The Effect of Ultraviolet Radiation on Bitumen Aging Depth

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Aging Procedure

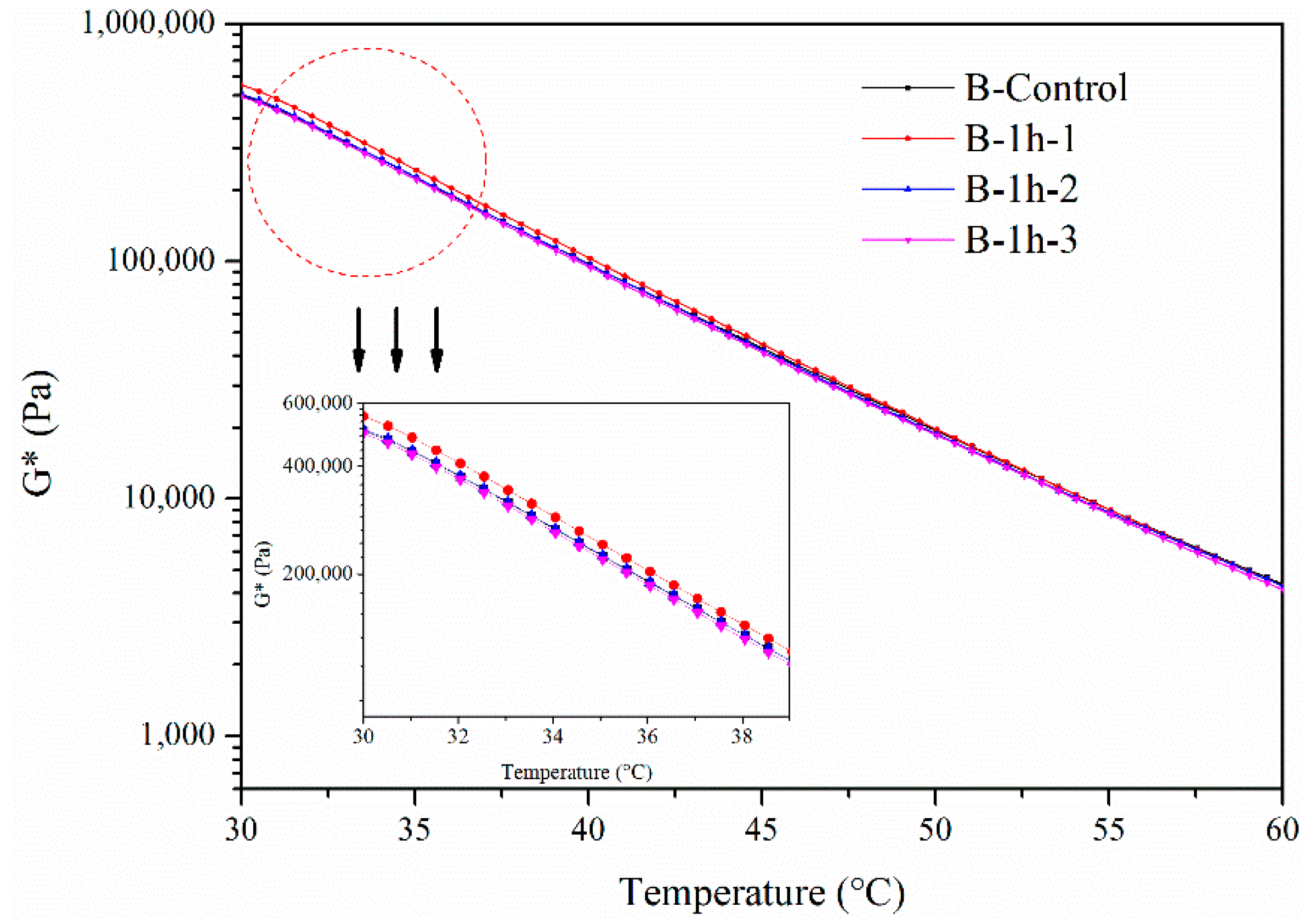

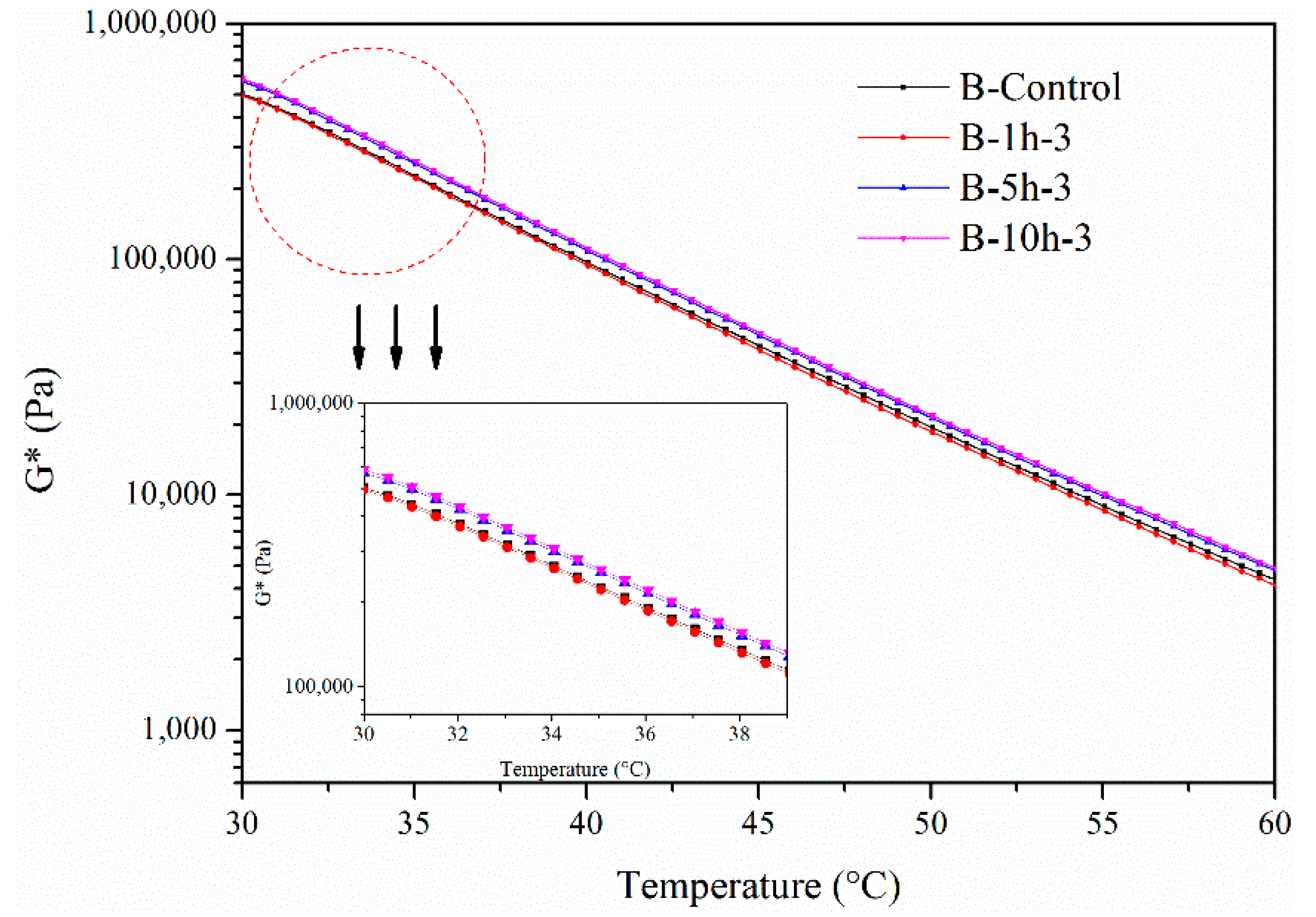

- The first group of samples was designed to investigate whether the aging depth would increase with aging time. Bitumen were poured into an Ø90 mm glass petri dish with its lid removed. The periphery of the dish was separated from the UV radiation by an insulating layer so that the UV radiation could only penetrate from the surface. Samples were UV aged for 1 h, 5 h and 10 h at 50 °C so that the UV aging procedure would not be affected by thermal oxidation aging [3]. The average intensity of UV radiation on the samples’ surface was 10 W/m2. The peeling procedure, dissolving layer by layer, is shown in Figure 1. After UV aging, bitumen on the surface was dissolved by carbon disulfide layer by layer (a) and (b). The dissolved bitumen for one layer was almost 0.8 g and the thickness of the layer was approximately 105 μm. Then the solutions were dried for 7 d (c) and the residues (d) were tested by DSR. Every sample was dissolved three times. The first layer means that the layer was dissolved at the beginning and the third layer means that the layer was dissolved at the end. The first, second and third layers of B aged by UV for 1 h were abbreviated as B-1h-1, B-1h-2 and B-1h-3.

