Microscopic View of Defect Evolution in Thermal Treated AlGaInAs Quantum Well Revealed by Spatially Resolved Cathodoluminescence

Abstract

:1. Introduction

2. Materials and Methods

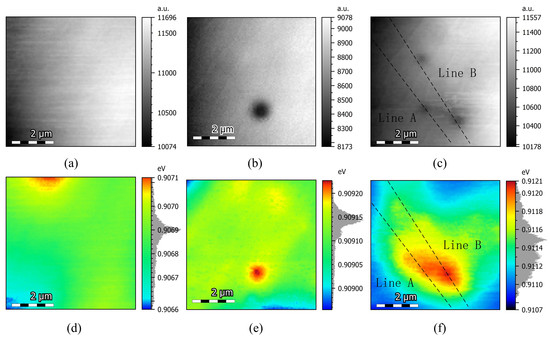

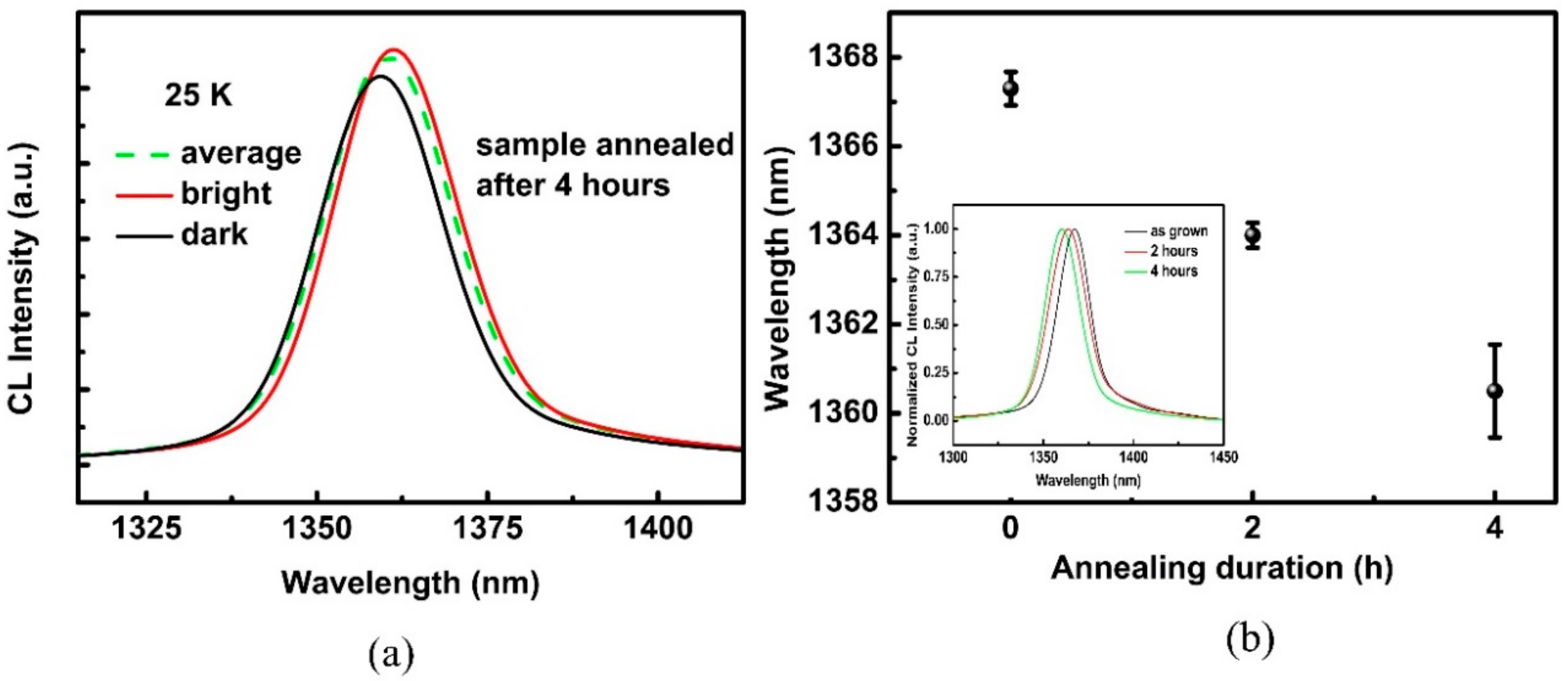

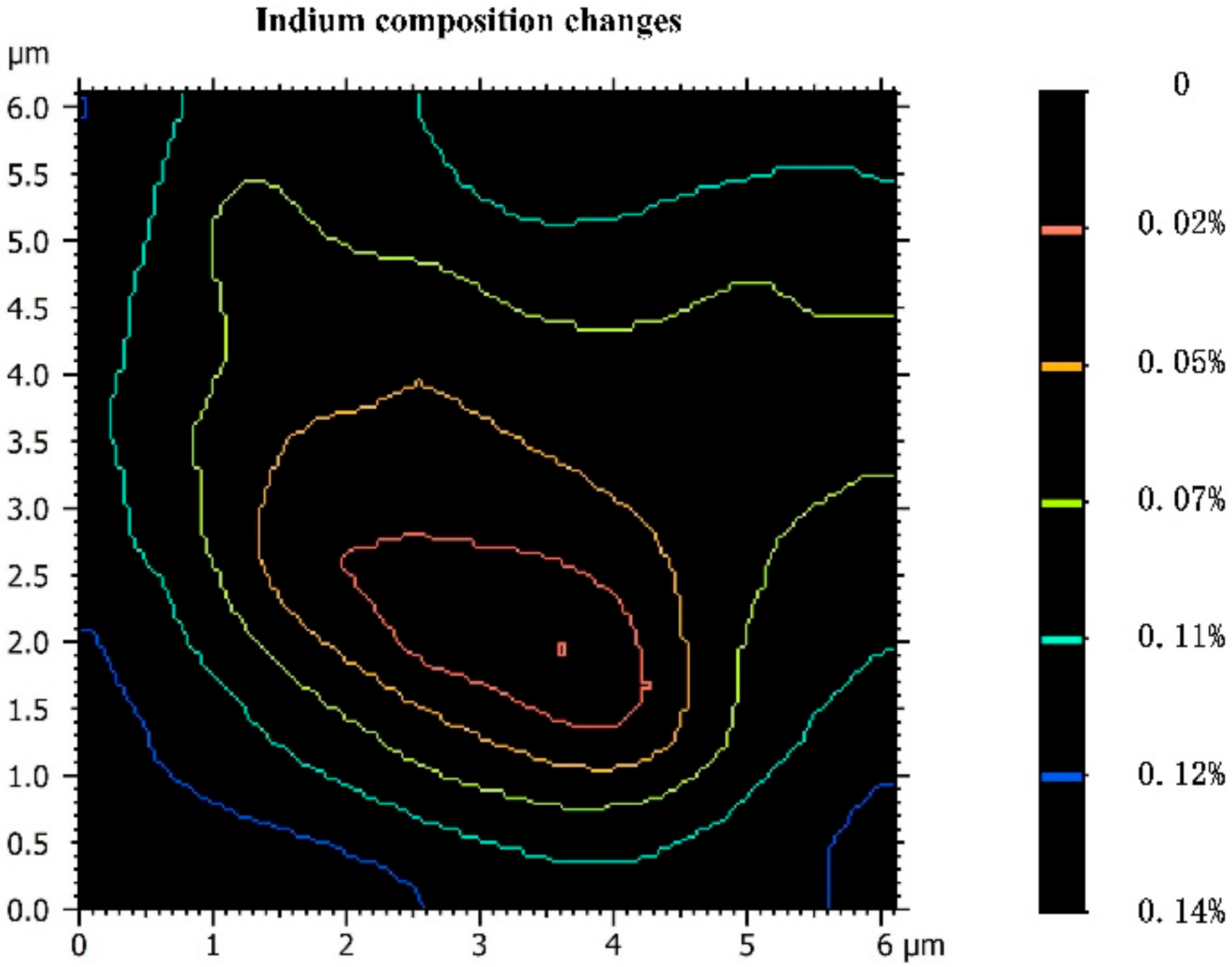

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amann, M.C.; Ortsiefer, M. Long-wavelength (λ ≥ 1.3 µm) InGaAlAs-InP vertical-cavity surface-emitting lasers for applications in optical communication and sensing. Phys. Status Solidi (a) 2006, 203, 3538–3544. [Google Scholar] [CrossRef]

- Pitts, O.J.; Benyon, W.; Springthorpe, A.J. Modeling and process control of MOCVD growth of InAlGaAs MQW structures on InP. J. Cryst. Growth 2014, 393, 81–84. [Google Scholar] [CrossRef]

- Caliman, A.; Mereuta, A.; Suruceanu, G.; Iakovlev, V.; Sirbu, A.; Kapon, E. 8 mW fundamental mode output of wafer-fused VCSELS emitting in the 1550-nm band. Opt. Express 2011, 19, 16996–17001. [Google Scholar] [CrossRef] [PubMed]

