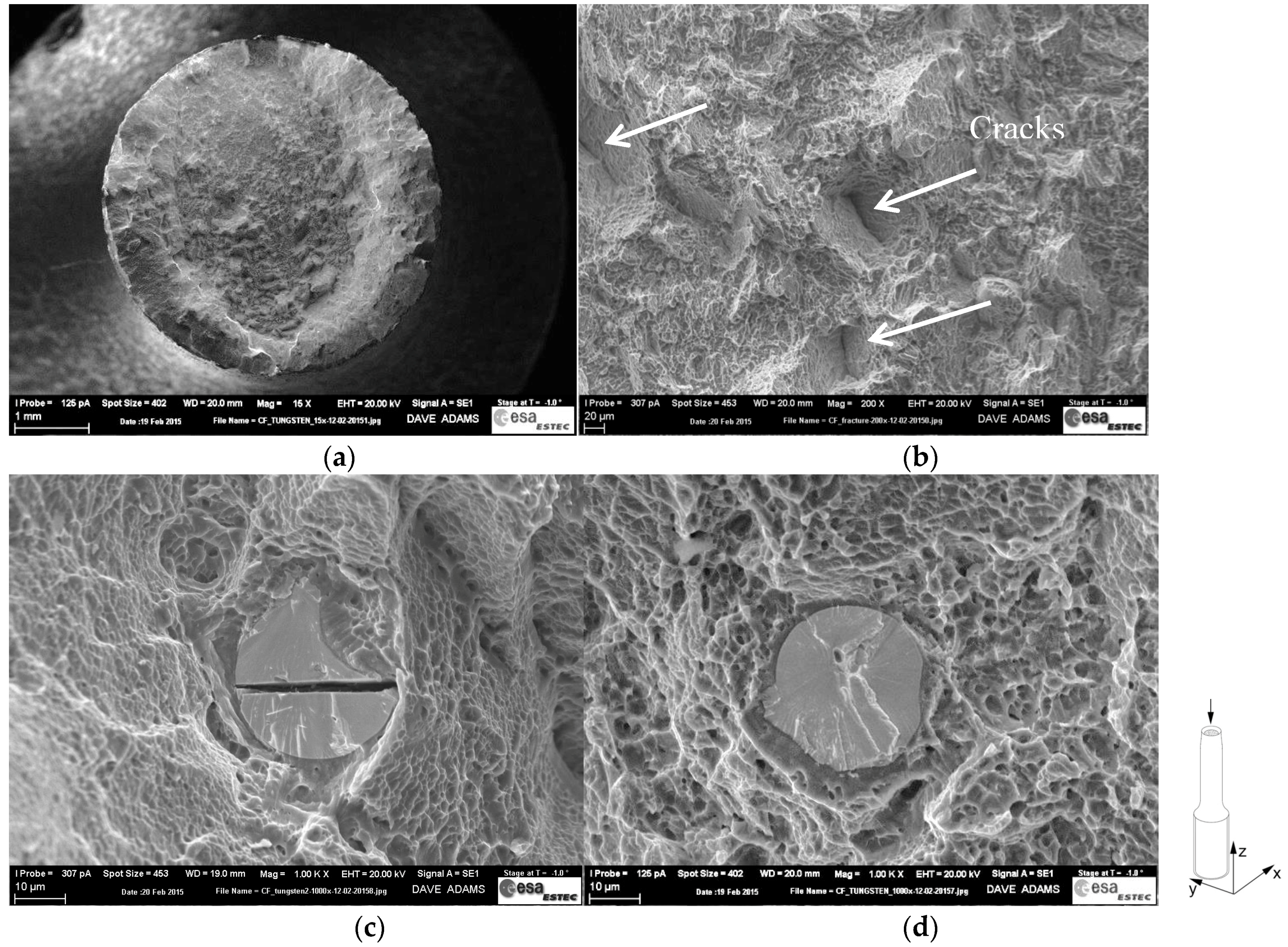

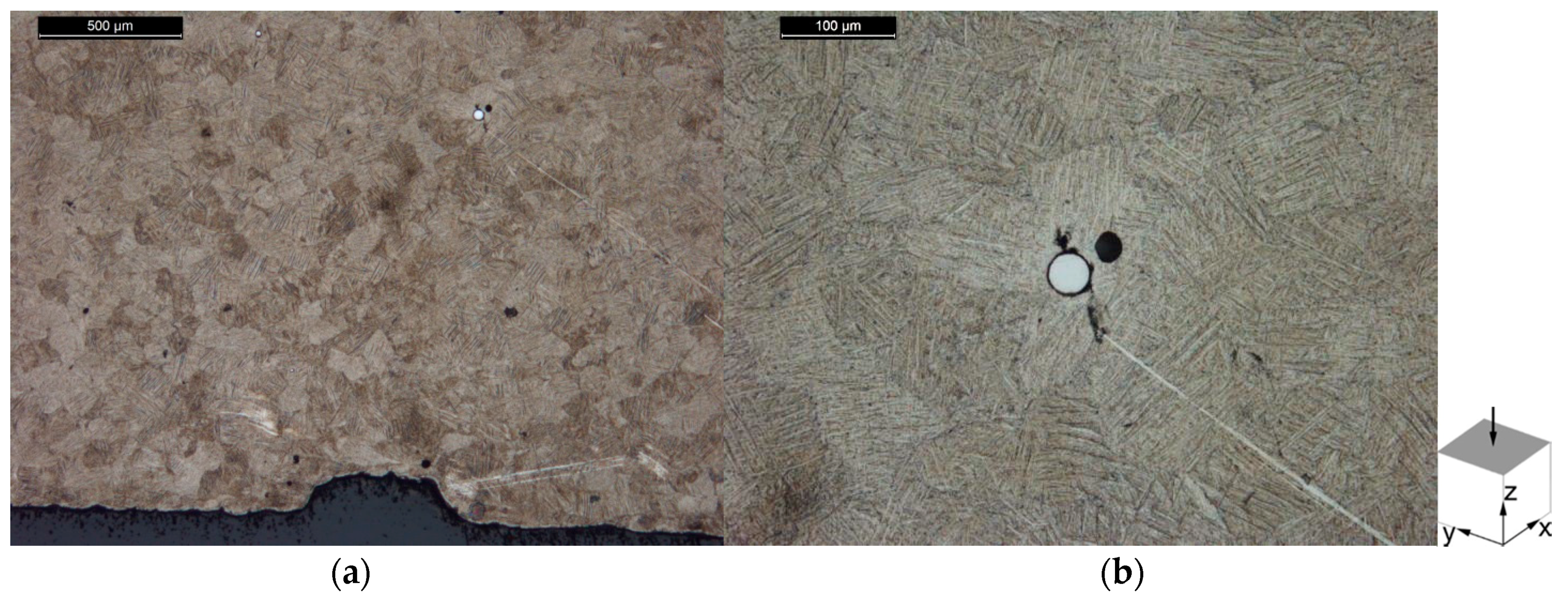

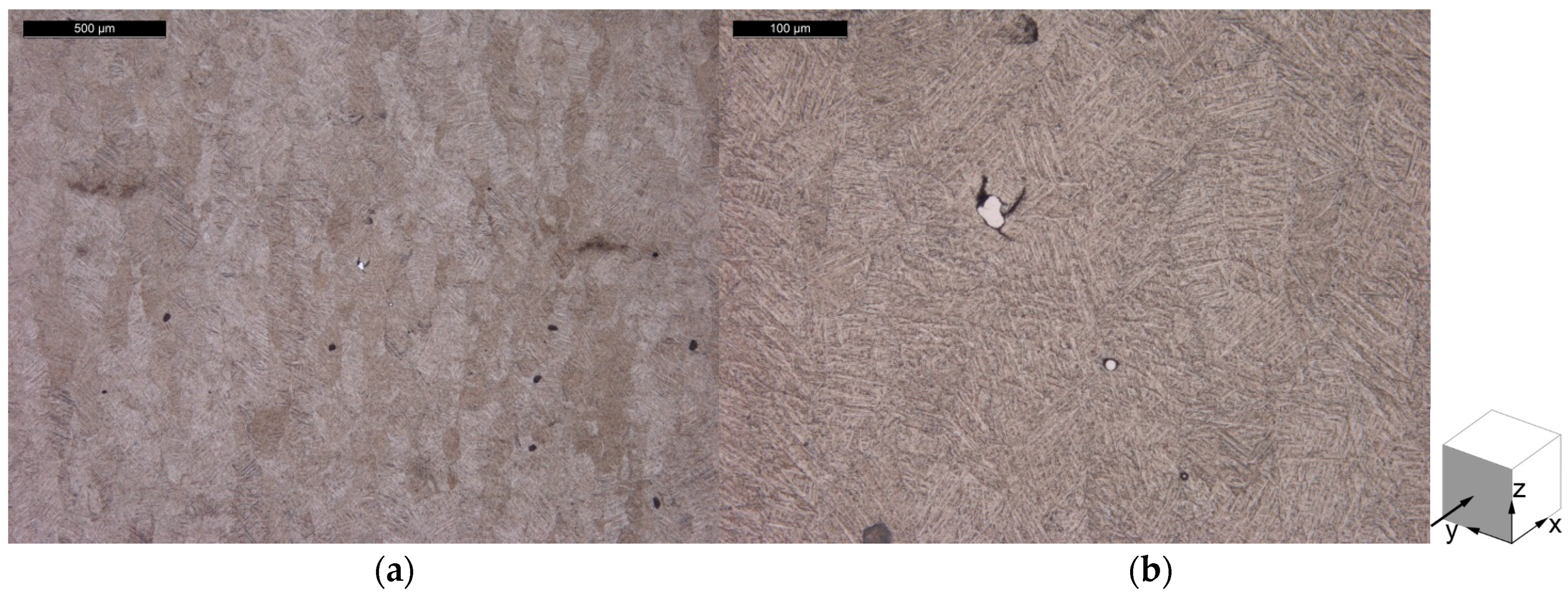

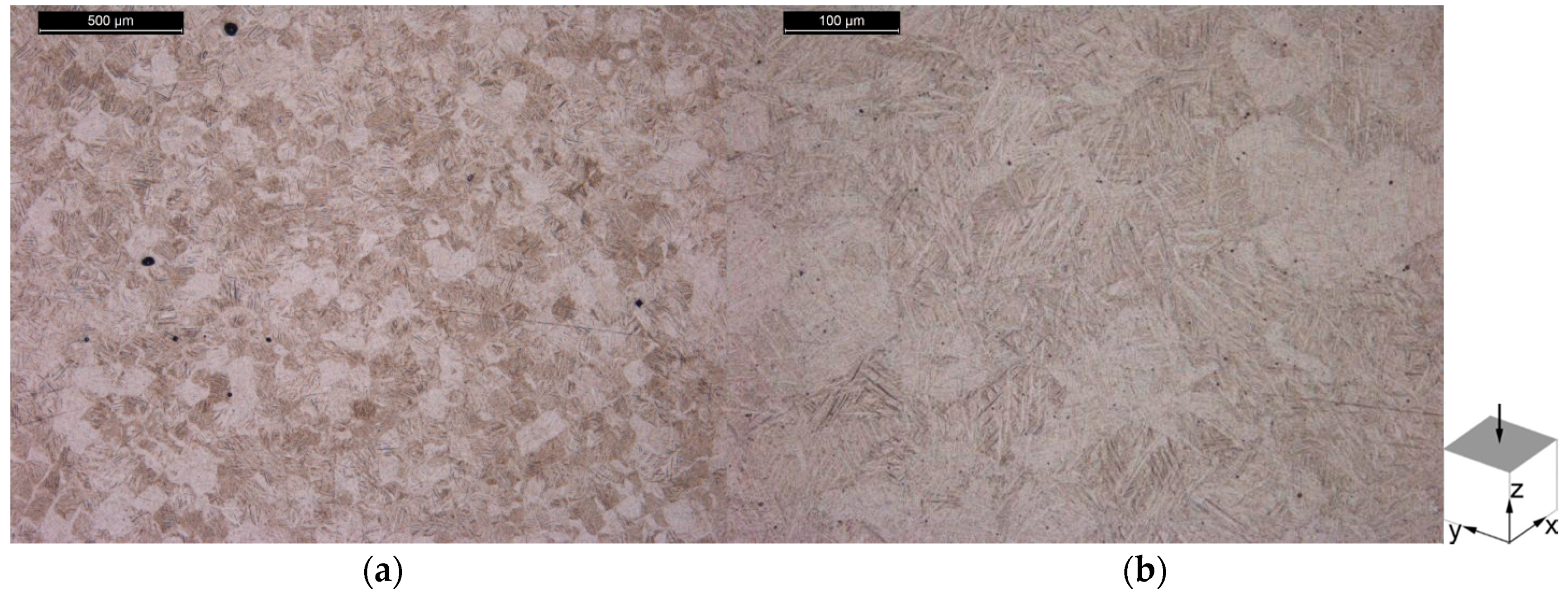

3.3. Microstructure

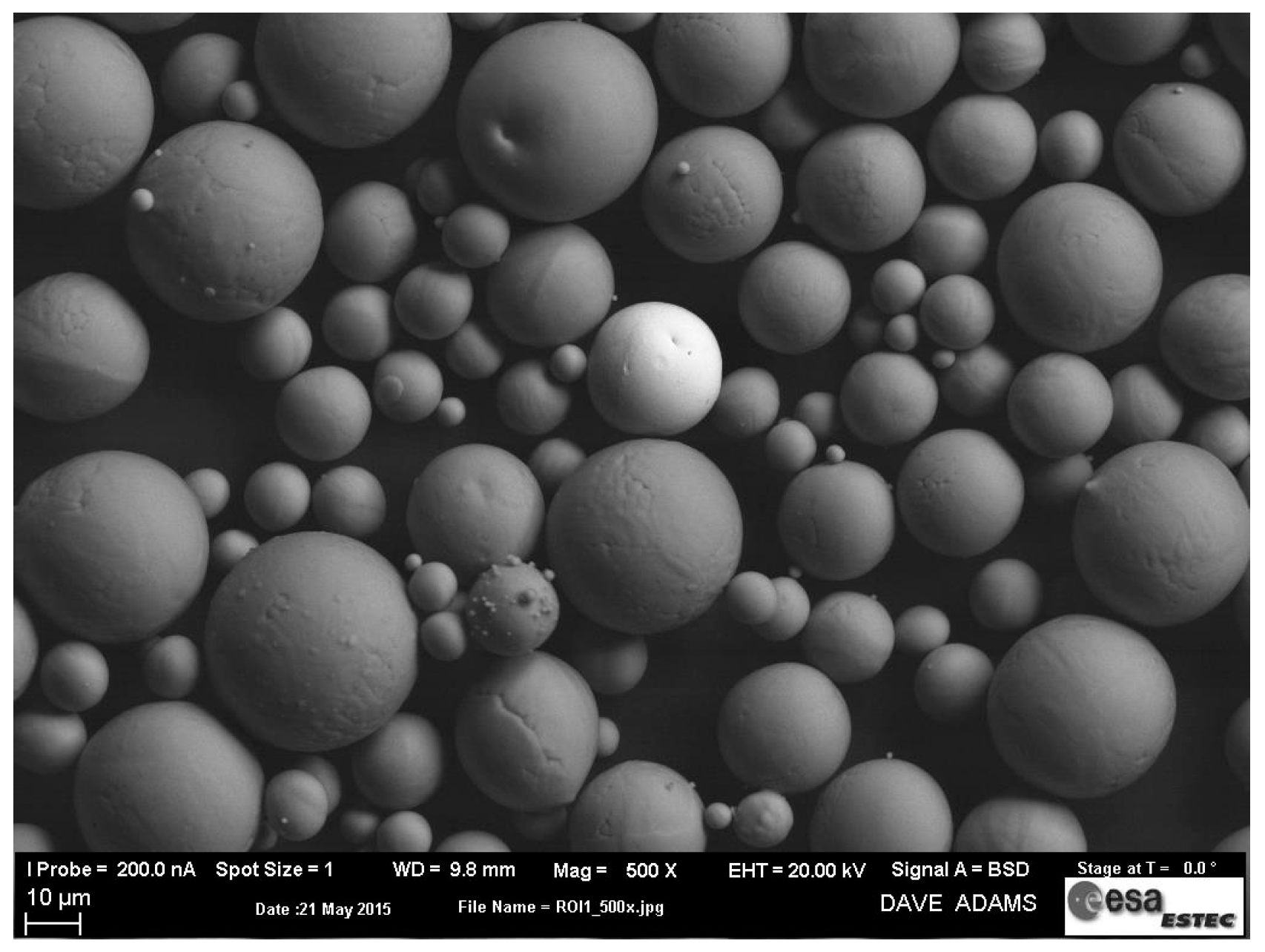

3.4. Powder Characterization

3.5. Contamination Investigation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and Mechanical Properties of Wire and Arc Additive Manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- ISO/ASTM52900-15, Standard Terminology for Additive Manufacturing–General Principles–Terminology; ASTM International: West Conshohocken, PA, USA, 2015.

- Ghidini, T.; Pambaguian, L.; Blair, S. Joining the Third Industrial Revolution: 3D Printing for Space; European Space Agency Bulletin; European Space Agency: Noordwijk, The Netherlands, 2015; Volume 163, pp. 24–33. [Google Scholar] [PubMed]

