Influence of Homogenization on Microstructural Response and Mechanical Property of Al-Cu-Mn Alloy

Abstract

:1. Introduction

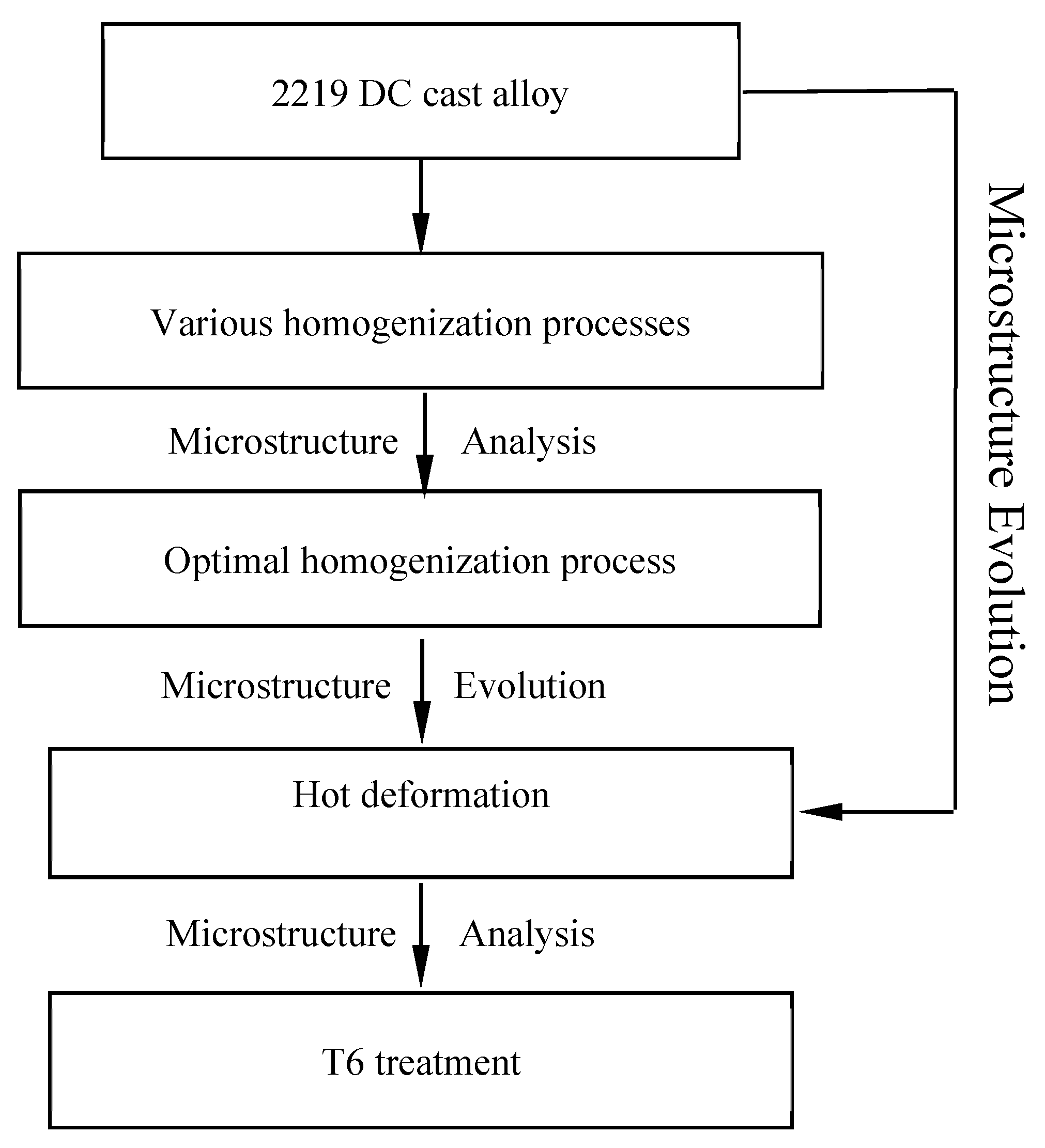

2. Experimental Procedures

3. Results and Discussion

