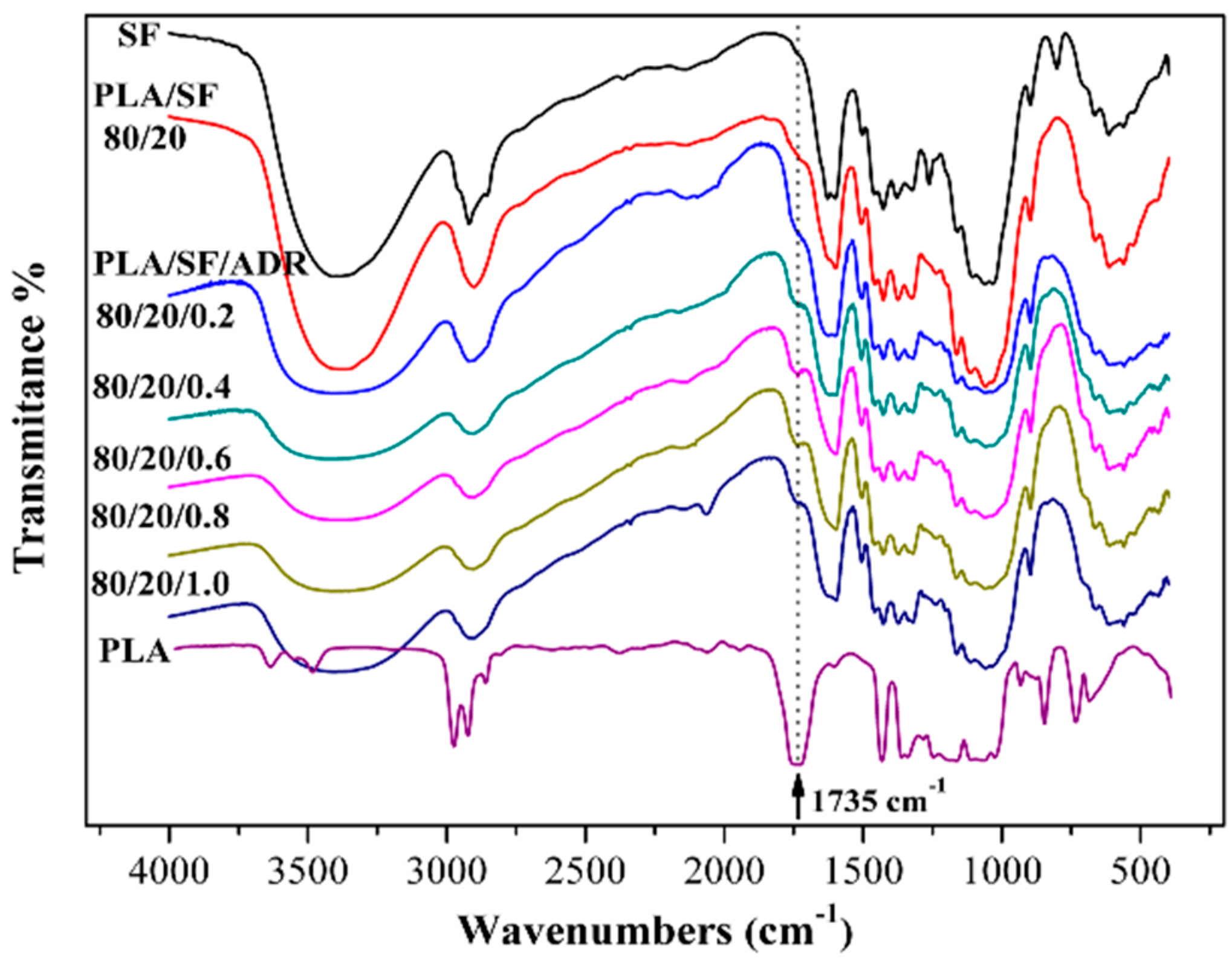

3.1. Morphology Analysis

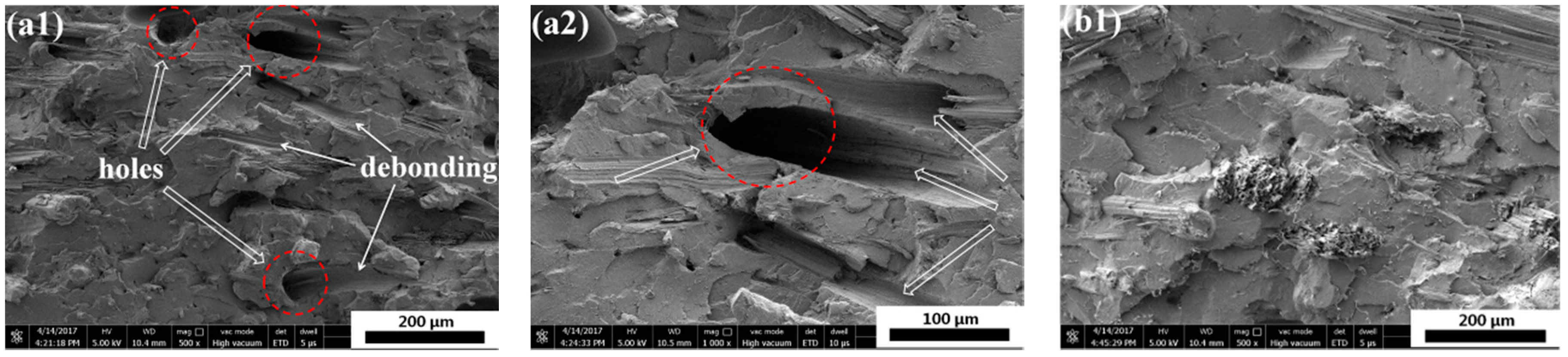

The impact fracture surfaces of PLA/SF and PLA/SF/ADR composites with constant 20 wt % SF content and different ADR addition are shown in

Figure 1. It can be seen from

Figure 1a, that for PLA/SF composites many fibers were directly pulled out from PLA matrix, and many holes were formed in the fracture surfaces, reflecting poor interfacial adhesion between the PLA matrix and sisal fibers. However, the addition of ADR into composites during melt-blending processing could effectively counteract this phenomenon, as shown in

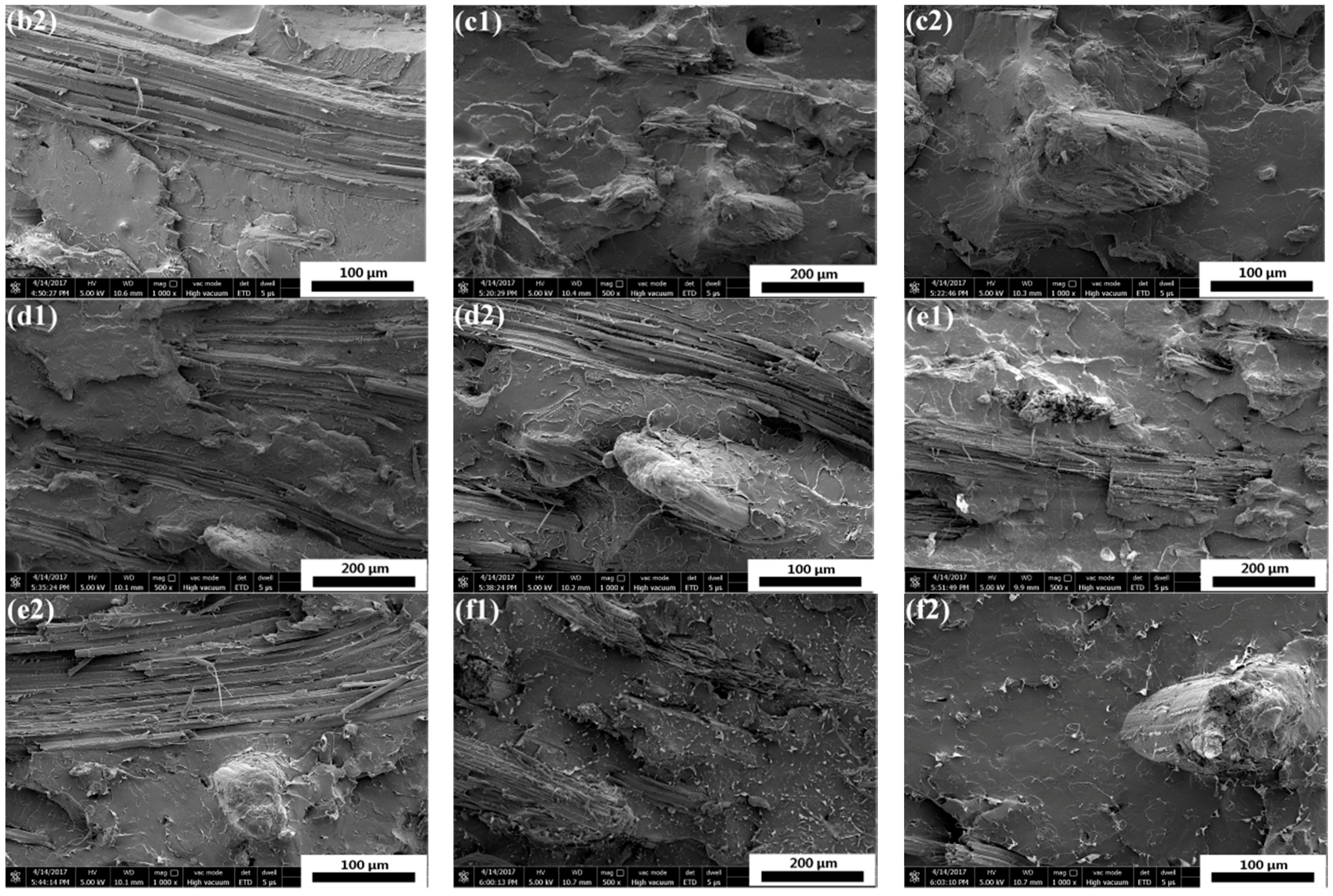

Figure 1b–f for which the ADR content varied from 0.2 wt % to 1.0 wt %. For PLA/SF/ADR composites, the fibers were tightly connected with matrix and it was observed that more fibers were broken up or torn off in composites with ADR addition compared with that of PLA/SF composites. These phenomena demonstrated the improved interfacial adhesion of PLA/SF/ADR composites via addition of ADR compared with that of PLA/SF composites. In order to further confirm this result, the impact fracture surfaces of PLA/SF composites and PLA/SF/ADR composites with different SF content are presented in

