Simulation of Laser Heating of Aluminum and Model Validation via Two-Color Pyrometer and Shape Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Thermal Modeling

2.1.1. Heat Equations

2.1.2. Heat Source

2.1.3. Material Properties

2.1.4. Virtual Specimen and Meshing

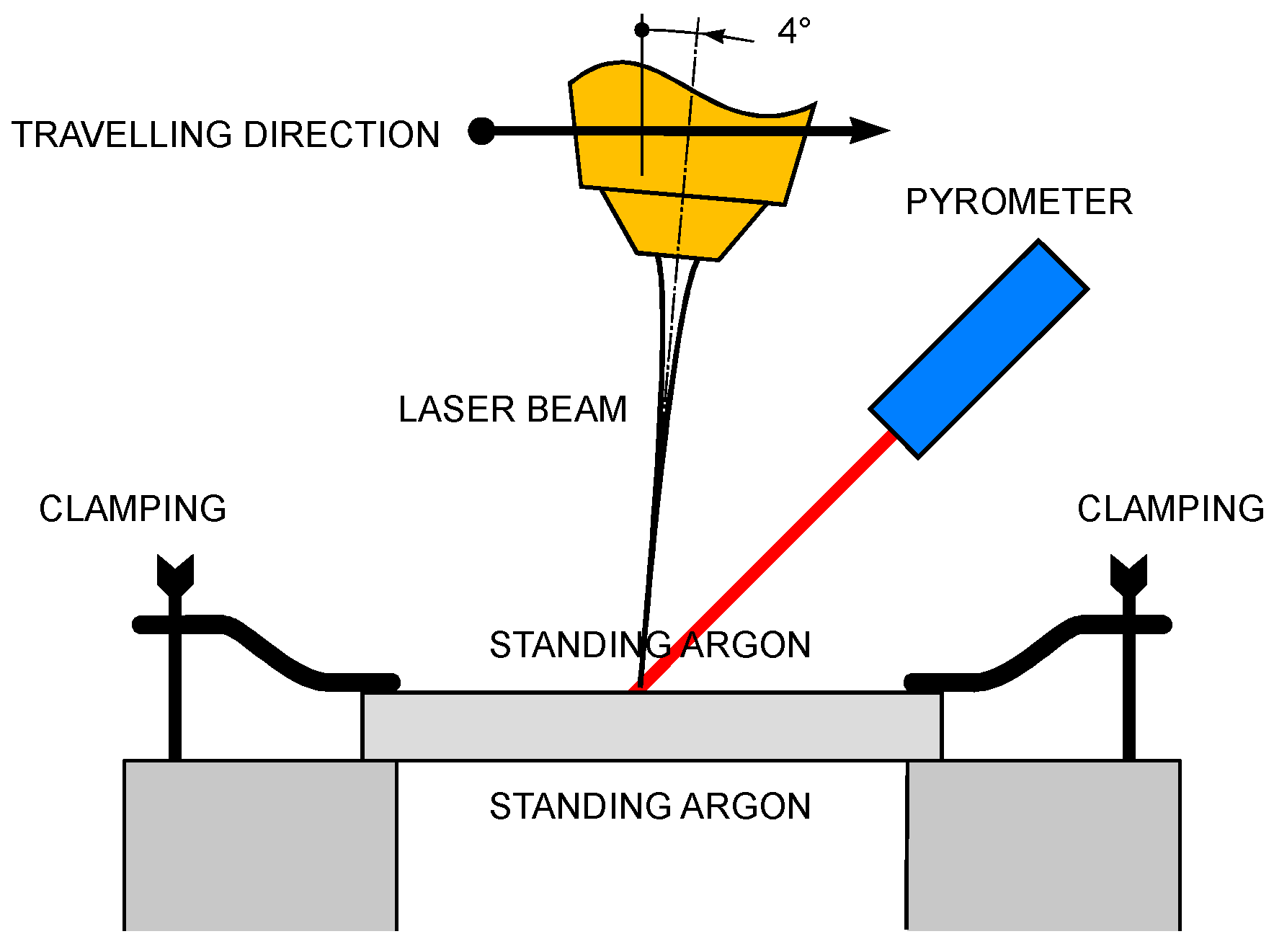

