Enhancement of the Mechanical Properties in Al–Si–Cu–Fe–Mg Alloys with Various Processing Parameters

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

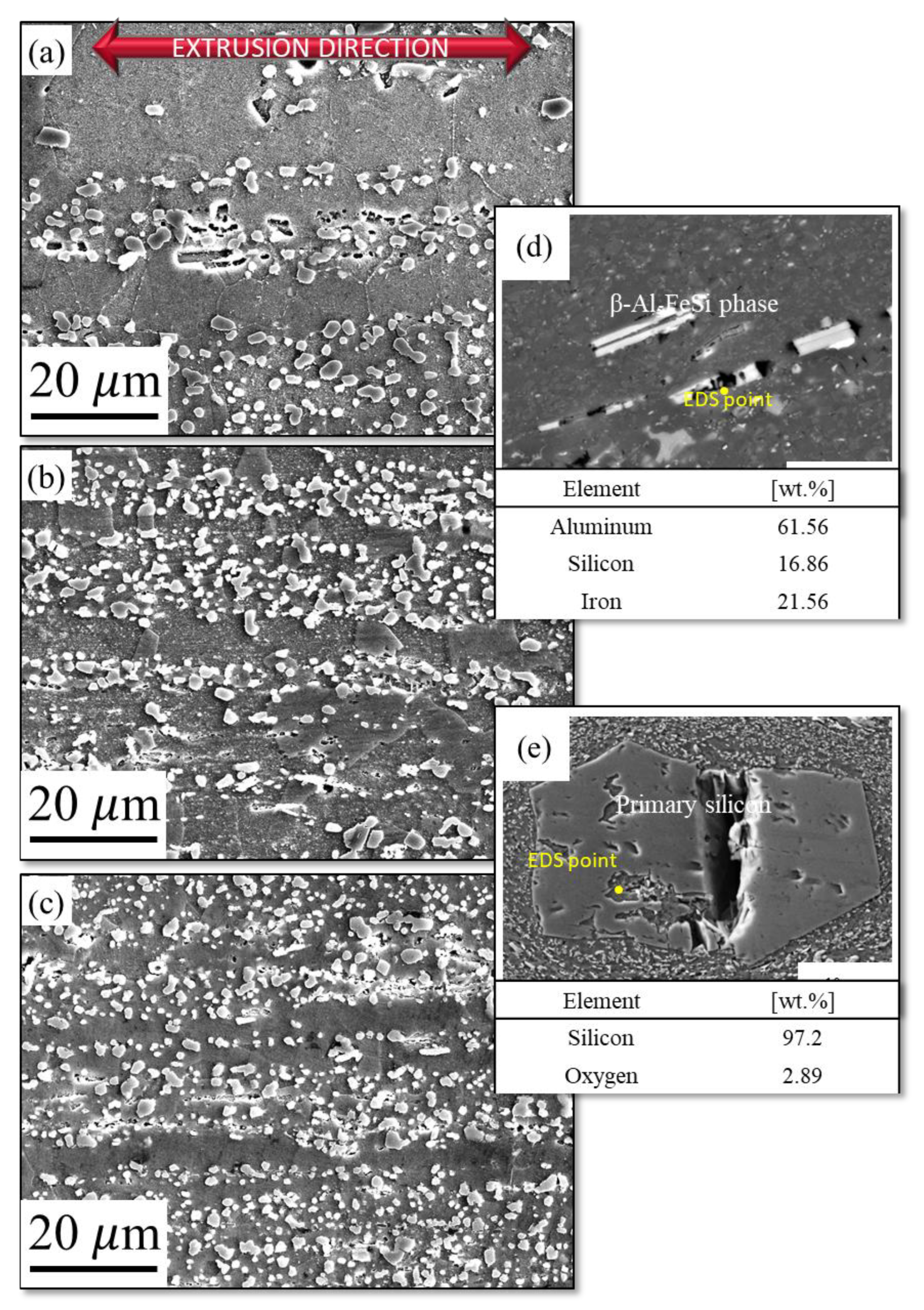

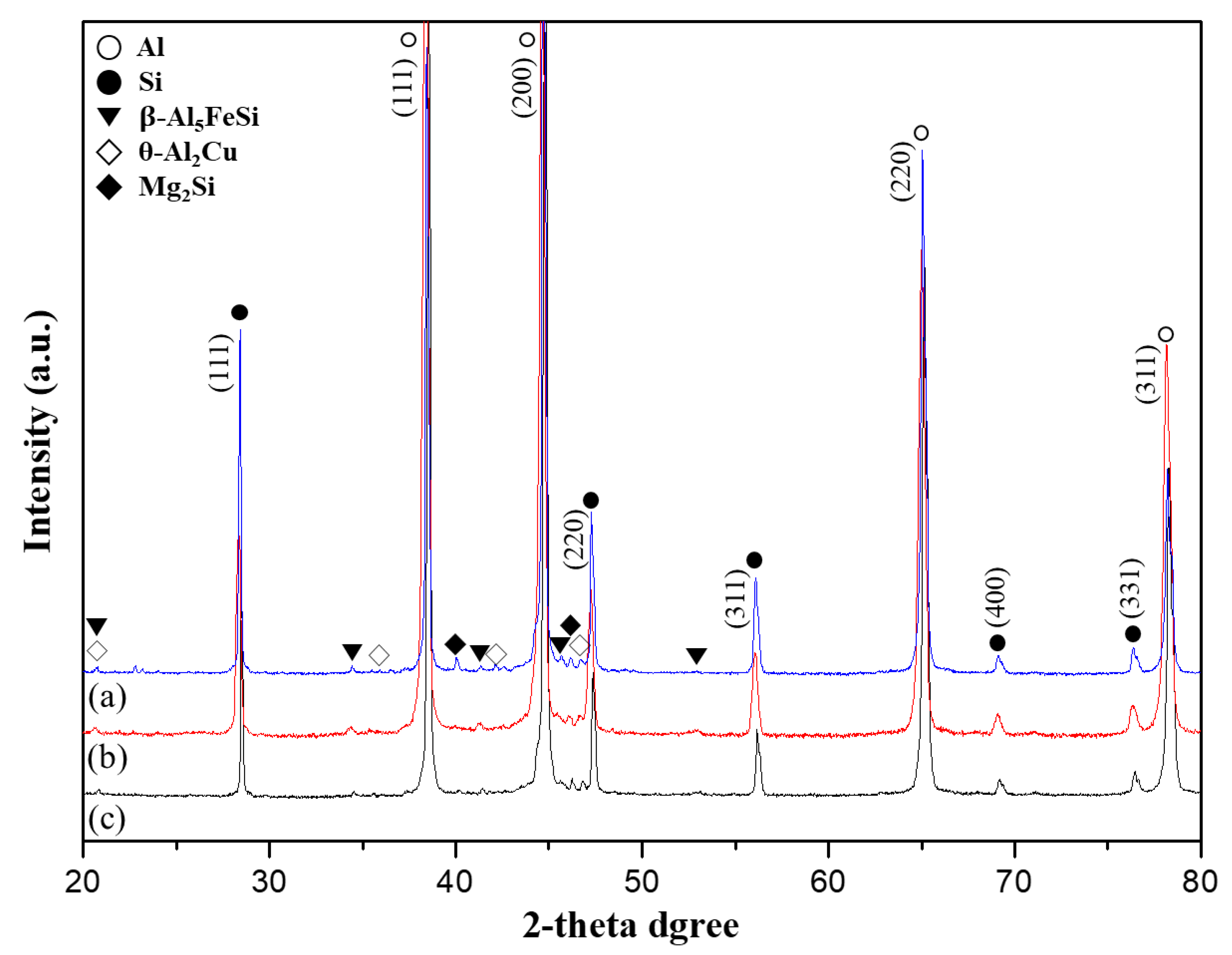

3.1. Microstructure Investigation of the Extruded Samples

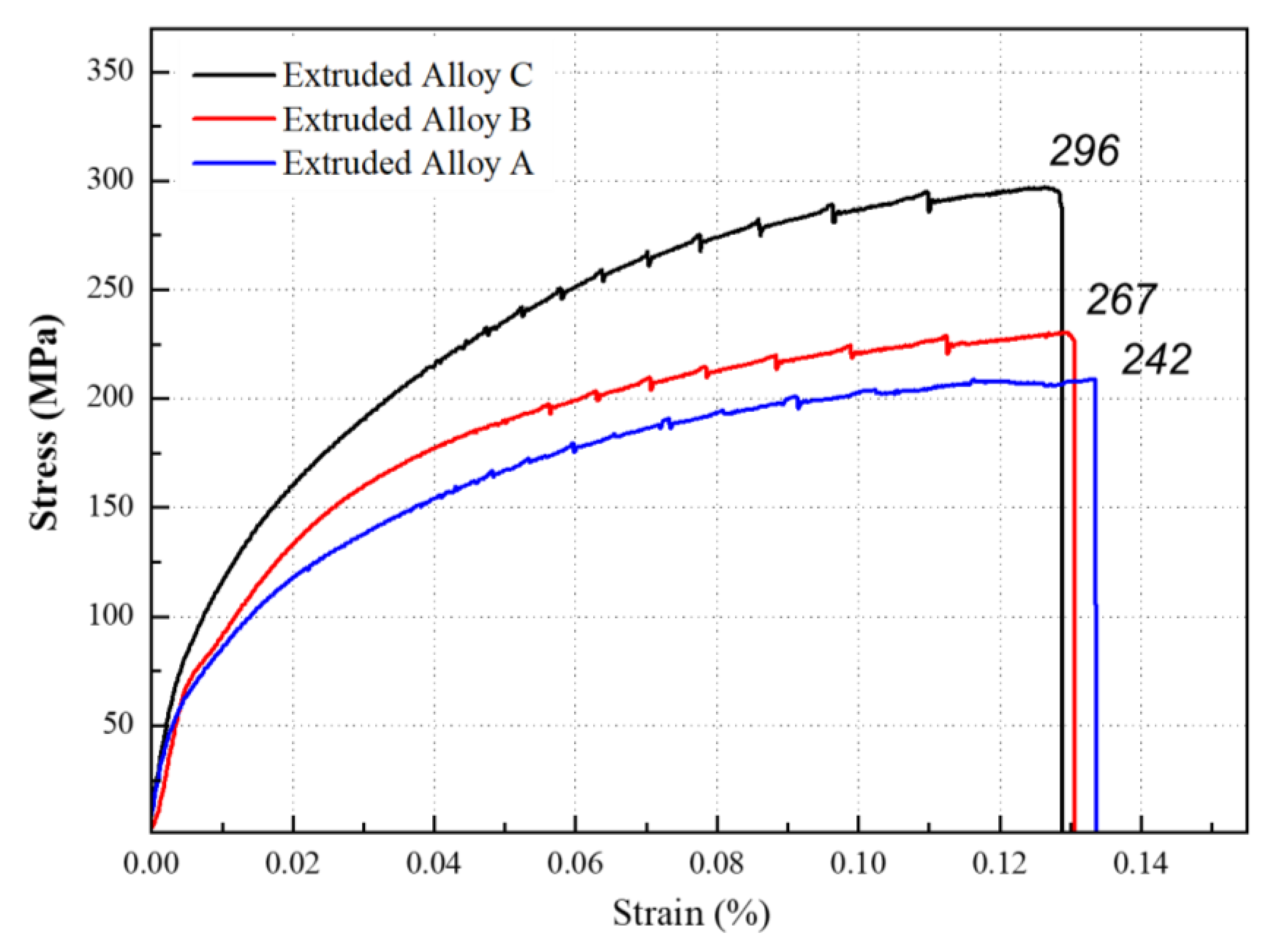

