The Impact of Graphene on the Fabrication of Thin Film Solar Cells: Current Status and Future Prospects

Abstract

:1. Introduction

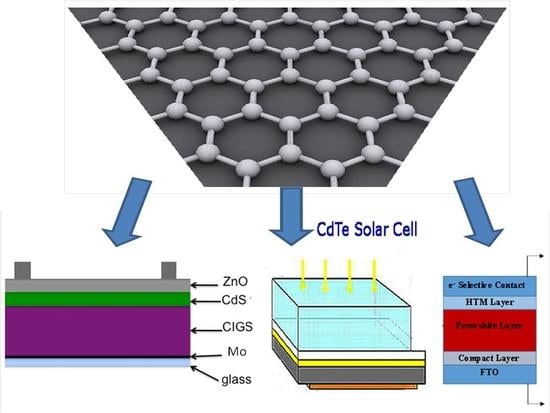

2. Graphene and Graphene-Based Schottky Diodes

3. Research Progress of Graphene-Composited Thin Film Solar Cell

3.1. Graphene with CdTe

3.2. Graphene with CIGS

3.3. Graphene with Perovskite

3.3.1. Graphene in ETL

3.3.2. Graphene Oxide in ETL

3.3.3. Graphene and Graphene Oxide in HTL

3.3.4. Graphene as Contacts

3.3.5. Other Applications of Graphene in PSCs

4. Applications and Future Research

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer grapheme. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended grapheme. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine structure constant defines visual transparency of grapheme. Science 2008, 20, 1308. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer grapheme. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Ganz, E.; Ganz, A.B.; Yang, L.; Dornfeld, M. The initial stages of melting of graphene between 4000 K and 6000 K. Phys. Chem. Chem. Phys. 2017, 19, 3756–3762. [Google Scholar] [CrossRef] [PubMed]

- Gautam, M.; Jayatissa, A.H. Gas sensing properties of graphene synthesized by chemical vapor deposition. Mater. Sci. Eng. C 2011, 31, 1405–1411. [Google Scholar] [CrossRef]

- Gautam, M.; Jayatissa, A.H. Ammonia gas sensing behavior of graphene surface decorated with gold nanoparticles. Solid State Electron. 2012, 78, 159–165. [Google Scholar] [CrossRef]

- Park, D.W.; Schendel, A.A.; Mikael, S.; Brodnick, S.K.; Richner, T.J.; Ness, J.P.; Hayat, M.R.; Atry, F.; Frye, S.T.; Pashaie, R.; et al. Graphene-based carbon-layered electrode array technology for neural imaging and optogenetic applications. Nat. Commun. 2014, 5, 5258. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.; Wang, F.; Xu, Y.; Ma, L.; Pi, X.; Yang, D. Graphene coupled with silicon quantum dots for high-performance bulk-silicon-based Schottky-junction photodetectors. Adv. Mater. 2016, 28, 4912–4919. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, R.; Yamada, H.; Karakaya, M.; Podila, R.; Rao, A.M.; Bandaru, P.R. Modulation of the electrostatic and quantum capacitances of few layered graphenes through plasma processing. Nano Lett. 2015, 15, 3067–3072. [Google Scholar] [CrossRef] [PubMed]

- De Arco, L.G.; Zhang, Y.; Schlenker, C.W.; Ryu, K.; Thompson, M.E.; Zhou, C. Continuous, highly flexible, and transparent graphene films by chemical vapor deposition for organic photovoltaics. ACS Nano 2010, 4, 2865–2873. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, J.; Mi, X.; Gullapalli, H.; Thomas, A.V.; Yavari, F.; Shi, Y.; Ajayan, P.M.; Koratkar, N.A. Wetting transparency of grapheme. Nat. Mater. 2012, 11, 217–222. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Drucker, J. Nucleation and growth of single layer graphene on electrodeposited Cu by cold wall chemical vapor deposition. Nanotechnology 2017, 28, 105601. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Sinha-Ray, S.; Park, J.J.; Lee, J.G.; Cha, Y.H.; Bae, S.H.; Ahn, J.H.; Jung, Y.C.; Kim, S.M.; Yarin, A.L.; et al. Self-healing reduced graphene oxide films by supersonic kinetic spraying. Adv. Funct. Mater. 2014, 24, 4986–4995. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.; Liu, Y.; Ruiz-Zepeda, F.; Ye, R.; Samuel, E.L.G.; Yacaman, M.J.; Yakoboson, B.I.; Tour, J.M. Laser-induced porous graphene films from commercial polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef] [PubMed]