Figure 2. For PLA/SF composites, similar phenomena were observed. Many fibers were directly pulled out from PLA matrix and many holes were formed in the fracture surfaces, reflecting poor interfacial adhesion (

Figure 2a–d). It was also observed that the more SF was added, the more fracture defects occurred. The presence of ADR improved the interfacial adhesion between SF and PLA matrix (

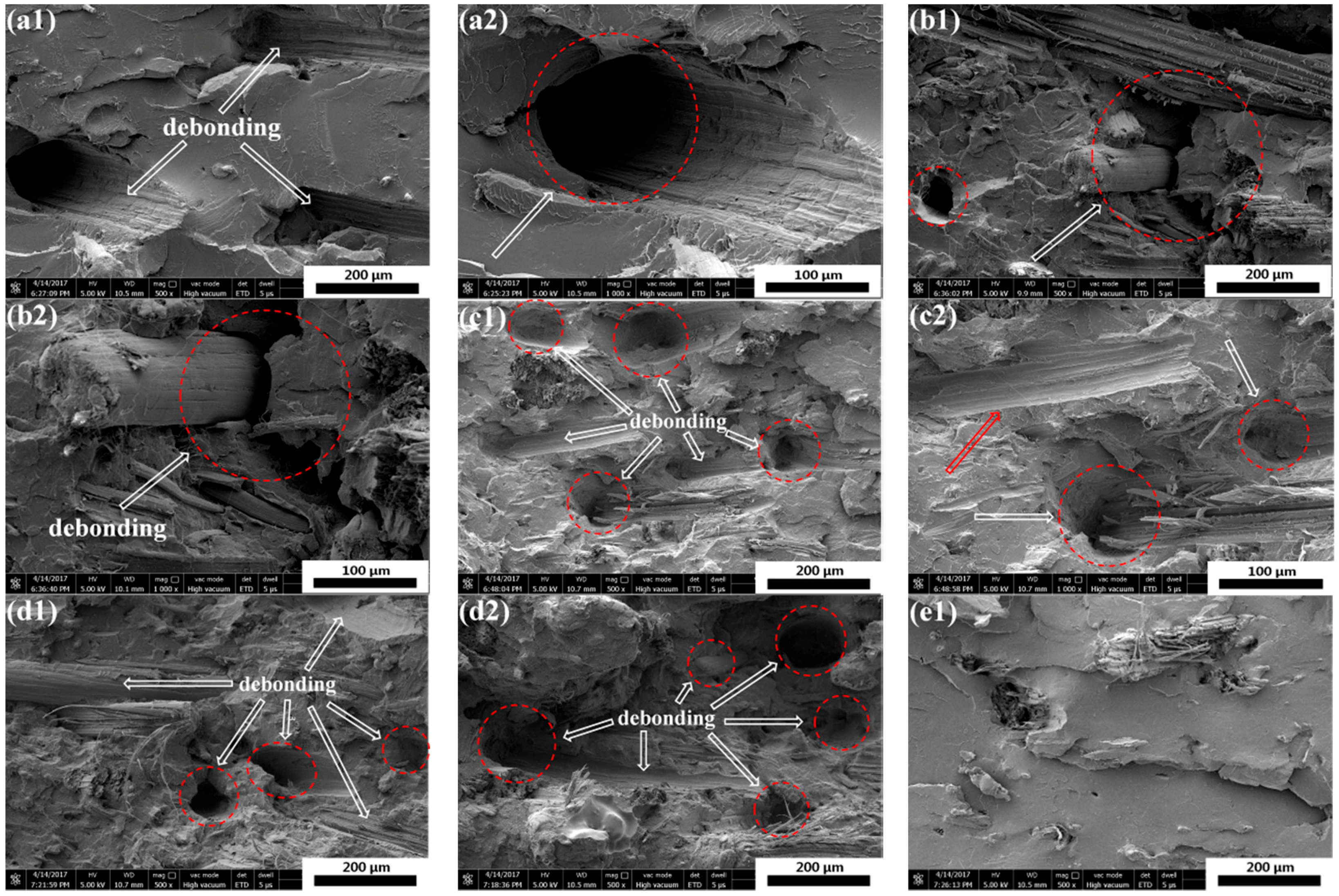

Figure 2e–h). Furthermore, the tensile fracture surfaces of PLA/SF composites and PLA/SF/ADR composites with different SF content are shown in

Figure 3. It can be seen from

Figure 3a–d that the sisal fibers were directly pulled out from the PLA matrix in PLA/SF composites, which impairs the reinforcing effect of SF during tensile tests. However, for PLA/SF/ADR composites, the improved interfacial adhesion between the SF and PLA matrix caused many fibers to be broken up or torn off in the tensile fracture surface, which indicated that the fibers bore the load in the tensile tests.

