Wood composite panels (WCPs), such as medium-density fibreboard (MDF) and particleboard (PB), are widely used in furniture manufacture, packaging, building construction, musical instruments, and other industrial sectors. Full-sized WCPs with a nominal size of 2440 mm × 1220 mm (length × width) are universal in the production and global market. For full-sized WCPs, mechanical properties, such as the modulus of elasticity (E) and in-plane shear modulus, are important performance characteristics that should be taken into consideration during manufacturing and quality control processes. Rapid and accurate determination of these elastic properties in full-sized panels is, therefore, very important for meeting the product specifications and ensuring satisfactory performance under different service conditions.

The application of non-destructive evaluation (NDE) methods, like transverse vibration or longitudinal stress-wave, for elastic properties determination of WCPs has been studied for many years [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22]. Among these studies, property evaluation of small wood composite specimens through the beam-vibrational method has been used with good success [

6,

8,

9,

10,

11,

12,

13,

16,

17,

22] and a dynamic cantilever beam apparatus for a variety of elastic properties determination of small wood composite materials was presented by Hunt, Zhou, and Guan [

12,

13,

16,

22]. However, NDE of full-sized WCPs through panel-vibrational method was still in the research stage. A fundamental aspect of this method is to support a panel in a well-defined position, induce a vibration to the panel by a short impact, and to measure the natural frequencies. Knowing the natural frequencies of different vibration modes and the boundary conditions, the elastic properties of the panel can be calculated, including the

E in both major and minor axes and the in-plane shear modulus of the panel. Coppens [

1] was one of the first using this method to test the elastic constants of PBs under the four sides completely free (FFFF) boundary condition by hanging them up on rubbers ties. A simultaneous measurement of elastic properties of a full-sized plywood panel with one edge simply supported and three edge free (SFFF) boundary condition by this vibration method was conducted by Sobue and Katoh [

2]. The dynamic elastic properties of full-scale PB and MDF panels were tested using the same vibration technique in a vertical cantilever (CFFF) arrangement [

3]. An on-line non-destructive apparatus, called VibraPann, was developed for evaluation of the

E and strength in both major and minor axes for wood-based panels [

5]. A laboratory testing apparatus was used to measure the dynamic

E and dynamic viscoelasticity of full-sized WCPs supported on their two nodal lines by a vibration testing way [

18,

20]. Based on a modal testing technique, Zhou et al. [

21] developed an NDE method for full-sized engineered wood-based panels with a boundary condition, in which two opposite sides were simply supported and the other two sides were free (SFSF). In terms of modal testing, the influence of the three boundary conditions (STSF, FFFF, and SFFF) for measurement of elastic constants of engineered wood-based panels was studied [

19]. In addition, finite element (FE) modelling was also used for estimation of the elastic properties of full-sized WCPs combined with the NDE method [

4,

7,

14]. These elastic constants were then estimated by minimizing the relative errors between experimental frequency and FE modelled values by an iteration process. Larsson [

4] and Niederwestberg [

14] tested full-sized oriented strand board (OSB) and cross-laminated timber (CLT) under the FFFF boundary condition using modal analysis, respectively. Gsell et al. [

7] developed an automated procedure to determine global elastic properties of full-scale CLT through both experimental modal analysis and an analytical model based on Reddy’s higher order plate theory. All three shear moduli and the two in-plane MOE were identified by minimizing the difference between measured and estimated natural frequencies using the least square method. The conclusion reached in all of these works is that there is a good correlation between elastic constants of full-sized WCPs obtained by this panel-vibrational method and those measured by the traditional static method. However, due to poor operation, hitherto it seems the reported methods in these studies above are only applicable to conduct in the laboratory and not widely used for on-line property evaluation of full-sized WCPs. Another conclusion can be also drawn from these studies that the elastic properties of WCPs are closely associated with their vibration modal parameters. In order to determine elastic properties of full-sized WCP, the key is to determine the vibration mode shapes required and measure the corresponding natural frequencies of the panel under the given boundary condition.