- Lopatriello, M.; Gasbarri, P.; Paris, C.; Brotzu, A.; Paiano, S. Thermo-mechanical characterization of a carbon micro-fibre reinforced polymer for additive manufacturing in space applications. In Proceedings of the 66th International Astronautical Congress 2015: Space—The Gateway for Mankind’s Future (IAC), New York, NY, USA, 12–16 October 2015; Volume 9, pp. 6758–6766. [Google Scholar]

- Greitemeier, D.; Palma, F.; Syassen, F.; Melz, T. Fatigue performance of additive manufactured TiAl6V4 using electron and laser beam melting. Int. J. Fatigue 2017, 44, 211–217. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of Materials Qualification Needs for Metal Additive Manufacturing. JOM-US 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Kong, C.J.; Tuck, C.J.; Ashcroft, A.I.; Wildman, R.D.; Hague, R. High density Ti-6Al-4V via SLM processing: Microstructure and mechanical properties. Proceeding of the 22nd Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2011; pp. 475–483. [Google Scholar]

- Baufeld, B.; Brandl, E.; Van Der Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.; Pal, D.; Stucker, B.; Christiansen, D.; Beuth, J.; Lewandowski, J. Melt pool Characterisation for Selective Laser Melting of Ti-6Al-4V Pre-alloyed Powder. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 256–267. [Google Scholar]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Tang, H.; Qian, M.; Liu, N.; Zhang, X.; Yang, G.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Gu, H.; Gong, H.; Dilip, J.J.S.; Pal, D.; Hicks, A.; Doak, H.; Stucker, B. Effects