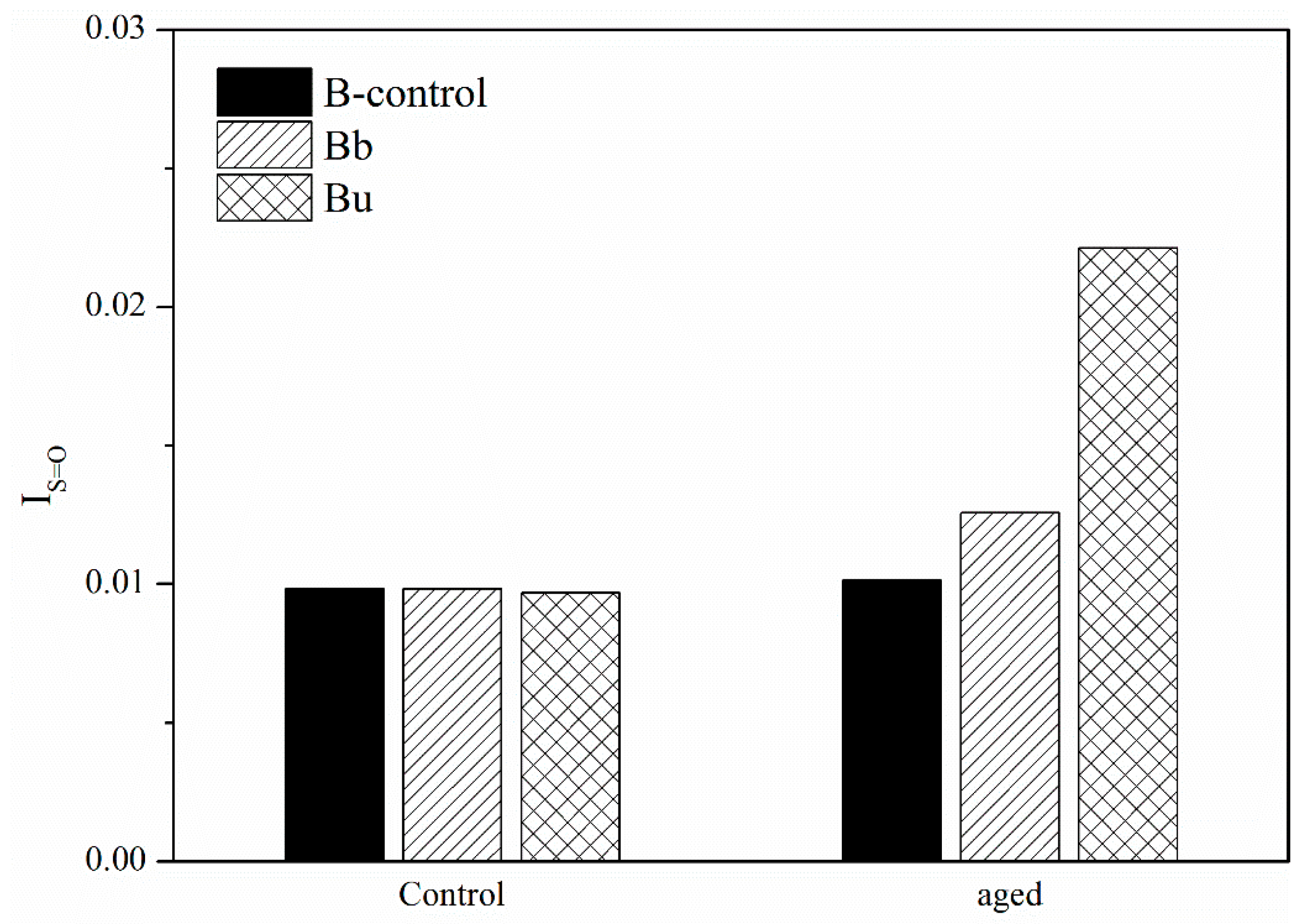

- The second group of samples was used to explore the aging effect between samples with and without UV radiation. Bitumen was dissolved by carbon disulfide first and then the solutions were dropped onto a blank KBr slide [29,30]. After drying, the solutions turned into a thin film. The concentration of the solutions was 5 wt % and the thickness of the film after drying was approximately 10 μm. Samples were divided into two parts, as shown in Figure 2. These parts were separated by a septum, which UV radiation cannot penetrate. The region between the septum and the samples below the septum was approximately 1 cm, which guaranteed that the atmosphere could circulate. Samples were UV aged for 5 d at 50 °C. The average intensity of UV radiation on the Bu’ surface was 10 W/m2. The ozone concentration was about 0.4 ppm in the environment and about 1.2 ppm in the oven, which was tested by a gas detector (uSafe 2000/300, Sundo Shenzhen Technology Co., Ltd., Shenzhen, China). After UV aging, samples were tested by Fourier Transform Infrared (FTIR, Nexus, Thermo Nicolet Corp., Waltham, MA, USA) Spectroscopy. Samples on the septum and samples below the septum were abbreviated as Bu and Bb respectively.

- The third and last group of samples was used to study the UV transmittance of bitumen with aging time. Bitumen was dissolved by carbon disulfide, then solutions with different concentrations (2.5%, 5%, 10%, 15%, 20%, and 30%) were dropped into a quartz glass slice, respectively, and different thicknesses (1.1 μm, 2.3 μm, 5.6 μm, 6.3 μm, 8.1 μm, and 13.1 μm) were obtained. Then, the slice was put on the spin coater and ultrathin bitumimous film was prepared. Samples were UV aged for 0 h, 1 h, 5 h, 10 h, or 50 h. Transmittance of the blankly quartz glass slice with 1 mm thickness is shown in Figure 3. The UV radiation transmittance of the slice from 200 nm to 400 nm was larger than 85%. It was considered that the slice would not influence the UV radiation transmittance in this paper.

2.3. Characterization Method

2.3.1. Dynamic Shear Rheometer (DSR)

2.3.2. Fourier Transform Infrared (FTIR) Spectroscopy

2.3.3. Ultraviolet Spectrophotometry

3. Results and Discussion

3.1. Aging Effect on Bitumen in Different Layers for Different Aging Times