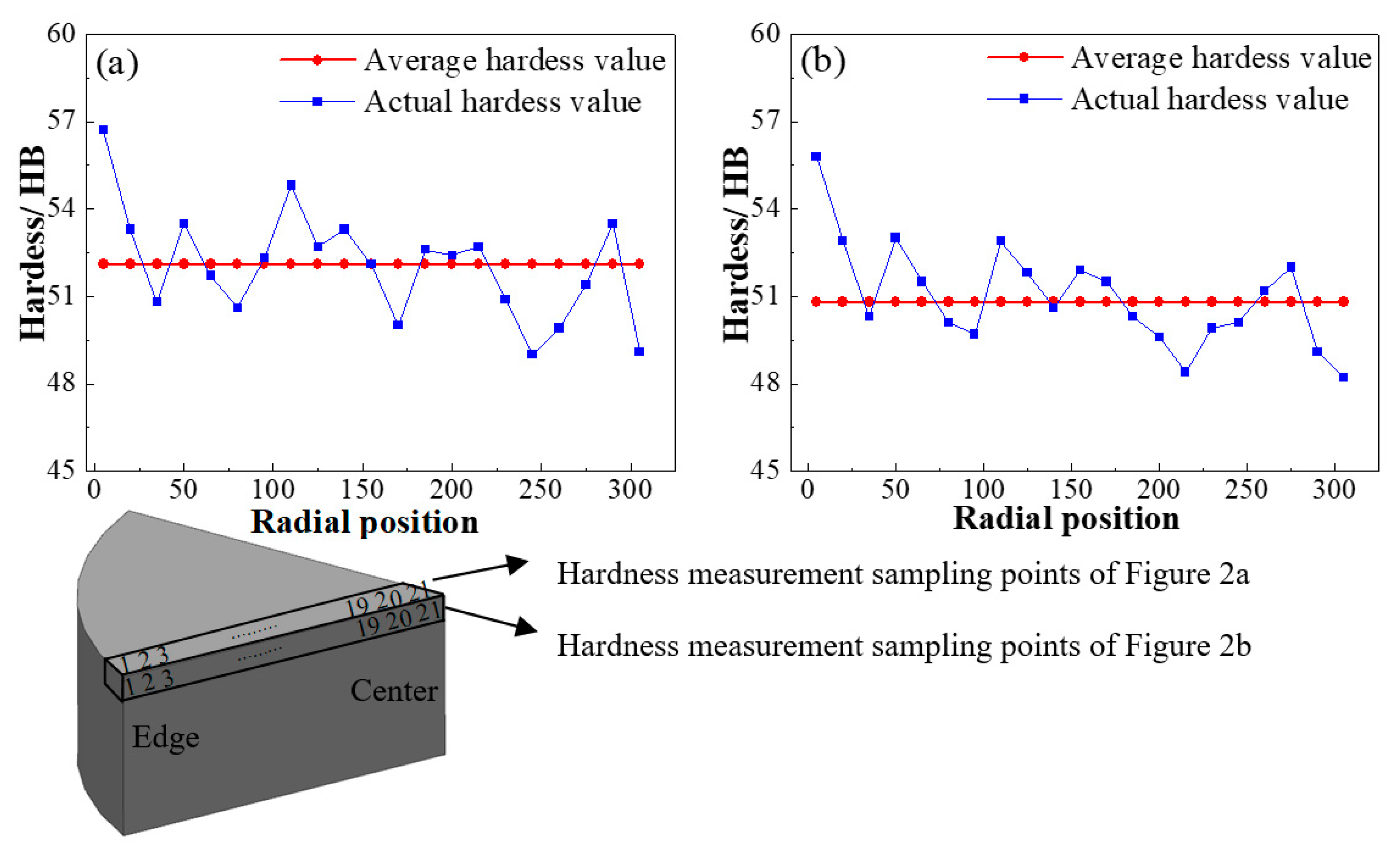

3.1. Characteristics of Large Ingot Prepared by DC Casting

3.2. As-Cast Microstructure

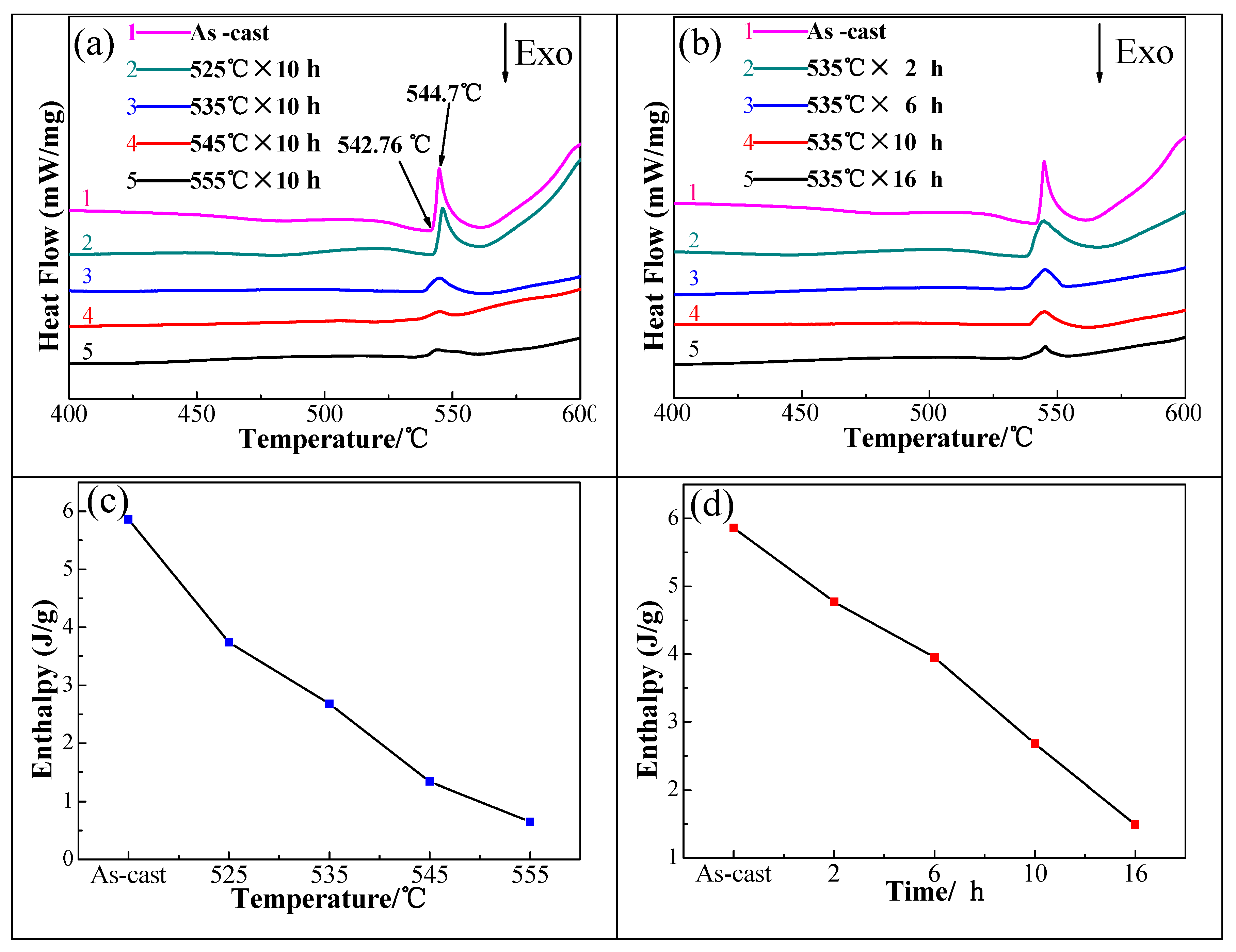

3.3. Dissolution Characteristics of Elements and Phases