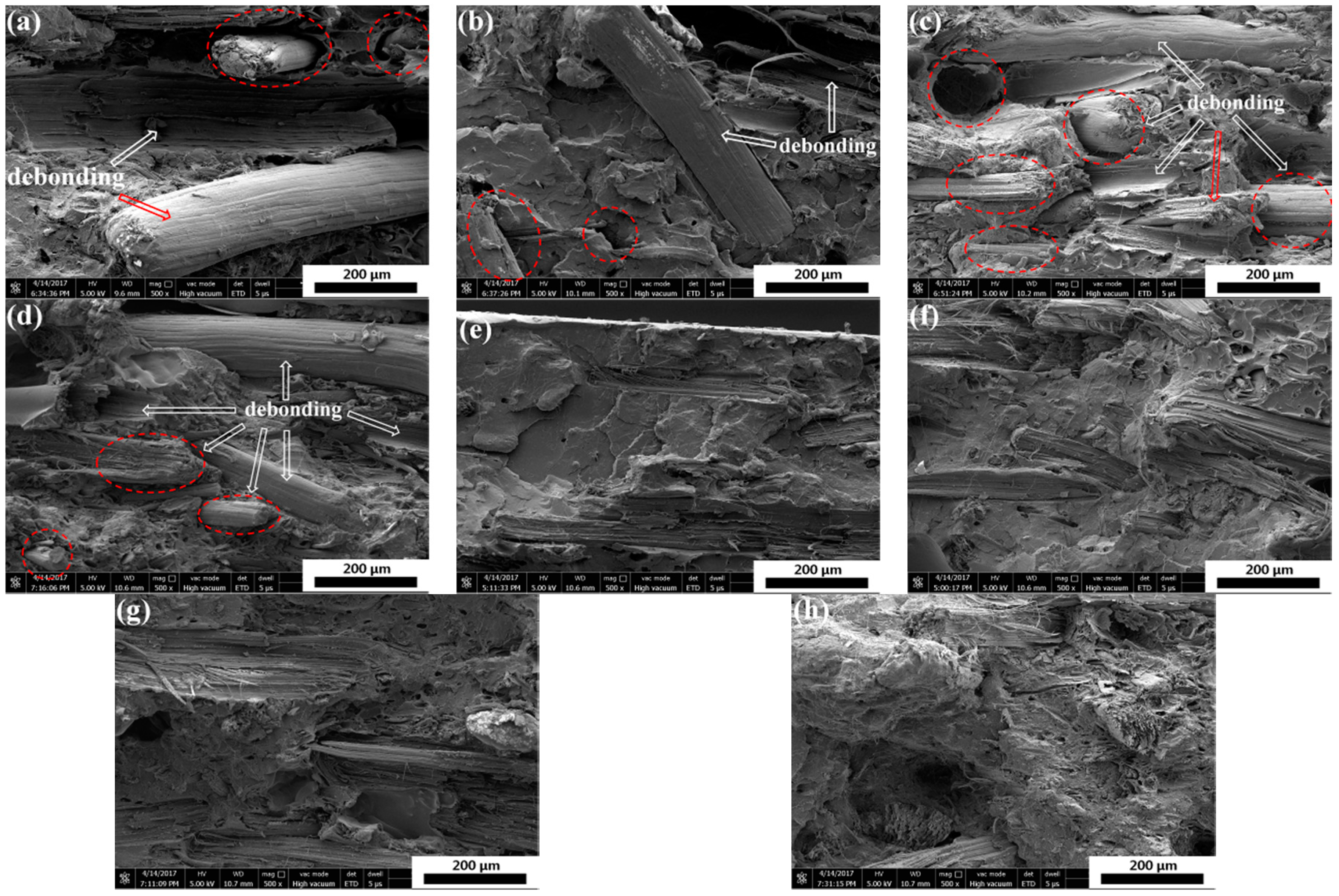

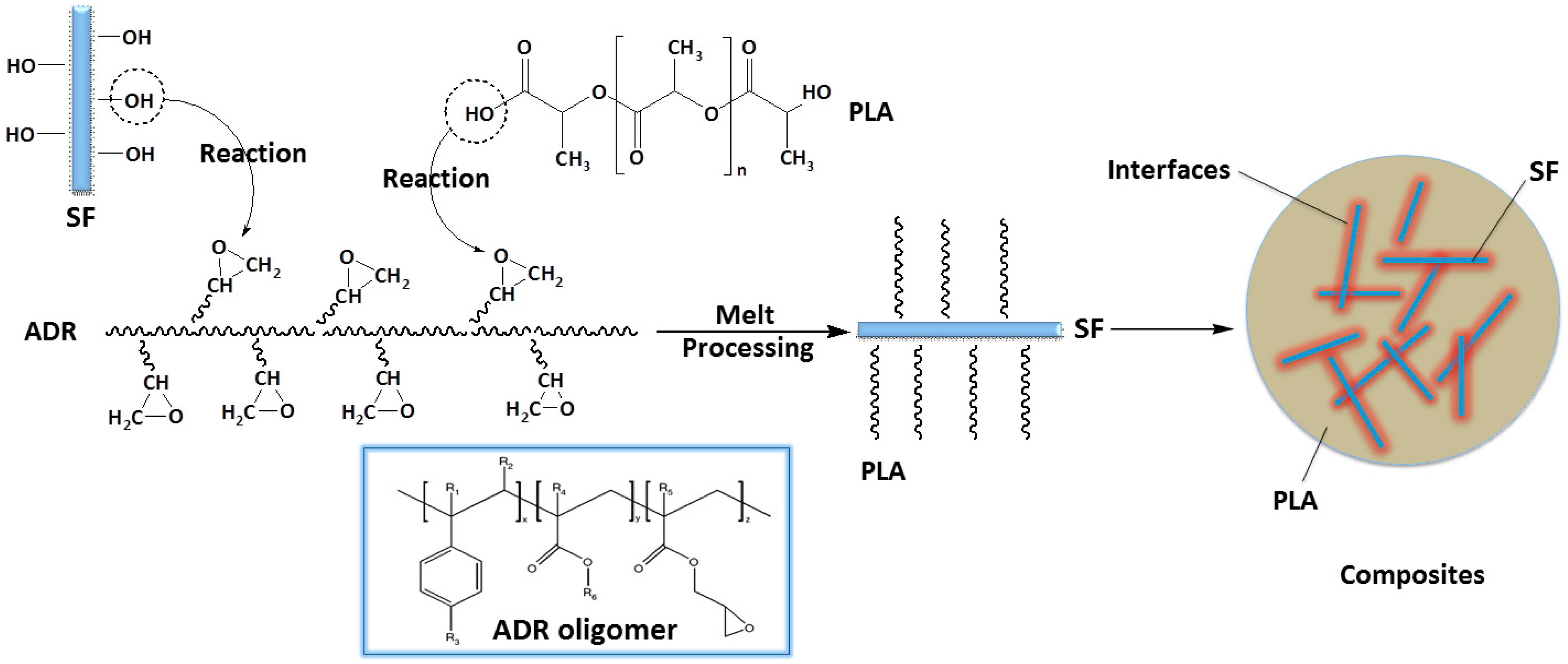

Many modification methods of PLA resin are based on the reaction ability of the end group of PLA molecule chain, that are hydroxyl and carboxyl, by which the typical works are reaction toughening of PLA [

22,

23,

24,

25,

26]. The presence of hydroxyl groups on the natural fiber surface enables the bonding of PLA by functional group reaction, therefore improving the interfacial compatibility between fibers and PLA matrix. In this study, PLA and sisal fibers were melt-blended to fabricate bio-based composites via in situ reactive interfacial compatibilization with addition of an epoxy-functionalized oligomer.

Figure 4 presents the illustration of interfacial compatibilization between PLA and SF via in situ reaction with the ADR oligomer during the melt-blending processing. ADR is a kind of multi-epoxy-functionalized oligomer [

19,

20,

21], which can react with end group of PLA and hydroxyl groups on natural fiber surfaces. It might bond PLA molecules onto the fiber surface and play a hinge-like role between sisal fibers and the PLA matrix. Therefore, the addition of ADR can improve the interfacial compatibility of composites. The improved interfacial adhesion of PLA/SF/ADR composites can be observed in the above-mentioned SEM images.

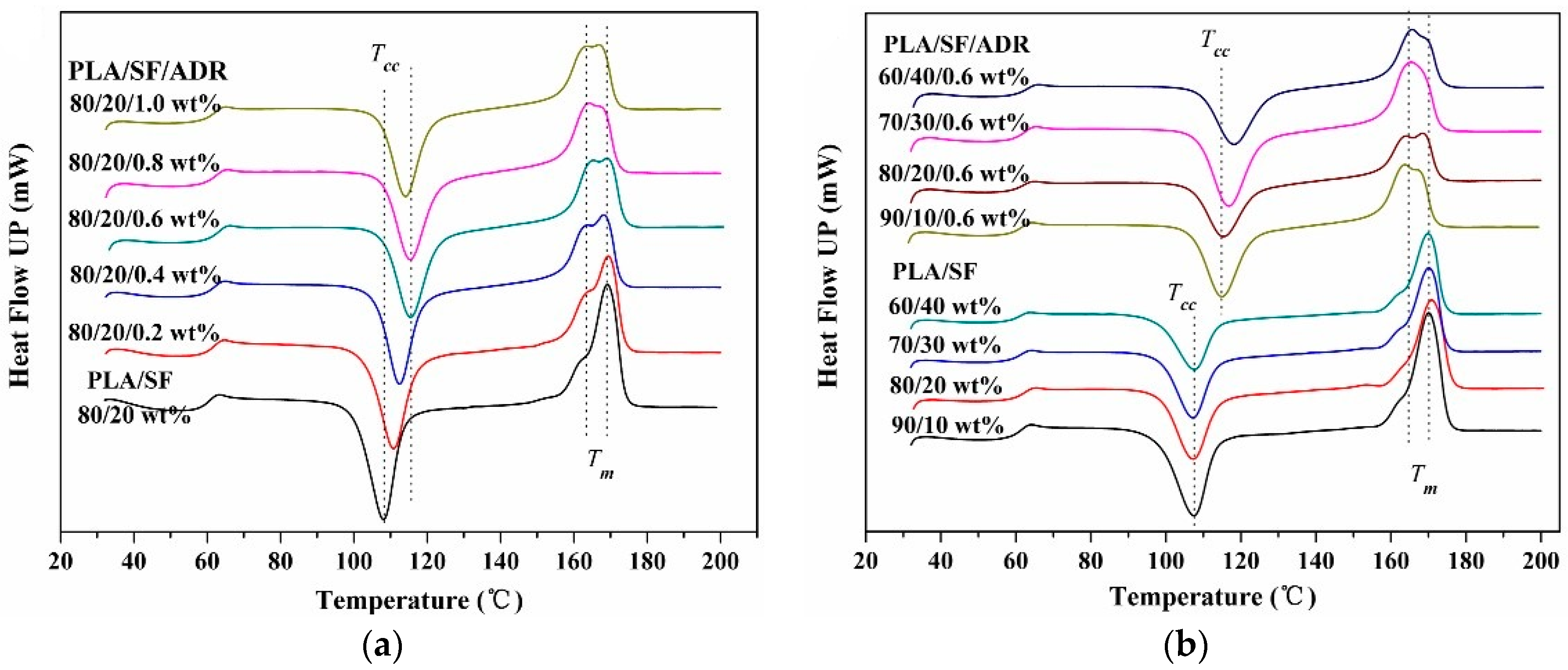

3.3. DSC Thermal Behaviors

Figure 6a shows the DSC thermograms of PLA/SF composites and PLA/SF/ADR composites with constant 20 wt % SF and different ADR addition, from 0.2 wt % to 1.0 wt %, at the second heating scan. A cold crystallization peak and melting peak occurred in

Figure 6a. At the second heating scan, as the temperature elevated, the frozen PLA chain segments regain movement ability, resulting in the presence of cold crystallization. It can be seen from

Figure 6a that the cold crystallization temperature (

Tcc) of PLA/SF/ADR composites shifts to a higher temperature region compared with PLA/SF composites. The cold crystallization temperatures (

Tcc) for PLA/SF and PLA/SF/ADR composites with different ADR additions are listed in

Table 2. The

Tcc was improved with the addition of ADR oligomer, which meant that PLA/SF/ADR composites need higher temperature to regain chain segments movement ability in comparison with that of PLA/SF composites. Therefore, this phenomenon demonstrated the restricted chain movement ability of PLA/SF/ADR composites [

27]. This result can be ascribed to the improved interfacial interaction between PLA and SF via addition of ADR. However, the

Tcc of PLA/SF/ADR (80/20/1.0) composites was 114.1 °C, which was reduced compared with that of PLA/SF/ADR (80/20/0.8) composites (115.5 °C), which implied that excessive addition of ADR might be detrimental to the connecting effect of ADR between SF and PLA matrix.

At the same time, it was also found that with the addition of ADR oligomer, an obvious shoulder peak appeared in the left of the melting endothermal peak (

Tm 169.5 °C) for PLA/SF/ADR composites, which indicated the formation of poor crystalline regions within PLA [

28,

29], corresponding to lower melting temperature. The improved interfacial interaction of PLA/SF/ADR composites resulted in restricted molecular chain movement of PLA and then more poor crystalline regions formed in the crystal growth stage, therefore a shoulder peak corresponding to lower melting temperature occurred for PLA/SF/ADR composites. The presence of a peak shoulder might also be ascribed to the formation of different crystalline structures within PLA, referred to as transcrystallinity [

15].

To further confirm these results,

Figure 6b presents the DSC thermograms of PLA/SF composites and PLA/SF/ADR composites with different SF content at the second heating scan. The cold crystallization temperatures are presented in

Table 3. For PLA/SF/ADR composites, the

Tcc increased considerably in comparison with PLA/SF composites, and an obvious shoulder peak arose in the left of the melting endothermal peak. These results were consistent with

Figure 6a. At the same time, it was found that the change of SF content had little effect on

Tcc of PLA/SF composites. However, the

Tcc of PLA/SF/ADR composites improved with increasing SF content. For PLA/SF composites, poor interfacial interaction between SF and PLA matrix revealed that excessive addition of SF has little effect on the movement of PLA chain segments. By contrast, for PLA/SF/ADR composites, the more SF was added, the more the sisal fibers participated in the interfacial reaction. As a result, the improved interfacial interaction between SF and the PLA matrix caused more severe restriction of PLA chain segment movement and the

Tcc of PLA/SF/ADR composites increased.