- Hummers, W.S.; Offeman, R.E. Preparation of graphite oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Gautam, M.; Shi, Z.; Jayatissa, A.H. Graphene films as transparent electrodes for photovoltaic devices based on cadmium sulfide thin films. Solar Energy Mater. Solar Cells 2017, 163, 1–8. [Google Scholar] [CrossRef]

- Becker, J.J.; Boccard, M.; Campbell, C.M.; Zhao, Y.; Lassise, M.; Holman, Z.C.; Zhang, Y. Loss analysis of monocrystalline CdTe solar cells with 20% active-area efficiency. IEEE J. Photovolt. 2017, 7, 900–905. [Google Scholar] [CrossRef]

- Kato, T.; Honda, A.; Yagioka, T.; Matsuura, T.; Yamamoto, K.; Higashi, S.; Wu, J.L.; Tai, K.F.; Hiroi, H.; Yoshiyama, T.; et al. Enhanced efficiency of Cd-free Cu(In, Ga)(Se, S)2 minimodule via (Zn, Mg)O second buffer layer and alkali post treatment. IEEE J. Photovolt. 2017, 7, 1773–1780. [Google Scholar] [CrossRef]

- Shi, Z.; Attygalle, D.; Jayatissa, A.H. Kesterite-based next generation high performance thin film solar cell: Current progress and future prospects. J. Mater. Sci. Mater. Electron. 2017, 28, 2290–2306. [Google Scholar] [CrossRef]

- Shi, Z.; Jayatissa, A.H. One-pot hydrothermal synthesis and fabrication of kesterite Cu2ZnSn(S, Se)4 thin films. Prog. Nat. Sci. Mater. Int. 2017, 27, 550–555. [Google Scholar] [CrossRef]

- Yang, W.S.; Park, B.W.; Jung, E.H.; Jeon, N.J.; Kim, Y.C.; Lee, D.U.; Shin, S.S.; Seo, J.; Kim, E.K.; Noh, J.H.; et al. Iodide management in formamidinium-lead-halide-based perovskite layers for efficient solar cells. Science 2017, 356, 1376–1379. [Google Scholar] [CrossRef] [PubMed]

- Arora, N.; Dar, M.I.; Hinderhofer, A.; Pellet, N.; Schreiber, F.; Grätzel, S.M.Z.M. Perovskite solar cells with CuSCN hole extraction layers yield stabilized efficiencies greater than 20%. Science 2017. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Jayatissa, A.H.; Peiris, F.C. Fabrication of semiconducting pyrite thin films from hydrothermally synthesized pyrite (FeS2) powder. J. Mater. Sci. Mater. Electron. 2016, 27, 535–542. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Oh, J.S.; Kim, K.N.; Yeom, G.Y. Graphene doping methods and device applications. J. Nanosci. Nanotechnol. 2014, 14, 1120–1133. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.J.; Zhao, Y.; Ryu, S.; Brus, L.E.; Kim, K.S.; Kim, P. Tuning the graphene work function by electric field effect. Nano Lett. 2009, 9, 3430–3434. [Google Scholar] [CrossRef] [PubMed]

- Parui, S.; Ruiter, R.; Zomer, P.J.; Wojtaszek, M.; van Wees, B.J.; Banerjee, T. Temperature dependent transport characteristics of graphene/n-Si diodes. J. Appl. Phys. 2014, 116, 244505. [Google Scholar] [CrossRef]