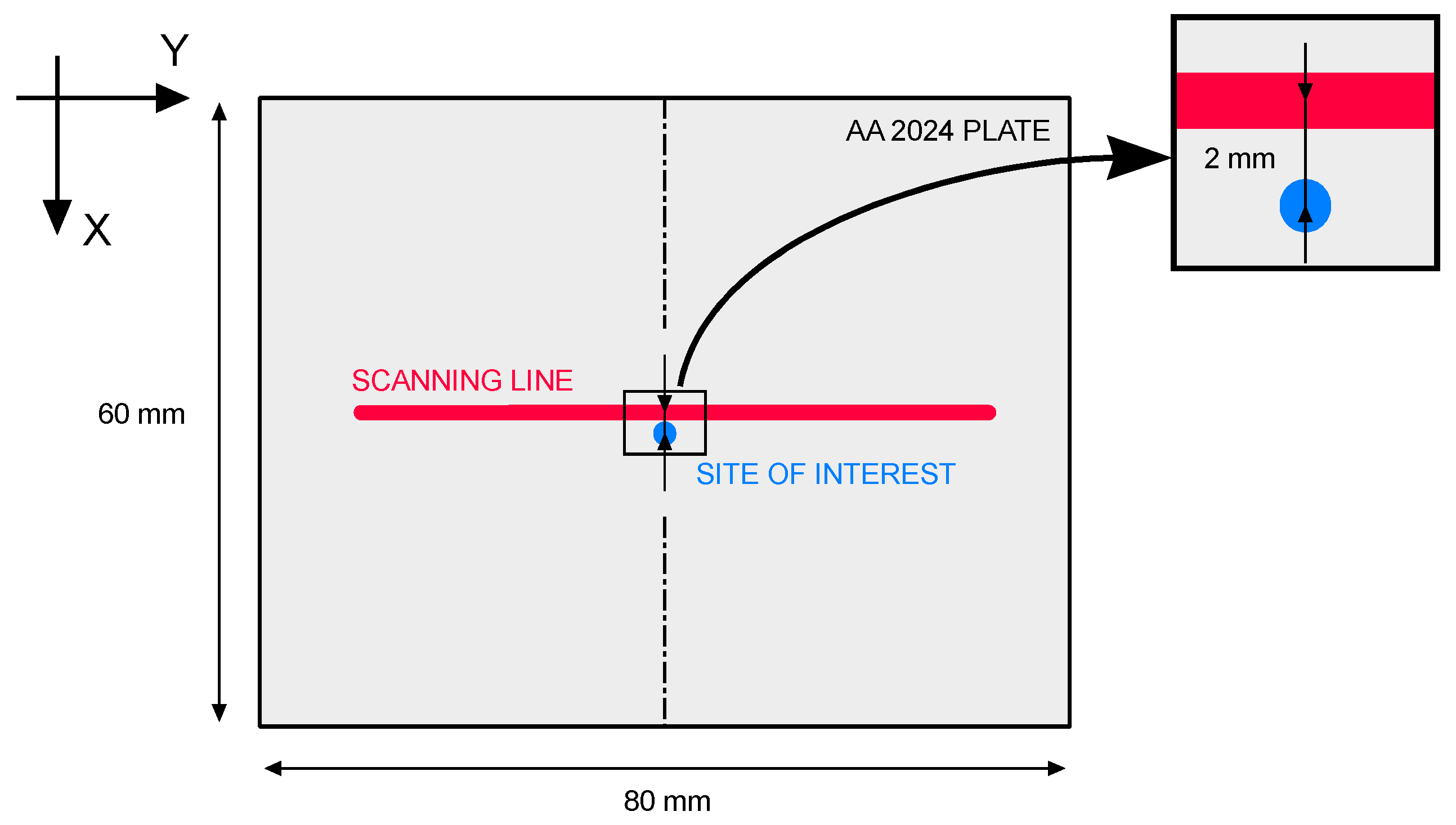

2.2. Experimental Procedure

3. Results and Discussion

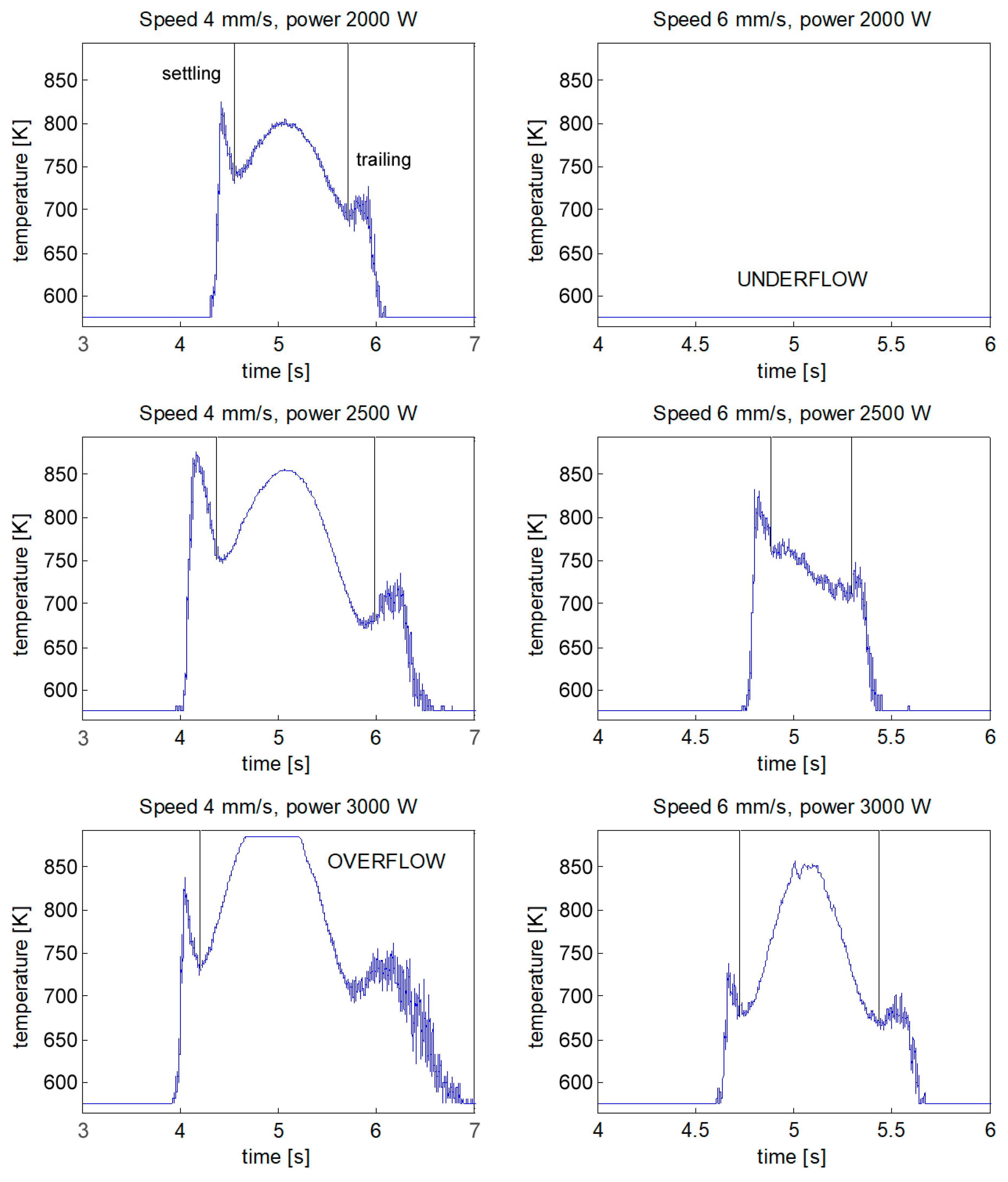

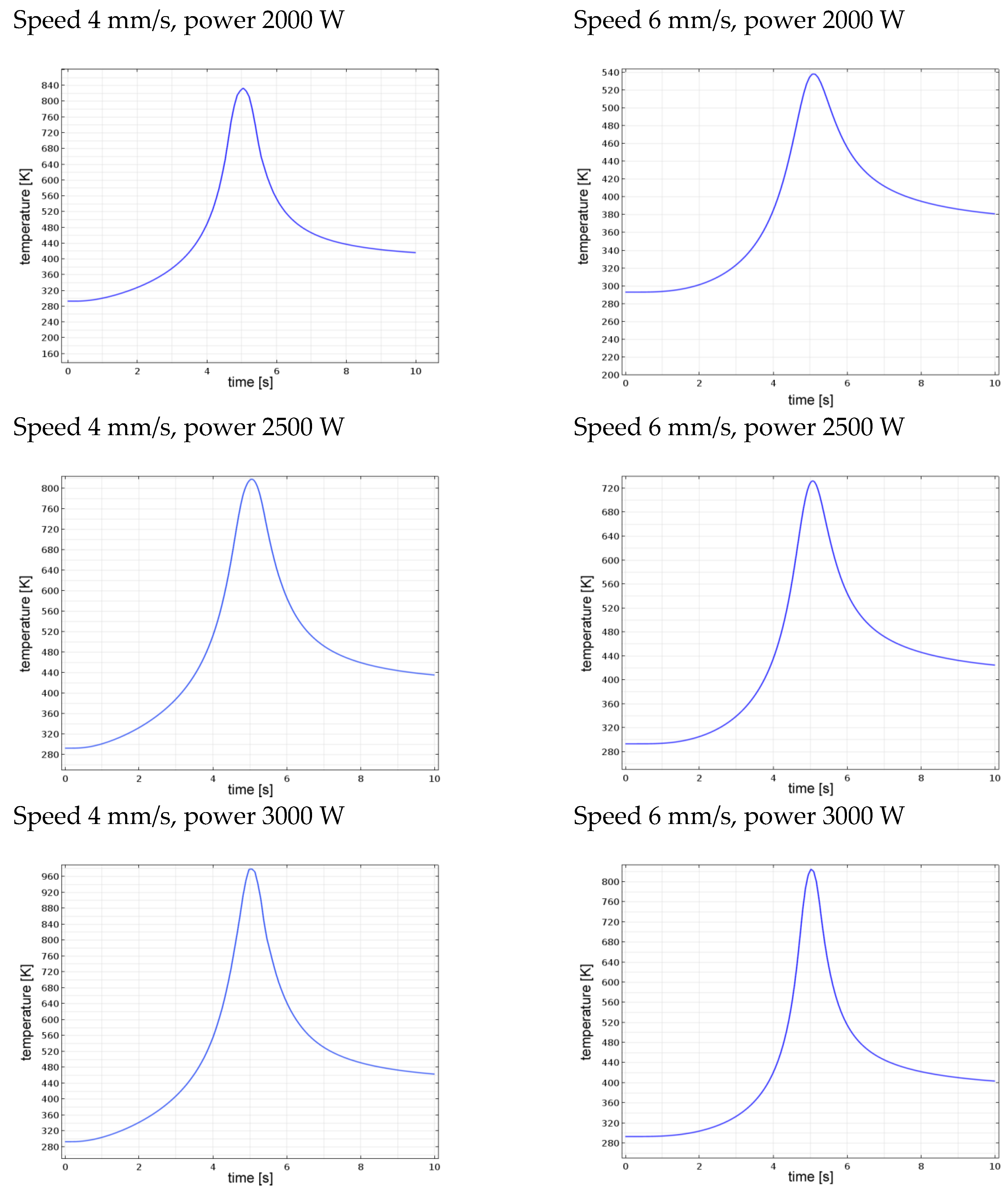

3.1. Local Thermal Cycle

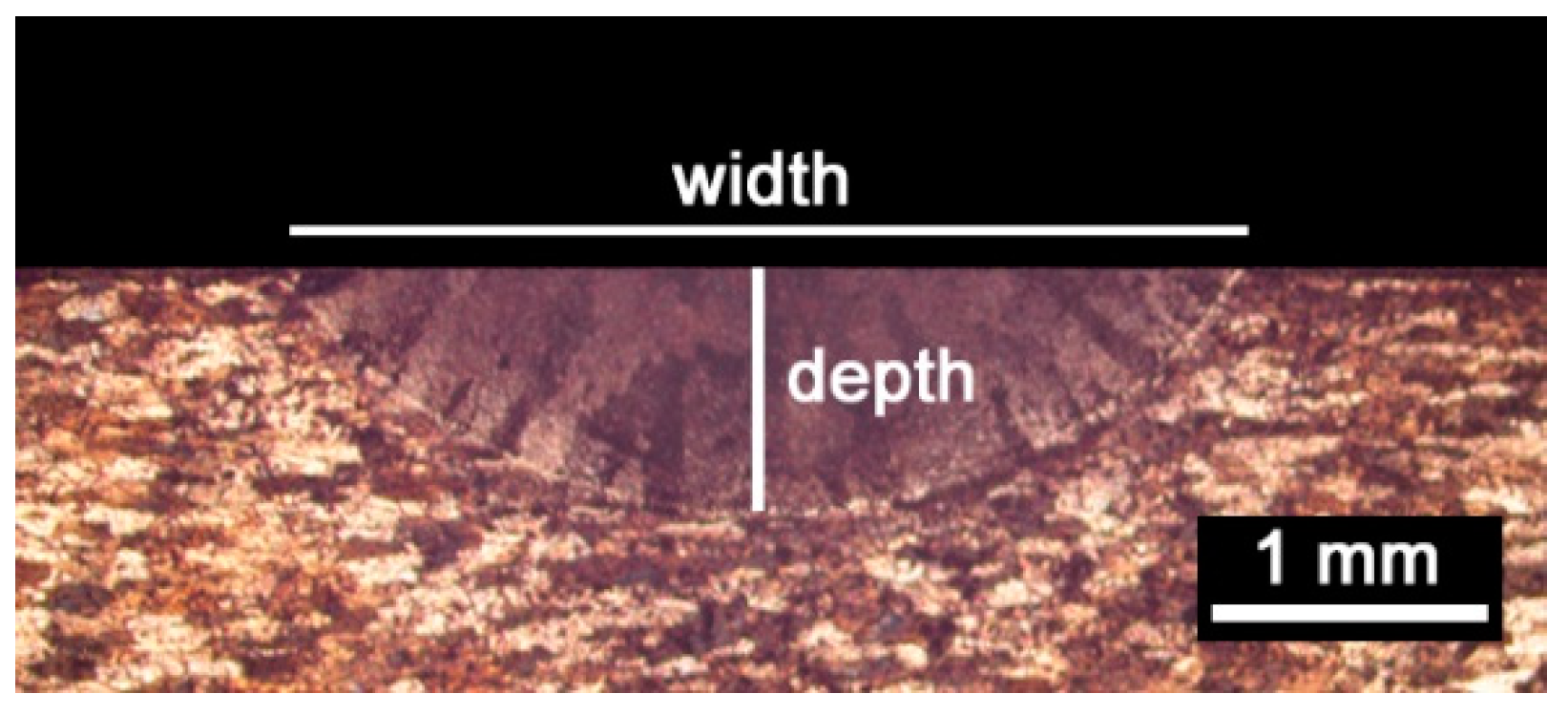

3.2. Geometry of the Fusion Zone

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, P. Simulation of Industrial Processes for Control Engineers; Butterworth-Heinemann: Oxford, UK, 1999. [Google Scholar]

- Muvvala, G.; Karmakar, D.P.; Nath, A.K. Online monitoring of thermo-cycles and its correlation with microstructure in laser cladding of nickel based super alloy. Opt. Laser Eng. 2017, 88, 139–152. [Google Scholar] [CrossRef]

- Mackwood, A.P.; Crafer, R.C. Thermal modelling of laser welding and related processes: A literature review. Opt. Laser Technol. 2005, 37, 99–115. [Google Scholar] [CrossRef]

- Lusquinos, F.; Conde, J.; Bonss, S.; Riveiro, A.; Guintero, F.; Comesana, F.; Pou, T. Theoretical and experimental analysis of high power diode laser (HPDL) hardening of AISI 1045 steel. Appl. Surf. Sci. 2007, 254, 948–954. [Google Scholar] [CrossRef]

- Ohkubo, T.; Sato, Y.; Matsunaga, E.; Tsukamoto, M. Three-dimensional numerical simulation during laser processing of CFRP. Appl. Surf. Sci. 2017, 417, 104–107. [Google Scholar] [CrossRef]