3.1.1. Complex Modulus of Bitumen in Different Layers at High Temperatures

3.1.2. Complex Modulus of Bitumen in the Third Layer for Different Aging Times

3.2. Aging Effect on the Second Group Caused by Ozone

3.3. Transmittance of Bitumen after UV Aging

3.3.1. Transmittance of Bitumen with Different Thicknesses after UV Aging

3.3.2. UV Aging Model

4. Conclusions

- After aging for 5 h, bitumen in the second and the third layers began to be aged by UV radiation. As aging time increased, aging depth increased.

- The aging effects of ozone were small. Bitumen is hard age if it has no contact with UV radiation.

- The UV radiation transmittance of bitumen increased after UV aging. After UV aging for 50 h, partial UV radiation could pass through bitumen with 13.1 μm thickness.

- After aging for 5 h, UV radiation from 200 nm to 400 nm still could not pass through bitumen with 13.1 μm thickness. The real reason why aging depth increased was permeation. Aged bitumen permeated fresh bitumen, which resulted in changes to the rheological properties of the second and third layers.

- Permeation is closely related to the thermal stability, therefore, bitumen on road surfaces should possess high thermal stability to ensure its performance.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Qin, Q.; Schabron, J.F.; Boysen, R.; Farrar, M.J. Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 2014, 121, 86–94. [Google Scholar] [CrossRef]

- Calabifloody, A.; Thenoux, G. Controlling asphalt aging by inclusion of byproducts from red wine industry. Constr. Build. Mater. 2012, 28, 616–623. [Google Scholar] [CrossRef]

- Zeng, W.; Wu, S.; Wen, J.; Chen, Z. The temperature effects in aging index of asphalt during UV aging process. Constr. Build. Mater. 2015, 93, 1125–1131. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N.; Karakouzian, M.; Khalili, M. Rheology evaluations of WMA binders using ultraviolet and PAV aging procedures. Constr. Build. Mater. 2015, 79, 56–64. [Google Scholar] [CrossRef]

- Mouillet, V.; Lamontagne, J.; Durrieu, F.; Planche, J.P.; Lapalu, L. Infrared microscopy investigation of oxidation and phase evolution in bitumen modified with polymers. Fuel 2008, 87, 1270–1280. [Google Scholar] [CrossRef]