- Yong, J.C.L.; Rorison, J.M.; White, I.H. 1.3-μm quantum-well InGaAsP, AlGaInAs, and InGaAsN laser material gain: A theoretical study. IEEE J. Quantum Electron. 2002, 38, 1553–1564. [Google Scholar] [CrossRef]

- Sweeney, S.J.; Higashi, T.; Andreev, A.; Adams, A.R.; Uchida, T.; Fujii, T. Superior temperature performance of 1.3 μm AlGaInAs-based semiconductor lasers investigated at high pressure and low temperature. Phys. Status Solidi (b) 2001, 223, 573–579. [Google Scholar] [CrossRef]

- Kubota, M.; Hamano, K.; Takemasa, K.; Kobayashi, M.; Wada, H.; Munakata, T. Thermal properties of 1.3 μm AlGaInAs multi quantum well ridge waveguide lasers. Jpn. J. Appl. Phys. 2000, 39, 2297–2300. [Google Scholar] [CrossRef]

- Bernussi, A.A.; Temkin, H. High temperature properties of quaternary quantum well laser diodes. Braz. J. Phys. 1997, 27, 29–37. [Google Scholar]

- Wong, S.L.; Nicholas, R.J.; Martin, R.W.; Thompson, J.; Wood, A.; Moseley, A.; Carr, N. A megnetooptical study of interdiffusion in InGaAs/InP quantum wells: Effects of heat treatment, substrates, and dopants. J. Appl. Phys. 1996, 79, 6826–6833. [Google Scholar] [CrossRef]

- Puchtler, T.J.; Woolf, A.; Zhu, T.; Gachet, D.; Hu, E.L.; Oliver, R.A. Effect of threading dislocations on the quality factor of InGaN/GaN microdisk cavities. ACS Photonics 2015, 2, 137–143. [Google Scholar] [CrossRef] [PubMed]

- David, S.; Roque, J.; Rochat, N.; Bernier, N.; Piot, L.; Alcotte, R.; Cerba, T.; Martin, M.; Moeyaert, J.; Bogumilowizc, Y.; et al. Spatially correlated structural and optical characterization of a single InGaAs quantum well fin selectively grown on Si by microscopy and cathodoluminescence techniques. APL Mater. 2016, 4, 056102. [Google Scholar] [CrossRef] [Green Version]

- Zheng, S.; So, J.; Liu, F.; Liu, Z.; Zheludev, N.I.; Fan, H.J. Giant enhancement of cathodoluminescence of monolayer transitional metal dichalcogenides semiconductors. Nano Lett. 2017, 17, 6475–6480. [Google Scholar] [CrossRef] [PubMed]

