Uncertainty Quantification for Ti-7Al Alloy Microstructure with an Inverse Analytical Model (AUQLin)

Abstract

:1. Introduction

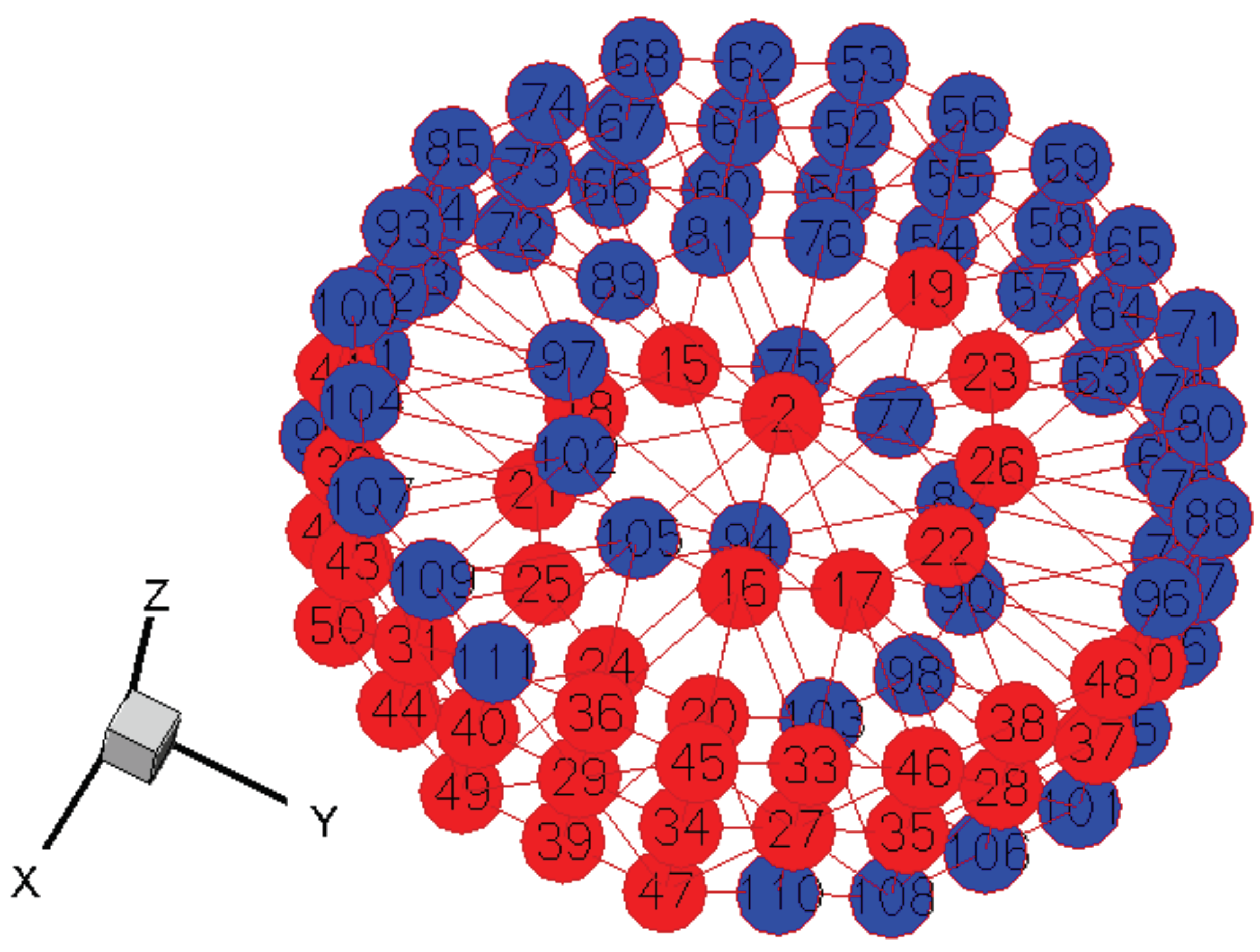

2. Microstructure Modeling

3. Uncertainty Quantification in Material Properties

3.1. Uncertainties in the Nonlinear Material Properties

3.2. Computation of the Uncertainty in the Microstructural Texture