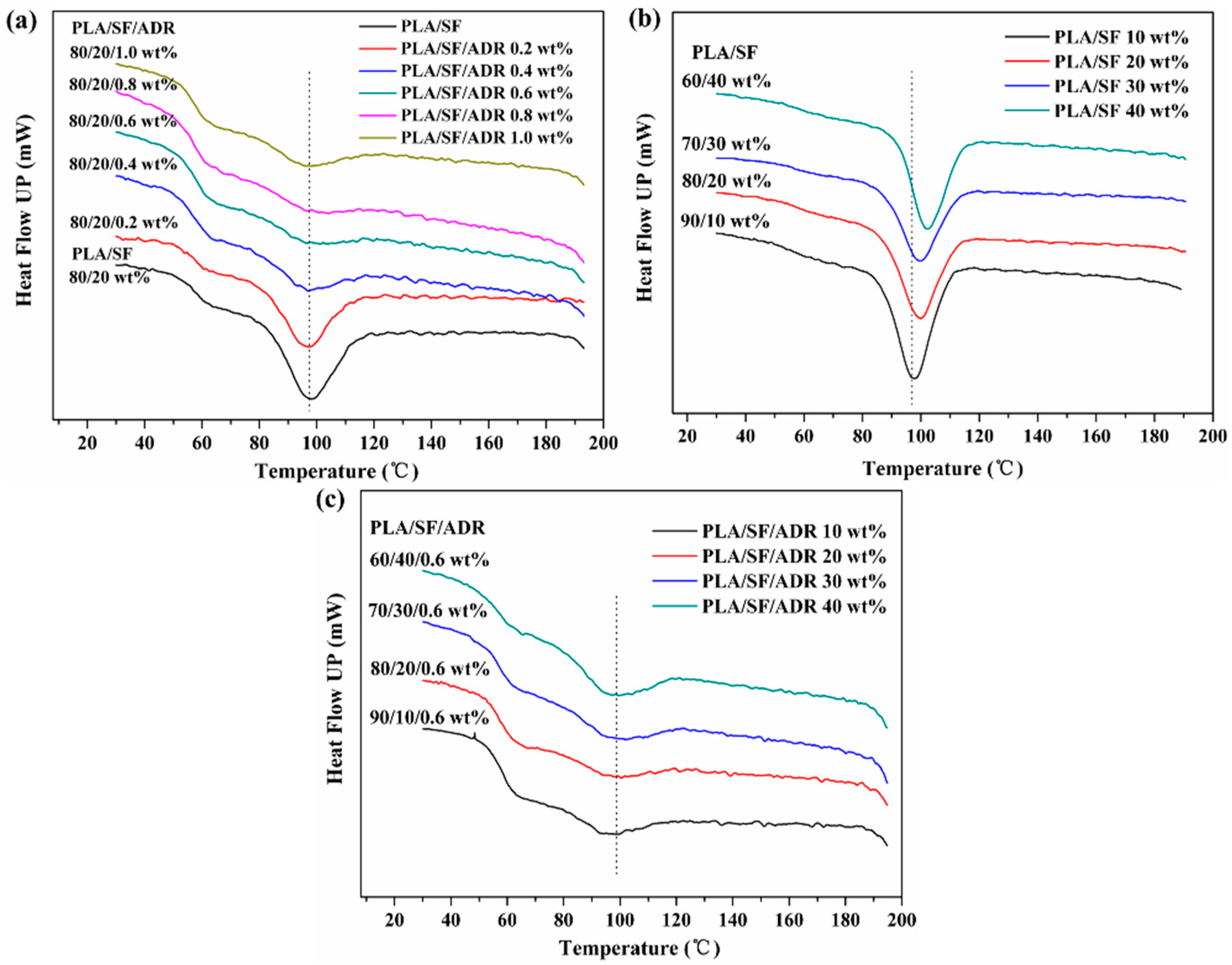

The DSC thermograms of PLA/SF composites and PLA/SF/ADR composites with different ADR addition and different SF content at a cooling rate of 5 °C/min are shown in

Figure 7. It was found that the cooling crystallization exothermal peak declined with the addition of ADR oligomer (

Figure 7a). In terms of previous analyses, the incorporation of ADR oligomer into PLA/SF composites improved the interfacial interaction between SF and PLA matrix, thus the movement of PLA segments were restricted, especially in the PLA matrix close to the interface. In the crystal growth stage during cooling, the mobility of polymer segments is significant for crystallization. It can be deduced that during the cooling process, no more PLA chain segments participated in cooling crystallization with the further addition of oligomer ADR due to restricted movement of the PLA chain segments, therefore the crystallization of PLA/SF/ADR composites declined. Similar crystallization behaviors were found in PLA/SF composites and PLA/SF/ADR composites with different SF content (

Figure 7b,c). The cooling crystallization exothermal peaks of PLA/SF/ADR composites were significantly decreased compared with that of PLA/SF composites. At the same time, it was found that the crystallization temperature improved as SF content increased, corresponding to an enhanced crystal nucleation ability with greater addition of SF. This can be attributed to the heterogeneous nucleation effect of SF.

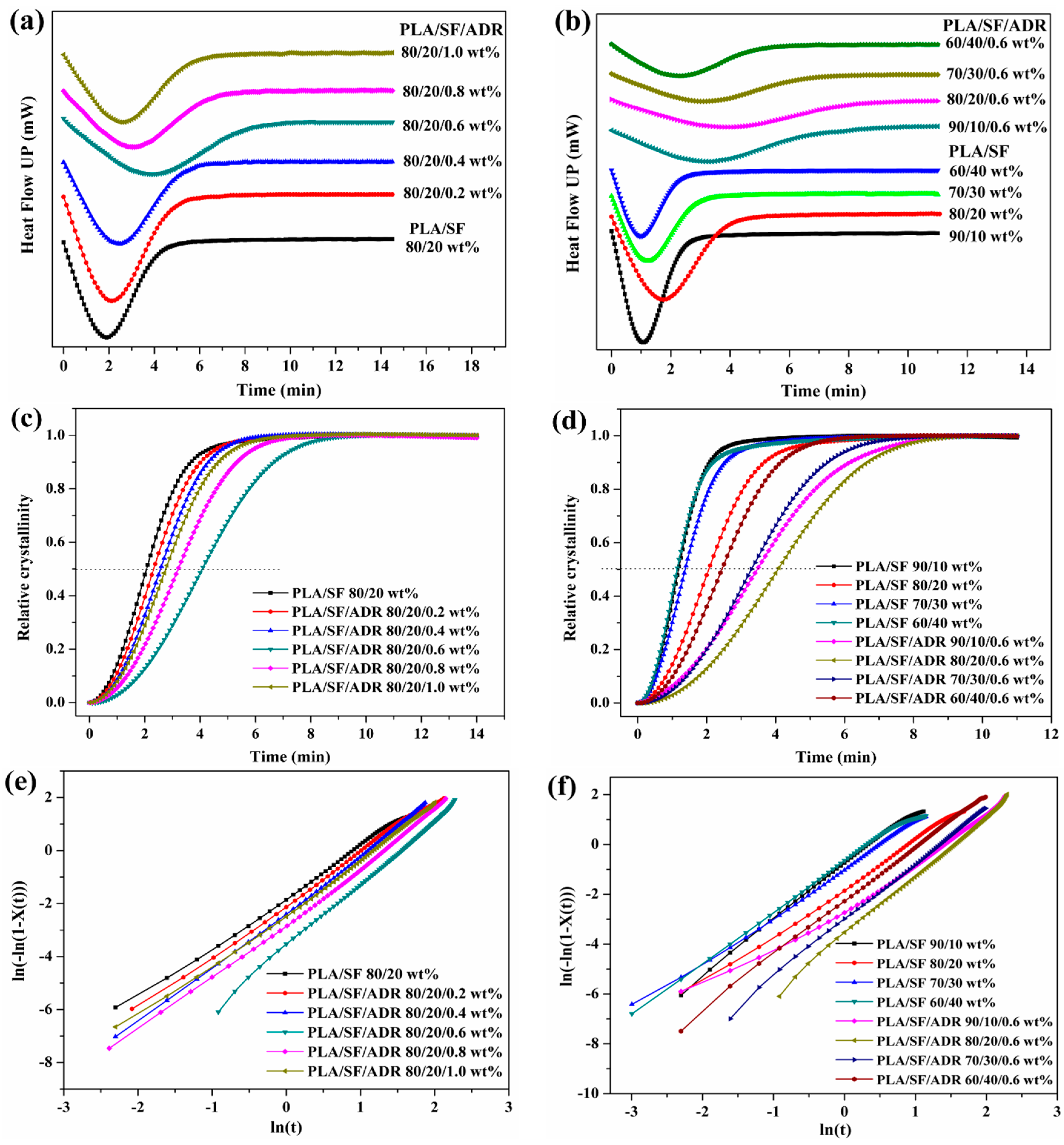

The isothermal crystallization behavior of PLA/SF composites and PLA/SF/ADR composites was investigated at 110 °C.

Figure 8a,b illustrate the isothermal crystallization thermograms of PLA/SF composites and PLA/SF/ADR composites with different ADR addition and different SF content at 110 °C. The thermograms recorded heat flow (

dH/

dt) as a function of time. From the isothermal crystallization thermograms, the relative crystallinity as a function of crystallization time can be calculated by the following equation:

where

X(

t) is the relative crystallinity, and

Q∞ and

Qt are the heat generated at infinite time and at time

t.

Figure 8c,d presents the change in relative crystallinity as a function of crystallization time. To further analyze the crystallization kinetics of composites, a classic Avrami equation was used [

30,

31].

where

X(t) is the relative crystallinity,

k is the crystallization rate constant, and

n is the Avrami exponent reflecting the mechanisms of crystal nucleation and growth, and the following equation can be deduced from Equation (2)

By plotting ln [−ln(1 −

X(t))] versus ln(

t), the Avrami exponent,

n, and crystallization rate constant,

k, were determined. Meanwhile, the crystallization half-time

t1/2, reflecting the crystallization rate, can be calculated with the below equation:

The obtained Avrami parameters of

n and

k, and calculated

t1/2 are summarized in

Table 4 and

Table 5.

For PLA/SF and PLA/SF/ADR composites with different ADR addition (

Figure 8a), the isothermal crystallization rate decreased with the addition of ADR oligomer. As can be seen from

Table 4, the crystallization half-time is 2.04 min for PLA/SF composites, and

t1/2 increased with addition of ADR. The crystallization half-time increased to 3.99 min for composites with 0.6 wt % ADR. However,

t1/2 tended to decrease for composites with 0.8 wt % and 1.0 wt % ADR, for which the

t1/2 values were 3.09 min and 2.68 min, respectively. The calculated crystallization half-time was consistent with the crystallization thermograms. In terms of the analyses mentioned above, the incorporation of ADR into PLA/SF composites improved the interfacial interaction between SF and PLA, but it also restricted the movement of the PLA chain segments. The decline in the crystallization rate of the composites with addition of ADR can be credited to the restricted movement of the PLA chain segments. The ADR oligomer connected PLA to the fiber surface via in situ reaction. However, it was found that excessive addition of ADR was detrimental to the bonding effect of ADR between SF and the PLA matrix. The increased crystallization rate of composites with 0.8 and 1.0 wt % ADR addition can be ascribed to the decline of the bonding effect of the ADR oligomer. In addition, ADR is a kind of oligomer with low molecular weight, and it might plasticize the PLA matrix in excessive quantities, thus facilitating chain segment movement and improving the crystallization rate. It was found that for PLA/SF composites and PLA/SF/ADR composites with different ADR addition, the

n value varied from 1.954 to 2.341, reflecting that the crystals tended to grow in two dimensions.

