Investigation of the Match Relation between Steel Fiber and High-Strength Concrete Matrix in Reactive Powder Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mixture of Concrete Matrix and Its Compressive Strength

2.3. Sample Preparation and Experiments

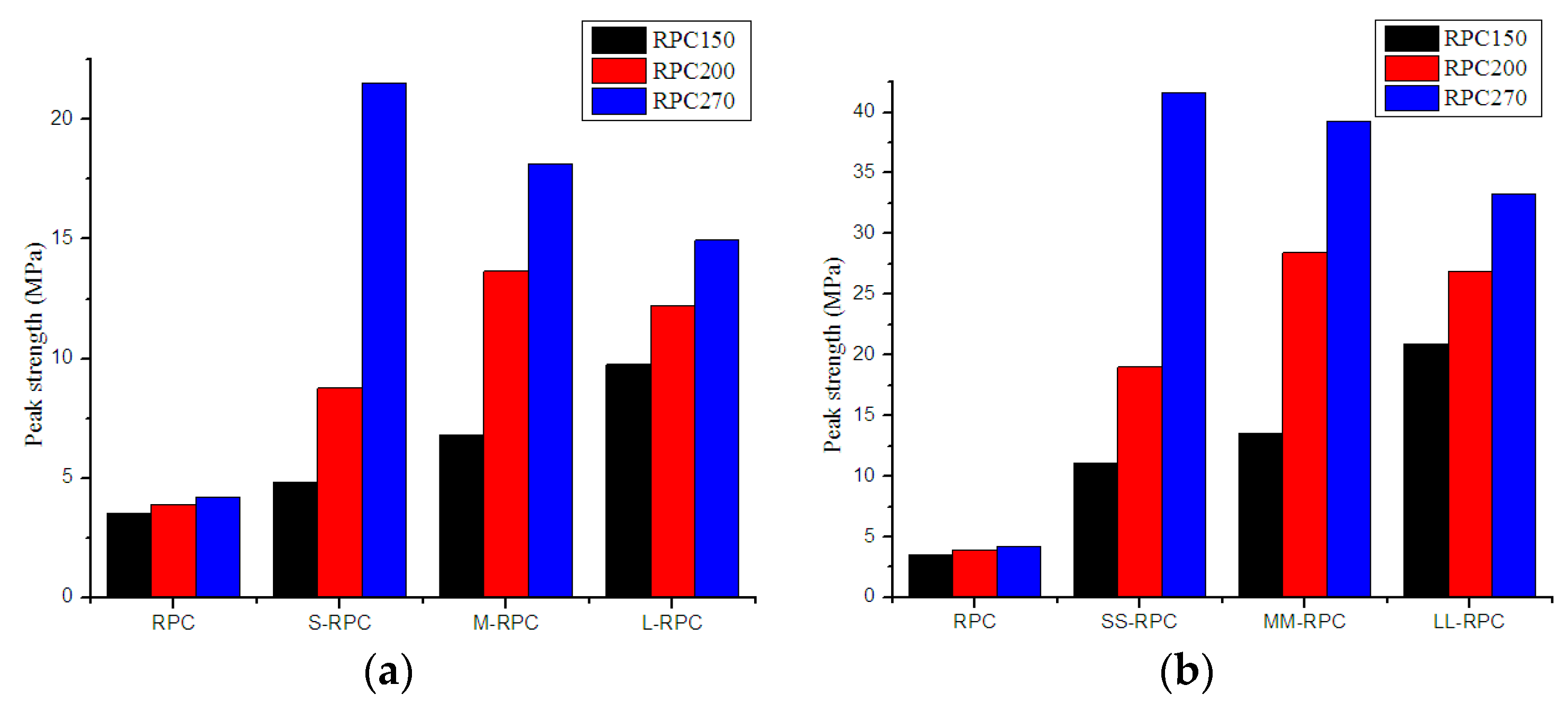

3. Mechanical Property Test Results

3.1. Compressive Strength