of powder variation on the microstructure and tensile strength of Ti6Al4V parts fabricated by selective laser melting. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 470–483. [Google Scholar]

- Clayton, J. Optimising metal powders for additive manufacturing. Met. Powder Rep. 2014, 69, 14–17. [Google Scholar] [CrossRef]

- Puris, LLC. Minimizing Contamination in Gas Atomized Metal Powders; White Paper; Puris, LLC: Bruceton Mills, WV, USA, 2014. [Google Scholar]

- Dawes, J.; Bowerman, R.; Trepleton, R. Introduction to the Additive Manufacturing Powder Metallurgy Supply Chain. Johnson Matthey Technol. Rev. 2015, 59, 243–256. [Google Scholar] [CrossRef]

- ASTM E8/E8M-11, Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2011.

- Maskery, I.; Aboulkhair, N.T.; Corfield, M.R.; Tuck, C.; Clare, A.T.; Leach, R.K.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Quantification and characterisation of porosity in selectively laser melted Al–Si10–Mg using X-ray computed tomography. Mater. Charact. 2016, 111, 193–204. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Satko, D.; Shaffer, J.; Lewandowski, J.J. Defect Distribution and Microstructure Heterogeneity Effects on Fracture Resistance and Fatigue Behavior of EBM Ti-6Al-4V. Int. J. Fatigue 2017, 94, 263–287. [Google Scholar] [CrossRef]

- V.G. Studio MAX 2.2 Reference Manual; Volume Graphics GmbH: Heidelberg, Germany, 2012.

- ASTM B213-13, Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM F2924-14, Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion; ASTM International: West Conshohocken, PA, USA, 2014.