3.4. Microstructure of Homogenized Alloys

3.5. Response Behaviors of Microstructure

3.5.1. SEM and TEM Observations

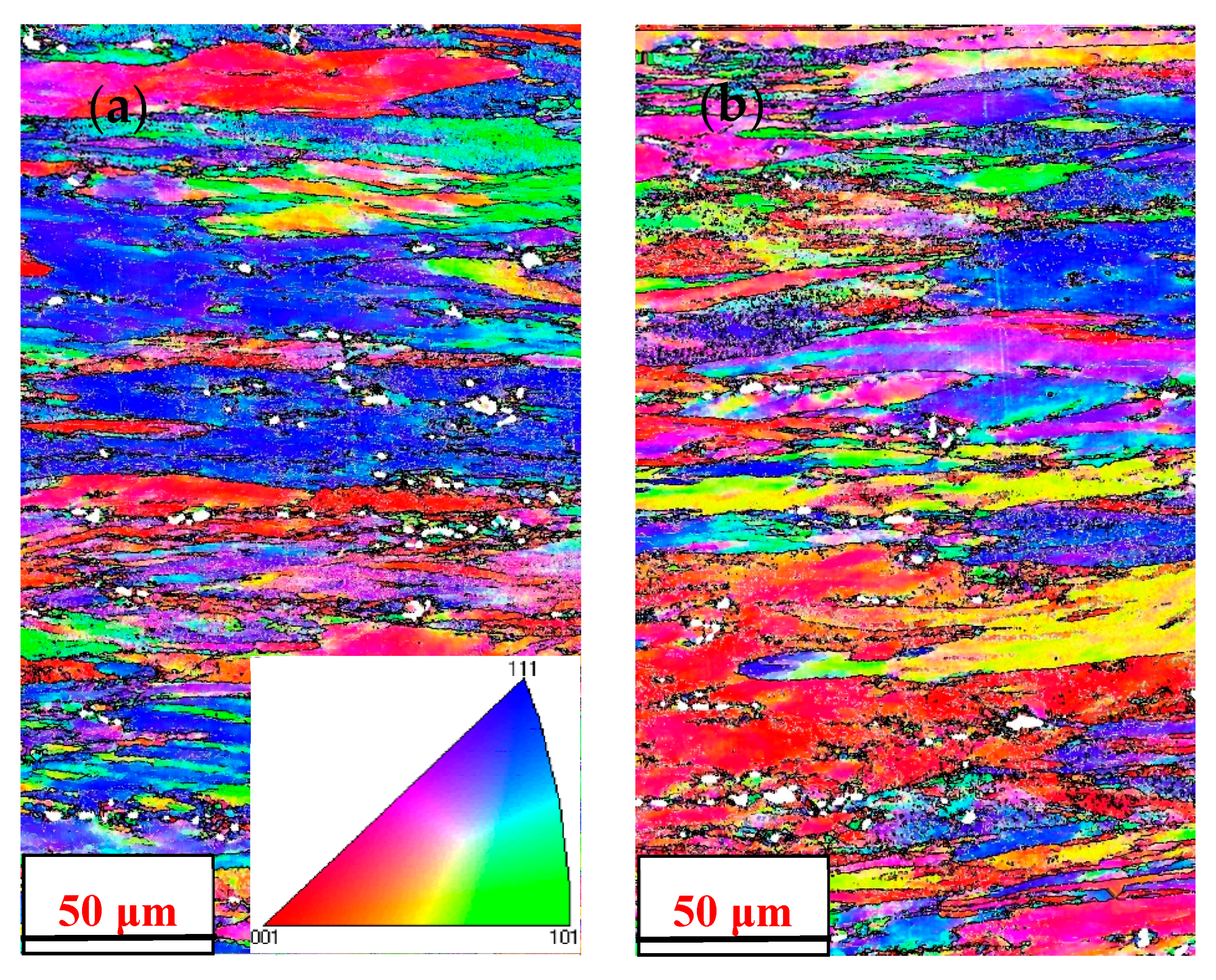

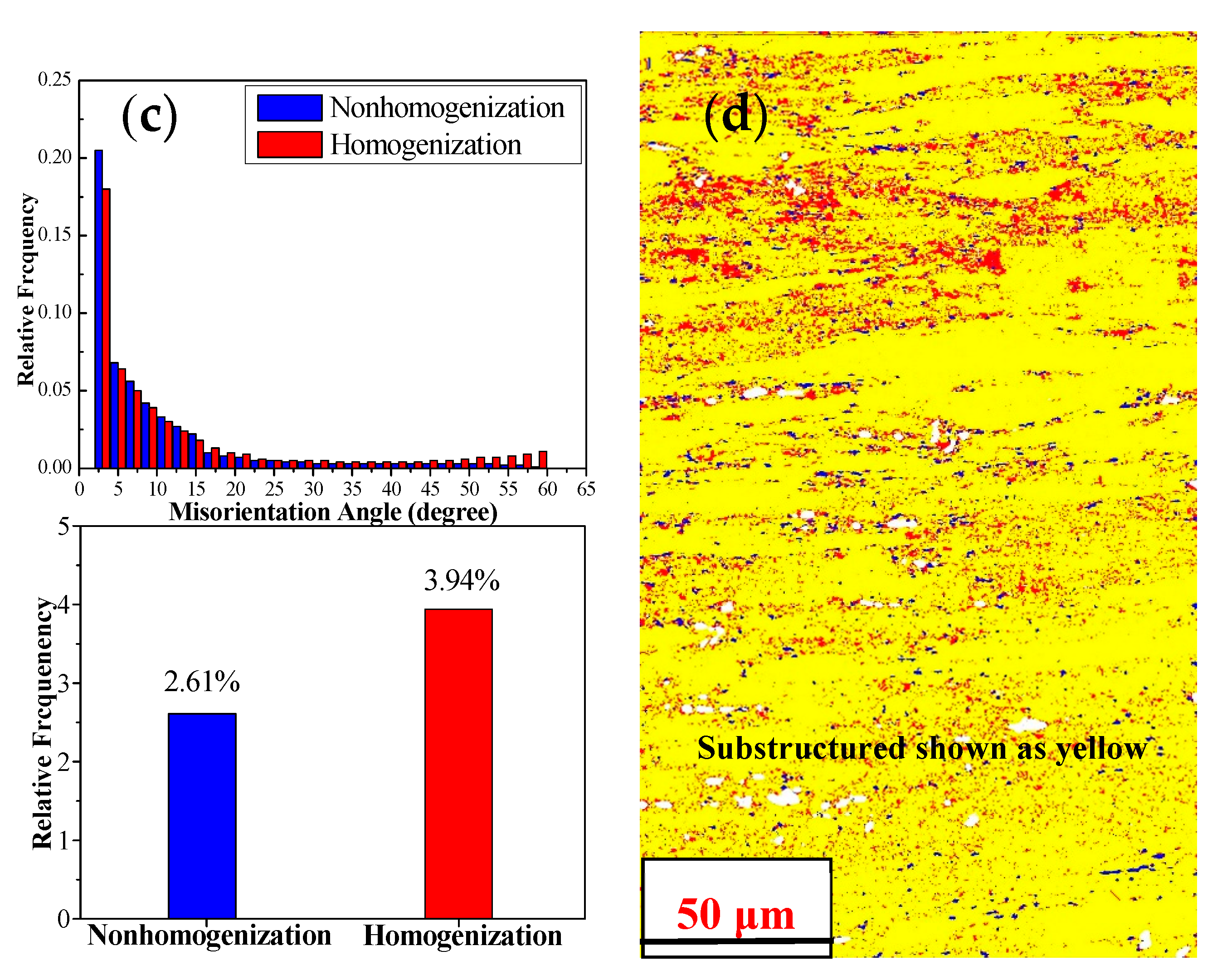

3.5.2. EBSD Analysis

3.6. Influence of the Microstructural Response on the Mechanical Properties

3.6.1. Mechanical Properties of Alloy Forging

3.6.2. Strengthening Mechanism of Alloy Forging

4. Conclusions

- Severe dendritic segregation was present in large-size DC-cast Al-Cu-Mn alloy ingots. The main elements Cu, Mn, Fe were largely segregated in the grain boundary. There were massive non-equilibrium eutectic phases in the as-cast alloy, and the dissolvable secondary phase was θ (Al2Cu).