- Massabuau, F.C.; Rhode, S.L.; Horton, M.K.; O’Hanlon, T.J.; Kovács, A.; Zielinski, M.S.; Kappers, M.J.; Dunin-Borkowski, R.E.; Humphreys, C.J.; Oliver, R.A. Dislocations in AlGaN: Core structure, atom segregation, and optical properties. Nano Lett. 2017, 17, 4846–4852. [Google Scholar] [CrossRef] [PubMed]

- Doan, M.H.; Lee, J. Spatially resolved cathodoluminescence in the vicinity of defects in the high-efficiency InGaN/GaN blue light emitting diodes. Adv. Condens. Matter Phys. 2014, 2014, 109–113. [Google Scholar] [CrossRef]

- Muraki, K.; Fukatsu, S.; Shiraki, Y.; Ito, R. Surface segregation of In atoms during molecular beam epitaxy and its influence on the energy levels in InGaAs/GaAs quantum wells. Appl. Phys. Lett. 1992, 61, 557–559. [Google Scholar] [CrossRef]

- Chichibu, S.F.; Uedono, A.; Onuma, T.; Haskell, B.A.; Chakraborty, A.; Koyama, T.; Fini, P.T.; Keller, S.; Denbaars, S.P.; Speck, J.S.; et al. Origin of defect-insensitive emission probability in In-containing (Al, In, Ga)N alloy semiconductors. Nat. Mater. 2006, 5, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Lu, J.; Gao, Z.; Lai, L.; Qin, R.; Li, H.; Zhou, J.; Li, G. Electron localization and emission mechanism in wurtzite (Al, In, Ga) N alloys. Phys. Status Solidi (b) 2010, 247, 109–114. [Google Scholar] [CrossRef]

- Marsh, J.H. Quantum well intermixing. Semicond. Sci. Technol. 1999, 8, 1136–1155. [Google Scholar] [CrossRef]

- Li, X.J.; Qi, L.F.; Guo, W.L.; Yu, J.L.; Zhao, Y.L.; Cai, D.M.; Yin, S.Z.; Mao, L.H. AlGaInAs multi-quantum wells ring laser with optical coupling waveguides. Chin. Sci. Bull. 2009, 54, 3716–3719. [Google Scholar] [CrossRef]

- Sin, Y.; Ives, N.; Lalumondiere, S.; Presser, N.; Moss, S.C. Catastrophic optical bulk damage (COBD) in high power multi-mode InGaAs-AlGaAs strained quantum well lasers. In High-Power Diode Laser Technology and Applications IX; Proceedings of SPIE LASE, San Francisco, CA, USA, 22–27 January 2011; International Society for Optics and Photonics: Bellingham, WA, USA, 2011; Volume 7918, p. 791803. [Google Scholar] [CrossRef]

- Binet, G.; Decobert, J.; Lagay, N.; Maia, A.D.B.; Lagrée, P.Y.; Rinaldi, F. Selective area grown AlGaInAs multi-quantum wells characterization and modeling for photonic integrated devices. In Proceedings of the 2016 Compound Semiconductor Week (CSW) [Includes 28th International Conference on Indium Phosphide & Related Materials (IPRM) & 43rd International Symposium on Compound Semiconductors (ISCS)], Toyama, Japan, 26–30 June 2016; pp. 1–2. [Google Scholar]

- Décobert, J.; Guillamet, R.; Mocuta, C.; Carbone, G.; Guerault, H. Structural characterization of selectively grown multilayers with new high angular resolution and sub-millimeter spot-size X-ray diffractometer. J. Cryst. Growth 2013, 370, 154–156. [Google Scholar] [CrossRef]