3.2. Flexural Load–Deflection Curves

3.3. Flexural Toughness Index

4. Discussion

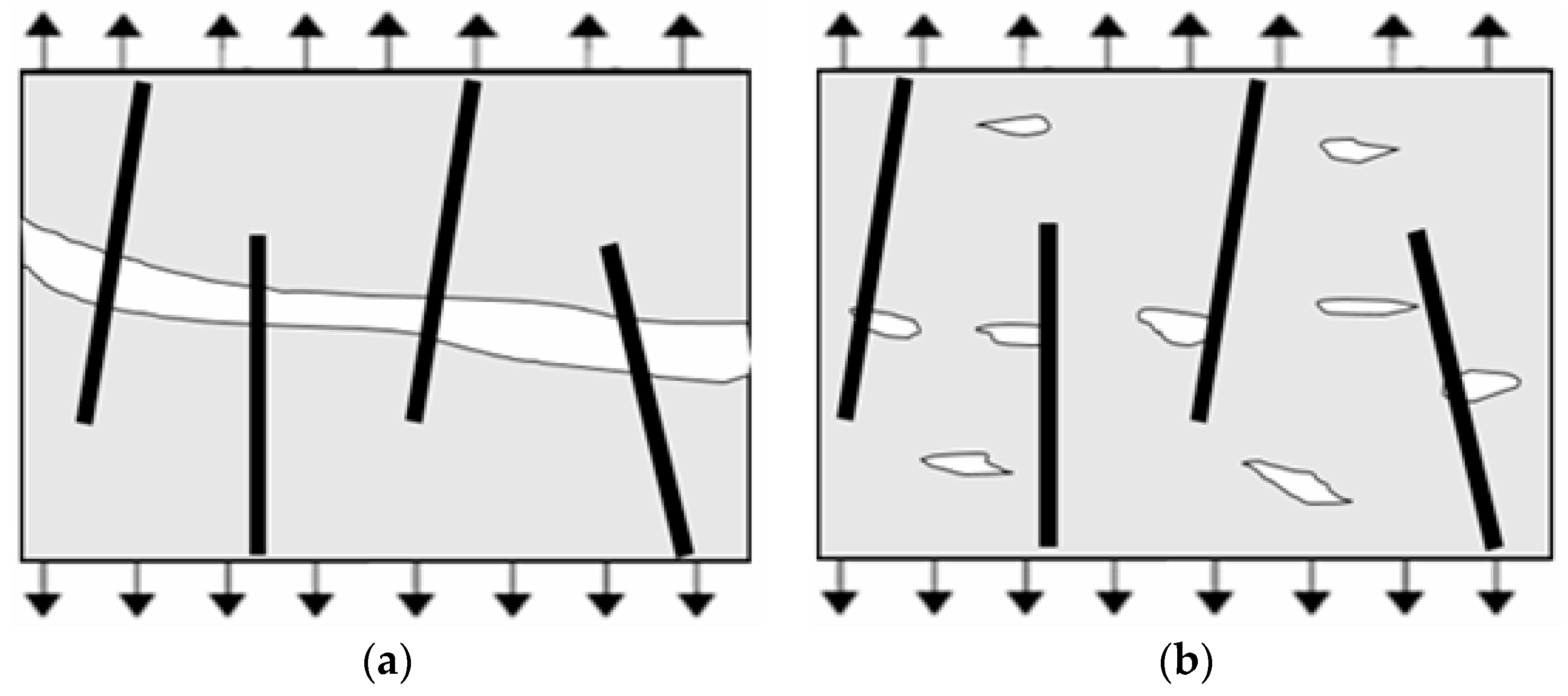

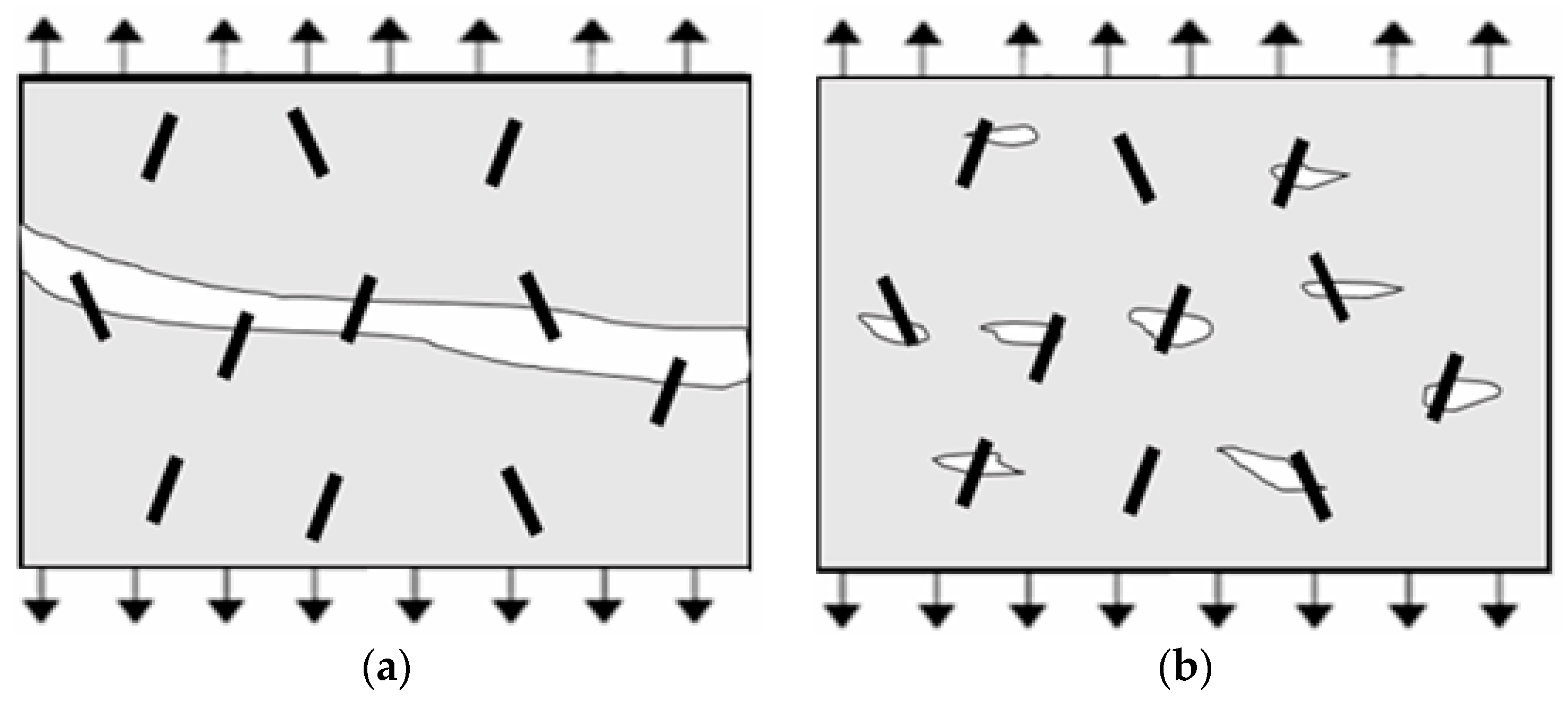

4.1. Mechanism of Fiber Reinforcement

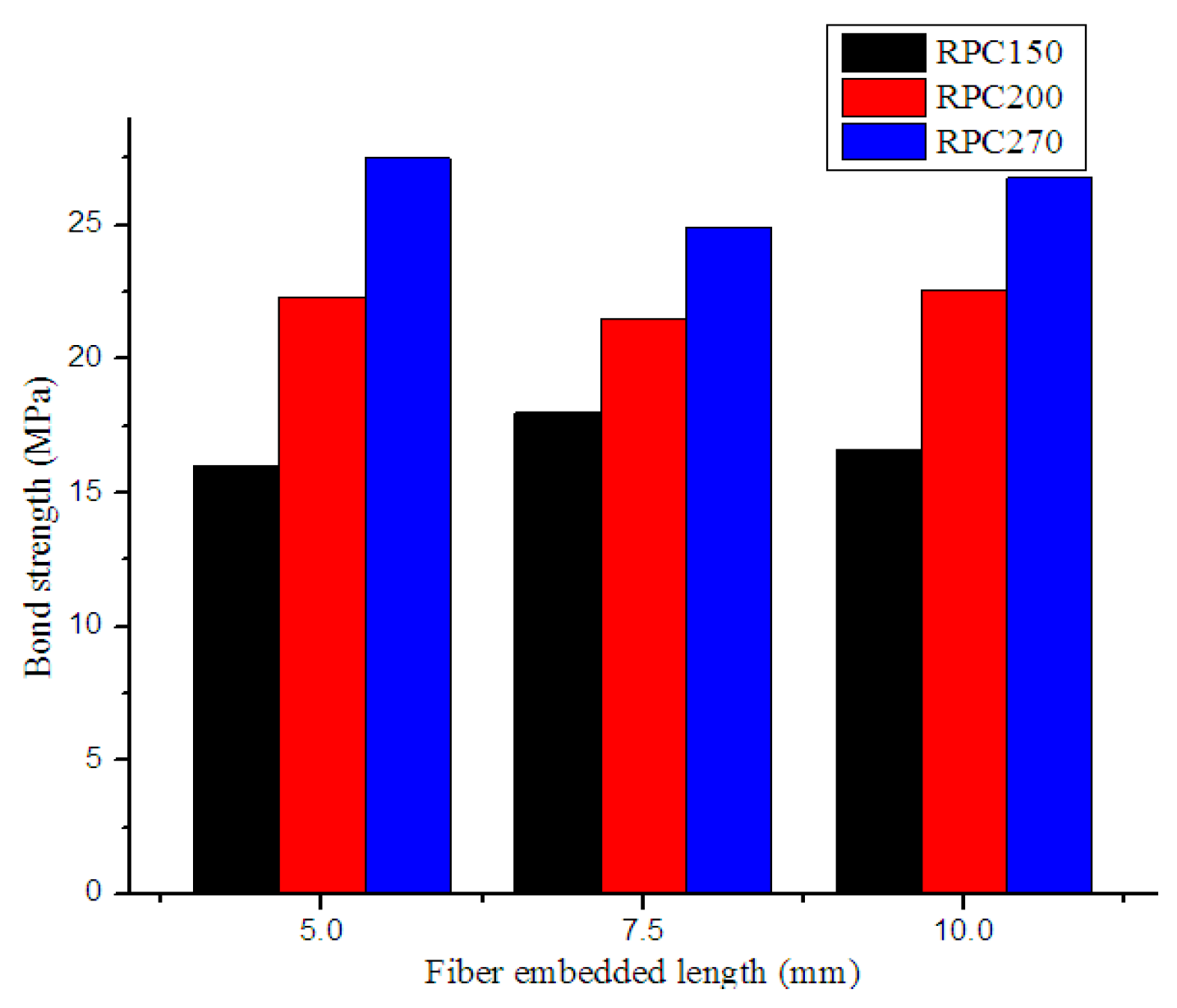

4.2. Single-Fiber Pull-Out Test

4.3. Match Relation between Steel Fibers and RPC Matrix

5. Conclusions

- (1)

- For RPC150, the samples reinforced with long steel fibers had the highest compressive strength, first-crack strength, peak strength, and toughness index.

- (2)

- For RPC270, the samples reinforced with short steel fibers had the highest compressive strength, first-crack strength, and peak strength, while the toughness index of RPC270 reinforced with medium-length steel fibers was the highest.

- (3)

- Consequently, we found a match relation between the length of the steel fibers and the strength of the RPC matrix. As a result of the higher bond adhesion between fibers and ultra-high-strength RPC matrix, long steel fibers were more effective for reinforcing RPC150, while short steel fibers were more effective for reinforcing RPC270.