- Mill, T. The role of hydroaromatics in oxidative aging in asphalt. Am. Chem. Soc. Div. Fuel Chem. 1996, 41, 1245–1249, preprints of papers. [Google Scholar]

- Petersen, J.C. A dual, sequential mechanism for the oxidation of petroleum asphalts. Pet. Sci. Technol. 1998, 16, 1023–1059. [Google Scholar] [CrossRef]

- Apeagyei, A.K. Laboratory evaluation of antioxidants for asphalt binders. Constr. Build. Mater. 2011, 25, 47–53. [Google Scholar] [CrossRef]

- Chen, Z.W.; Wu, S.P.; Xiao, Y.; Zeng, W.B.; Yi, M.W.; Wan, J.M. Effect of hydration and silicone resin on Basic Oxygen Furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.P.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sus. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Cui, P.Q.; Wu, S.P.; Xiao, Y.; Wan, M.; Cui, P.D. Inhibiting effect of layered double hydroxides on the emissions of volatile organic compounds from bituminous materials. J. Clean. Prod. 2015, 108, 987–991. [Google Scholar] [CrossRef]

- Xu, S.; Li, L.; Yu, J.; Zhang, C.; Zhou, J.; Sun, Y. Investigation of the ultraviolet aging resistance of organic layered double hydroxides modified bitumen. Constr. Build. Mater. 2015, 96, 127–134. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, S.; Wang, Q.; Yao, H. Rheological and structural evolution of SBS modified asphalts under natural weathering. Fuel 2016, 184, 242–247. [Google Scholar] [CrossRef]

- Verhasselt, A.F. A Kinetic Approach to the Aging of Bitumens. Dev. Pet. Sci. 2000, 40, 475–497. [Google Scholar] [CrossRef]

- Lins, V.F.; Araujo, M.F.; Yoshida, M.I.; Ferraz, V.P.; Andrada, D.M.; Lameiras, F.S. Photodegradation of hot-mix asphalt. Fuel 2008, 87, 3254–3261. [Google Scholar] [CrossRef]

- Durrieu, F.; Farcas, F.; Mouillet, V. The influence of UV aging of a Styrene/Butadiene/Styrene modified bitumen: Comparison between laboratory and on site aging. Fuel 2007, 86, 1446–1451. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

- Migliori, F.; Corte, J. Comparative Study of Rtfot and Pav Aging Simulation Laboratory Tests. Transp. Res. Rec. 1998, 1638, 56–63. [Google Scholar] [CrossRef]

- Xiao, F.; Newton, D.; Putman, B.J. A long-term ultraviolet aging procedure on foamed WMA mixtures. Mater. Struct. 2013, 46, 1987–2001. [Google Scholar] [CrossRef]

- Mouillet, V.; Farcas, F.; Chailleux, E.; Sauger, L. Evolution of bituminous mix behaviour submitted to UV rays in laboratory compared to field exposure. Mater. Struct. 2014, 47, 1287–1299. [Google Scholar] [CrossRef]

- Traxler, R.N. Durability of Asphalt Cements (with Discussion); Association of Asphalt Paving Technologists Proceedings: St. Paul, MN, USA, 1963; Volume 32, pp. 44–63. [Google Scholar]

- Yamaguchi, K.; Sasaki, I.; Nishizaki, I.; Meiarashi, S.; Moriyoshi, A. Effects of film thickness, wavelength, and carbon black on photodegradation of asphalt. J. Jpn. Pet. Inst. 2005, 48, 150–155. [Google Scholar] [CrossRef]

- Mouillet, V.; Farcas, F.; Besson, S. Ageing by UV radiation of an elastomer modified bitumen. Fuel 2008, 87, 2408–2419. [Google Scholar] [CrossRef]

- Araujo, M.D.; Lins, V.D.; Pasa, V.M.; Leite, L.F. Weathering aging of modified asphalt binders. Fuel Process. Technol. 2013, 115, 19–25. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yu, J.; Shi, C.; Zhang, D. Influence of surface modification on physical and ultraviolet aging resistance of bitumen containing inorganic nanoparticles. Constr. Build. Mater. 2015, 98, 735–740. [Google Scholar] [CrossRef]

- Feng, Z.; Yu, J.; Zhang, H.; Kuang, D.; Xue, L. Effect of ultraviolet aging on rheology, chemistry and morphology of ultraviolet absorber modified bitumen. Mater. Struct. 2013, 46, 1123–1132. [Google Scholar] [CrossRef]

