Effect of Co-Production of Renewable Biomaterials on the Performance of Asphalt Binder in Macro and Micro Perspectives

Abstract

:1. Introduction

2. Materials and Performance Testing

2.1. Materials

2.1.1. Asphalt Binder

2.1.2. Bio-Oil

2.1.3. Material Preparation

2.2. Performance Testing Procedures

2.2.1. Fourier Transform Infrared Spectroscopy (FTIR) Test

2.2.2. Complex Shear Modulus Test

2.2.3. Linear Amplitude Sweep (LAS) Test

3. Performance Testing Results

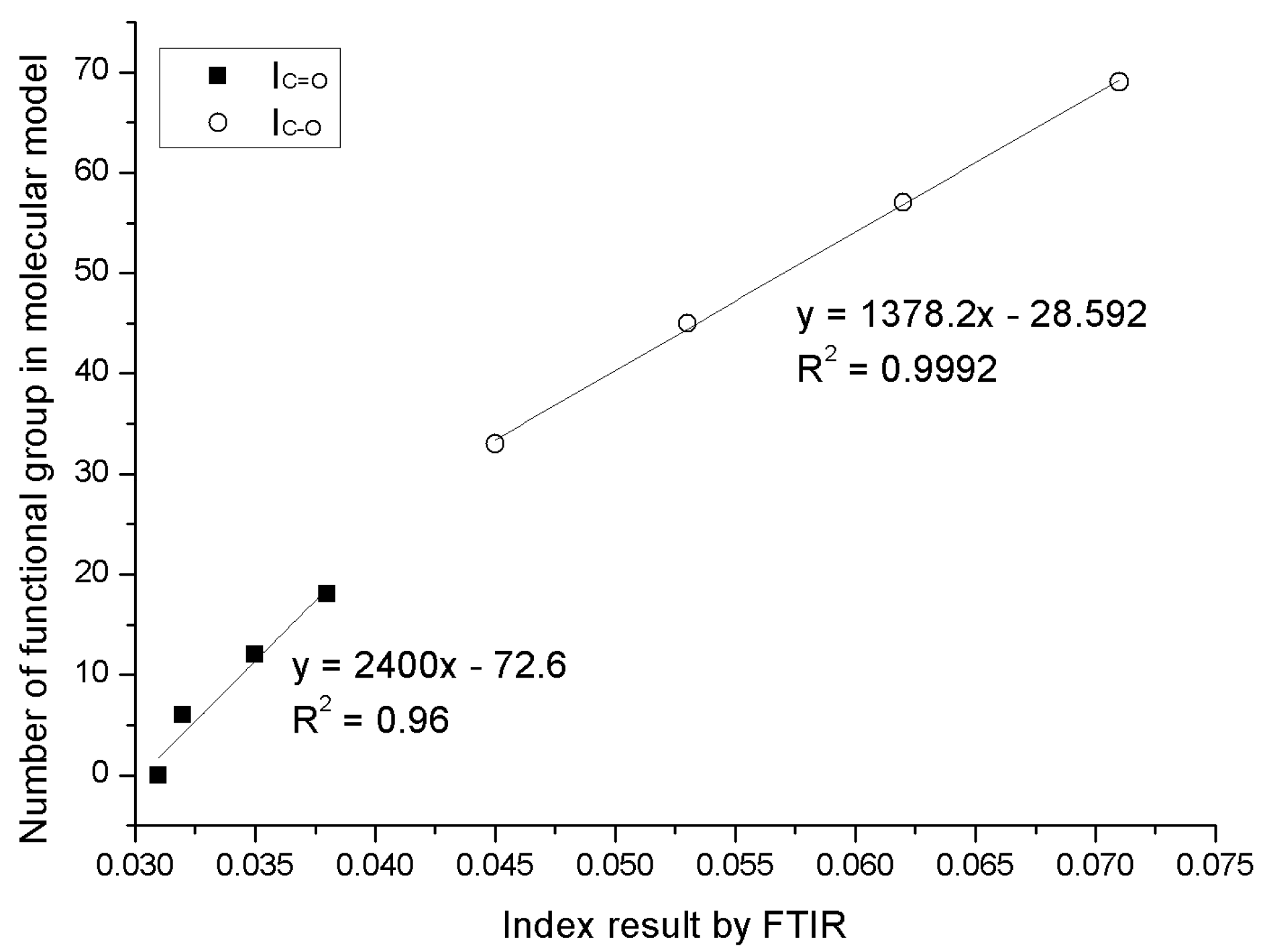

3.1. FTIR Chemical Group Analysis

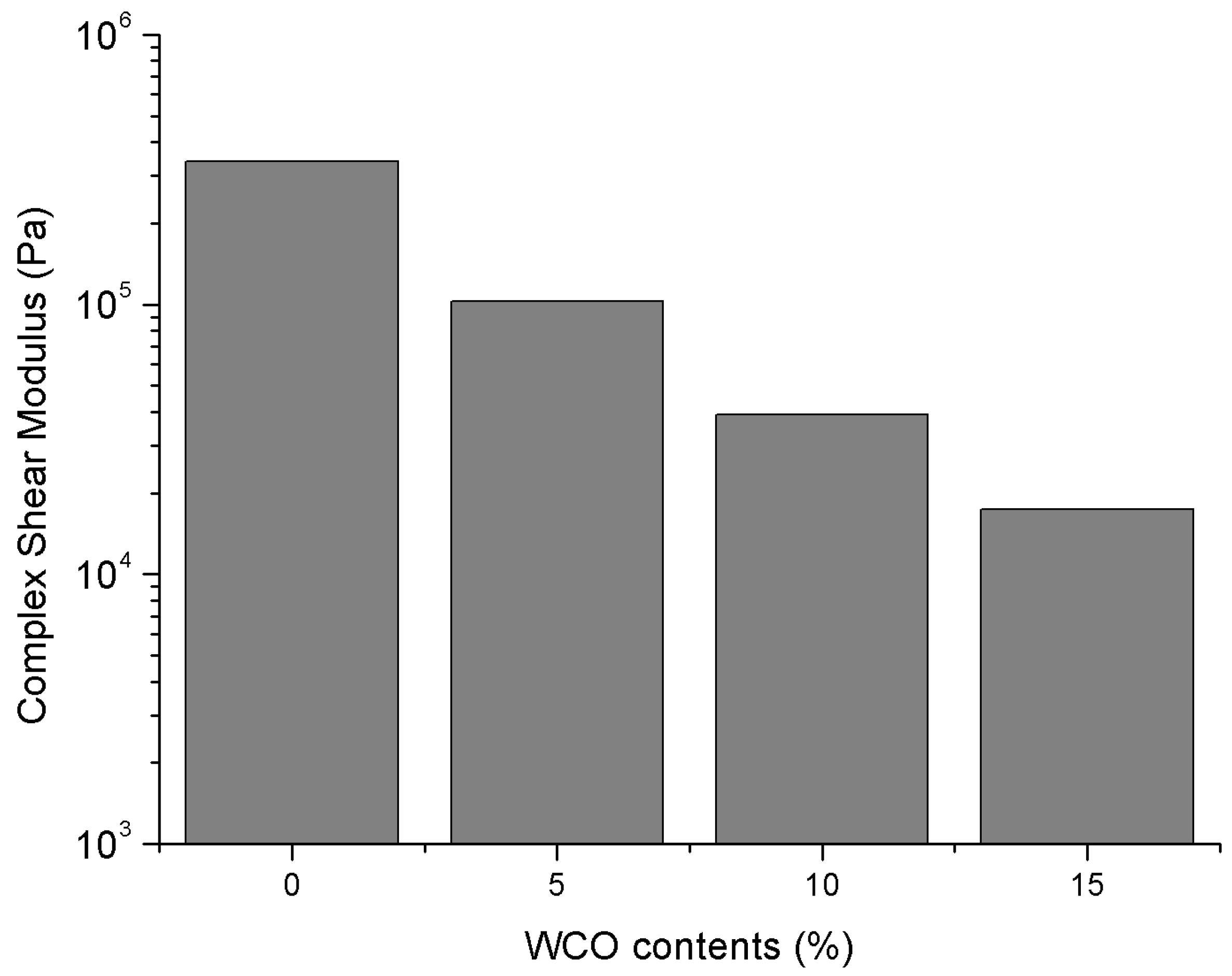

3.2. Complex Shear Modulus

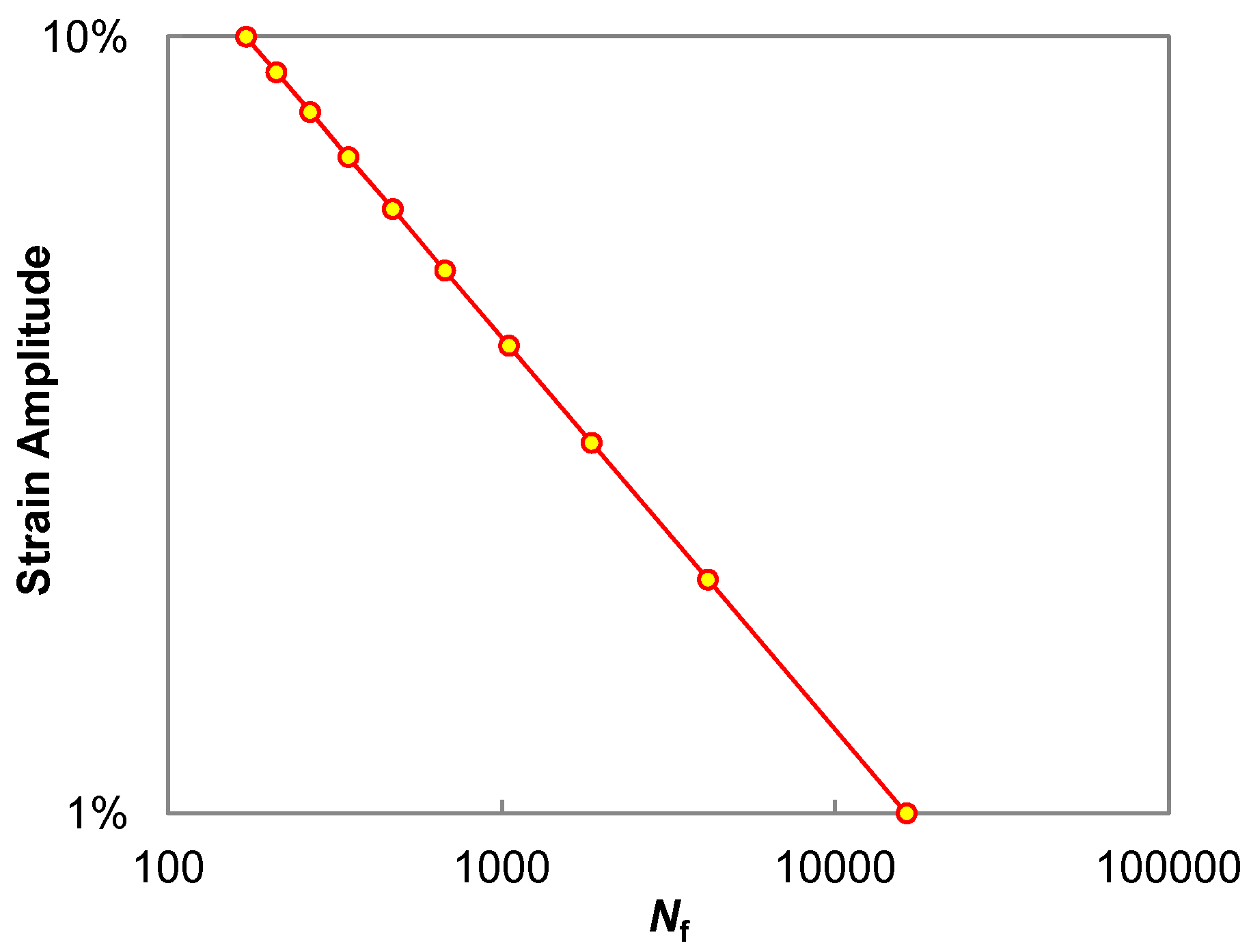

3.3. Fatigue Performance

4. Creation and Validation of Molecular Structure Models

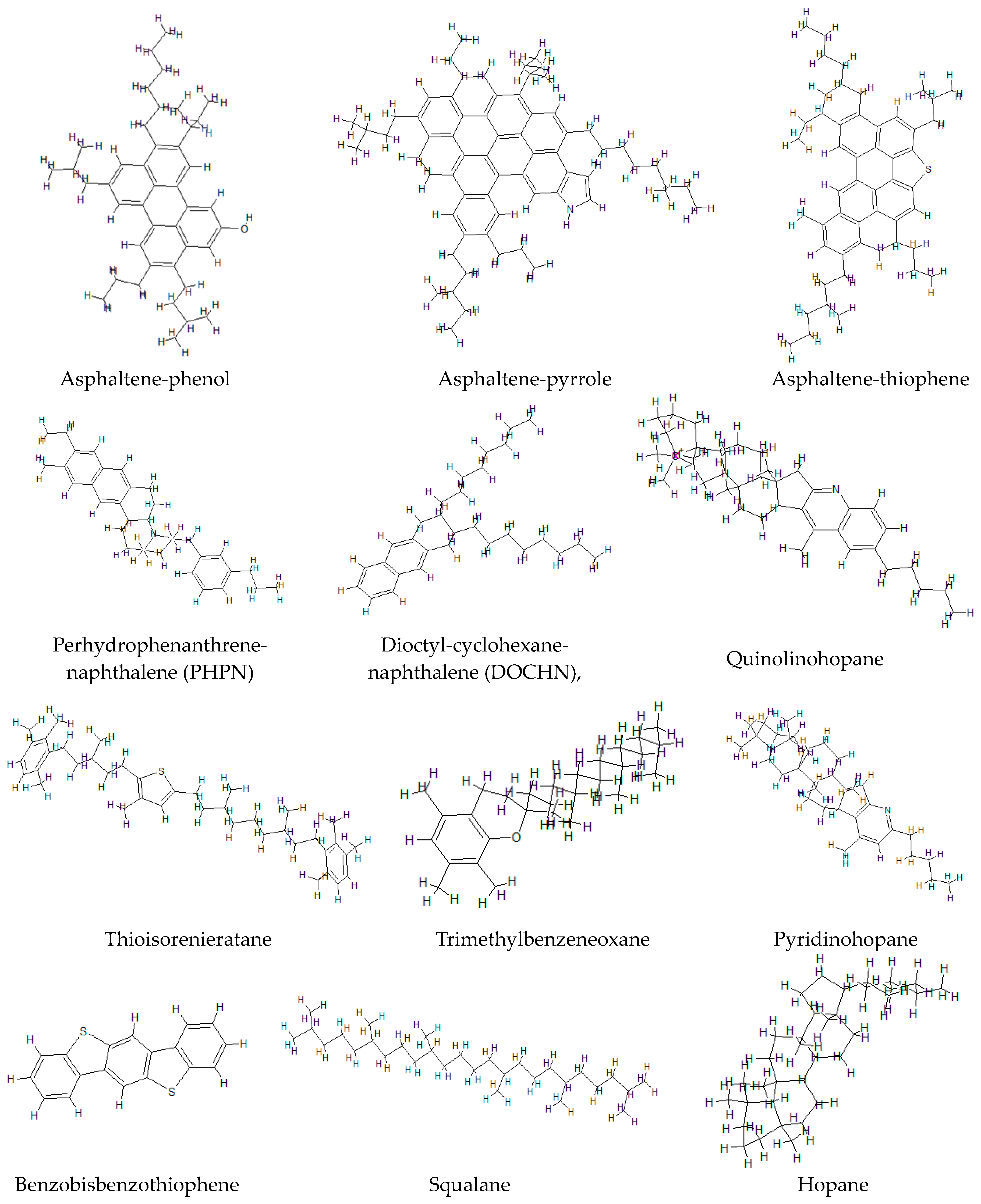

4.1. Molecular Structure Model of Asphalt Binder