Author Contributions

Funding

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Vernet, C.P. Ultra-durable concretes: structure at the micro- and nano-scale. Mater. Res. Soc. 2004, 29, 324–327. [Google Scholar] [CrossRef]

- Roux, N.; Andrade, C.; Sanjuan, M.A. Experimental study of durability of reactive powder concretes. J. Mater. Civil Eng. 1996, 8, 1–6. [Google Scholar] [CrossRef]

- Bonneau, O.; Lachemi, M.; Dallaire, E.; Dugat, J.; Aitcin, P.C. Mechanical properties and durability of two industrial reactive powder concretes. ACI Mater. J. 1997, 94, 286–289. [Google Scholar]

- Richard, P.; Cheyrezy, M. Reactive powder concretes with high ductility and 200–800 MPa compressive strength. ACI Spec. Publ. 1994, 144, 507–518. [Google Scholar]

- Collepardi, S.; Coppola, L.; Troli, R.; Collepardi, M. Mechanical properties of modified reactive powder concrete. ACI Spec. Publ. 1997, 173, 1–22. [Google Scholar]

- Matte, V.; Moranville, M. Durability of reactive powder composites: influence of silica fume on the leaching properties of very low water/binder pastes. Cem. Concr. Compos. 1999, 21, 1–9. [Google Scholar] [CrossRef]

- Chan, Y.; Chu, S. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Canbaz, M. The effect of high temperature on reactive powder concrete. Constr. Build. Mater. 2014, 70, 508–513. [Google Scholar] [CrossRef]

- Bonneau, O.; Poulin, C.; Dugat, M.; Tcin, P.C.A. Reactive powder concretes: from theory to practice. Concr. Int. 1996, 18, 47–49. [Google Scholar]

- Shafigh, P.; Mahmud, H.; Jumaat, M.Z. Effect of steel fiber on the mechanical properties of oil palm shell lightweight concrete. Mater. Des. 2011, 32, 3926–3932. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Liu, S.; Jiao, C.; Lai, J. Preparation of C200 green reactive powder concrete and its static-dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar]

- Dong, J.K.; Seung, H.P.; Ryu, G.S.; Koh, K.T. Comparative flexural behavior of Hybrid Ultra High Performance Fiber Reinforced Concrete with different macro fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar]

- Gao, J.; Sun, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem. Concr. Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Bayard, O.; Ple, O. Fracture mechanics of reactive powder concrete: material modelling and experimental investigations. Eng. Fract. Mech. 2003, 70, 839–851. [Google Scholar] [CrossRef]

- Al-Tikrite, A.; Hadi, M. Mechanical properties of reactive powder concrete containing industrial and waste steel fibres at different ratios under compression. Constr. Build. Mater. 2017, 154, 1024–1034. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Tomasz, Z.; Jacek, S. The influence of steel fiber content and curing conditions on mechanical properties and deformability of reactive powder concrete at bending. In Proceedings of the 9th International Symposium on Brittle Matrix Composites, Warsaw, Poland, 25–28 October 2009; pp. 33–42. [Google Scholar]

- Mostofinejad, D.; Nikoo, M.R.; Hosseini, S.A. Determination of optimized mix design and curing conditions of reactive powder concrete. Constr. Build. Mater. 2016, 123, 754–767. [Google Scholar] [CrossRef]

- Olivito, R.; Zuccarello, F. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Ipek, M. The flexural strength and fracture toughness of reactive powder concrete in response to changing fibre size and pre-setting pressure. Fatigue Frat. Eng. Mater. Stuct. 2012, 35, 412–424. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Sovjak, R.; Maca, P.; Imlauf, T. Effect of fibre length on the fracture energy of UHPFRC. Procedia Eng. 2017, 193, 74–79. [Google Scholar] [CrossRef]

- Sovjak, R.; Maca, P.; Imlauf, T. Effect of fibre aspect ratio and fibre volume fraction on the effective fracture energy of ultra-high-performance fibre-reinforced concrete. Acta Polytech. 2016, 56, 319–327. [Google Scholar] [CrossRef]

- Xia, H.; Wang, W.; Shi, Z. Mechanical properties of reactive powder concrete with ultra-short brass-coated steel fibres. Mag. Concr. Res. 2015, 67, 308–316. [Google Scholar] [CrossRef]

- Kim, K.; Yang, I.; Joh, C. Effects of single and hybrid steel fiber lengths and fiber contents on the mechanical properties of high-strength fiber-reinforced concrete. Adv. Civil Eng. 2018, 1–14. [Google Scholar] [CrossRef]

- Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM C78-2008; ASTM International: West Conshohocken, PA, USA, 2008.

- Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-reniforced Concrete (Using Beam with Third-point Loading); ASTM C1018-1997; ASTM International: West Conshohocken, PA, USA, 1997.

- De Santis, R.; Prisco, D.; Apicella, A.; Ambrosio, L.; Rengo, S.; Nicolais, L. Carbon fiber post adhesion to resin luting cement in the restoration of endodontically treated teeth. J. Mater. Sci. Mater. Med. 2000, 11, 201–206. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Jamshidi, M.; Latifi, M.; Pacheco-Torgal, F. Evaluation of adhesion in polymeric fibre reinforced cementitious composites. Int. J. Adhes. Adhes. 2012, 32, 53–60. [Google Scholar] [CrossRef] [Green Version]

- Beglarigale, A.; Yazıcı, H. Pull-out behavior of steel fiber embedded in flowable RPC and ordinary mortar. Constr. Build. Mater. 2015, 75, 255–265. [Google Scholar] [CrossRef]

- Lebdeh, T.A.; Hamoush, S.; Heard, W.; Zornig, B. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites. Constr. Build. Mater. 2011, 25, 39–46. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C.; Ferreras, A. Pull-out behaviour and interface critical parameters of polyolefin fibres embedded in mortar and self-compacting concrete matrixes. Constr. Build. Mater. 2016, 112, 607–622. [Google Scholar] [CrossRef]

- Foon, L.S.; Stefan, J. Study of interfacial microstructure, fracture energy, compressive energy and debonding load of steel fiber-reinforced mortar. Mater. Stuct. 2011, 44, 1451–1465. [Google Scholar] [Green Version]

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 19.66 | 4.29 | 3.37 | 62.52 | 0.85 | 0.62 | 0.08 | 2.61 | 0.24 |

| Silica fume | 95.74 | 0.50 | / | 1.25 | 0.63 | 1.07 | 0.33 | 0.15 | / |

| Abbreviation | Length (mm) | Equivalent Diameter (mm) | Aspect Ratio | Density (g/cm3) | Tensile Strength (MPa) | Elastic Module (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|---|

| S | 6 | 0.16 | 37.5 | 7.8 | >3000 | >210 | <4 |

| M | 12 | 0.16 | 75 | 7.8 | >3000 | >210 | <4 |

| L | 20 | 0.16 | 125 | 7.8 | >3000 | >210 | <4 |

| Batch no. | Cement (C) | Silica Fume (SF/C) | Sand (S/C) | Quartz Powder (Qu/C) | Water (W/C) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| RPC150 | 1 | 0.2 | 1.3 | / | 0.19 | 159.24 |

| RPC200 | 1 | 0.2 | 1.3 | / | 0.15 | 205.46 |

| RPC270 | 1 | 0.25 | 0.5 | 0.4 | 0.17 | 277.64 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Wei, J.; Yu, Q.; Huang, H.; Li, F. Investigation of the Match Relation between Steel Fiber and High-Strength Concrete Matrix in Reactive Powder Concrete. Materials 2019, 12, 1751. https://doi.org/10.3390/ma12111751

Yang G, Wei J, Yu Q, Huang H, Li F. Investigation of the Match Relation between Steel Fiber and High-Strength Concrete Matrix in Reactive Powder Concrete. Materials. 2019; 12(11):1751. https://doi.org/10.3390/ma12111751

Chicago/Turabian StyleYang, Guangyao, Jiangxiong Wei, Qijun Yu, Haoliang Huang, and Fangxian Li. 2019. "Investigation of the Match Relation between Steel Fiber and High-Strength Concrete Matrix in Reactive Powder Concrete" Materials 12, no. 11: 1751. https://doi.org/10.3390/ma12111751