- An, Y.; Behnam, A.; Pop, E.; Ural, A. Metal-semiconductor-metal photodetectors based on graphene/p-type silicon Schottky junctions. Appl. Phys. Lett. 2013, 102, 013110. [Google Scholar] [CrossRef]

- Tongay, S.; Lemaitre, M.; Miao, X.; Gila, B.; Appleton, B.R.; Hebard, A.F. Rectification at graphene-semiconductor interfaces: Zero-gap semiconductor-based diodes. Phys. Rev. X 2012, 2, 011002. [Google Scholar] [CrossRef]

- Sonde, S.; Giannazzo, F.; Raineri, V.; Yakimova, R.; Huntzinger, J.R.; Tiberj, A.; Camassel, J. Electrical properties of the graphene/4H-SiC (0001) interface probed by scanning current spectroscopy. Phys. Rev. B 2009, 80, 241406. [Google Scholar] [CrossRef]

- Tongay, S.; Schumann, T.; Hebard, A.F. Graphite based Schottky diodes formed on Si, GaAs, and 4H-SiC substrates. Appl. Phys. Lett. 2009, 95, 222103. [Google Scholar] [CrossRef]

- Wang, J.; Deng, S.; Liu, Z.; Liu, Z. The Rare Two-Dimensional Materials with Dirac Cones. arXiv 2015, arXiv:1410.5895. [Google Scholar]

- Riazimehr, S.; Bablich, A.; Schneider, D.; Kataria, S.R.; Passi, V.; Yim, C.; Duesberg, G.S.; Lemme, M.C. Spectral sensitivity of graphene/silicon heterojunction photodetectors. arXiv 2016, arXiv:1509.01021. [Google Scholar]

- Bi, H.; Huang, F.; Liang, J.; Xie, X.; Jiang, M. Transparent conductive graphene films synthesized by ambient pressure chemical vapor deposition used as the front electrode of CdTe solar cells. Adv. Mater. 2011, 23, 3202–3206. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Zhai, J.; Wang, D.; Chen, Y.; Jiang, L. Two-dimensional graphene bridges enhanced photoinduced charge transport in dye-sensitized solar cells. ACS Nano 2010, 4, 887–894. [Google Scholar] [CrossRef] [PubMed]

- Bi, H.; Huang, F.; Liang, J.; Tang, Y.; Lv, X.; Xie, X.; Jiang, M. Large-scale preparation of highly conductive three dimensional graphene and its applications in CdTe solar cells. J. Mater. Chem. 2011, 21, 17366–17370. [Google Scholar] [CrossRef]

- Liang, J.; Bi, H.; Wan, D.; Huang, F. Novel Cu nanowires/graphene as the back contact for CdTe solar cells. Adv. Funct. Mater. 2012, 22, 1267–1271. [Google Scholar] [CrossRef]

- Lin, T.; Huang, F.; Liang, J.; Wang, Y. A facile preparation route for boron-doped graphene, and its CdTe solar cell application. Energy Environ. Sci. 2011, 4, 862–865. [Google Scholar] [CrossRef]

- Brus, V.V.; Maryanchuk, P.D.; Ilashchuk, M.I.; Rappich, J.; Babichuk, I.S.; Kovalyuk, Z.D. Graphitic carbon/n-CdTe Schottky-type heterojunction solar cells prepared by electron-beam evaporation. Sol. Energy 2015, 112, 78–84. [Google Scholar] [CrossRef]

- Lin, S.; Li, X.; Zhang, S.; Wang, P.; Xu, Z.; Zhong, H.; Wu, Z.; Chen, H. Graphene/CdTe heterostructure solar cell and its enhancement with photo-induced doping. Appl. Phys. Lett. 2015, 107, 191106. [Google Scholar] [CrossRef]

- Aldosari, M.; Sohrabpoor, H.; Gorji, N.E. Optical modeling of graphene contacted CdTe solar cells. Superlattices Microstruct. 2016, 92, 242–248. [Google Scholar] [CrossRef]