4.2. Molecular Structure Model of WCO Based Bio-Oil

4.3. Creation of Asphalt Binder Molecular Structure Model

4.4. Validation of Molecular Structure Models

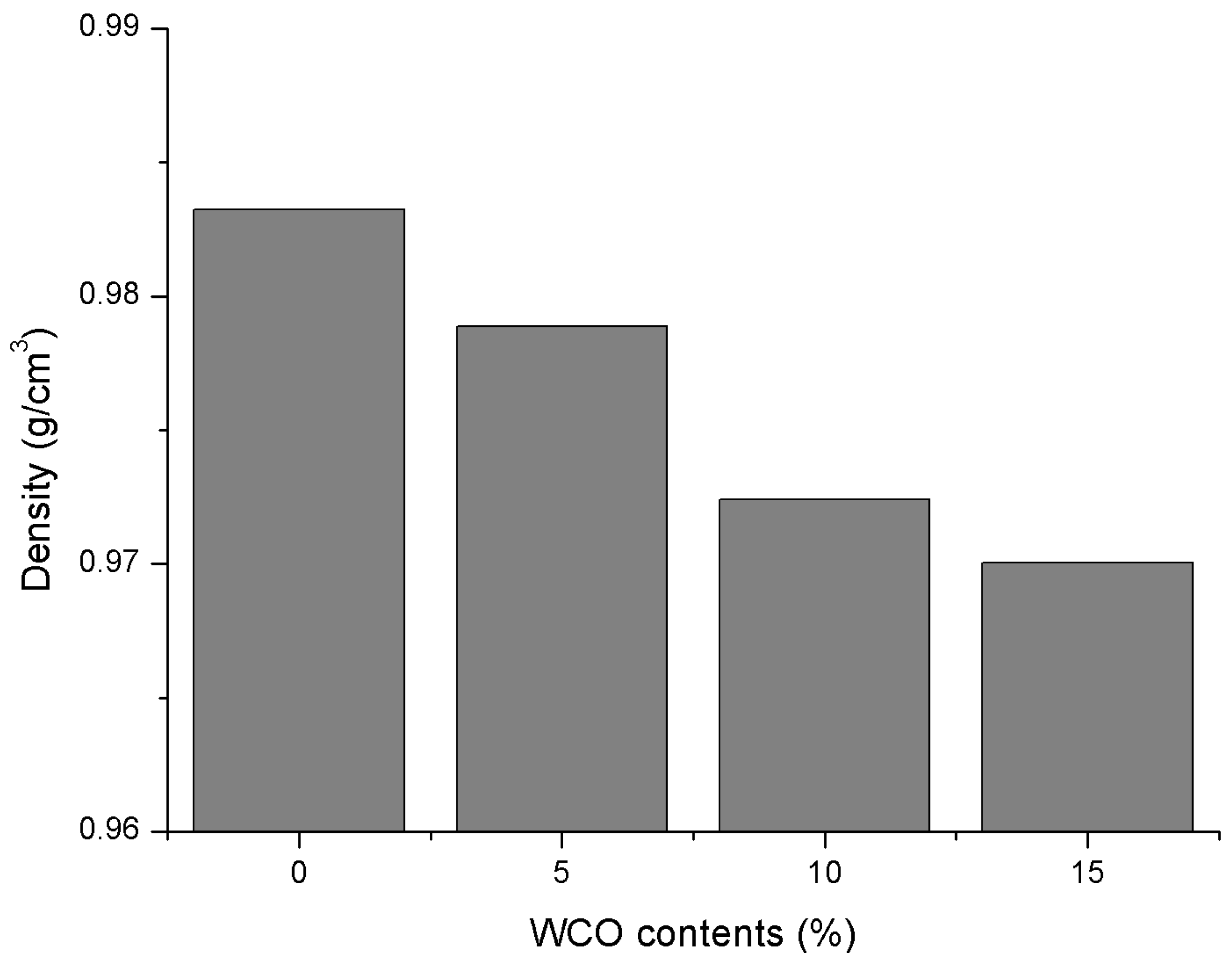

4.4.1. Density

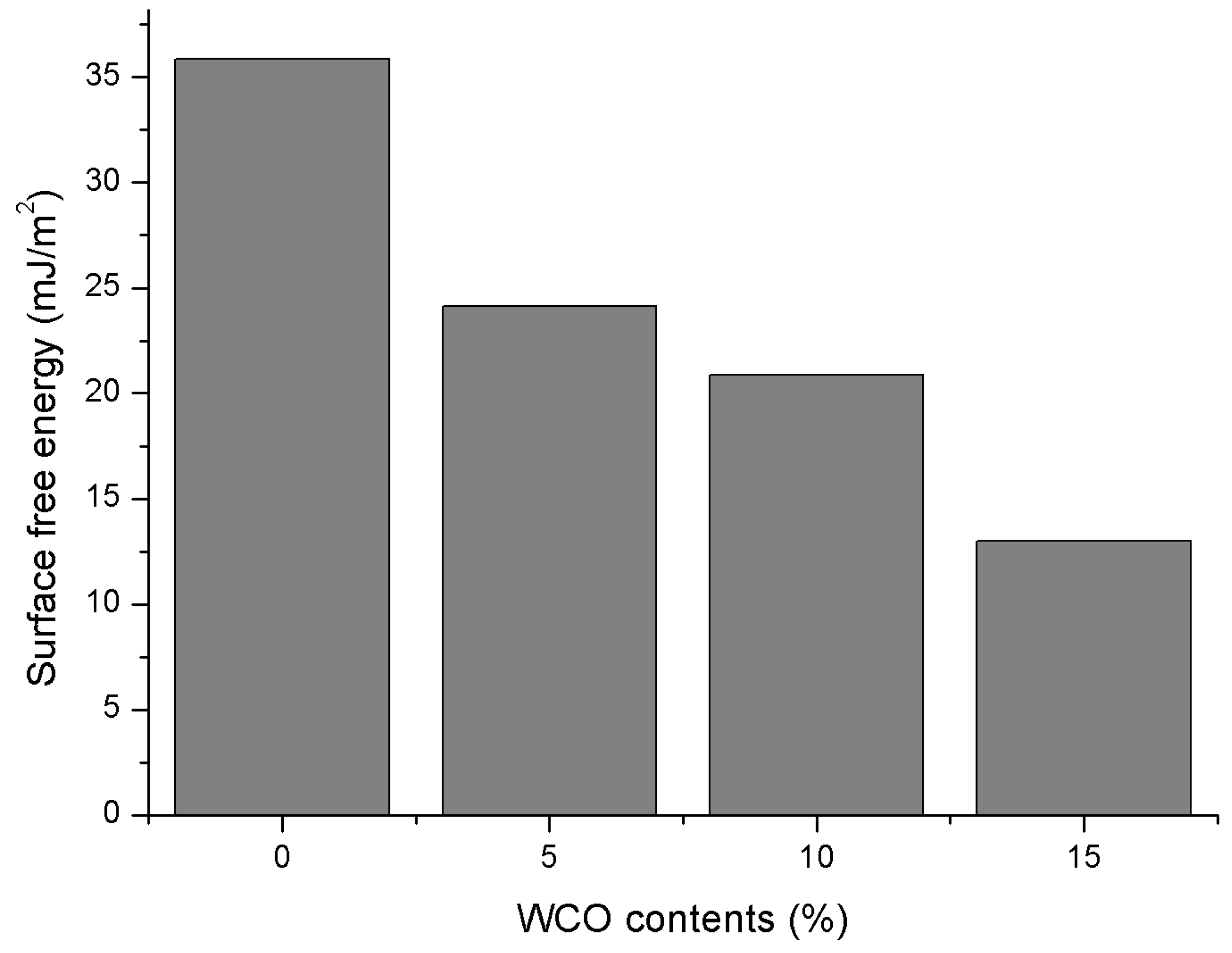

4.4.2. Surface Free Energy

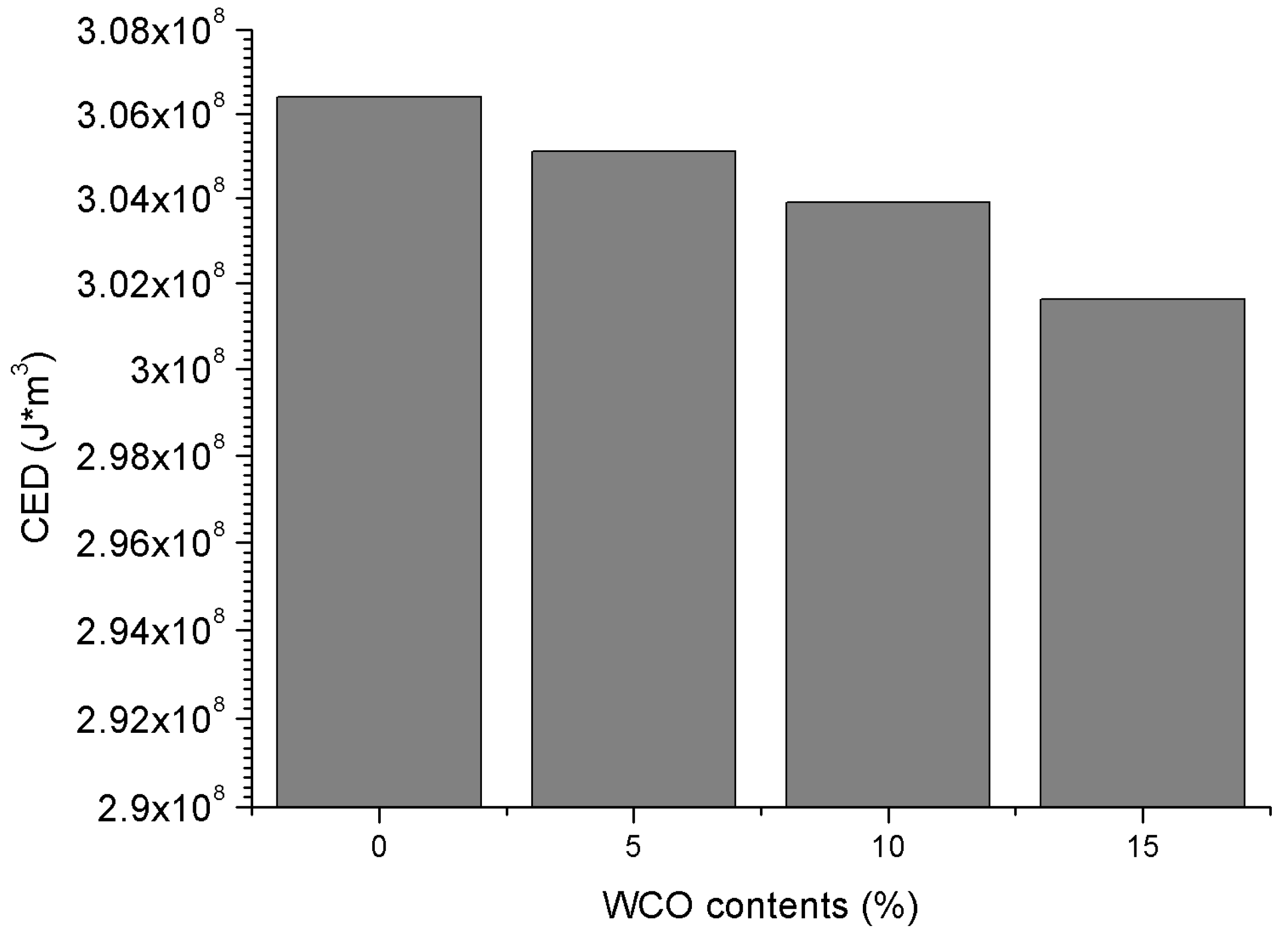

4.4.3. Cohesion Energy Density