- Kobryn, P.A.; Semiatin, S.L. Mechanical properties of laser-deposited Ti–6Al–4V. In Proceedings of the 12th Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2001; pp. 179–186. [Google Scholar]

- Qiu, C.; Ravi, G.A.; Dance, C.; Ranson, A.; Dilworth, S.; Attallah, M.M. Fabrication of large Ti–6Al–4V structures by direct laser deposition. J. Alloys Compd. 2015, 629, 351–361. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, Engineering Materials and Processes; Springer: Heidelberg, Germany, 2007. [Google Scholar]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Kruth, J.P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining (ISEM XVI), Shanghai, China, 19–23 April 2010. [Google Scholar]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 4, 041101. [Google Scholar] [CrossRef]

- Yan, M.; Yu, P. An Overview of Densification, Microstructure and Mechanical Property of Additively Manufactured Ti-6Al-4V—Comparison among Selective Laser Melting, Electron Beam Melting, Laser Metal Deposition and Selective Laser Sintering, and with Conventional Powder Metallurgy. In Sintering Techniques of Materials; Arunachalam, L., Ed.; InTech: Rijeka, Croatia, 2015; Chapter 5. [Google Scholar] [CrossRef]

- Tietz, T.E.; Wilson, J.W. Behavior and Properties of Refractory Metals; Stanford University Press: Palo Alto, CA, USA, 1965; p. 276, p. 285, and p. 297. [Google Scholar]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Zhao, H.; Léonard, F.; Derguti, F.; Todd, I.; Prangnell, P.B. XCT analysis of the influence of melt strategies on defect population in Ti-6Al-4V components manufactured by Selective Electron Beam Melting. Mater. Charact. 2015, 102, 47–61. [Google Scholar] [CrossRef]

- Krzywinski, M.; Altman, N. Visualizing samples with box plots. Nat. Methods 2014, 11, 119–120. [Google Scholar] [CrossRef] [PubMed]

- Fleck, N.A.; Smith, R.A. Effect of density on tensile strength, fracture toughness, and fatigue crack propagation behaviour of sintered steel. Powder Metall. 1981, 24, 121–125. [Google Scholar] [CrossRef]

- Magnusen, P.E.; Follansbee, P.S.; Koss, D.A. The Influence of Strain Rate and Porosity on the Deformation and Fracture of Titanium and Nickel; Report No. 25; Department of Metallurgical Engineering, Michigan Technological University: Houghton, MI, USA, 1984. [Google Scholar]

- Firstov, S.A.; Podrezov, Yu, N.; Zherdin, A.G.; Shtyka, L.G.; Pioro, E.C.; Golovkova, M.E.; Pioro, N.C. Effect of porosity on the ductility and ductile failure mechanism of powder iron. Sov. Powder Metall. Met. Ceram. 1987, 26, 855–861. [Google Scholar] [CrossRef]

- Galarraga, H.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2016, 10, 47–57. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Janaki Ram, G.D.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Chlebus, E.; Bogumila, K.; Kurzynowski, T.; Dybala, B. Microstructure and mechanical behaviour of Ti-6Al-7Nb alloy produced by selective laser melting. Mater. Charact. 2011, 62, 488–495. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Further understanding of Ti-6Al-4V selective laser melting using texture analysis. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 6–8 August 2012; pp. 480–491. [Google Scholar]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, V.J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Weigand, H.H. Zur Umwandlung von α + β -Titanlegierungen mit Aluminium. Z. Metallkunde 1963, 54, 43–49. [Google Scholar]

- ASTM F3049-14, Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes; ASTM International: West Conshohocken, PA, USA, 2014.

- Slotwinski, J.A.; Garboczi, E.J.; Stutzman, P.E.; Ferraris, C.F.; Watson, S.S.; Peltz, M.A. Characterization of Metal Powders Used for Additive Manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 460–493. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Shinmura, T.; Iimura, K.; Hirota, M. Study of the Wall Effect on Particle Packing Structure Using X-ray Micro Computed Tomography. Adv. Powder Technol. 2008, 19, 183–195. [Google Scholar] [CrossRef]