4. Results and Discussion

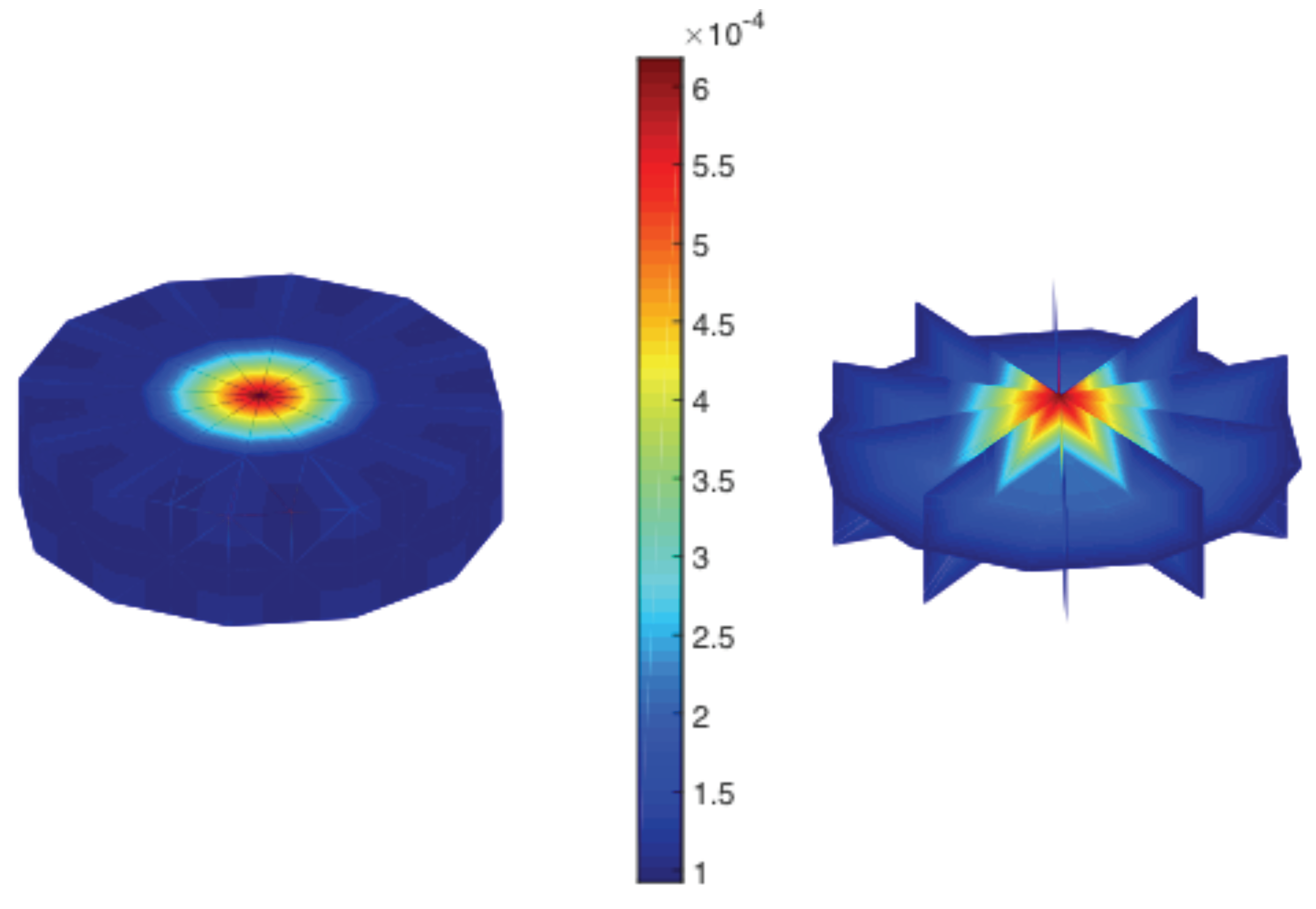

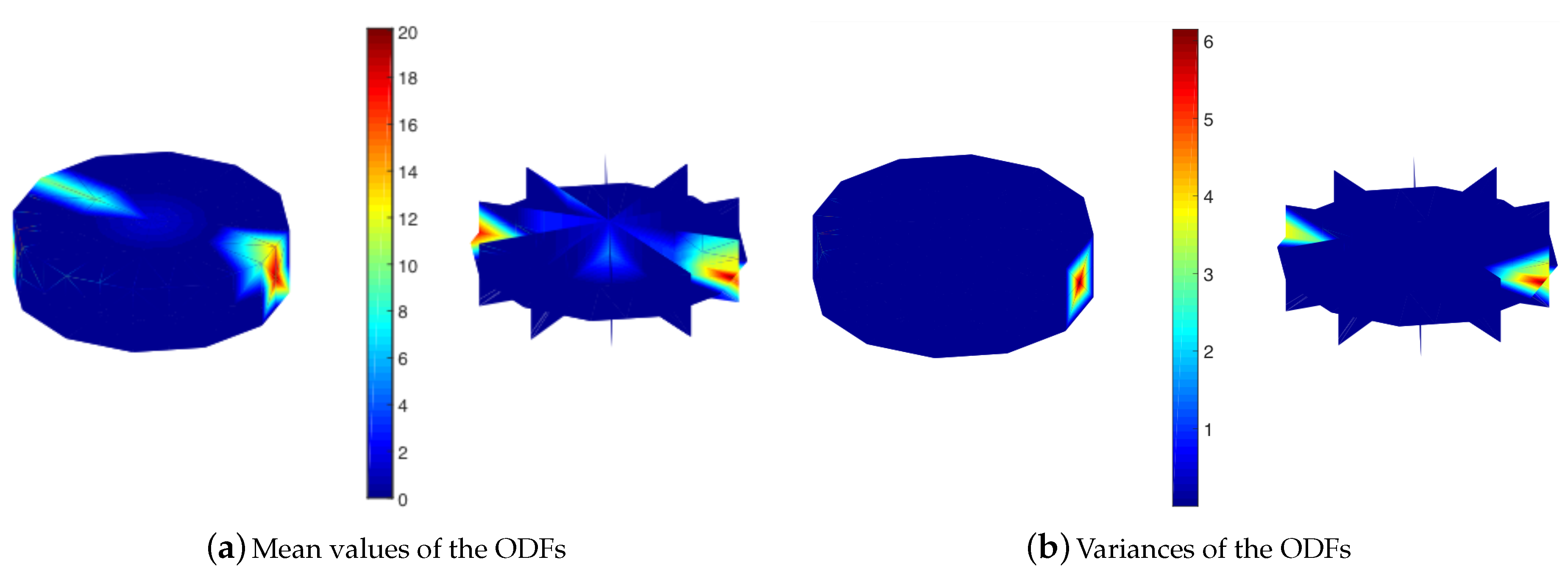

4.1. LP Problem for ODF Mean Values

4.2. LP Problem for ODF Variances

4.3. Finding the Uncertainty in Microstructural Texture

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| EBSD | Electron Backscatter Diffraction |

| ODF | Orientation Distribution Function |

| Probability Density Function | |

| UQ | Uncertainty Quantification |

References

- Allison, J.; Backman, D.; Christodoulou, L. Integrated Computational Materials Engineering: A New Paradigm for the Global Materials Profession. J. Min. Met. Mater. Soc. 2006, 10, 25–27. [Google Scholar] [CrossRef]