- Housemand, M.; Zandi, M.H.; Gorji, N.E. SCAPS modeling for degradation of ultrathin CdTe Films: Materials interdiffusion. J. Miner. Met. Mater. Soc. 2015, 67, 2062–2070. [Google Scholar] [CrossRef]

- Okamoto, T.; Hayashi, R.; Ogawa, Y.; Hosono, A.; Doi, M. Fabrication of polycrystalline CdTe thin-film solar cells using carbon electrodes with carbon nanotubes. Jpn. J. Appl. Phys. 2015, 54, 04DR01. [Google Scholar] [CrossRef]

- Kuhn, L.; Gorji, N.E. Review on the graphene/nanotube application in thin film solar cells. Mater. Lett. 2016, 171, 323–326. [Google Scholar] [CrossRef]

- Yin, E.; Zhang, K.; Luo, H.; Cheng, G.; Ma, X.; Xiong, Z.; Xiao, X. Highly efficient graphene-based Cu(In, Ga)Se2 solar cells with large active area. Nanoscale 2014, 6, 10879–10886. [Google Scholar] [CrossRef] [PubMed]

- Dissanayake, D.M.N.M.; Ashraf, A.; Dwyer, D.; Kisslinger, K.; Zhang, L.; Pang, Y.; Efstathiadis, H.; Eisaman, M.D. Spontaneous and strong multi-layer graphene n-doping on soda-lime glass and its application in graphene-semiconductor junctions. Sci. Rep. 2016, 6, 21070. [Google Scholar] [CrossRef] [PubMed]

- Houshmand, M.; Zandi, M.H. Modeling of optical losses in graphene contacted CIGS solar cells. Mod. Phys. Lett. B 2016, 30, 1650342. [Google Scholar] [CrossRef]

- Nikita, K.N.; Gaffar, M.A.; Chowdhury, M.I.B. Exploring the opportunity of using graphene as the transparent conducting layer in CZTS-based thin film solar cells. In Proceedings of the 3rd International Conference on Electrical Engineering and Information Communication Technology (ICEEICT), Dhaka, Bangladesh, 22–24 September 2016; pp. 1–6. [Google Scholar]

- Ishikawa, R.; Oya, T.; Yamada, T.; Nomoto, T.; Tsuboi, N. Highly oriented CuInS2 thin films on graphene electrodes for solar-cell applications. Thin Solid Films 2017, 634, 1–5. [Google Scholar] [CrossRef]

- Kamalanathan, M.; Karuppusamy, S.; Sivakumar, R.; Gopalakrishnan, R. Synthesis of reduced graphene oxide-copper tin sulphide composites and their photoconductivity enhancement for photovoltaic applications. J. Mater. Sci. 2015, 50, 8029–8037. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Seo, J.Y.; Domanski, K.; Correa-Baena, J.P.; Nazeeruddin, M.K.; Zakeeruddin, S.M.; Tress, W.; Abate, A.; Hagfeldt, A.; et al. Cesium-containing triple cation perovskite solar cells: Improved stability, reproducibility and high efficiency. Energy Environ. Sci. 2016, 9, 1989–1997. [Google Scholar] [CrossRef] [PubMed]

- Jeon, N.J.; Noh, J.H.; Yang, W.S.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. Compositional engineering of perovskite materials for high-performance solar cells. Nature 2015, 517, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef] [PubMed]

- Anaraki, E.H.; Kermanpur, A.; Steier, L.; Domanski, K.; Matsui, T.; Tress, W.; Saliba, M.; Abate, A.; Gratzel, M.; Hagfeldt, A.; et al. Highly efficient and stable planar perovskite solar cells by solution-processed tin oxide. Energy Environ. Sci. 2016, 9, 3128–3134. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Domanski, K.; Seo, J.-Y.; Ummadisingu, A.; Zakeeruddin, S.M.; Correa-Baena, J.P.; Tress, W.R.; Abate, A.; Hagfeldt, A.; et al. Incorporation of rubidium cations into perovskite solar cells improves photovoltaic performance. Science 2016, 354, 206–209. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.T.W.; Ball, J.M.; Barea, E.M.; Abate, A.; Webber, J.A.A.; Huang, J.; Saliba, M.; Mora-Sero, I.; Bisquert, J.; Snaith, H.J.; et al. Low-temperature processed electron collection layers of graphene/TiO2 nanocomposites in thin film perovskite solar cells. Nano Lett. 2014, 14, 724–730. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Ma, J.; Wang, Z.; Mu, C.; Fan, Z.; Du, L.; Bai, Y.; Fan, L.; Yan, H.; Phillips, D.L.; et al. Efficiency enhancement of perovskite solar cells through fast electron extraction: The role of graphene quantum dots. J. Am. Chem. Soc. 2014, 136, 3760–3763. [Google Scholar] [CrossRef] [PubMed]