- Yilbas, B. Laser cutting quality assessment and numerical methods for modeling of cutting. In The Laser Cutting Process—Analysis and Applications; Elsevier: New York, NY, USA, 2017; pp. 149–203. [Google Scholar]

- Abidou, D.; Yusoff, N.; Nazri, N.; Awang, M.; Hassan, M.; Sarhan, A.A. Numerical simulation of metal removal in laser drilling using radial point interpolation method. Eng. Anal. Bound. Elem. 2017, 77, 89–96. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, M.; Zhao, Z.; Zhang, Y.; Li, S.S. Measurements of laser-induced plasma temperature field in deep penetration laser welding. Opt. Laser Technol. 2013, 45, 551–557. [Google Scholar] [CrossRef]

- Pocorni, J.; Han, S.; Cheon, J.; Na, S.; Kaplan, A.; Bang, H. Numerical simulation of laser ablation driven melt waves. J. Manuf. Process. 2017, 30, 303–312. [Google Scholar] [CrossRef]

- Leitz, K.; Singer, P.; Plankensteiner, A.; Tabernig, B.; Kestler, H.; Sigl, L. Multi-physical simulation of selective laser melting. Met. Powder Rep. 2017, 72, 5. [Google Scholar] [CrossRef]

- Kundakcioglu, E.; Lazoglu, I.; Rawal, S. Transient thermal modeling of laser-based additive manufacturing for 3D freeform structures. Int. J. Adv. Manuf. Tech. 2016, 85, 493–501. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.; Zhang, Y. Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling. Addit. Manuf. 2016, 12, 231–239. [Google Scholar] [CrossRef]

- Bi, G.; Gasser, A.; Wissenbach, K.; Drenker, A.; Poprawe, R. Identification and qualification of temperature signal for monitoring and control in laser cladding. Opt. Lasers Eng. 2006, 12, 1348–1359. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Bertrand, P.; Smurov, I. Pyrometry in laser surface treatment. Surf. Coat. Tech. 2006, 201, 1955–1961. [Google Scholar] [CrossRef]

- Yu, J.; Lin, X.; Wang, J.; Chen, J.; Huang, W. Mechanics and energy analysis on molten pool spreading during laser solid forming. Appl. Surf. Sci. 2010, 256, 4612–4620. [Google Scholar] [CrossRef]

- Tapetado, A.; Diaz-Alvarez, J.; Miguelez, M.; Vazquez, C. Two-color pyrometer for process temeprature measurement during machining. J. Lightwave Technol. 2016, 34, 4. [Google Scholar] [CrossRef]

- Heigel, J.; Michaleris, P.; Reutzel, E. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Fan, Z.; Frank, L. Numerical modeling of the additive manufacturing (AM) process of titanium alloy. In Titanium Alloys—Towards Achieving Enhanced Properties for Diversified Applications; Nurul Amin, A.K.M., Ed.; InTech: Hong Kong, China, 2012; pp. 3–28. [Google Scholar]

- Paschotta, R. Encyclopedia of Laser Physics and Technology; Wiley-VCH: Berlin, Germany, 2008. [Google Scholar]

- Suresh Kumar, K.; Sparks, T.; Liou, F. Parameter determination and experimental validation of a wire feed Additive Manufacturing model. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2015. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Argenio, P.; Sergi, V. Additive manufacturing by means of laser-aided directed metal deposition of 2024 aluminium powder: Investigation and optimization. Adv. Mech. Eng. 2017, 9, 1–12. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Geauga County, OH, USA, 1993. [Google Scholar]

- Kurochkin, A.; Popel, P.; Yagodin, D.; Borisenko, A.; Okhapkin, A. Density of copper–aluminum alloys at temperatures up to 1400 °C determined by the gamma ray technique. High Temp. 2013, 51, 197–205. [Google Scholar] [CrossRef]

- Sarmast, A.; Serajzadeh, S.; Kokabi, A. A study on thermal responses, microstructural issues, and natural aging in gas tungsten arc welding of AA2024-T4. J. Eng. Manuf. 2013, 228, 413–421. [Google Scholar] [CrossRef]

- Hrbek, J. Induction heating of thin nonmagnetic sheets in transverse time-variable magnetic field. Acta Tech. 2015, 60, 15–29. [Google Scholar]