3.2. Mechanical Properties of the Extruded Alloys Without T6 Heat Treatment

3.3. SEM Analysis of Tensile Fractured Surfaces Without T6 heat Treatment

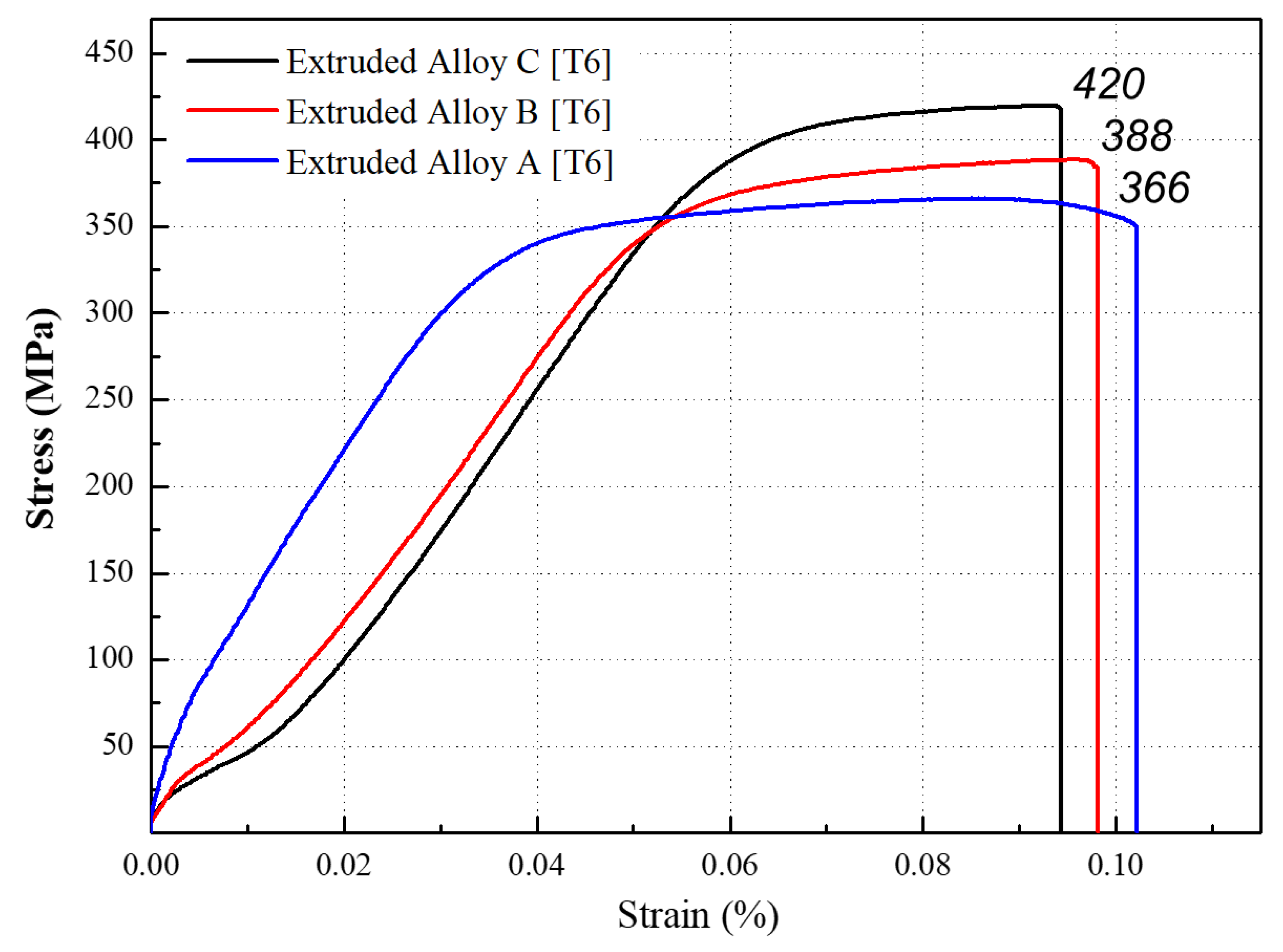

3.4. Influence of T6 Heat Treatment on Al-Si Extruded Alloys

4. Conclusions

- The Si phase was finely distributed in the Al matrix along the extrusion direction, and the amount of Si phase increased with the increase of Si content. Cracks in the Si phases and fragmented intermetallic (β-Al5FeSi) phase were observed in the Al matrix.

- The tensile strength of the extruded bar improved with the increase of Si content, while the ductility decreased. The maximum tensile value obtained was 296 MPa for the 14 wt.% Si-doped sample.

- To further improve the tensile strength, T6 heat treatment was carried out. The optimum aging time was confirmed by the Vickers hardness values. The HV1 value increased after up to 3 h of aging and reached a maximum value of 150 HV1.