- Han, G.S.; Song, Y.H.; Jin, Y.U.; Lee, J.W.; Park, N.G.; Kang, B.K.; Lee, J.K.; Cho, I.S.; Yoon, D.H.; Jung, H.S. Reduced graphene oxide/mesoporous TiO2 nanocomposite based perovskite solar cells. ACS Appl. Mater. Interfaces 2015, 7, 23521–23526. [Google Scholar] [CrossRef] [PubMed]

- Tomokazu, U.; Daichi, M.; Jinseok, B.; Satyajit, G.; Seigo, I.; Vaidyanathan (Ravi), S.; Hiroshi, I. Boosting of the performance of perovskite solar cells through systematic introduction of reduced graphene oxide in TiO2 layers. Chem. Lett. 2015, 44, 1410–1412. [Google Scholar]

- Agresti, A.; Pescetelli, S.; Cinà, L.; Konios, D.; Kakavelakis, G.; Kymakis, E.; Carlo, A.D. Efficiency and stability enhancement in perovskite solar cells by inserting lithium-neutralized graphene oxide as electron transporting layer. Adv. Funct. Mater. 2016, 26, 2686–2694. [Google Scholar] [CrossRef]

- Poh, H.L.; Šanek, F.; Ambrosi, A.; Zhao, G.; Sofer, Z.; Pumera, M. Graphenes prepared by Staudenmaier, Hofmann and Hummers methods with consequent thermal exfoliation exhibit very different electrochemical properties. Nanoscale 2012, 4, 3515–3522. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Bai, S.; Xiang, J.; Yuan, Z.; Yang, Y.; Cui, W.; Gao, X.; Liu, Z.; Jin, Y.; Sun, B. Efficient planar heterojunction perovskite solar cells employing graphene oxide as hole conductor. Nanoscale 2014, 6, 10505–10510. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Robinson, J.T.; Sun, X.; Dai, H. PEGylated nanographene oxide for delivery of water-insoluble cancer drugs. J. Am. Chem. Soc. 2008, 130, 10876–10877. [Google Scholar] [CrossRef] [PubMed]

- Yun, J.-M.; Yeo, J.-S.; Kim, J.; Jeong, H.-G.; Kim, D.-Y.; Noh, Y.J.; Kim, S.-S.; Ku, B.-C.; Na, S.-I. Solution-processable reduced graphene oxide as a novel alternative to PEDOT:PSS hole transport layers for highly efficient and stable polymer solar cells. Adv. Mater. 2011, 23, 4923–4928. [Google Scholar] [CrossRef] [PubMed]

- Palma, A.L.; Cinà, L.; Pescetelli, S.; Agresti, A.; Raggio, M.; Paolesse, R.; Bonaccorso, F.; Carlo, A.D. Reduced graphene oxide as efficient and stable hole transporting material in mesoscopic perovskite solar cells. Nano Energy 2016, 22, 349–360. [Google Scholar] [CrossRef]

- Cao, J.; Liu, Y.-M.; Jing, X.; Yin, J.; Li, J.; Xu, B.; Tan, Y.-Z.; Zheng, N. Well-Defined thiolated nanographene as hole-transporting material for efficient and stable perovskite solar cells. J. Am. Chem. Soc. 2015, 137, 10914–10917. [Google Scholar] [CrossRef] [PubMed]