- The dendritic-network structures were eliminated sufficiently, the non-equilibrium phases along the grain boundaries became sparser and the distribution of all the elements became more homogenized by using the optimal homogenization process. Besides, the morphology of insoluble compounds Al7Cu2Fe was not regular and it remained nearly unchanged during homogenization.

- Homogenization can generate more homogenous microstructures with higher number density of dislocation networks, higher density of evenly-distributed θ′ or θ phase (Al2Cu), finer grains, higher volume fraction of high-angle grain boundaries, and higher volume fraction of recrystallized grains compared with unhomogenized alloys during rolling and subsequent T6 treatment.

- The tensile strength, yield strength and the elongation of the alloys with homogenization treatment were increased by 5.87%, 6.83%, and 11.07% compared to nonhomogenized alloy. The suitable homogenization processing was determined to be 535 °C × 10 h.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, R.Z.; Wang, Z.T. Aluminum Alloy and Its Processing Manual; Central South University Press: Changsha, China, 2000. (In Chinese) [Google Scholar]

- Lu, Y.L.; Wang, J.; Li, X.C.; Chen, Y.; Zhou, D.S.; Zhou, G.; Xu, W.T. Effect of pre-deformation on the microstructures and properties of2219 aluminum alloy during aging treatment. J. Alloys Compd. 2017, 699, 1140–1145. [Google Scholar] [CrossRef]

- Owolabi, G.M.; Bolling, D.T.; Tiamiyu, A.A.; Abu, R.; Odeshi, A.G.; Whitworth, H.A. Shear strain localization in AA 2219-T8 aluminum alloy at high strain rates. Mater. Sci. Eng. A 2016, 655, 212–220. [Google Scholar] [CrossRef]

- Lin, Y.T.; Wang, M.C.; Zhang, Y.; He, Y.Z.; Wang, D.P. Investigation of microstructure evolution after post-weld heat treatment and cryogenic fracture toughness of the weld metal of AA2219 VPTIG joints. Mater. Des. 2017, 113, 54–59. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Sitdikov, O.; Mazurina, I.; Lesuer, D.R. Deformation behavior of a 2219 Al alloy. Mater. Sci. Eng. A 2002, 334, 104–113. [Google Scholar] [CrossRef]

- Mazutina, I.; Sakai, T.; Miura, H.; Sitdikov, O.; Kaibyshev, R. Effect of deformation temperature on microstructure evolution in aluminum alloy 2219 during hot ECAP. Mater. Sci. Eng. A 2008, 486, 662–671. [Google Scholar] [CrossRef]

- Prabhu, T.R. Effects of ageing time on the mechanical and conductivity properties for various round bar diameters of AA 2219 Al alloy. Eng. Sci. Technol. Int. J. 2017, 20, 133–142. [Google Scholar] [CrossRef]

- Yang, Y.L.; Zhan, L.H.; Shen, R.L.; Yin, X.N.; Li, X.C.; Li, W.K.; Huang, M.H.; He, D.Q. Effect of pre-deformation on creep age forming of 2219 aluminum alloy: Experimental and constitutive modeling. Mater. Sci. Eng. A 2017, 683, 227–235. [Google Scholar] [CrossRef]

- Lu, Y.L.; Li, M.Q.; Li, X.C.; Li, X.P. Microscopic characterization of semi-solid aluminum alloys. Int. J. Miner. Metall. Mater. 2010, 17, 290–296. [Google Scholar] [CrossRef]