For PLA/SF composites and PLA/SF/ADR composites with different SF content (

Figure 8b), a similar crystallization behavior occurred. The addition of 0.6 wt % ADR decreased the crystallization rate for each SF content, from 10 wt % to 40 wt %. It was also found that as the SF content increased, the crystallization half-time improved, then decreased significantly (see

Table 5). This phenomenon occurred in both PLA/SF composites and PLA/SF/ADR composites with different SF content. These results are related to the heterogeneous nucleation effect of SF. Excessive addition of SF restricted the movement of PLA chain segments; meanwhile, it provided more heterogeneous nucleation points. The enhanced heterogeneous nucleation resulted in increase in the crystallization rate of composites with high SF content (30 wt % and 40 wt %).

3.4. Dynamic Rheological Behaviors

The viscoelastic response of polymers and polymer composites are very sensitive to changes of microstructure, including chain structure and phase morphology, which has attracted fundamental interest in this study. Dynamic small amplitude oscillatory shear (SAOS) was performed to probe the effect of melting reactive processing with ADR oligomer on the microstructure of PLA/SF composites.

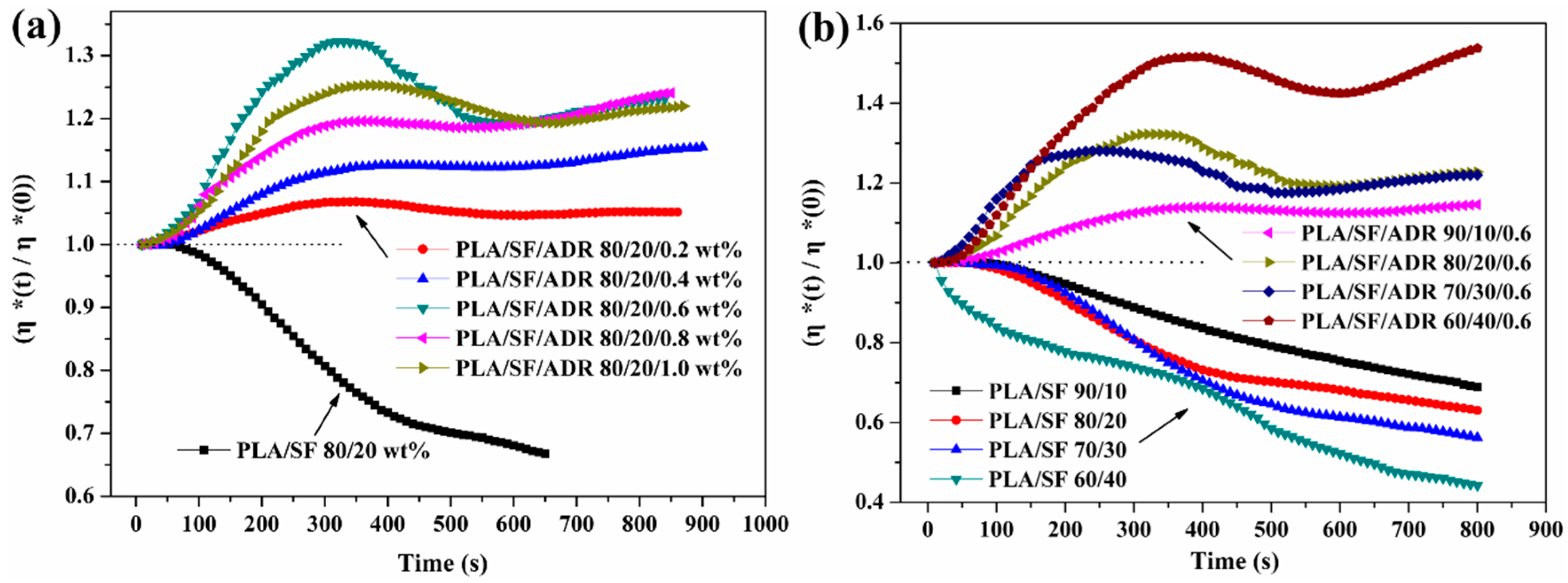

To detect the in situ reaction of composite melts, dynamic time sweep tests were performed in this study. The relative complex viscosity (η*(t)/η*(0)) versus time of PLA/SF composites and PLA/SF/ADR composites with different ADR addition are shown in

Figure 9a. It was found that the complex viscosity of PLA/SF (80/20 wt %) composites decreased dramatically within the time sweep because of thermal degradation. However, the presence of ADR oligomers counteracted the degradation of the composite melts. The relative complex viscosity even increased at the early stage of the time sweep. This phenomenon can be ascribed to the improved interfacial interaction between SF and the PLA matrix via in situ reaction of ADR oligomers with SF and PLA, and meanwhile, the chain extension effect of ADR on PLA also contributed to the improvement of complex viscosity. Furthermore, it was found that the η*(t)/η*(0) value of PLA/ADR/ADR (80/20/0.6 wt %) composites possess the most significant improvement in the early stage of the time sweep. These results were consistent with the analyses mentioned above. Excessive addition of ADR oligomer, more than 0.6 wt % content, did not improve the interfacial interaction of the composites.

Figure 9b shows the relative complex viscosity (η*(t)/η*(0)) versus time of PLA/SF composites and PLA/SF/ADR composites with different SF content. For PLA/SF composites with different SF content, the complex viscosity declined severely within the time sweep. The addition of 0.6 wt % ADR oligomer effectively inhibited the reduction of the complex viscosity of the composites. As can be seen from

Figure 10b, the η*(t)/η*(0) value of PLA/SF/ADR composites tended to be enhanced within the time sweep. Furthermore, it was found that for PLA/SF composites, the more SF was added, the more the η*(t)/η*(0) value would decrease. That is because the presence of SF aggravated the thermal degradation of composites. However, for PLA/SF/ADR composites with 0.6 wt % ADR oligomer, the η*(t)/η*(0) value of composites increased with increasing SF content because more SF addition could improve the interfacial interaction between SF and the PLA matrix. The PLA/SF/ADR (60/40/0.6 wt %) composites exhibited the greatest improvement in the η*(t)/η*(0) value.

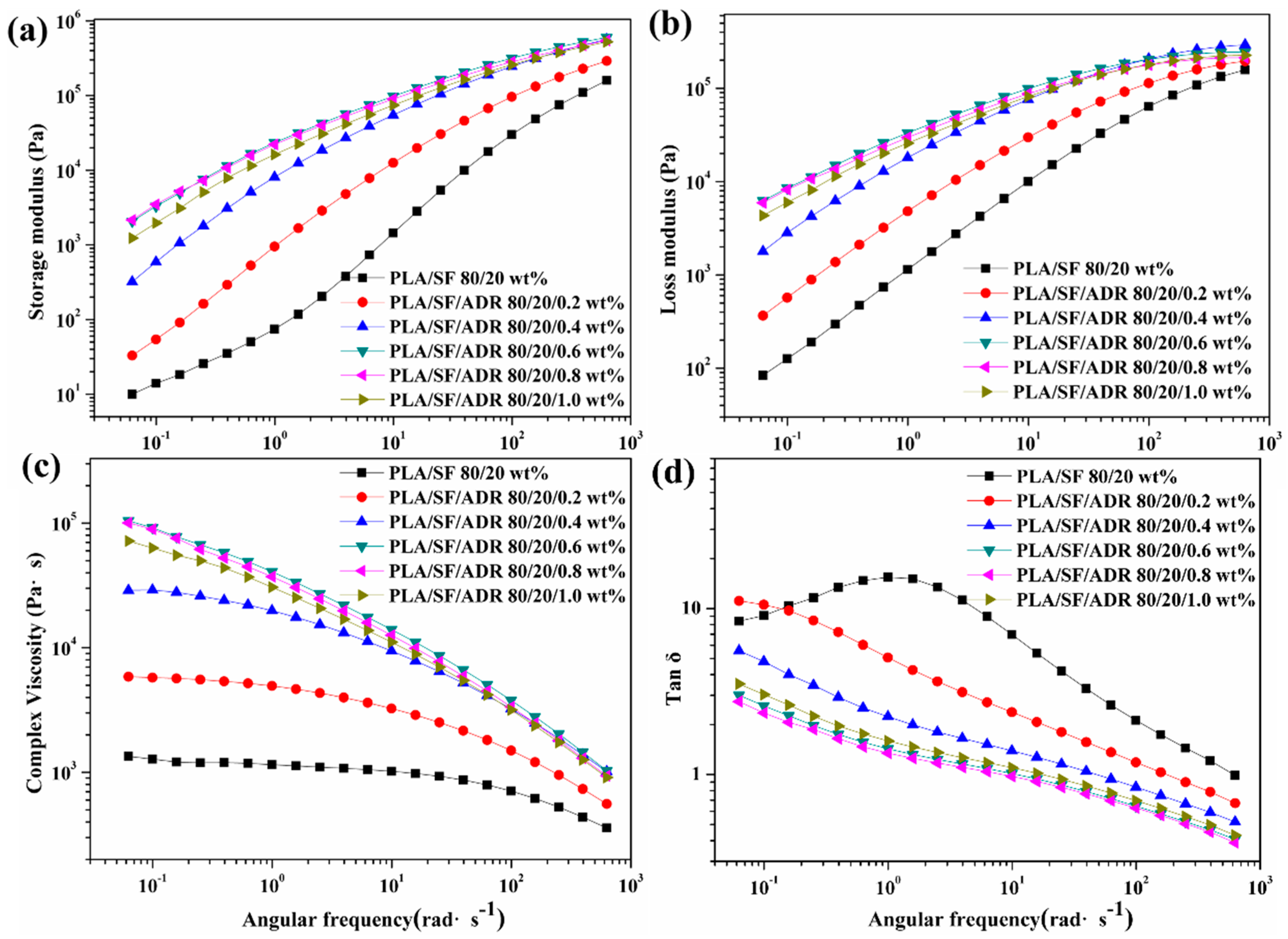

The changes of storage modulus (G′), loss modulus (G″), complex viscosity |η*| and loss tangent as functions of angular frequency for PLA/SF and PLA/SF/ADR composites with different ADR addition are shown in

Figure 10. It can be seen from

Figure 10a,b that the addition of ADR oligomer improved the storage modulus and loss modulus of PLA/SF composites. It reflects the enhanced viscoelastic response of PLA/SF/ADR composites compared with that of PLA/SF composites.