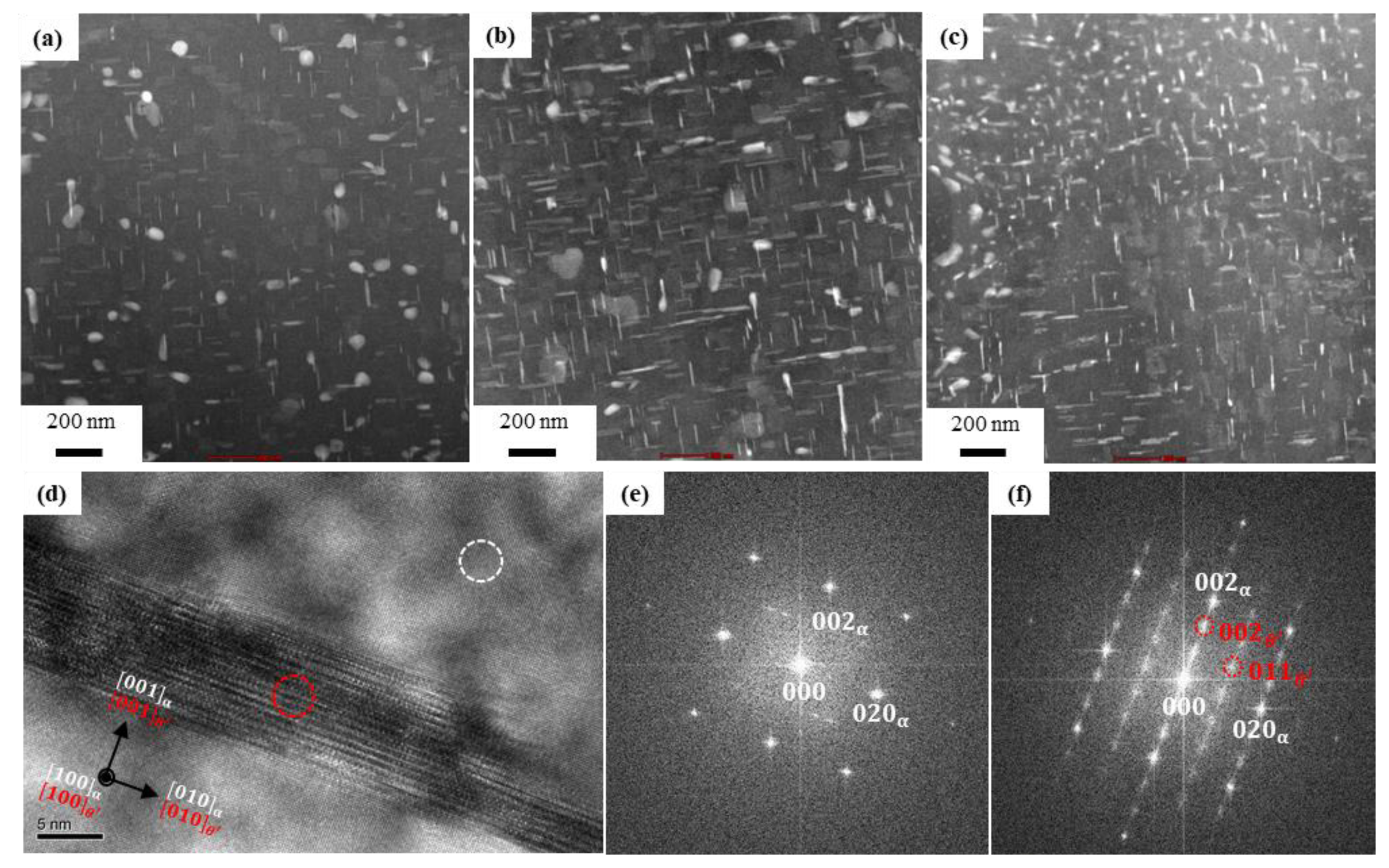

- The TEM images of T6 heated specimens displayed a coherent Al2Cu phase in the Al matrix. A precipitated θ′-Al2Cu phase was confirmed by the FFT patterns.

- The tensile strength improved by ~45 % compared to non-heat-treated alloys. A maximum tensile strength of 420 MPa was obtained for the Al-14Si-3Cu-0.5Fe-0.6Mg alloy, due to the formation of the θ′-Al2Cu phase in the Al matrix.