- Wang, M.; Huang, L.P.; Liu, W.S.; Ma, Y.Z.; Huang, B.Y. Influence of cumulative strain on microstructure and mechanical properties of multi-directional forged 2A14 aluminum alloy. Mater. Sci. Eng. A 2016, 674, 40–51. [Google Scholar] [CrossRef]

- Hou, L.G.; Cai, Y.H.; Cui, H.; Zhang, J.S. Microstructure evolution and phase transformation of traditional cast and spray-formed hypereutectic aluminum-silicon alloys induced by heat treatment. Int. J. Miner. Metall. Mater. 2010, 17, 297–306. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martinez, S.; Ukar, E.; De Lacalle, L.L. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- El Aal, M.I.; Um, H.Y.; Choi, K.H.; Kim, H.S. Effect of homogenization treatment on the microstructure and mechanical property evolutions of as-cast Al-Cu alloy during high-pressure torsion. Mater. Trans. 2014, 55, 1405–1413. [Google Scholar] [CrossRef]

- El Aal, M.I. Influence of the pre-homogenization treatment on the microstructure evolution and the mechanical properties of Al-Cu alloys processed by ECAP. Mater. Sci. Eng. A 2011, 528, 6946–6957. [Google Scholar] [CrossRef]

- El Aal, M.I. The effect of the pre-homogenization treatment on the fracture characteristics and wear properties of ECAPed Al-Cu alloys. Mater. Sci. Eng. A 2012, 539, 308–323. [Google Scholar] [CrossRef]

- Wu, Y.M.; Xiong, J.; Lai, R.M.; Zhang, X.Y.; Guo, Z.X. The microstructure evolution of an Al-Mg-Si-Mn-Cu-Ce alloy during homogenization. J. Alloys Compd. 2009, 475, 332–338. [Google Scholar] [CrossRef]

- Du, Z.M.; Chen, G.; Han, F.; Cao, G.X.; Liu, J.; Li, H.W.; Zhang, X.; Xie, S.S. Homogenization on microstructure and mechanical properties of 2A50 aluminum alloy prepared by liquid forging. Trans. Nonferr. Met. Soc. China 2011, 21, 2384–2390. [Google Scholar] [CrossRef]

- Liu, X.Y.; Pan, Q.L.; Fan, X.; He, Y.B.; Li, W.B.; Liang, W.J. Microstructural evolution of Al-Cu-Mg-Ag alloy during homogenization. J. Alloys Compd. 2009, 484, 790–794. [Google Scholar] [CrossRef]

- Wang, G.J.; Xiong, B.Q.; Zhang, Y.A.; Li, Z.H.; Li, P.Y. Microstructural characterization of as-cast and homogenized 2D70 aluminum alloy. Int. J. Miner. Metall. Mater. 2009, 16, 427–431. [Google Scholar] [CrossRef]

- Xiao, D.H.; Wang, J.N.; Chen, K.H.; Huang, B.Y. Superplastic deformation of a heat-resistant Al-Cu-Mg-Ag-Mn alloy. J. Mater. Process. Technol. 2009, 209, 3300–3305. [Google Scholar]

- Wang, H.J.; Xu, J.; Kang, Y.L.; Tang, M.G.; Zhang, Z.F. Study on inhomogeneous characteristics and optimize homogenization treatment parameter for large size DC ingots of Al-Zn-Mg-Cu alloys. J. Alloys Compd. 2014, 585, 19–24. [Google Scholar] [CrossRef]

- Hou, W.R.; Ji, W.B.; Zhang, Z.H.; Xie, J.X.; Cheng, X.L. The effect of homogenization temperature on the corrosion resistance of extruded 7050 Al-alloy bars. J. Mater. Process. Technol. 2014, 214, 635–640. [Google Scholar] [CrossRef]

- Fan, X.G.; Jiang, D.M.; Meng, Q.C.; Zhong, L. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization. Mater. Lett. 2006, 60, 1475–1479. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys; Elsevier: London, UK; Boston, MA, USA, 1976. [Google Scholar]