In many cases, small MDF and PB specimens are always regarded as being in-plane quasi-isotropic materials, which have nearly the same property values in the major and minor directions [

6,

9,

12,

17,

22]. However, full-sized MDF and PB panels can be modelled as orthotropic materials with non-uniform values in the major, minor, and thickness directions in many studies [

3,

15,

19,

21]. Zhang et al. [

23] also found that

E along the major direction was 56% higher than that along the minor direction for a 20 mm thick full-sized MDF panels using cantilever-beam bending. Thus, full-sized MDF and PB panels were considered to be orthotropic materials in this study.

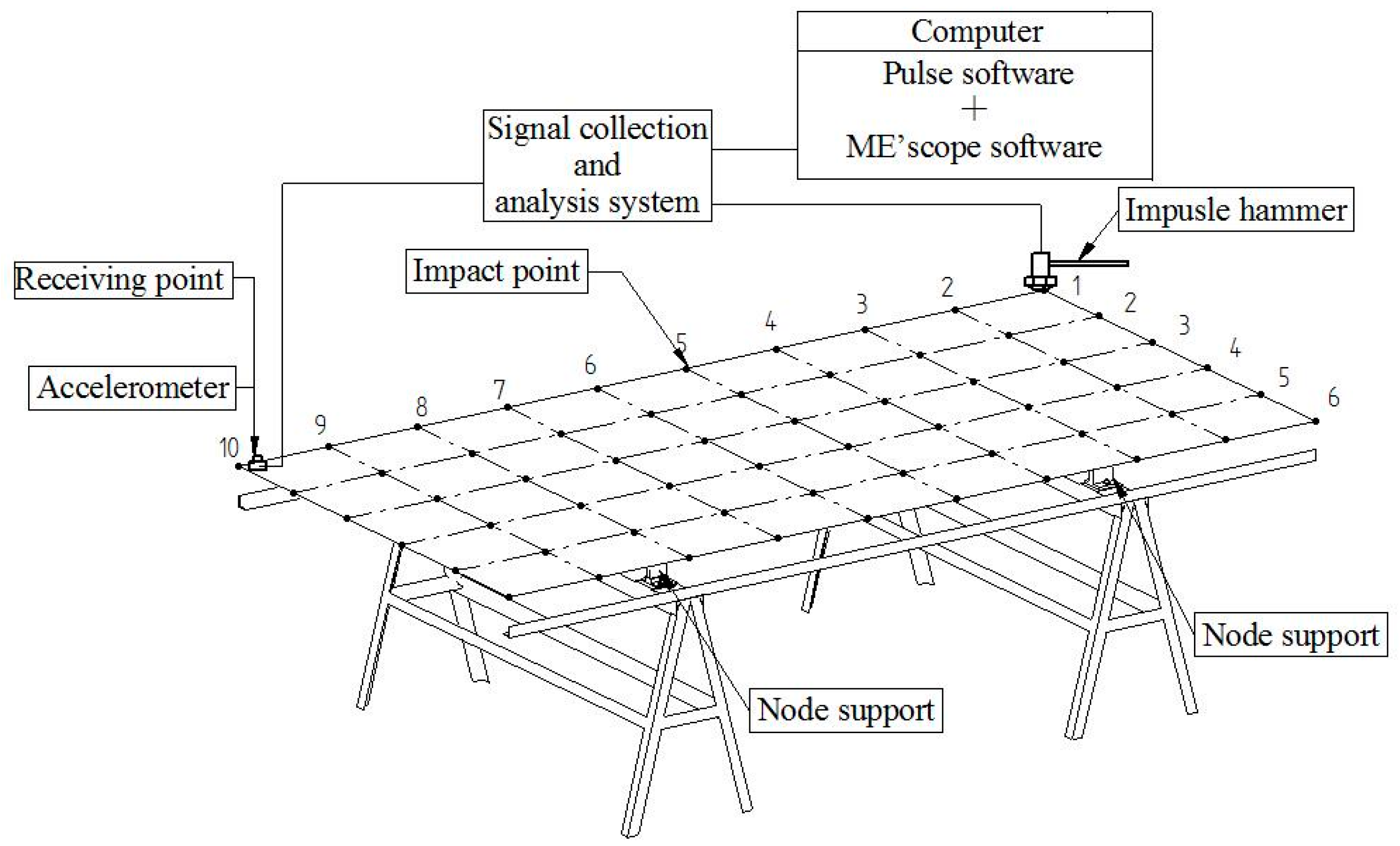

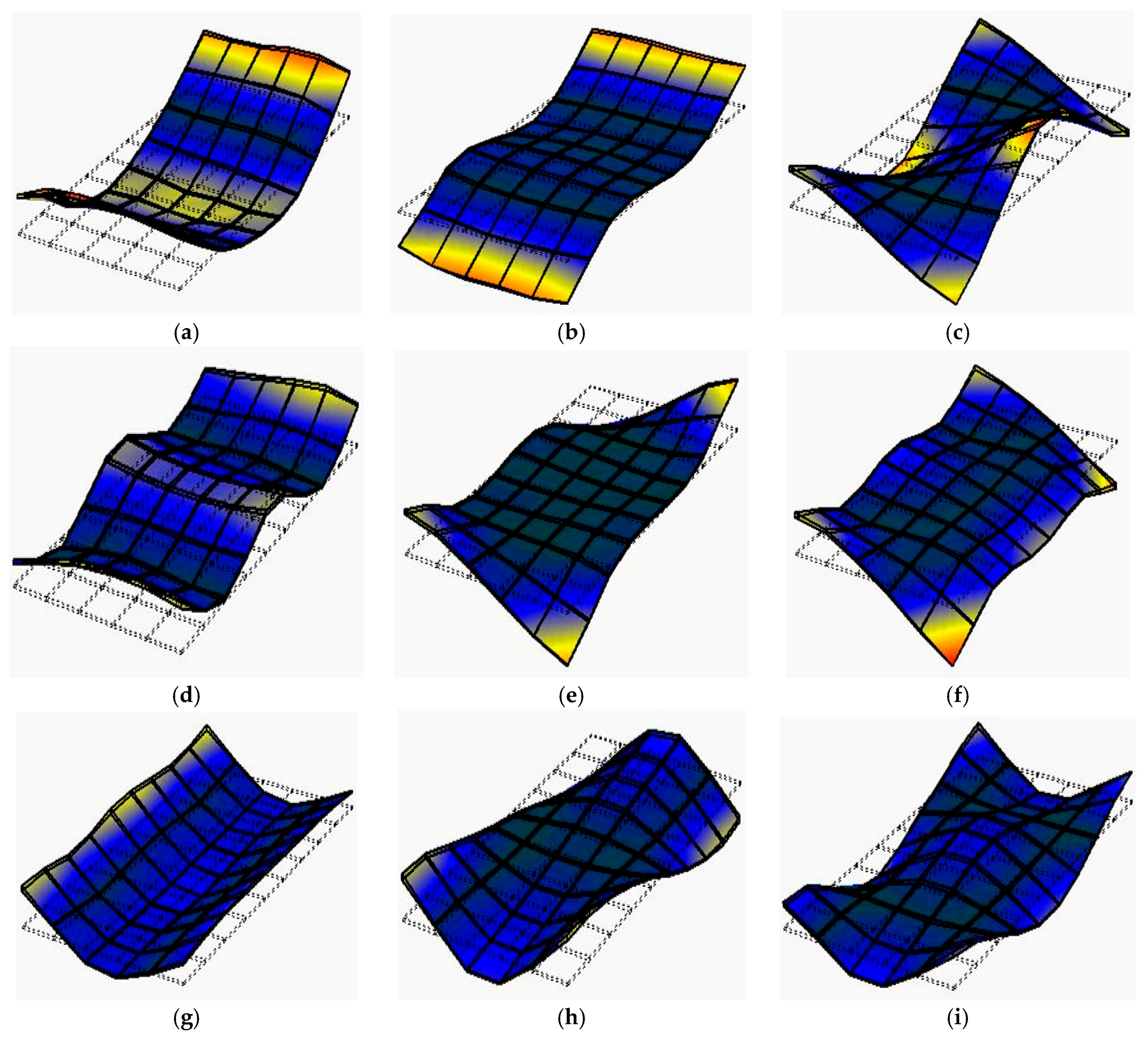

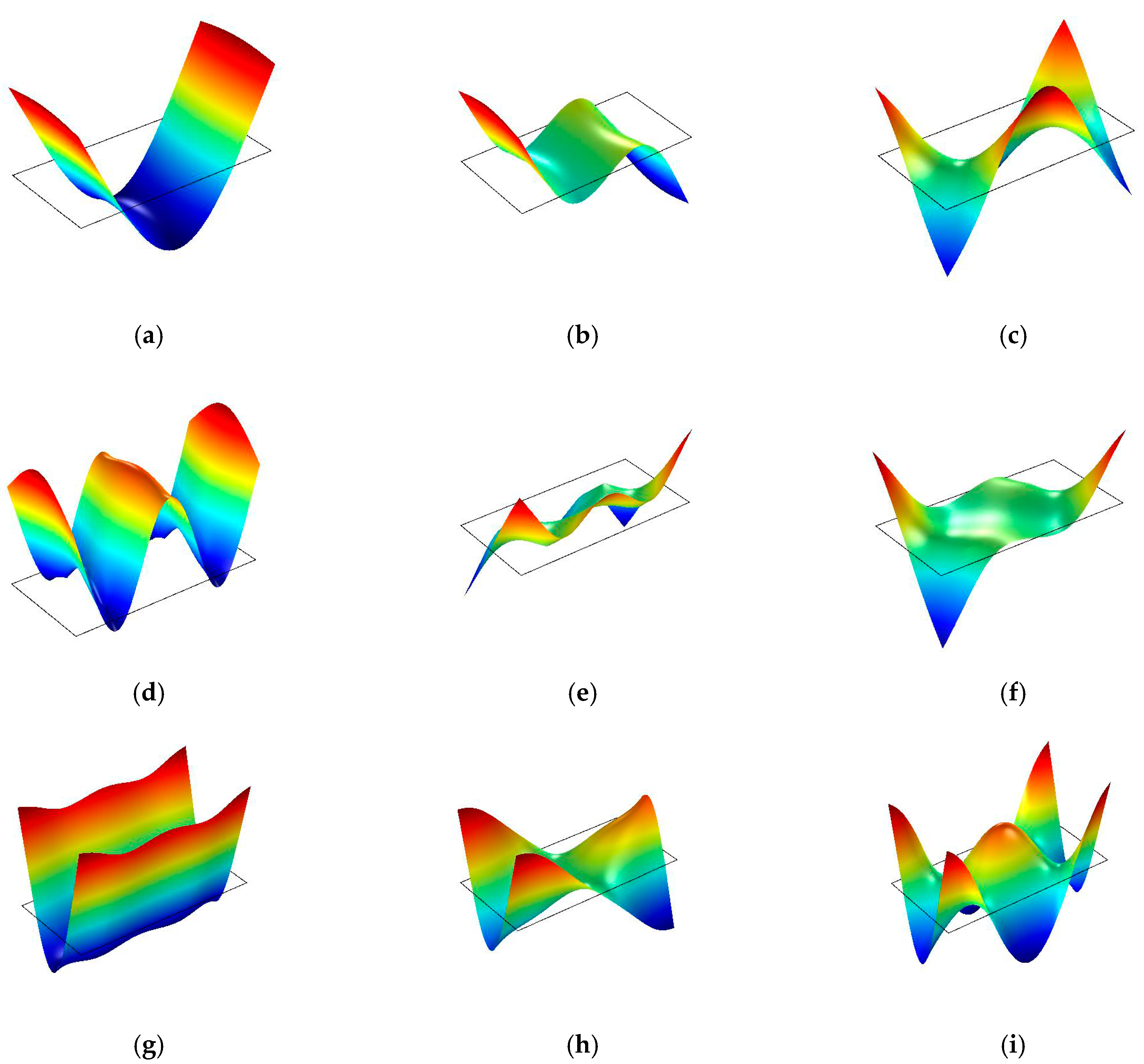

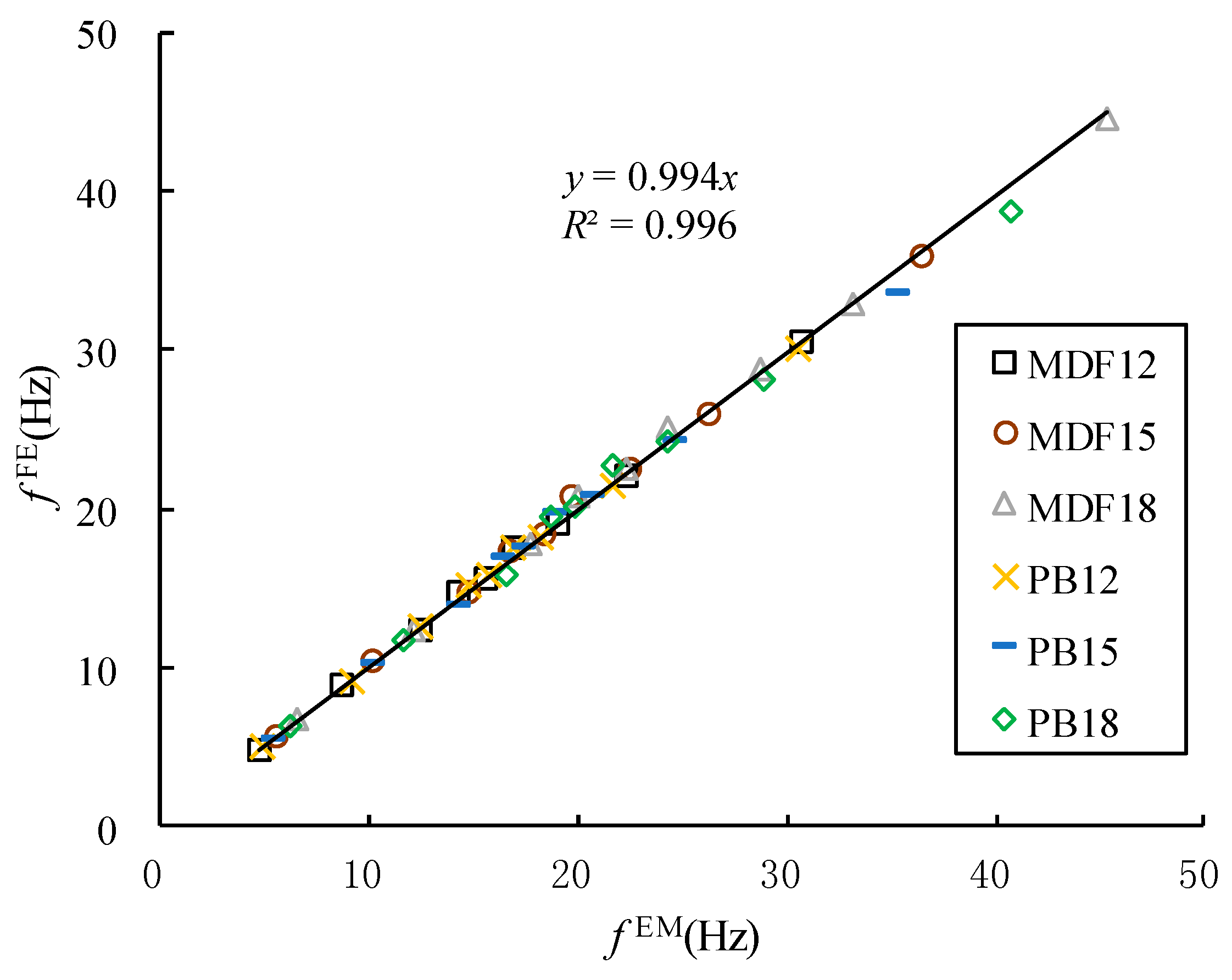