- Yan, K.; Wei, Z.; Li, J.; Chen, H.; Yi, Y.; Zheng, X.; Long, X.; Wang, Z.; Wang, J.; Xu, J.; et al. High-performance graphene-based hole conductor-free perovskite solar cells: Schottky junction enhanced hole extraction and electron blocking. Small 2015, 11, 2269–2274. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Zhang, Y.; Liu, C.; Li, J.; Wang, N.; Lin, H. Iodide-reduced graphene oxide with dopant-free spiro-OMeTAD for ambient stable and high-efficiency perovskite solar cells. J. Mater. Chem. A 2015, 3, 15996–16004. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Na, S.-I.; Kim, S.-S. Graphene oxide/PEDOT:PSS composite hole transport layer for efficient and stable planar heterojunction perovskite solar cells. Nanoscale 2016, 8, 1513–1522. [Google Scholar] [CrossRef] [PubMed]

- You, P.; Liu, Z.; Tai, Q.; Liu, S.; Yan, F. Efficient semitransparent perovskite solar cells with graphene electrodes. Adv. Mater. 2015, 27, 3632–3638. [Google Scholar] [CrossRef] [PubMed]

- Sung, H.; Ahn, N.; Jang, M.S.; Lee, J.-K.; Yoon, H.; Park, N.-G.; Choi, M. Transparent conductive oxide-free graphene-based perovskite solar cells with over 17% efficiency. Adv. Energy Mater. 2016, 6, 1501873. [Google Scholar] [CrossRef]

- Yoon, J.; Sung, H.; Lee, G.; Cho, W.; Ahn, N.; Jung, H.S.; Choi, M. Superflexible, high-efficiency perovskite solar cells utilizing graphene electrodes: Towards future foldable power sources. Energy Environ. Sci. 2017, 10, 337–345. [Google Scholar] [CrossRef]

- Hadadian, M.; Correa-Baena, J.-P.; Goharshadi, E.K.; Ummadisingu, A.; Seo, J.-Y.; Luo, J.; Gholipour, S.; Zakeeruddin, S.M.; Saliba, M.; Abate, A.; et al. Enhancing efficiency of perovskite solar cells via n-doped graphene: Crystal modification and surface passivation. Adv. Mater. 2016, 28, 8681–8686. [Google Scholar] [CrossRef] [PubMed]

- Agresti, A.; Pescetelli, S.; Taheri, B.; Castillo, A.E.D.R.; Cinà, L.; Bonaccorso, F.; Carlo, A.D. Graphene-perovskite solar cells exceed 18% efficiency: A stability study. ChemSusChem 2016, 9, 2609–2619. [Google Scholar] [CrossRef] [PubMed]

| Back Contact Material | σ [S cm-1] | μ [cm2 V-1 s-1] | Voc [mV] | Jsc [mA cm-2] | FF [%] | Eff. [%] |

|---|---|---|---|---|---|---|

| Cu NWs/Graphene | 16.7 | 16.2 | 801 | 22.4 | 67.4 | 12.1 |

| Cu Ps/Graphene | 14.2 | 13.2 | 805 | 21.3 | 68.1 | 11.7 |

| Cu Ps/Graphite | 5.5 | 5.0 | 790 | 21.2 | 62.5 | 10.5 |

| Cu TF | - | - | 740 | 21.1 | 58.0 | 9.1 |

| Samples | TCE | Process [Thickness of i-ZnO] | Voc [mV] | Jsc [mA/cm2] | Fill Factor [%] | PCE [%] |