5. Relationship between Micro-Properties and Macro-Performance

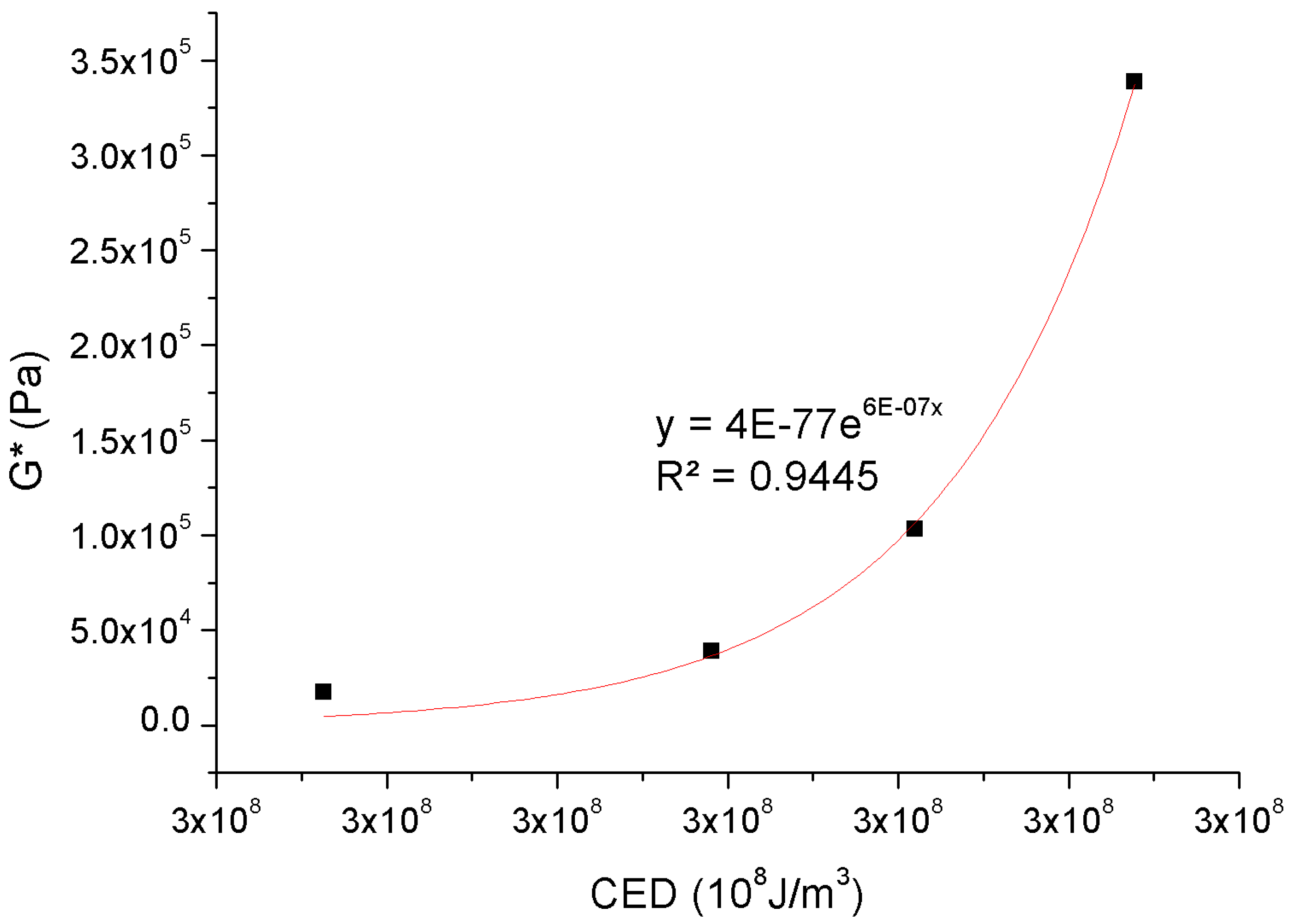

5.1. CED vs. Dynamic Modulus

5.2. Flexibility Index vs. Fatigue Life

6. Conclusions

- (1)

- From FTIR tests, it is demonstrated that the bio-oil modified binders displayed increased carbonyl index when increasing the bio-oil content, whereas the sulfoxide index almost exhibited the same level as that of the control asphalt. Further rheological performance tests indicated that the addition of bio-oil softened the stiffness and improved the fatigue resistance of the control asphalt.

- (2)

- A reasonable averaged molecular structure for bio-oil is created based on previous research findings and further validated with the FTIR results and the micro-scale properties in terms of density, SFE and CED from the MD simulation.