- Xia, S.L.; Zhao, X.Q.; Shi, M.J.; Chen, J.H.; Wang, S.B.; Wu, C.L. Homogenization heat treatment of 2519 aluminum alloy. J. Chin. Electron Microsc. Soc. 2012, 31, 469–475. (In Chinese) [Google Scholar]

- Fuller, C.B.; Mahoney, M.W.; Calabrese, M.; Micona, L. Evolution of microstructure and mechanical properties in naturally aged 7050 and 7075 Al friction stir welds. Mater. Sci. Eng. A. 2010, 527, 2233–2240. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.M.; Cong, F.G. Intermetallic phase evolution of 7050 aluminum alloy during homogenization. Intermetallics 2012, 26, 114–121. [Google Scholar] [CrossRef]

- Cong, F.G.; Zhao, G.; Jiang, F.; Tian, N.; Li, R.F. Effect of homogenization treatment on microstructure and mechanical properties of DC cast 7X50 aluminum alloy. Trans. Nonferr. Met. Soc. China 2015, 25, 1027–1034. [Google Scholar] [CrossRef]

- Jiang, H.C.; Ye, L.Y.; Zhang, X.M.; Gu, G.; Zhang, P.; Wu, Y.L. Intermetallic phase evolution of 5059 aluminum alloy during homogenization. Trans. Nonferr. Met. Soc. China 2013, 23, 3553–3560. [Google Scholar] [CrossRef]

- Um, H.Y.; Choi, K.H.; Guo, Z.; Zhao, G.; Chen, X.G. Effects of two-step homogenization on precipitation behavior of Al3Zr dispersoids and recrystallization resistance in 7150 aluminum alloy. Mater. Charact. 2015, 102, 122–130. [Google Scholar]

- Deng, Y.; Yin, Z.M.; Zhao, K.; Duan, J.Q.; Hu, J.; He, Z.B. Effects of Sc and Zr microalloying additions and aging time at 120 °C on the corrosion behaviour of an Al-Zn-Mg alloy. Corros. Sci. 2012, 65, 288–298. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.M.; Zhao, K.; Duan, J.Q.; Hu, J.; He, Z.B. Effects of Sc and Zr microalloying additions on the microstructure and mechanical properties of new Al-Zn-Mg alloys. J. Alloys Compd. 2012, 530, 71–80. [Google Scholar] [CrossRef]

- Gu, J.L.; Ding, J.L.; Williams, S.W.; Gu, H.M.; Bai, J.; Zhai, Y.C.; Ma, P.H. The strengthening effect of inter-layer cold working and post-deposition heat treatment on the additively manufactured Al-6.3Cu alloy. Mater. Sci. Eng. A 2016, 651, 18–26. [Google Scholar] [CrossRef]

- El Aal, M.I.; El Mahallawy, N.; Shehata, F.A.; El Hameed, M.A.; Yoon, E.Y.; Kim, H.S. Wear properties of ECAP-processed ultrafine grained Al-Cu alloys. Mater. Sci. Eng. A 2010, 527, 3726–3732. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Lu, Y.; Zhou, D.; Sun, L.; Li, R.; Xu, W. Influence of Homogenization on Microstructural Response and Mechanical Property of Al-Cu-Mn Alloy. Materials 2018, 11, 914. https://doi.org/10.3390/ma11060914

Wang J, Lu Y, Zhou D, Sun L, Li R, Xu W. Influence of Homogenization on Microstructural Response and Mechanical Property of Al-Cu-Mn Alloy. Materials. 2018; 11(6):914. https://doi.org/10.3390/ma11060914

Chicago/Turabian StyleWang, Jian, Yalin Lu, Dongshuai Zhou, Lingyan Sun, Renxing Li, and Wenting Xu. 2018. "Influence of Homogenization on Microstructural Response and Mechanical Property of Al-Cu-Mn Alloy" Materials 11, no. 6: 914. https://doi.org/10.3390/ma11060914