Figure 10c presents the changes of complex viscosity as a function of angular frequency. It can be seen that the complex viscosity improved with addition of ADR oligomer, especially in the low angular frequency region. In addition, the pattern of dependence of complex viscosity on frequency (the change tendency of complex viscosity with frequency) varied to some extent due to the addition of ADR. For PLA/SF composites and PLA/SF/ADR composites with low ADR content (0.2 wt % and 0.4 wt %) the complex viscosity remained nearly constant in the low angular frequency region, and then decreased as angular frequency increased. This transition from the Newtonian plateau to the power law regime at the inflection point is a typical phenomenon of polymer materials. However, it was found that the Newtonian plateau region decreased with the addition of ADR oligomer. For composites with high ADR content (0.6 wt %, 0.8 wt %, and 1.0 wt %), the shear-thinning behavior occurred in the whole angular frequency region, which more obviously exhibited the power law regime [

32,

33]. The enhanced shear-thinning behavior of PLA/SF/ADR composites can be ascribed to the improved interfacial interaction of composites. For PLA/SF/ADR composites, for which the interfacial interaction between SF and PLA matrix were enhanced, the sisal fibers can act as physical crossing points in composite melts. Therefore, it can be deduced that more significant disentanglement of the polymer chain occurred as the angular frequency increased, resulting in more obvious shear-thinning behavior than that of PLA/SF composites.

Figure 10d presents the changes of loss tangent (tan

δ = G″/G′) as a function of angular frequency. It can be seen that the tan

δ of PLA/SF/ADR composites decreased in comparison with that of PLA/SF composites. The PLA/SF/ADR composites possess a more dramatically elastic response. The frequency dependence of the loss tangent can be used to characterize the gel point of the cross-linking system [

34,

35]. This method can be adopted for polymer composites to evaluate the percolation thresholds of the fillers [

36,

37]. The tan

δ of PLA/SF/ADR composites displayed less dependence on the angular frequency, which exhibited a gel-like behavior. In terms of the analyses mentioned above, the presence of ADR improved the interfacial interaction of composites, and the physical crossing points of sisal fibers in composite melts. Therefore, the stress relaxation of the PLA molecular chain became more difficult in the melt state; the elastic response of the PLA/SF/ADR composite melt was enhanced and tended to exhibit a gel-like behavior.

3.5. DMA Characterization

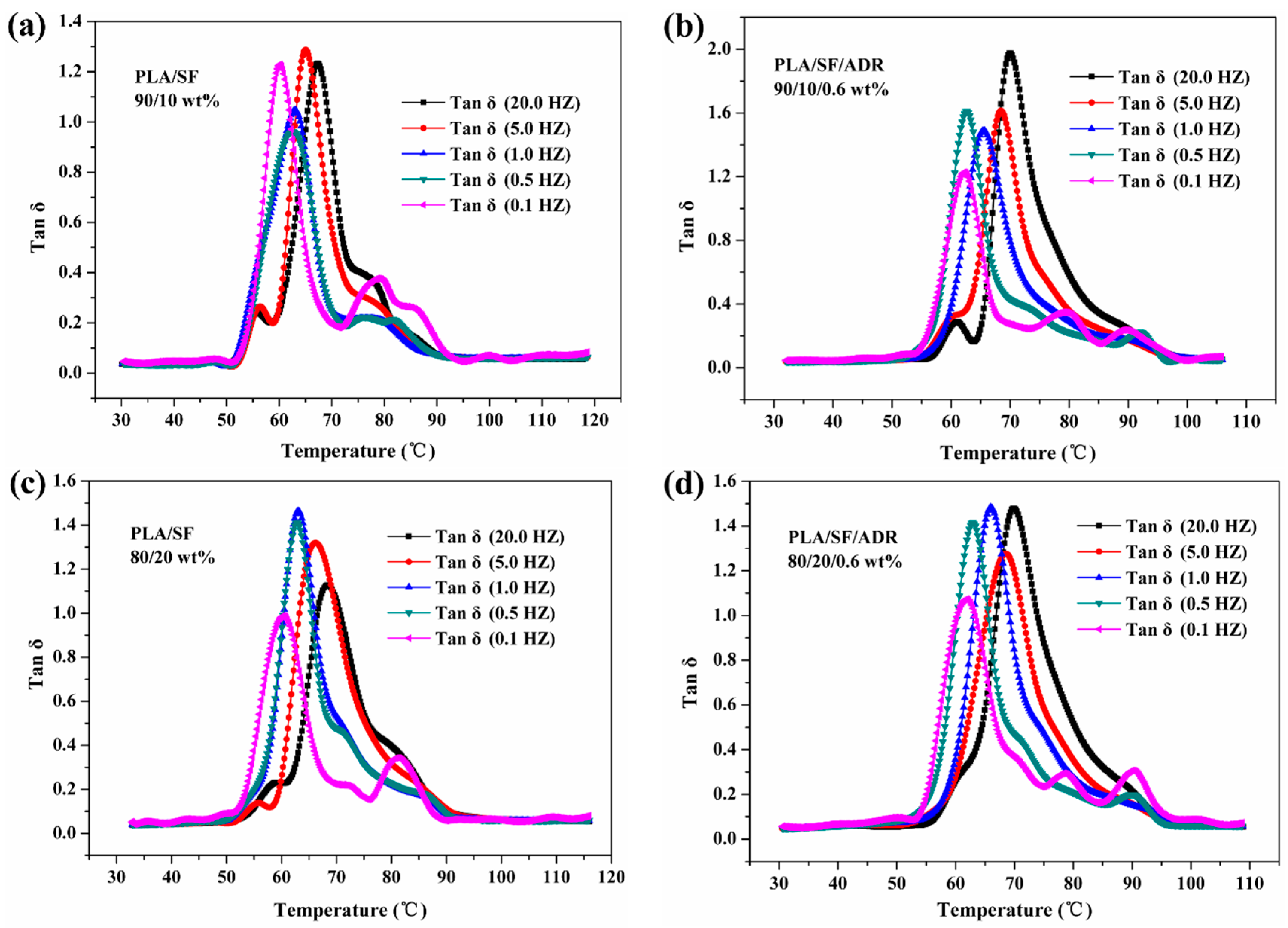

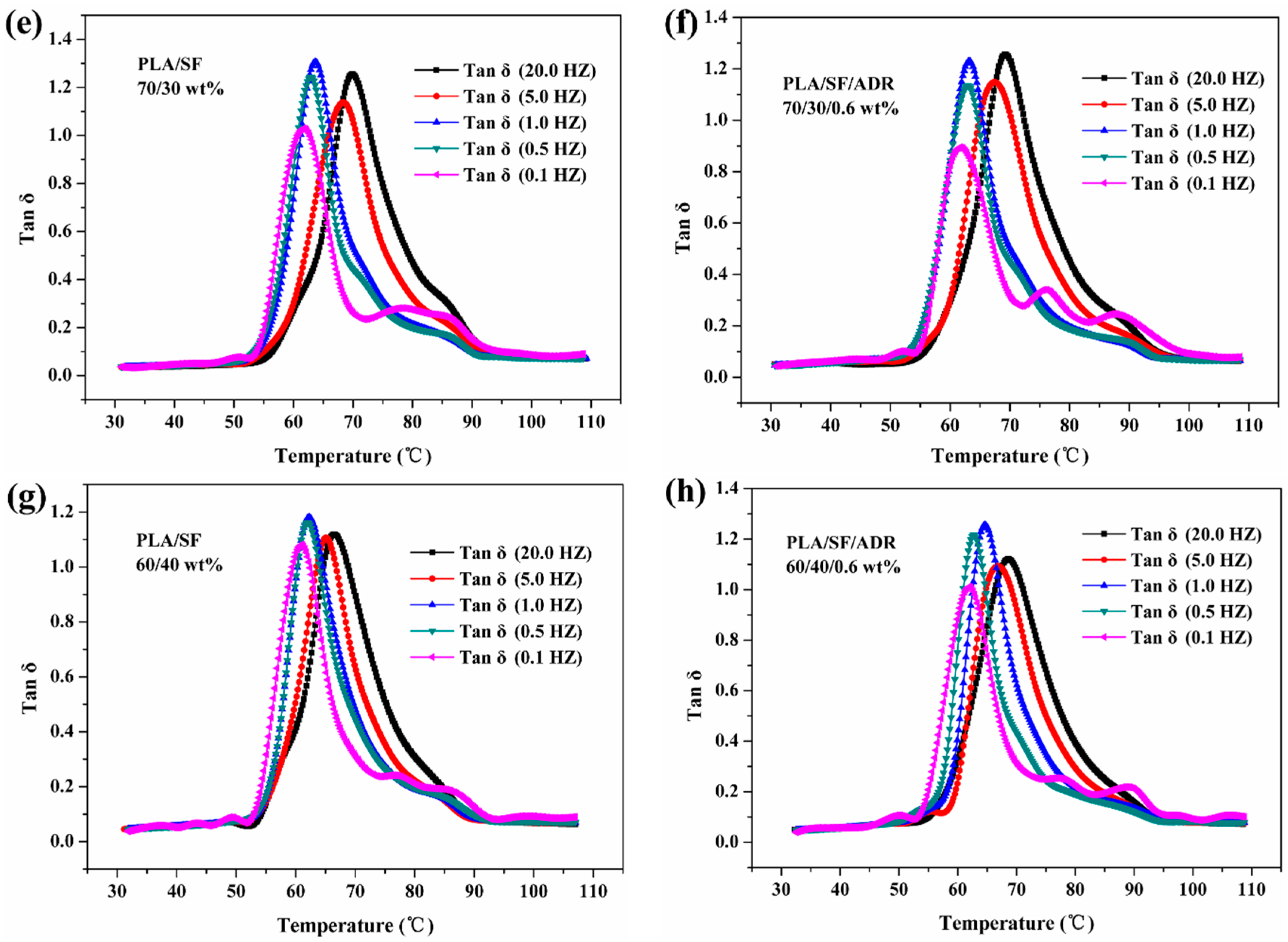

In order to evaluate the dynamic mechanical properties and investigate the effect of ADR on the glass transition of composites, the DMA measurements of PLA/SF composites and PLA/SF/ADR composites with different SF content were carried out at different frequencies. The effect of different frequencies on the loss tangent (tan

δ) of PLA/SF and PLA/SF/ADR composites with different SF content with a heating rate of 2 °C/min is shown in

Figure 11. It was observed that in the whole temperature range, the α relaxation for PLA/SF and PLA/SF/ADR composites was between 60 °C and 70 °C which corresponds to the glass transition temperature (

Tg) of the composites. The glass transition temperature of the composites is summarized in

Table 6. The

Tg of the composites increased as the frequencies elevated. It was found that the

Tg of PLA/SF/ADR composites was improved compared with that of PLA/SF composites at the same test frequencies, which demonstrated that PLA chain segment mobility was restrained. This result confirmed the enhanced interfacial interaction between SF and the PLA matrix via in situ interfacial reaction.