- (3)

- A larger CED at micro-scale level represents a stronger link between the molecules within asphalt binder to provide a better stability against shear deformation in the macro-scale. Therefore, the observed complex shear modulus decrease due to the bio-oil addition is well related to simulated CED properties for all tested binders. Meanwhile, a parameter of Flexibility Index (FI) is utilized to investigate the micro-scale fundamental mechanisms for the improved binder fatigue life from the addition of bio-oil. The more flexible the binder molecule is obtained, the better its fatigue resistance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Podolsky, J.H.; Buss, A.; Williams, R.C.; Cochran, E. Comparative performance of bio-derived/chemical additives in warm mix asphalt at low temperature. Mater. Struct. 2016, 49, 563–575. [Google Scholar] [CrossRef]

- Podolsky, J.H.; Buss, A.; Williams, R.C.; Cochran, E.W. The rutting and stripping resistance of warm and hot mix asphalt using bio-additives. Constr. Build. Mater. 2016, 112, 128–139. [Google Scholar] [CrossRef]

- Chen, C.; Podolsky, J.H.; Hernández, N.B.; Hohmann, A.D.; Williams, R.C.; Cochran, E.W. Preliminary investigation of bioadvantaged polymers as sustainable alternatives to petroleum-derived polymers for asphalt modification. Mater. Struct. 2017, 50, 225. [Google Scholar] [CrossRef]

- Król, J.B.; Niczke, Ł.; Kowalski, K.J. Towards understanding the polymerization process in bitumen bio-fluxes. Materials 2017, 10, e1058. [Google Scholar] [CrossRef] [PubMed]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterisation and modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Guarin, A.; Khan, A.; Butt, A.A.; Birgisson, B.; Kringos, N. An extensive laboratory investigation on the use of bio-oil modified asphalt in road construction. Constr. Build. Mater. 2016, 106, 133–139. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and fatigue evaluation of asphalt mixtures containing rap treated with a bio-agent. Appl. Sci. 2017, 7, 216. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q.; Mills-Beale, J. Mechanical performance of asphalt mixtures modified by bio-oils derived from waste wood resources. Constr. Build. Mater. 2014, 51, 424–431. [Google Scholar] [CrossRef]

- Raouf, M.; Williams, R. Temperature and shear susceptibility of a nonpetroleum binder as a pavement material. Trans. Res. Rec. J. Trans. Res. Board 2010, 9–18. [Google Scholar] [CrossRef]

- Raouf, M.A.; Williams, R.C. Temperature susceptibility of non-petroleum binders derived from bio-oils. In Proceedings of the 7th Asia Pasific Conference on Transportation and the Environment, Semarang, Indonesia, 3–5 June 2010. [Google Scholar]

- Seidel, J.C.; Haddock, J.E. Soy fatty acids as sustainable modifier for asphalt binders. In Alternative Binders for Sustainable Asphalt Pavements; Purdue University: Washington, DC, USA, 2012. [Google Scholar]

- Peralta, J.; Raouf, M.A.; Tang, S.; Williams, R.C. Bio-Renewable Asphalt Modifiers and Asphalt Substitutes; Springer: London, UK, 2012; Volume 62, pp. 89–115. [Google Scholar]

- Mohamed, A.R.; Williams, C. General rheological properties of fractionated switchgrass bio-oil as a pavement material. Road Mater. Pavement Des. 2010, 11, 325–353. [Google Scholar]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Mills-Beale, J. Asphalt binders blended with a high percentage of biobinders: Aging mechanism using ftir and rheology. J. Mater. Civ. Eng. 2015, 27, 04014157. [Google Scholar] [CrossRef]

- Pahlavan, F.; Mousavi, M.; Hung, A.M.; Fini, E.H. Characterization of oxidized asphaltenes and the restorative effect of a bio-modifier. Fuel 2018, 212, 593–604. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H. Chemical characterization of biobinder from swine manure: Sustainable modifier for asphalt binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Bennert, T.; Ericson, C.; Corun, R.; Fee, F.; Bennert, T.; Ericson, C. Performance of asphalt binders modified with Re-refined Engine Oil Bottoms (REOB). In Proceedings of the Chinese–European Workshop on Functional Pavement Design, Delft, The Netherlands, 29 June–1 July 2016; pp. 427–434. [Google Scholar]

- Li, X.; Gibson, N.; Andriescu, A.; Arnold, T.S. Performance evaluation of reob-modified asphalt binders and mixtures. Road Mater. Pavement Des. 2017, 18, 128–153. [Google Scholar] [CrossRef]

- Cooper, S.B.; Mohammad, L.N.; Elseifi, M.A. Laboratory performance of asphalt mixtures containing recycled asphalt shingles and re-refined engine oil bottoms. J. Mater. Civ. Eng. 2017, 29, 04017106. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Austerman, A.; Al-Qadi, I.L.; Buttlar, W.; Ozer, H.; Hill, B. Using binder and mixture space diagrams to evaluate the effect of re-refined engine oil bottoms on binders and mixtures after ageing. Road Mater. Pavement Des. 2017, 18, 154–182. [Google Scholar] [CrossRef]

- Yaakob, Z.; Mohammad, M.; Alherbawi, M.; Alam, Z.; Sopian, K. Overview of The Production of Biodiesel from Waste Cooking Oil. Renew. Sustain. Energy Rev. 2013, 18, 184–193. [Google Scholar] [CrossRef]

- Mohammadshirazi, A.; Akram, A.; Rafiee, S.; Kalhor, E.B. Energy and Cost Analyses of Biodiesel Production from Waste Cooking Oil. Renew. Sustain. Energy Rev. 2014, 33, 44–49. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Z.; Zhou, D.; Cao, J. Waste Cooking Oil-to-Energy under Incomplete Information: Identifying Policy Options through an Evolutionary Game. Appl. Energy 2017, 185, 547–555. [Google Scholar] [CrossRef]

- Wen, H.; Bhusal, S.; Wen, B. Laboratory Evaluation of Waste Cooking Oil-Based Bio-Asphalt as an Alternative Binder for Hot Mix Asphalt. ASCE J. Mater. Civ. Eng. 2013, 25, 1432–1437. [Google Scholar] [CrossRef]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of Asphalt Binder Modified by Bio-Oil Derived from Waste Cooking Oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Chemical Modification of Waste Cooking Oil to Improve the Physical and Rheological Properties of Asphalt Binder. Constr. Build. Mater. 2016, 126, 218–226. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on Physical Properties of Waste Cooking Oil – Rejuvenated Bitumen Binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of The Possibility of Using Waste Cooking Oil as a Rejuvenating Agent for Aged Bitumen. J. Hazard. Mater. 2012, 233, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Xiao, F.; Putman, B.; Leng, B.; Wu, S. High Temperature Properties of Rejuvenating Recovered Binder with Rejuvenator, Waste Cooking and Cotton Seed Oils. Constr. Build. Mater. 2014, 59, 10–16. [Google Scholar] [CrossRef]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, Chemical and Rheological Properties of Waste Edible Vegetable Oil Rejuvenated Asphalt Binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Su, J.; Qiu, J.; Schlangen, E.; Wang, Y. Investigation the Possibility of a New Approach of Using Microcapsules Containing Waste Cooking Oil: In Situ Rejuvenation for Aged Bitumen. Constr. Build. Mater. 2015, 74, 83–92. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical–Chemical Properties of Aged Asphalt Rejuvenated by Bio-oil Derived from Biodiesel Residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Hou, Y.; Sun, W.; Huang, Y.; Ayatollahi, M.; Wang, L.; Zhang, J. Diffuse Interface Model to Investigate the Asphalt Concrete Cracking Subjected to Shear Loading at a LowTemperature. J. Cold Reg. Eng. 2017, 31, 04016009. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, L.; Wang, D.; Liu, P.; Guo, M.; Yu, J. Characterization of Bitumen Micro-mechanical Behaviors Using AFM, Phase Dynamics Theory and MD Simulation. Materials 2017, 10, 208. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Guo, M.; Ge, Z.; Wang, L.; Sun, W. Mixed-Mode I-II Cracking Characterization of Mortar using Phase-Field Method. J. Eng. Mech. 2017, 143, 04017033. [Google Scholar] [CrossRef]