Authors Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zuo, K.; Zhang, H.; Qin, K.; Han, X.; Shao, B.; Cui, J. Effects of heat treatment and extrusion on microstructure and properties of A390 alloy hollow billet fabricated via DC casting. Mater Trans. 2015, 56, 1591–1598. [Google Scholar] [CrossRef]

- Costa, T.A.; Dias, M.; Gomes, L.G.; Rocha, O.L.; Garcia, A. Effect of solution time in T6 heat treatment on microstructure and hardness of a directionally solidified Al-Si-Cu alloy. J. Alloys Compd. 2016, 683, 485–494. [Google Scholar] [CrossRef]

- Sharma, A.; Shin, Y.S.; Jung, J.P. Influence of various additional elements in Al based filler alloys for automotive and brazing industry. J. Weld. Join. 2015, 33, 1–8. [Google Scholar] [CrossRef]

- Ye, H.Z. An overview of the development of Al-Si-Alloy based material for engine applications. J. Mater. Eng. Perform. 2003, 12, 288–297. [Google Scholar] [CrossRef]

- Hong, S.J.; Suryanarayana, C. Mechanical properties and fracture behavior of an ultrafine-grained Al-20 Wt Pct Si alloy. Metall. Mater. Trans. A 2005, 36, 715–723. [Google Scholar] [CrossRef]

- Ma, P.; Jia, Y.; Prashanth, K.; Yu, Z.; Li, C.; Zhao, J.; Yang, S.; Huang, L. Effect of Si content on the microstructure and properties of Al-Si alloys fabricated using hot extrusion. J. Mater. Res. 2017, 32, 2210–2217. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Samuel, F.H. A review on the heat treatment of Al-Si-Cu/Mg casting alloys. In Heat Treatment-Conventional and Novel Applications; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Ke, D.; Hengcheng, L.; Qiumin, J.; Yun, T. Effect of hot extrusion on mechanical properties and microstructure of near eutectic Al-12.0%Si-0.2%Mg alloy. Mater. Sci. Eng. A 2010, 527, 887–6892. [Google Scholar] [CrossRef]

- Lucas, A.; Caceres, C.H.; Taylor, J.A. The effect of Si content on the size of β-Al5FeSi intermetallics in Al-Si-Cu-Mg casting alloys. In Proceedings of the 9th International Conference on Aluminium Alloys, Brisbane, Australia, 2–5 August 2004. [Google Scholar]

- Sivarupan, T.; Taylor, J.; Caceres, C. SDAS, Si and Cu content, and the size of Intermetallics in Al-Si-Cu-Mg-Fe alloys. Metall. Mater. Trans. A. 2015, 46, 2082–2107. [Google Scholar] [CrossRef]

- Gupta, M.; Ling, S. Microstructure and mechanical properties of hypo/hyper-eutectic Al-Si alloys synthesized using a near-net shape forming technique. J. Alloys Compd. 1999, 287, 284–294. [Google Scholar] [CrossRef]

- Lasa, L.; Rodriguez, J.M. Characterization of the dissolution of the Al2Cu phase in two Al-Si-Cu-Mg casting alloys using calorimetry. Mater. Charact. 2002, 48, 371–378. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, H.; Wu, Y.; Chun, B.S. Effect of Si content on microstructure and mechanical properties of Al-Si-Mg alloys. Mater. Des. 2014, 53, 634–638. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Srivastava, V.C.; Gloter, A.; Ojha, S.N. Microstructural features induced by spray processing and hot extrusion of an Al-18% Si-5% Fe-1.5% Cu alloy. Acta Mater. 2006, 54, 1741–1748. [Google Scholar] [CrossRef]

- Li, R.X.; Yu, F.X.; Zuo, L. Effect of hot extrusion process on microstructure and mechanical properties of hypereutectic Al-Si alloys. China Foundry 2011, 8, 145–149. [Google Scholar]

- Saha, P.K. Fundamentals of Extrusion. Aluminium Extrusion Technology; ASM international: Geauga, OH, USA, 2000. [Google Scholar]