- Alfieri, V.; Caiazzo, F.; Sergi, V. Autogenous laser welding of AA2024 aluminium alloy: Process issues and bead features. Procedia CIRP 2015, 33, 406–411. [Google Scholar] [CrossRef]

- Steen, W.; Mazumder, J. Laser Material Processing; Springer: Berlin, Germany, 2010. [Google Scholar]

- Marla, D.; Bhandarkar, U.V.; Joshi, S.S; Marla, D.; Bhandarkar, U.V.; Joshi, S.S. Models for predicting temperature dependence of material properties of aluminum. J. Appl. Phys. 2014, 10, 1–13. [Google Scholar] [CrossRef]

- Wen, C.; Mudawar, I. Experimental investigation of emissivity of aluminum alloys and temperature determination using multispectral radiation thermometry (MRT) algorithms. J. Mater. Eng. Perform. 2002, 11, 551–562. [Google Scholar] [CrossRef]

- Alfieri, V.; Cardaropoli, F.; Caiazzo, F.; Sergi, V. Investigation on porosity content in 2024 aluminum alloy welding by Yb:YAG disk laser. Adv. Mater. Res. 2012, 383, 6265–6269. [Google Scholar] [CrossRef]

| Speed (mm/s) | Power (W) | Scanning length (mm) |

|---|---|---|

| 4 | 2000 | 40 |

| 4 | 2500 | 40 |

| 4 | 3000 | 40 |

| 6 | 2000 | 60 |

| 6 | 2500 | 60 |

| 6 | 3000 | 60 |

| Parameter | Value |

|---|---|

| Maximum output power (kW) | 4.0 |

| Operating nominal wavelength (nm) | 1030 |

| Beam Parameter Product (mm × mrad) | 8.0 |

| M2 quality factor | 24.3 |

| Core diameter of the delivering fiber (µm) | 300 |

| Spot size of the laser beam on the surface (mm) | 3.0 |

| Speed (mm/s) | Power (W) | Tp (K) | ||

|---|---|---|---|---|

| Actual | Simulated | Difference | ||

| 4 | 2000 | 803 | 815 | 1.5% |

| 4 | 2500 | 848 | 828 | −2.4% |

| 4 | 3000 | overflow | 990 | n/a |

| 6 | 2000 | underflow | 543 | n/a |

| 6 | 2500 | 753 | 728 | −3.3% |

| 6 | 3000 | 851 | 821 | −3.5% |

| Speed (mm/s) | Power (W) | Depth of Fusion (mm) | Width of Fusion (mm) | ||||

|---|---|---|---|---|---|---|---|

| Actual | Simulated | Difference | Actual | Simulated | Difference | ||

| 4 | 2000 | 1.55 | 1.42 | −8.3% | 5.17 | 4.22 | −18.4% |

| 4 | 2500 | 1.71 | 1.72 | 2.8% | 5.45 | 4.53 | −16.9% |

| 4 | 3000 | 2.11 | 2.19 | 1.1% | 6.81 | 5.55 | −18.5% |

| 6 | 2000 | 1.06 | 1.09 | 3.3% | 4.06 | 3.57 | −12.1% |

| 6 | 2500 | 1.55 | 1.60 | 4.2% | 5.13 | 4.38 | −14.6% |

| 6 | 3000 | 1.95 | 2.00 | 2.6% | 6.21 | 5.10 | −17.9% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caiazzo, F.; Alfieri, V. Simulation of Laser Heating of Aluminum and Model Validation via Two-Color Pyrometer and Shape Assessment. Materials 2018, 11, 1506. https://doi.org/10.3390/ma11091506

Caiazzo F, Alfieri V. Simulation of Laser Heating of Aluminum and Model Validation via Two-Color Pyrometer and Shape Assessment. Materials. 2018; 11(9):1506. https://doi.org/10.3390/ma11091506

Chicago/Turabian StyleCaiazzo, Fabrizia, and Vittorio Alfieri. 2018. "Simulation of Laser Heating of Aluminum and Model Validation via Two-Color Pyrometer and Shape Assessment" Materials 11, no. 9: 1506. https://doi.org/10.3390/ma11091506