- Bhasin, A.; Bommavaram, R.; Greenfield, M.L.; Little, D.N. Use of molecular dynamics to investigate self-healing mechanisms in asphalt binders. J. Mater. Civ. Eng. 2010, 23, 485–492. [Google Scholar] [CrossRef]

- Bhasin, A.; Motamed, A. Analytical models to characterise crack growth in asphaltic materials and healing in asphalt binders. Int. J. Pavement Eng. 2011, 12, 371–383. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Study of cohesion and adhesion properties of asphalt concrete with molecular dynamics simulation. Comput. Mater. Sci. 2016, 112, 161–169. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel 2017, 188, 1–10. [Google Scholar] [CrossRef]

- Guo, M.; Huang, Y.; Wang, L.; Yu, J.; Hou, Y. Using Atomic Force Microscopy and Molecular Dynamics Simulation to Investigate the Asphalt Micro Properties. Int. J. Pavement Res. Technol. 2017. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.; Wang, L.; Hou, Y. Diffusion of asphaltene, resin, aromatic and saturate components of asphalt on mineral aggregates surface: Molecular dynamics simulation. Road Mater. Pavement Des. 2017, 18, 1–10. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X.; Zhang, Y.; Woods, M.E. Use of molecular dynamics to investigate diffusion between virgin and aged asphalt binders. Fuel 2016, 174, 267–273. [Google Scholar] [CrossRef]

- Standard Test Method for Penetration of Bituminous Materials; D5; ASTM: West Conshohocken, PA, USA, 1992.

- Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); D36; ASTM: West Conshohocken, PA, USA, 2009.

- Standard Test Method for Ductility of Asphalt Materials; D113; ASTM: West Conshohocken, PA, USA, 2009.

- Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; D4402; ASTM: West Conshohocken, PA, USA, 2015.

- Wang, Y. The effects of using reclaimed asphalt pavements (RAP) on the long-term performance of asphalt concrete overlays. Constr. Build. Mater. 2016, 120, 335–348. [Google Scholar] [CrossRef]

- AASHTO. Standard Method of Test for Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep; AASHTP TP 101; AASHTO: Washington, DC, USA, 2014. [Google Scholar]

- Johnson, C.M. Estimating Asphalt Binder Fatigue Resistance Using an Accelerated Test Method. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 2010. [Google Scholar]

- Hintz, C.; Bahia, H. Simplification of linear amplitude sweep test and specification parameter. Trans. Res. Rec. J. Trans. Res. Board 2013, 2370, 10–16. [Google Scholar] [CrossRef]

- Kim, Y.R.; Lee, H.J.; Little, D.N. Fatigue characterization of asphalt concrete using viscoelasticity and continuum damage theory (with discussion). J. Assoc. Asph. Paving Technol. 1997, 66, 520–569. [Google Scholar]

- Daniel, J.S.; Kim, Y.R. Development of a simplified fatigue test and analysis procedure using a viscoelastic, continuum damage model (with discussion). J. Assoc. Asph. Paving Technol. 2002, 71, 619–650. [Google Scholar]

- Underwood, B.S. Multiscale Constitutive Modeling of Asphalt Concrete; North Carolina State University: Raleigh, NC, USA, 2011. [Google Scholar]

- Wang, C.; Castorena, C.; Zhang, J.; Richard Kim, Y. Unified failure criterion for asphalt binder under cyclic fatigue loading. Road Mater. Pavement Des. 2015, 16, 125–148. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.; Bahia, H. Comparison of the fatigue failure behaviour for asphalt binder using both cyclic and monotonic loading modes. Constr. Build. Mater. 2017, 151, 767–774. [Google Scholar] [CrossRef]

- Lamontagne, J.; Dumas, P.; Mouillet, V.; Kister, J. Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: Application to road bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

- Wiehe, I.A.; Liang, K.S. Asphaltenes, resins, and other petroleum macromolecules. Fluid Phase Equilib. 1996, 117, 201–210. [Google Scholar] [CrossRef]

- Corbett, L.W. Composition of asphalt based on generic fractionation, using solvent deasphaltening, elution-adsorption chromatography and densimetric characterization. Anal. Chem. 1969, 41, 576–579. [Google Scholar] [CrossRef]

- Šebor, G.; Blažek, J.; Nemer, M.F. Optimization of the preparative separation of petroleum maltenes by liquid adsorption chromatographiy. J. Chromatogr. A 1999, 847, 323–330. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphaltsystems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Oldenburg, T.B.P.; Huang, H.; Donohoe, P.; Willsch, H.; Larter, S.R. High molecular weight aromatic nitrogen and other novel hopanoid-related compounds in crude oils. Org. Geochem. 2004, 35, 665–678. [Google Scholar] [CrossRef]

- Strausz, O.P.; Peng, P.; Murgich, J. About the colloidal nature of asphaltenes and the MW of covalent monomeric units. Energy Fuels 2002, 16, 809–822. [Google Scholar] [CrossRef]

- Lira-Galeana, C.; Hammami, A. Wax Precipitation from Petroleum Fluids: A Review; Yen, T.F., Chilingarian, G.V., Eds.; Asphalts and Asphaltenes, 2. Developments in Petroleum Science Series; Elsevier: New York, NY, USA, 2000; Volume 40b, pp. 557–608. [Google Scholar]

- Simanzhenkov, V.; Idem, R. Crude Oil Chemistry; Marcel Dekker, Inc.: New York, NY, USA, 2003. [Google Scholar]

- Li, D.D.; Greenfield, M.L. High internal energies of proposed asphaltene structures. Energy Fuels 2011, 25, 3698–3705. [Google Scholar] [CrossRef]