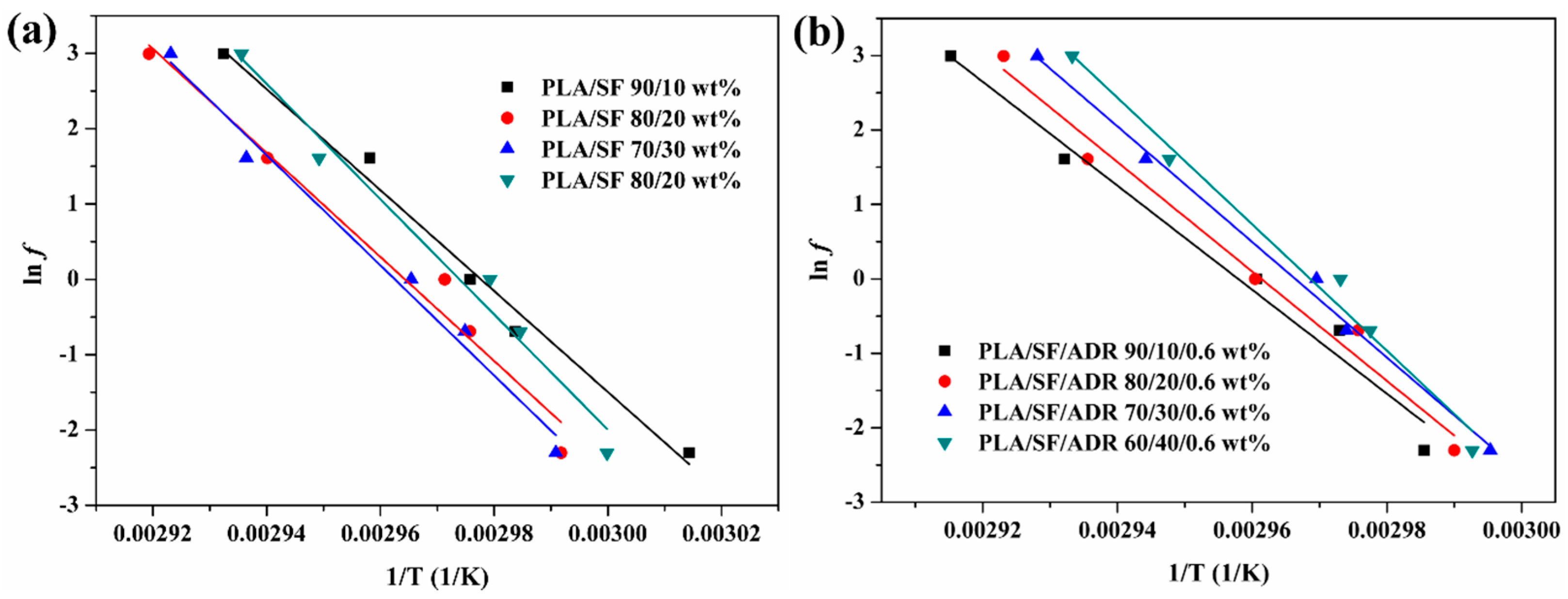

To further analyze the glass transition of the composites, the activation energies of glass transition relaxation (∆

Ea) were calculated based on the dependence of

Tg on frequency. The ∆

Ea represents the energy barrier of glass transition relaxation. It can be adopted to characterize the relationship between polymer chain segment mobility and the time scale. Five different test frequencies were used in this study (0.1, 0.5, 1, 5, and 20 HZ). The changes of glass transition temperature were interrelated with test frequencies using the Arrhenius equation [

38,

39]. On the basis of classic Arrhenius equation, the molecular relaxation time can be expressed as:

where ∆

E and

σ are the activation energy of relaxation and the stress, respectively,

τ0 is the hypothetical relaxation time at an infinite temperature,

T is the absolute temperature,

γ is the variable and R is the gas constant.

Here, the stress (

σ) is small, thus Equation (5) can be simplified as:

The relaxation times were calculated from the relationship:

A combination of Equations (7) and (8) leads to:

According to Equation (9), a plot of ln

f versus 1/

T should give a straight line with a slope that is proportional to activation energy associated to the glass transition relaxation.

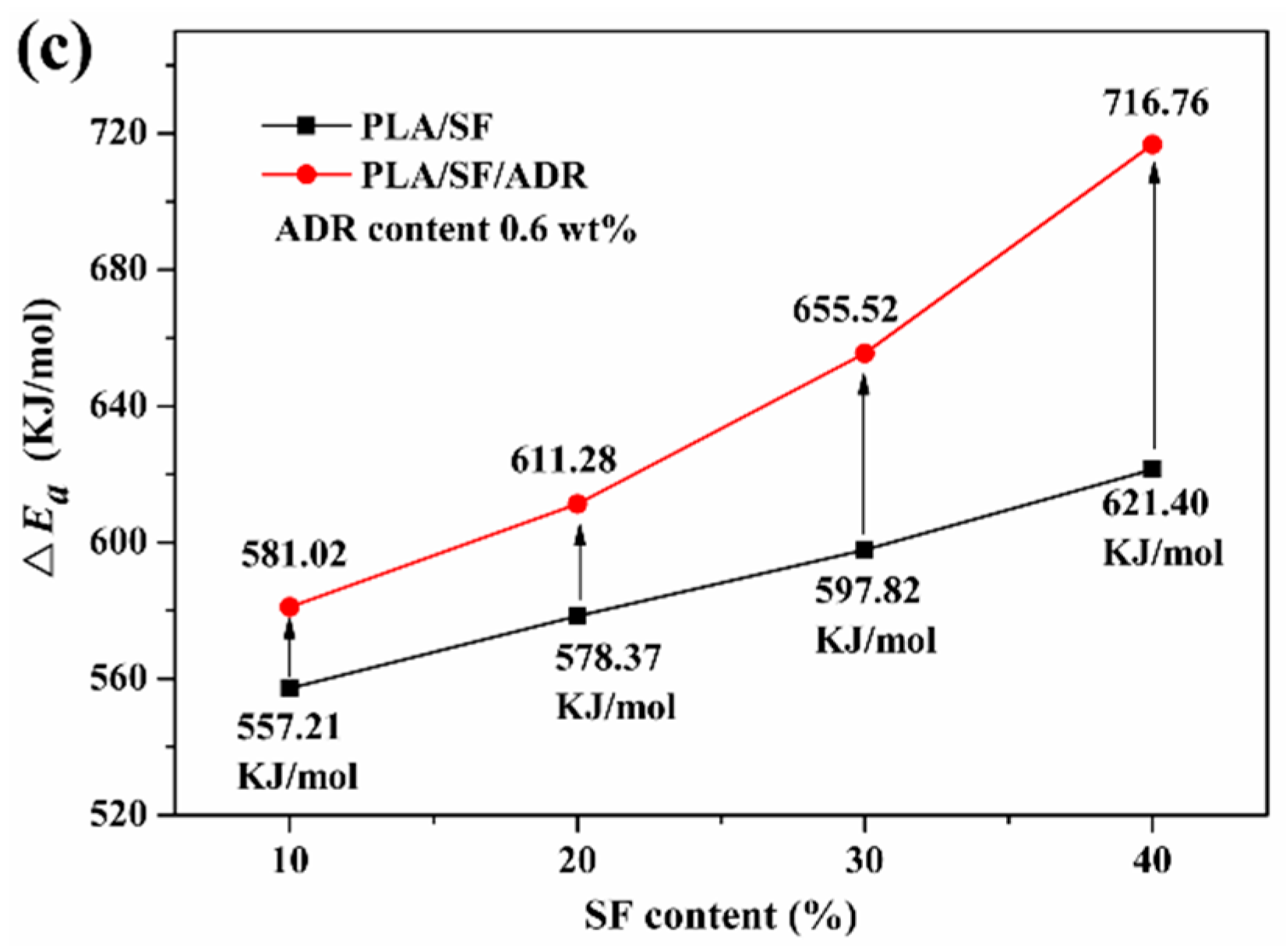

Figure 12 shows the Arrhenius plots of relaxation times versus 1/

T, the respective linear fits of PLA/SF composites and PLA/SF/ADR composites with different SF content, and the calculated activation energies of glass transition relaxation. As can be seen from

Table 7 and

Figure 12c, the calculated ∆

Ea of composites increased with the addition of ADR oligomer at equal SF content, which implied that the improved interfacial adhesion of composites increased the energy barrier of the mobility of the PLA chain segments. In addition, for both PLA/SF composites and PLA/SF/ADR composites, the ∆

Ea value increased with increasing SF content. Furthermore, the improvement in activation energy of PLA/SF/ADR composites compared with that of PLA/SF composites at the identical SF content was elevated with increased SF content (see

Figure 12c). The greater the addition of SF, the more sisal fibers participated in interfacial reaction, resulting in increased restriction of PLA chain segments. These results are in accordance with the thermal and rheological analyses mentioned above.