- Cong, P.; Wang, X.; Xu, P.; Liu, J.; He, R.; Chen, S. Investigation on properties of polymer modified asphalt containing various antiaging agents. Polym. Degrad. Stab. 2013, 98, 2627–2634. [Google Scholar] [CrossRef]

- Xu, S.; Yu, J.; Zhang, C.; Sun, Y. Effect of ultraviolet aging on rheological properties of organic intercalated layered double hydroxides modified asphalt. Constr. Build. Mater. 2015, 75, 421–428. [Google Scholar] [CrossRef]

- Pieri, N. Etude du vieillissement simulé et in situ des bitumes routiers par IRTF et fluorescence UV en excitation-émission synchrones: Détermination des relations structures chimiques—propriétés rhéologiques par analyse en composantes principales. 1994, 84, 164–165. Available online: http://www.theses.fr/1994AIX30102 (accessed on 7 May 2018).

- Feng, Z.; Bian, H.; Li, X.; Yu, J. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2016, 49, 1381–1389. [Google Scholar] [CrossRef]

- Lamontagne, J. Vieillissement des Bitumes Modifiés Polymères à Usage Routier par Simulation et Techniques Spectroscopiques. Chimie Analytique: Aix-Marseille 3, 2002. Available online: http://www.theses.fr/2002AIX30002 (accessed on 7 May 2018).

- Lamontagne, J.; Dumas, P.; Mouillet, V.; Kister, J. Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: Application to road bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

| Author | UV Aging Conditions | Sample Thickness | References |

|---|---|---|---|

| Virginie Mouillet | Temperature: 60 °C Aging time: 60 h | Sample thickness: 10 μm | [23] |

| Franҫoise Durrieu | Temperature: 60 °C Aging time: 170 h | Sample thickness: 10 μm | [16] |

| Xinyu Zhao | Temperature: 60 °C Aging time: 72 h | Sample thickness: 0.5 mm | [13] |

| de Sá Araujo | Temperature: 60 °C Aging time: 10, 20, 30, 40, 50, 100, 150 and 200 h | Sample thickness: 0.6 mm | [24] |

| Henglong Zhang | Temperature: 60 °C Aging time: 12 d | Sample thickness: 1.92 mm | [25] |

| Zhengang Feng | Temperature: 60 °C Aging time: 6 d | Sample thickness: 2 mm | [26] |

| Peiliang Cong | Temperature: 60 °C Aging time: 7 d | Sample thickness: 3 mm | [27] |

| Song Xu | Temperature: 60 °C Aging time: 9 d | Sample thickness: 3.2 mm | [28] |

| Physical Properties | B |

|---|---|

| Softening point (°C) | 49.0 |

| Penetration (25 °C, 0.1 mm) | 77.5 |

| Ductility (5 °C, 1 cm/min) | 8.9 |

| Viscosity (60 °C, Pa s) | 205 |

| Viscosity (135 °C, Pa s) | 0.46 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Wu, S.; Liu, Q.; García Hernández, M.I.; Zeng, W.; Nie, S.; Wan, J.; Zhang, D.; Li, Y. The Effect of Ultraviolet Radiation on Bitumen Aging Depth. Materials 2018, 11, 747. https://doi.org/10.3390/ma11050747

Hu J, Wu S, Liu Q, García Hernández MI, Zeng W, Nie S, Wan J, Zhang D, Li Y. The Effect of Ultraviolet Radiation on Bitumen Aging Depth. Materials. 2018; 11(5):747. https://doi.org/10.3390/ma11050747

Chicago/Turabian StyleHu, Jinxuan, Shaopeng Wu, Quantao Liu, Maria Inmaculada García Hernández, Wenbo Zeng, Shuai Nie, Jiuming Wan, Dong Zhang, and Yuanyuan Li. 2018. "The Effect of Ultraviolet Radiation on Bitumen Aging Depth" Materials 11, no. 5: 747. https://doi.org/10.3390/ma11050747

APA StyleHu, J., Wu, S., Liu, Q., García Hernández, M. I., Zeng, W., Nie, S., Wan, J., Zhang, D., & Li, Y. (2018). The Effect of Ultraviolet Radiation on Bitumen Aging Depth. Materials, 11(5), 747. https://doi.org/10.3390/ma11050747