- Koopmans, M.P.; De Leeuw, J.W.; Lewan, M.D.; Damsté, J.S.S. Impact of dia- and catagenesis on sulphur and oxygen sequestration of biomarkers as revealed by artificial maturation of an immature sedimentary rock. Org. Geochem. 1996, 25, 391–426. [Google Scholar] [CrossRef]

- Koopmans, M.P.; De Leeuw, J.W.; Damsté, J.S.S. Novel cyclised and aromatized diagenetic products of b-carotene in the Green River shale. Org. Geochem. 1997, 26, 451–466. [Google Scholar] [CrossRef]

- Marynowski, L.; Rospondek, M.J.; Reckendorf, R.M.; Simoneit, B.R.T. Phenyldibenzofurans and phenyldibenzothiophenes in marine sedimentary rocks and hydrothermal petroleum. Org. Geochem. 2002, 33, 701–714. [Google Scholar] [CrossRef]

- Cai, C.; Zhang, C.; Cai, L.; Wu, G.; Jiang, L.; Xu, Z. Origins of palaeozoic oils in the Tarim basin: Evidence from sulfur isotopes and biomarkers. Chem. Geol. 2009, 268, 197–210. [Google Scholar] [CrossRef]

- Mullins, O.C. The modified Yen model. Energy Fuels 2010, 24, 2179–2207. [Google Scholar] [CrossRef]

- Dickie, J.P.; Yen, T.F. Macrostructures of asphaltic fractions by various instrumental methods. Anal. Chem. 1967, 39, 1847–1852. [Google Scholar] [CrossRef]

- Svennerholm, L. The nomenclature of lipids. IUPAC-IUB Commission on Biochemical Nomenclature (CBN). Eur. J. Biochem. 1977, 79, 11–21. [Google Scholar]

- Liu, Q.; Cai, B.; Yuan, L.; Zhou, Y.; Huang, J.; He, Y. The clustering analysis of the illegal cooked oil based on high pressure liquid chromatography. J. Food Saf. Qual. 2013, 4, 401–409. [Google Scholar]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnology advances. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y. Study on the composition of edible oil triglycerides and HPLC determination. Ph.D. Thesis, Southern Yangtze University, Wuxi, China, 2015. [Google Scholar]

- Bunte, S.W.; Sun, H. Molecular modeling of energetic materials: The parameterization and validation of nitrate esters in the COMPASS force field. J. Phys. Chem. B 2000, 104, 2477–2489. [Google Scholar] [CrossRef]

- Information of Glycerol Tristearate in Chemicalbook. Available online: http://www.chemicalbook.com/ChemicalProductProperty_EN_CB1110089.htm (accessed on 8 November 2017).

- Wei, J.; Dong, F.; Li, Y.; Zhang, Y. Relationship analysis between surface free energy and chemical composition of asphalt binder. Constr. Build. Mater. 2014, 71, 116–123. [Google Scholar] [CrossRef]

- Bristow, G.M.; Watson, W.F. Cohesive energy densities of polymers. part 2.—Cohesive energy densities from viscosity measurements. Trans. Faraday Soc. 1958, 54, 1742–1747. [Google Scholar] [CrossRef]

- Cheng, G.; Li, Z.; Qi, D. Mechano-chemical molecular chains model of fatigue damage for fibre-reinforced polymeric matrix composites. Chin. J. Mater. Res. 2004, 18, 25–33. [Google Scholar]

- Kier, L.B. An index of molecular flexibility from kappa shape attributes. Qsar Comb. Sci. 2010, 8, 221–224. [Google Scholar] [CrossRef]

| Properties | Standard Test Method | Test Results |

|---|---|---|

| Penetration at 25 °C/0.1 mm | ASTM D5 [44] | 75 |

| Softening point/°C | ASTM D36 [45] | 49 |

| Ductility at 5 °C/mm | ASTM D113 [46] | 35.5 |

| Viscosity at 135 °C/Pa s | ASTM D4402 [47] | 0.35 |

| Materials | Binder ID | Percent Weight of Bio-Oil Addition |

|---|---|---|

| Control 60/80 asphalt binder | 70# | - |

| WCO-based Bio-oil modified asphalt binders | 70# + 5% WCO | 5% WCO |

| 70# + 10% WCO | 10% WCO | |

| 70# + 15% WCO | 15% WCO |

| Binder ID | IC=O | IC-O | IS=O |

|---|---|---|---|

| 70# | 0.031 | 0.045 | 0.030 |

| 70# + 5% WCO | 0.032 | 0.053 | 0.027 |

| 70# + 5% WCO | 0.035 | 0.062 | 0.030 |

| 70# + 5% WCO | 0.038 | 0.071 | 0.028 |

| WCO | 0.058 | 0.225 | 0.032 |

| Molecule | Number | Molecule | Number |

|---|---|---|---|

| Squalane | 4 | DOCHN | 13 |

| Hopane | 4 | Quinolinohopane | 4 |

| Asphaltene-phenol | 3 | Thioisorenieratane | 4 |

| Asphaltene-pyrrole | 2 | Trimethylbenzeneoxane | 5 |

| Asphaltene-thiophene | 3 | Pyridinohopane | 4 |

| PHPN | 11 | Benzobisbenzothiophene | 15 |

| Molecule | Flexibility Index | Molecule | Flexibility Index |

|---|---|---|---|

| Squalane | 19.67 | Quinolinohopane | 6.13 |

| Hopane | 6.87 | Thioisorenieratane | 13.22 |

| Asphaltene-phenol | 12.03 | Trimethylbenzeneoxane | 9.92 |

| Asphaltene-pyrrole | 8.76 | Pyridinohopane | 6.11 |

| Asphaltene-thiophene | 9.01 | Benzobisbenzothiophene | 2.07 |

| PHPN | 6.50 | WCO | 55.53 |

| DOCHN | 10.27 | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, X.; Liu, Q.; Wang, C.; Wang, D.; Oeser, M. Effect of Co-Production of Renewable Biomaterials on the Performance of Asphalt Binder in Macro and Micro Perspectives. Materials 2018, 11, 244. https://doi.org/10.3390/ma11020244

Qu X, Liu Q, Wang C, Wang D, Oeser M. Effect of Co-Production of Renewable Biomaterials on the Performance of Asphalt Binder in Macro and Micro Perspectives. Materials. 2018; 11(2):244. https://doi.org/10.3390/ma11020244

Chicago/Turabian StyleQu, Xin, Quan Liu, Chao Wang, Dawei Wang, and Markus Oeser. 2018. "Effect of Co-Production of Renewable Biomaterials on the Performance of Asphalt Binder in Macro and Micro Perspectives" Materials 11, no. 2: 244. https://doi.org/10.3390/ma11020244