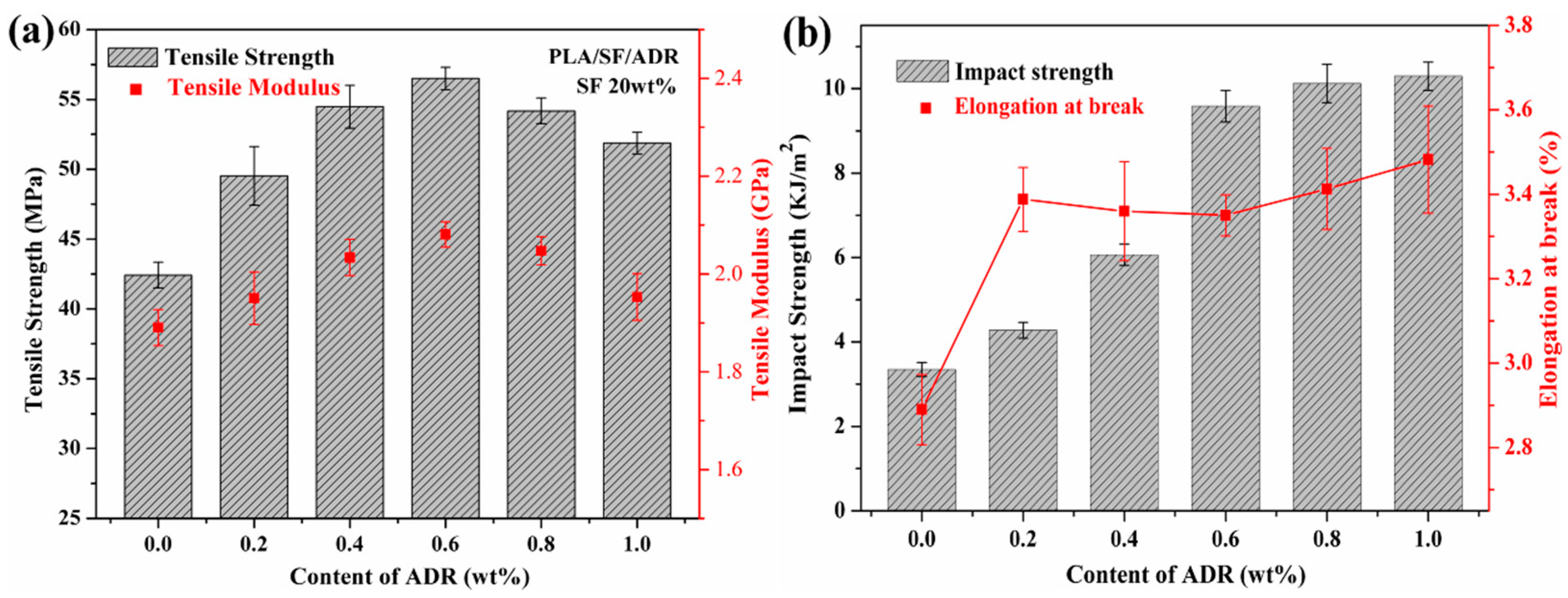

3.6. Mechanical Properties

Figure 13 shows the tensile properties and impact strength of PLA/SF composites and PLA/SF/ADR composites with different ADR addition. It was found that the addition of ADR oligomer improved the tensile strength of the composites (

Figure 13a). Moreover, as the ADR content increased, the tensile strength of PLA/SF/ADR composites increased at first and then decreased. The PLA/SF/ADR (80/20/0.6 wt %) composites possessed the highest tensile strength. A similar variation tendency occurred for the tensile modulus of the composites, which reflected the enhanced stiffness of PLA/ADR/SF composites compared with that of PLA/SF composites. Furthermore, it was found that the elongation at break and the impact strength of PLA/SF/ADR composite were improved in comparison with that of PLA/SF composites (

Figure 13b), which indicated an enhanced toughness of composites with addition of ADR oligomer. These results demonstrated that the incorporation of ADR oligomers simultaneously reinforce and toughen the PLA/SF composites.

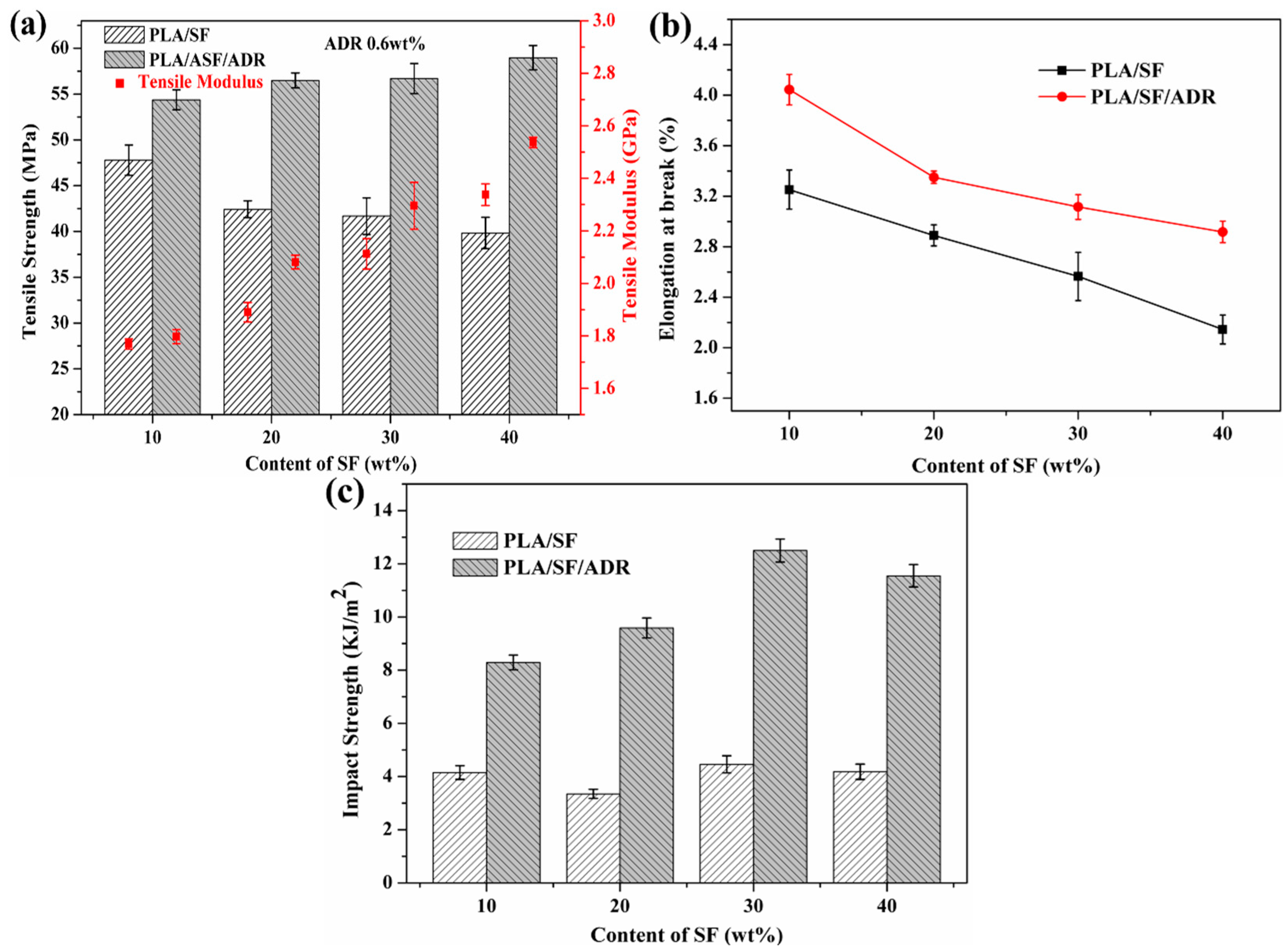

Figure 14 shows the tensile properties and impact strength of PLA/SF composites and PLA/SF/ADR composites with different SF content. For PLA/SF composites, the tensile strength decreased as SF content increased. However, for PLA/SF/ADR composites with 0.6 wt % ADR oligomer, the tensile strength improved with the increase of SF content, exhibiting that the greater the addition of SF, the greater the tensile strength compared with that of PLA/SF composites at the identical SF content (

Figure 14a). In addition, the tensile modulus of PLA/SF and PLA/SF/ADR composites were enhanced with high SF content, and the elevation of tensile modulus became greater at higher SF content.

Figure 14b presents that the elongation at break of the composites decreases with increasing SF content, and at the identical SF content the elongation at break is improved via addition of ADR oligomer. The impact strength of PLA/SF/ADR composites with different SF content was also improved in comparison with that of PLA/SF composites (see

Figure 14c).

In brief, when the fiber-reinforced plastic is bearing force, the role of the interface is to transmit stress from the polymer matrix to the fibers; therefore, the mechanical properties of PLA/SF composites in this study were significantly influenced by fiber–matrix interaction [

40]. According to the microstructure characterization and analyses mentioned above, the addition of ADR oligomer improved the interfacial adhesion of PLA/SF composites via in situ interfacial reaction during melt-blending and processing. The improved interfacial interaction of PLA/SF composites enhanced the efficiency of transmitting stress from the PLA matrix to sisal fibers, thus improving the mechanical properties. However, excessive addition of ADR was detrimental to the connecting effect of ADR between SF and the PLA matrix, which did not facilitate the enhancement of interfacial adhesion. Therefore, the interfacial adhesion of PLA/SF/ADR composites with high ADR addition (0.8 wt % or 1.0 wt %) slightly decreased as compared with composites with 0.6 wt % ADR. ADR is a kind of oligomer with lower molecular weight and a more flexible chain compared with PLA. It had a plasticizing effect on a PLA matrix, which also contributed to the toughening of composites.

At the same time, poorer interfacial adhesion resulted in more microstructural defects of the composites (

Figure 1,

Figure 2 and

Figure 3). The microstructure defects would cause stress concentration points when the composites bearing force, which were bad for the mechanical properties of composites. In addition, the low interfacial bonding of PLA/SF composites permitted composites to debond facilely. These factors resulted in forward breakage of PLA/SF composite samples compared with that of PLA/SF/ADR composites in tensile tests. The elongation at break of PLA/SF/ADR composites were improved compared with that of PLA/SF composites.

Improving the interfacial interaction between SF and the PLA matrix contributed to the formation of a moderate interface in the composites. A moderate interface can effectively relieve the stress concentration under loading conditions, and transmit stress uniformly from the matrix to the fibers [

41,

42]. For PLA/SF composites with different SF content, the greater the addition of sisal fibers, the more microstructural defects were present in the composites. This resulted in a decline in the mechanical properties of PLA/SF composites with increased SF content. By contrast, the mechanical properties of PLA/SF/ADR composites were improved because of enhanced interfacial adhesion of the composites via in situ reactive interfacial compatibilization by the addition of ADR oligomers.