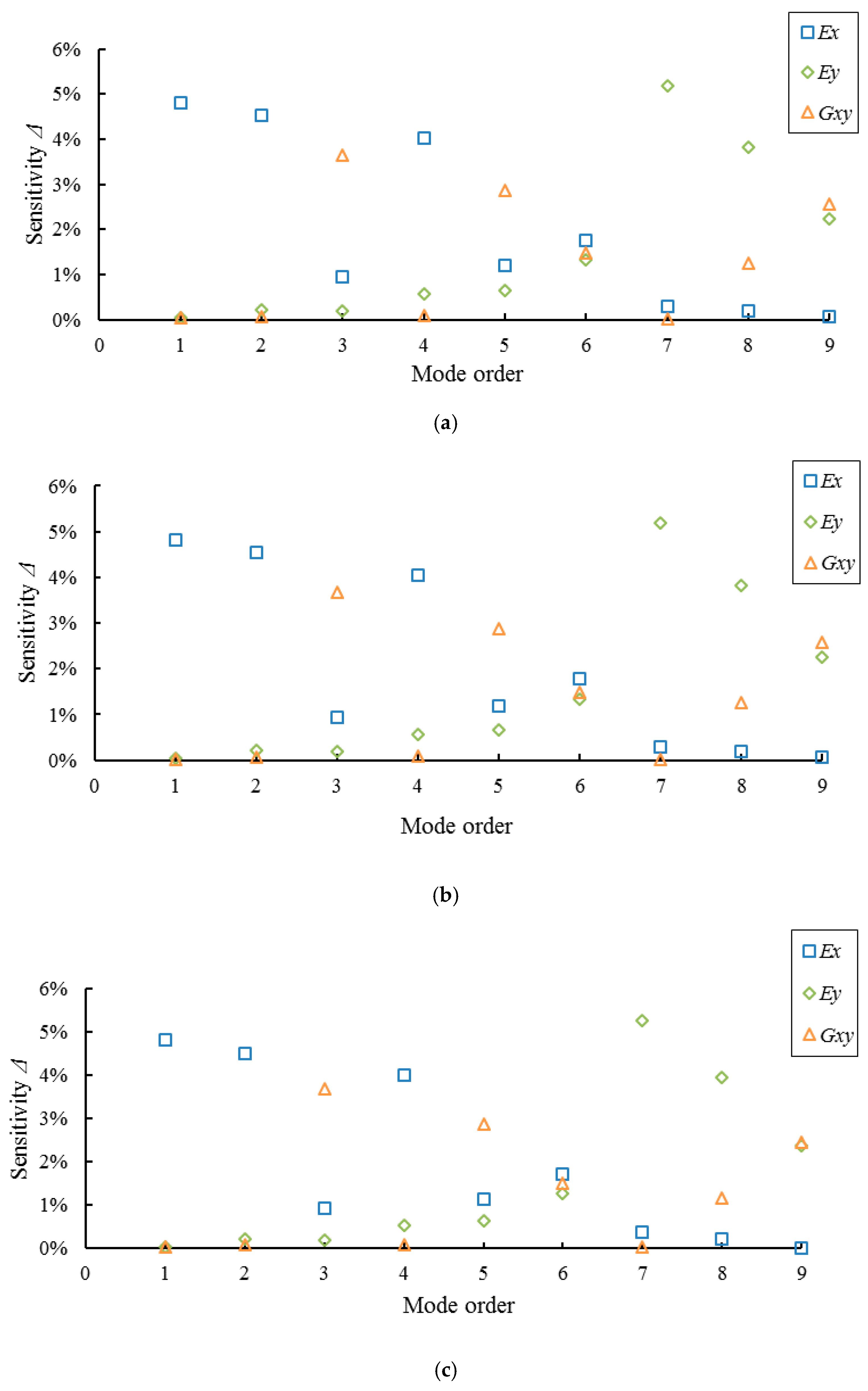

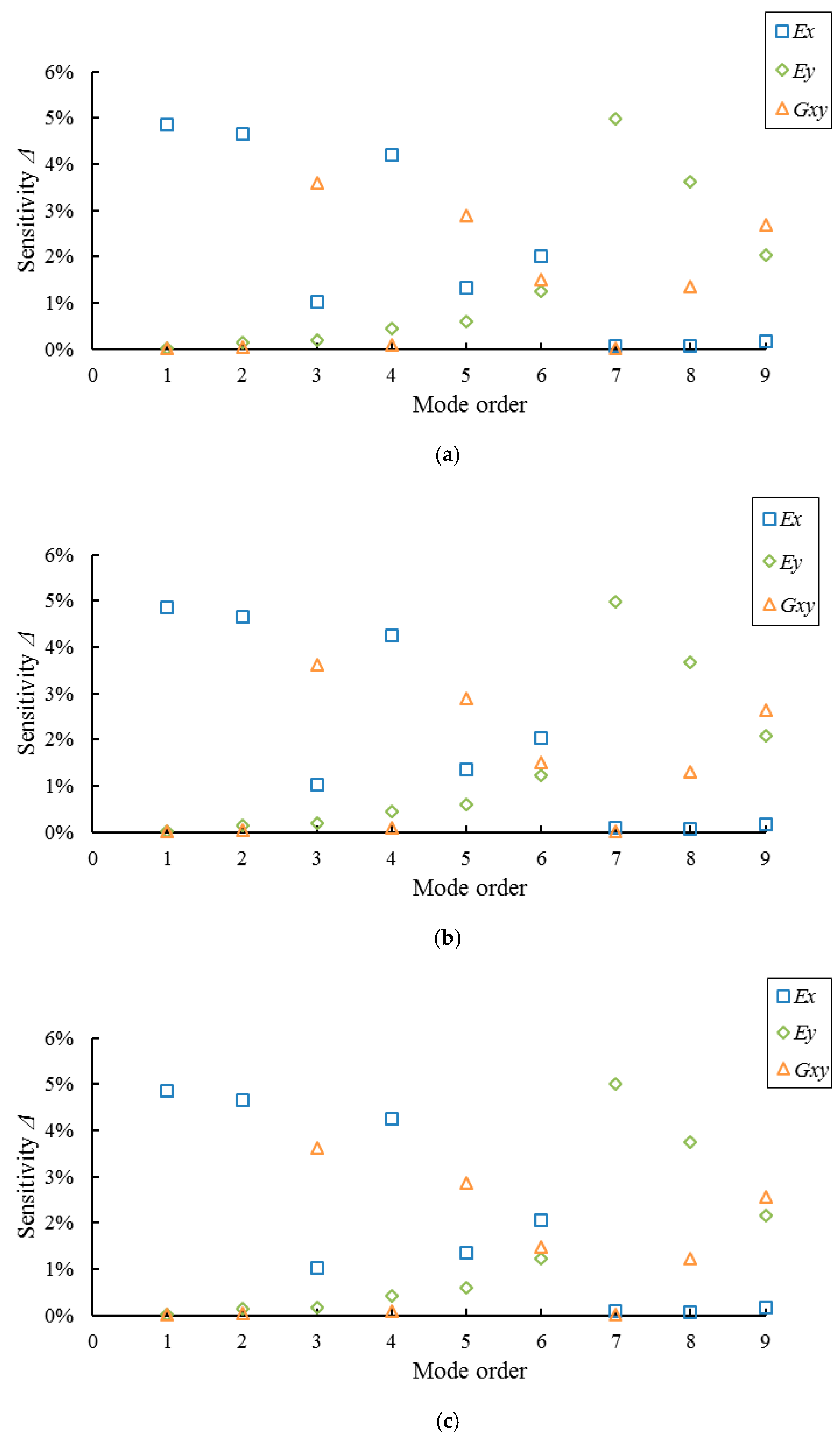

The objective of this presented study was to lay a foundation for determining elastic properties of full-sized WCP by a vibration method for on-line non-destructive testing. The first nine modal parameters (natural frequency and mode shape) of the vibration of full-sized WCPs supported on four nodes were tested by experimental modal analysis. The panels tested include MDF and PB with three different thicknesses. Results from experimental modal testing were compared with theoretical modal analysis by COMSOL Multiphysics® software (COMSOL Inc., Stockholm, Sweden). The sensitivity analysis was then performed to determine the sensitive modes for calculation of E in both major and minor axes, as well as the in-plane shear modulus of full-sized MDF and PB panels with four nodes of support.