|---|---|---|---|---|---|---|

| #1 | 150nm AZO | Reference [50 nm] | 601 | 32.8 | 74.3 | 14.9 |

| #2 | 1-layer G | Process A [50 nm] | 543 | 0.93 | 25.3 | 0.43 |

| #3 | 400nm PMMA/1-layer G | Process B [50 nm] | 595 | 23.5 | 40.4 | 5.63 |

| #4 | 400nm PMMA/4-layer G | Process B [50 nm] | 596 | 27.4 | 44.2 | 7.20 |

| #5 | 400nm PMMA/4-layer G | Process C [125 nm] | 595 | 31.2 | 56.3 | 10.5 |

| #6 | 400nm PMMA/4-layer G | Process C [200 nm] | 603 | 30.1 | 52.2 | 9.50 |

| #7 | 150nm PMMA/4-layer G | Process D [125 nm] | 601 | 32.4 | 69.1 | 13.5 |

| HTM | Voc [V] | Jsc [mA cm−2] | FF [%] | PCE [%] | PCE Relative Variation [%] |

|---|---|---|---|---|---|

| Spiro-OMeTAD As-Prepared | 1.02 | 15.70 | 68.78 | 11.06 | −41 |

| Spiro-OMeTAD 1987 h | 1.00 | 10.50 | 61.75 | 6.50 | |

| RGO As-Prepared | 0.91 | 8.95 | 59.78 | 4.87 | +36 |

| RGO 1987 h | 0.95 | 11.5 | 60.54 | 6.62 |

| Sample ID | Electrode | MoO3 Thickness [nm] | Voc [V] | Jsc [mA cm-2] | FF | PCE [%] | Best PCE [%] |

|---|---|---|---|---|---|---|---|

| G-M1 | Graphene | 1 | 0.72 ± 0.36 | 17.6 ± 6.3 | 0.45 ± 0.09 | 6.7 ± 4.2 | 12.1 |

| G-M2 | 2 | 1.03 ± 0.02 | 21.9 ± 0.4 | 0.72 ± 0.02 | 16.1 ± 0.6 | 17.1 | |

| G-M4 | 4 | 1.00 ± 0.01 | 22.9 ± 0.4 | 0.70 ± 0.02 | 15.9 ± 0.5 | 16.2 | |

| ITO-M0 | ITO | 0 | 0.96 ± 0.01 | 21.4 ± 0.5 | 0.83 ± 0.02 | 17.0 ± 0.4 | 17.6 |

| ITO-M1 | 1 | 0.97 ± 0.01 | 22.6 ± 0.4 | 0.83 ± 0.01 | 18.2 ± 0.5 | 18.8 | |

| ITO-M2 | 2 | 0.95 ± 0.01 | 22.2 ± 0.4 | 0.76 ± 0.01 | 16.1 ± 0.4 | 16.9 | |

| ITO-M4 | 4 | 0.94 ± 0.01 | 21.0 ± 0.4 | 0.74 ± 0.01 | 14.7 ± 0.6 | 15.7 |

| System | Front Contact | Back Contact | Absorber | ETL | HTL |

|---|---|---|---|---|---|

| CdTe | Thin-layer graphene (1–5 layers) | Multi-layer graphene with metal | - | - | - |

| CIGS or CZTS | 1–5 layer graphene, need extra surface treatment to decrease Rs | Multi-layer graphene with metal, need extra surface treatment to decrease Rs | - | Reduced-GO/TiO2 enhanced η. | - |

| PSC | Thin-layer graphene with interfacial layer for better wettability | Graphene or graphene with metal, need interfacial layer, thickness profile vary | Mix graphene from the initial synthesis | Low concentration with TiO2, mixed or separately coated | Need suitable interfacial layer to connect graphene and perovskite |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Jayatissa, A.H. The Impact of Graphene on the Fabrication of Thin Film Solar Cells: Current Status and Future Prospects. Materials 2018, 11, 36. https://doi.org/10.3390/ma11010036

Shi Z, Jayatissa AH. The Impact of Graphene on the Fabrication of Thin Film Solar Cells: Current Status and Future Prospects. Materials. 2018; 11(1):36. https://doi.org/10.3390/ma11010036

Chicago/Turabian StyleShi, Zhengqi, and Ahalapitiya H. Jayatissa. 2018. "The Impact of Graphene on the Fabrication of Thin Film Solar Cells: Current Status and Future Prospects" Materials 11, no. 1: 36. https://doi.org/10.3390/ma11010036