- Qiao, Y.B.; Feng, S.W.; Xiong, C.; Wang, X.W.; Ma, X.Y.; Zhu, H.; Wei, G.H. Spatial hole burning degradation of AlGaAs/GaAs laser diodes. Appl. Phys. Lett. 2011, 99, 103506. [Google Scholar] [CrossRef]

- Albrecht, M.; Grillo, V.; Remmele, T.; Strunk, H.P. Effect of annealing on the In and N distribution in InGaAsN quantum wells. Appl. Phys. Lett. 2002, 81, 2719–2721. [Google Scholar] [CrossRef]

- Corfdir, P.; Simeonov, D.; Feltin, E.; Carlin, J.F.; Lefebvre, P.; Grandjean, N.; Deveaud-Plédran, B.; Ganière, J.D. Time-resolved cathodoluminescence on polychromatic light emitting (In, Ga) N quantum wells grown on (11-22) GaN facets. Phys. Status Solidi (c) 2011, 8, 1394–1397. [Google Scholar] [CrossRef]

- Garrett, G.A.; Collins, C.J.; Sampath, A.V.; Shen, H.; Wraback, M.; Leboeuf, S.F.; Flynn, J.; Brandes, G. Defect density dependence of carrier dynamics in AlGaN multiple quantum wells grown on GaN substrates and templates. Phys. Status Solidi (c) 2005, 2, 2332–2336. [Google Scholar] [CrossRef]

- Kagaya, M.; Corfdir, P.; Ganière, J.D.; Deveaud-Plédran, B.; Grandjean, N.; Chichibu, S.F. Implementation of spatio-time-resolved cathodoluminescence spectroscopy for studying local carrier dynamics in a low dislocation density m-plane In0.05Ga0.95N epilayer grown on a freestanding GaN substrate. Jpn. J. Appl. Phys. 2011, 50, 111002. [Google Scholar] [CrossRef]

- Shahmohammadi, M.; Ganière, J.D.; Zhang, H.; Ciechonski, R.; Vescovi, G.; Kryliouk, O.; Tchernycheva, M.; Jacopin, G. Excitonic diffusion in InGaN/GaN core-shell nanowires. Nano Lett. 2015, 16, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Pinault, M.A.; Tournié, E. On the origin of carrier localization in Ga1−xInxNyAs1−y/GaAs quantum wells. Appl. Phys. Lett. 2001, 78, 1562–1564. [Google Scholar] [CrossRef]

- Romero, M.J.; Gutiérrez, M.; Sánchez, J.J.; González, D.; Aragón, G.; Izpura, I.; Garcı́A, R. Cathodoluminescence study of pyramidal facets in piezoelectric InGaAs/GaAs multiple quantum well pin photodiodes. Microelectron. J. 1999, 30, 427–431. [Google Scholar] [CrossRef]

- Miguel-Sánchez, J.; Jahn, U.; Guzmán, A.; Muñoz, E. Cathodoluminescence investigations of GaInNAs on GaAs(111)B. Appl. Phys. Lett. 2006, 89, 231901. [Google Scholar] [CrossRef]

- Massabuau, C.P.; Chen, P.; Horton, M.K.; Rhode, S.L.; Ren, C.X.; O’Hanlon, T.J.; Kovács, A.; Kappers, M.J.; Humphreys, C.J.; Dunin-Borkowski, R.E. Carrier localization in the vicinity of dislocations in InGaN. J. Appl. Phys. 2017, 121, 013104. [Google Scholar] [CrossRef] [Green Version]

- Cipro, R.; Baron, T.; Martin, M.; Moeyaert, J.; David, S.; Gorbenko, V.; Bassani, F.; Bogumilowicz, Y.; Barnes, J.P.; Rochat, N.; et al. Low defect InGaAs quantum well selectively grown by metal organic chemical vapor deposition on Si(100) 300 mm wafers for next generation non planar devices. Appl. Phys. Lett. 2014, 104, 262103. [Google Scholar] [CrossRef]