- Gulay, V.; Khalifa, N.B.; Tekayya, A.E. The effect of extrusion ratio and material flow on the mechanical properties of aluminium profiles solid state recycled from 6060 aluminium alloy chips. AIP Conf. Proc. 2011, 1353, 1609–1614. [Google Scholar]

- Chen, Y.; Wang, Q.; Peng, J.; Zhai, C.; Ding, W. Effect of extrusion ratio on the microstructure and mechanical properties of AZ31 Mg alloy. J. Mater. Process. Technol. 2007, 182, 281–285. [Google Scholar] [CrossRef]

- Xiong, B.Q.; Zhang, Y.G.; Wei, Q.; Shi, L.K.; Xie, C.G.; Shang, C.J.; He, X.L. The study of primary Si phase in spray forming hypereutectic Al-Si alloy. J. Mater. Process. Technol. 2003, 137, 183–186. [Google Scholar]

- Gowri, S.; Samuel, F.H. Effect of alloying elements on the solidification characteristics and microstructure of Al-Si-Cu-Mg-Fe 380 alloy. Metall. Mater. Trans. A 1994, 25, 437–448. [Google Scholar] [CrossRef]

- Hong, S.J.; Kim, T.S.; Kim, W.T.; Chun, B.S. The effects of Cr and Zr addition on the microstructure and mechanical properties of rapidly solidified Al-20Si-5Fe alloys. Mater. Sci. Eng. A 1997, 226–228, 878–882. [Google Scholar] [CrossRef]

- Sjolander, E.; Seifeddine, S. The heat treatment of Al-Si-Cu-Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Wu, C.; Lee, S.; Hsieh, M.; Lin, J. Effects of Mg content on microstructure and mechanical properties of Al-14.5Si-4.5Cu alloy. Metall. Mater. Trans. A. 2010, 41, 751–757. [Google Scholar] [CrossRef]

- Caceres, C.H.; Svensson, I.L.; Taylor, J.A. Strength-ductility behavior of Al-Si-Cu-Mg casting alloys in T6 temper. Int. J. Cast Metals Res. 2003, 15, 531–543. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Moemeni, H. Effect of copper and solidification conditions on the microstructure and mechanical properties of Al-Si-Mg alloys. J. Mater. Process. Technol. 2004, 153, 193–198. [Google Scholar] [CrossRef]

| Alloy | Composition (wt.%) | Density of Casting Alloy (g/cm3) | ||||

|---|---|---|---|---|---|---|

| Si | Cu | Mg | Fe | Al | ||

| 4007A | 9.0~10.5 | 2.5~3.5 | 0.5~0.7 | <0.5 | Bal. | - |

| Alloy A | 10 | 3 | 0.6 | 0.5 | Bal. | 2.715 |

| Alloy B | 12.6 | 3 | 0.6 | 0.5 | Bal. | 2.701 |

| Alloy C | 14 | 3 | 0.6 | 0.5 | Bal. | 2.688 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S.-S.; Pathan, S.; Koo, J.-M.; Baeg, C.-H.; Jeong, C.-U.; Son, H.-T.; Kim, Y.-H.; Lee, K.-H.; Hong, S.-J. Enhancement of the Mechanical Properties in Al–Si–Cu–Fe–Mg Alloys with Various Processing Parameters. Materials 2018, 11, 2150. https://doi.org/10.3390/ma11112150

Ahn S-S, Pathan S, Koo J-M, Baeg C-H, Jeong C-U, Son H-T, Kim Y-H, Lee K-H, Hong S-J. Enhancement of the Mechanical Properties in Al–Si–Cu–Fe–Mg Alloys with Various Processing Parameters. Materials. 2018; 11(11):2150. https://doi.org/10.3390/ma11112150

Chicago/Turabian StyleAhn, Su-Seong, Sharief Pathan, Jar-Myung Koo, Chang-Hyun Baeg, Chan-Uk Jeong, Hyoen-Taek Son, Yong-Ho Kim, Kap-Ho Lee, and Soon-Jik Hong. 2018. "Enhancement of the Mechanical Properties in Al–Si–Cu–Fe–Mg Alloys with Various Processing Parameters" Materials 11, no. 11: 2150. https://doi.org/10.3390/ma11112150