- National Research Council. Forensic Analysis: Weighing Bullet Lead Evidence; The National Academies Press: Washington, DC, USA, 2004; Chapter 2. [Google Scholar] [CrossRef]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium, Engineering Materials and Processes; Springer Science & Business Media: Berlin, Germany, 2007; Chapter 3. [Google Scholar]

- Lampman, S. Weld Integrity and Performance. In A Source Book Adapted from ASM International Handbooks, Conference Proceedings, and Technical Books; ASM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

| Specimen Orientation | Yield Strength [MPa] ± SD | Tensile Strength [MPa] ± SD | Fracture Elongation [%] ± SD |

|---|---|---|---|

| X | 1092 ± 12 | 1168 ± 12 | 7.5 ± 1 |

| 111 | 1134 ± 6 | 1192 ± 6 | 8.3 ± 0.7 |

| Z | 1100 ± 56 | 1186 ± 45 | 2.9 ± 0.5 |

| Build Direction | No. Total | Plane | Total Area | Minimum | 1st Quartile | Median | 3rd Quartile | Maximum |

|---|---|---|---|---|---|---|---|---|

| X | 153 | Pyz | 1.78 × 10−1 | 1.90 × 10−4 | 1.06 × 10−3 | 1.15 × 10−3 | 1.28 × 10−3 | 3.23 × 10−3 |

| Pxz | 1.83 × 10−1 | 1.90 × 10−4 | 1.06 × 10−3 | 1.18 × 10−3 | 1.34 × 10−3 | 3.07 × 10−3 | ||

| Pxy | 1.85 × 10−1 | 1.60 × 10−4 | 1.06 × 10−3 | 1.17 × 10−3 | 1.30 × 10−3 | 3.01 × 10−3 | ||

| Z | 210 | Pyz | 2.23 × 10−1 | 1.90 × 10−4 | 8.3 × 10−4 | 1.02 × 10−3 | 1.22 × 10−3 | 3.20 × 10−3 |

| Pxz | 2.43 × 10−1 | 1.90 × 10−4 | 9.4 × 10−4 | 1.09 × 10−3 | 1.28 × 10−3 | 4.48 × 10−3 | ||

| Pxy | 2.92 × 10−1 | 1.90 × 10−4 | 1.02 × 10−3 | 1.34 × 10−3 | 1.60 × 10−3 | 4.55 × 10−3 |

| Element [wt %] | H | O | N | C | Fe | Al | V | W | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Method | CGHE | CGHE | CGHE | Combustion method | Flame AAS | ICP-OES | ICP-OES | ICP-OES | ICP-OES |

| Powder sample (Batch 1) | 0.008 | 0.2 | 0.014 | 0.012 | 0.19 | 6.69 | 4.06 | <0.005 | Balance |

| Bulk sample (Batch 1) | 0.004 | 0.21 | 0.016 | 0.012 | 0.18 | 6.444 | 3.99 | <0.005 | Balance |

| Bulk sample (Batch 2) | 0.003 | 0.18 | 0.022 | 0.008 | 0.19 | 6.33 | 3.91 | <0.005 | Balance |

| ASTM F2924 | 0.015 | 0.20 | 0.05 | 0.08 | 0.30 | 5.50–6.75 | 3.50–4.50 | 0.10 | Balance |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brandão, A.D.; Gerard, R.; Gumpinger, J.; Beretta, S.; Makaya, A.; Pambaguian, L.; Ghidini, T. Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and Its Impact on End Products. Materials 2017, 10, 522. https://doi.org/10.3390/ma10050522

Brandão AD, Gerard R, Gumpinger J, Beretta S, Makaya A, Pambaguian L, Ghidini T. Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and Its Impact on End Products. Materials. 2017; 10(5):522. https://doi.org/10.3390/ma10050522

Chicago/Turabian StyleBrandão, Ana D., Romain Gerard, Johannes Gumpinger, Stefano Beretta, Advenit Makaya, Laurent Pambaguian, and Tommaso Ghidini. 2017. "Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and Its Impact on End Products" Materials 10, no. 5: 522. https://doi.org/10.3390/ma10050522

APA StyleBrandão, A. D., Gerard, R., Gumpinger, J., Beretta, S., Makaya, A., Pambaguian, L., & Ghidini, T. (2017). Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and Its Impact on End Products. Materials, 10(5), 522. https://doi.org/10.3390/ma10050522