- Lazzarini, L.; Salviati, G.; Franchi, S.; Napolitani, E. A TEM and SEM-cathodoluminescence study of oval defects in graded InGaAs/GaAs buffer layers. Mater. Sci. Eng. B 2001, 80, 120–124. [Google Scholar] [CrossRef]

- Ryczko, K.; Sęk, G.; Motyka, M.; Janiak, F.; Kubisa, M.; Misiewicz, J.; Belahsene, S.; Boissier, G.; Rouillard, Y. Effect of annealing-induced interdiffusion on the electronic structure of mid infrared emitting GaInAsSb/AlGaInAsSb quantum wells. Jpn. J. Appl. Phys. 2011, 50, 031202. [Google Scholar] [CrossRef]

- Tchernycheva, M.; Neplokh, V.; Zhang, H.; Lavenus, P.; Rigutti, L.; Bayle, F.; Julien, F.H.; Babichev, A.; Jacopin, G.; Largeau, L. Core-shell InGaN/GaN nanowire light emitting diodes analyzed by electron beam induced current microscopy and cathodoluminescence mapping. Nanoscale 2015, 7, 11692–11701. [Google Scholar] [CrossRef] [PubMed]

- Jensen, J.R.; Hvam, J.M.; Langbein, W. InAlGaAs/AlGaAs quantum wells: Line widths, transition energies and segregation. Microelectron. Eng. 2000, 51–52, 257–264. [Google Scholar] [CrossRef]

- Mei, T. Interpolation of quaternary III-V alloy parameters with surface bowing estimations. J. Appl. Phys. 2007, 101, 013520. [Google Scholar] [CrossRef]

- Yekta, V.B.; Kaatuzian, H. Simulation and temperature characteristics improvement of 1.3 μm AlGaInAs multiple quantum well laser. Int. J. Opt. Appl. 2014, 4, 46–53. [Google Scholar] [CrossRef]

- Fang, Z.M.; Ma, K.Y.; Jaw, D.H.; Cohen, R.M.; Stringfellow, G.B. Photoluminescence of InSb, InAs, and InAsSb grown by organometallic vapor phase epitaxy. J. Appl. Phys. 1990, 67, 7034–7039. [Google Scholar] [CrossRef]

- Ishikawa, T.; Bowers, J.E. Band lineup and in-plane effective mass of InGaAsP or InGaAlAs on InP strained-layer quantum well. IEEE J. Quantum Electron. 1994, 30, 562–570. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Zhang, L.; Zeng, Y.; Qin, L.; Zhou, Y.; Ning, Y.; Wang, L. Microscopic View of Defect Evolution in Thermal Treated AlGaInAs Quantum Well Revealed by Spatially Resolved Cathodoluminescence. Materials 2018, 11, 1049. https://doi.org/10.3390/ma11061049

Song Y, Zhang L, Zeng Y, Qin L, Zhou Y, Ning Y, Wang L. Microscopic View of Defect Evolution in Thermal Treated AlGaInAs Quantum Well Revealed by Spatially Resolved Cathodoluminescence. Materials. 2018; 11(6):1049. https://doi.org/10.3390/ma11061049

Chicago/Turabian StyleSong, Yue, Ligong Zhang, Yugang Zeng, Li Qin, Yinli Zhou, Yongqiang Ning, and Lijun Wang. 2018. "Microscopic View of Defect Evolution in Thermal Treated AlGaInAs Quantum Well Revealed by Spatially Resolved Cathodoluminescence" Materials 11, no. 6: 1049. https://doi.org/10.3390/ma11061049

APA StyleSong, Y., Zhang, L., Zeng, Y., Qin, L., Zhou, Y., Ning, Y., & Wang, L. (2018). Microscopic View of Defect Evolution in Thermal Treated AlGaInAs Quantum Well Revealed by Spatially Resolved Cathodoluminescence. Materials, 11(6), 1049. https://doi.org/10.3390/ma11061049