- Creuziger, A.; Syed, K.; Gnaupel-Herold, T. Measurement of uncertainty in orientation distribution function calculations. Scr. Mater. 2014, 72–73, 55–58. [Google Scholar] [CrossRef]

- Juan, L.; Liu, G.; Wang, H.; Ullah, A. On the sampling of three-dimensional polycrystalline microstructures for distribution determination. J. Microsc. 2011, 44, 214–222. [Google Scholar]

- Hiriyur, B.; Waisman, H.; Deodatis, G. Uncertainty quantification in homogenization of heterogeneous microstructures modeled by XFEM. Int. J. Numer. Methods Eng. 2011, 88, 257–278. [Google Scholar] [CrossRef]

- Huyse, L.; Maes, M.A. Random Field Modeling of Elastic Properties Using Homogenization. J. Eng. Mech. 2001, 127, 27–36. [Google Scholar] [CrossRef]

- Sakata, S.; Ashida, F.; Kojima, T.; Zako, M. Three-dimensional stochastic analysis using a perturbation-based homogenization method for elastic properties of composite material considering microscopic uncertainty. Int. J. Solids Struct. 2008, 45, 894–907. [Google Scholar] [CrossRef] [Green Version]

- Sakata, S.; Ashida, F.; Zako, M. Kriging-based approximate stochastic homogenization analysis for composite materials. Comput. Methods Appl. Mech. Eng. 2008, 197, 1953–1964. [Google Scholar] [CrossRef]

- Acar, P. Multi-Scale Computational Modeling of Lightweight Aluminum-Lithium Alloys. Heliyon 2019, 5, e01225. [Google Scholar] [CrossRef] [PubMed]

- Tosin, A.; Zanella, M. Boltzmann-type models with uncertain binary interactions. Commun. Math. Sci. 2018, 16, 962–984. [Google Scholar] [CrossRef]

- Dimarco, G.; Pareschi, L.; Zanella, M. Uncertainty quantification in socio economic and life sciences. In Uncertainty Quantification for Hyperbolic and Kinetic Equations; SEMA SIMAI Springer Series; Springer: Cham, Switzerland, 2017; Volume 14, pp. 151–191. [Google Scholar]

- Hu, J.; Jin, S. Uncertainty quantification for kinetic equations. In Uncertainty Quantification for Hyperbolic and Kinetic Equations; SEMA SIMAI Springer Series; Springer: Cham, Switzerland, 2017; Volume 14, pp. 193–229. [Google Scholar]

- Acar, P.; Sundararaghavan, V. Uncertainty Quantification of Microstructural Properties due to Variability in Measured Pole Figures. Acta Mater. 2017, 124, 100–108. [Google Scholar] [CrossRef]

- Acar, P.; Sundararaghavan, V. Uncertainty Quantification of Microstructural Properties due to Experimental Variations. AIAA J. 2017, 55, 2824–2832. [Google Scholar] [CrossRef]

- Acar, P.; Sundararaghavan, V. Stochastic Design Optimization of Microstructural Features using Linear Programming for Robust Material Design. AIAA J. 2019, 57, 448–455. [Google Scholar] [CrossRef]

- Acar, P. Reliability Based Design Optimization of Microstructures with Analytical Formulation. J. Mech. Des. 2018, 140, 11402. [Google Scholar] [CrossRef]

- Bunge, H.J. Texture Analysis in Materials Science; Butterworths: London, UK, 1982. [Google Scholar]

- Heinz, A.; Neumann, P. Representation of Orientation and Disorientation Data for Cubic, Hexagonal, Tetragonal and Orthorhombic Crystals. Acta Crystallogr. 1991, A47, 780–789. [Google Scholar] [CrossRef]

- Acar, P.; Ramazani, A.; Sundararaghavan, V. Crystal Plasticity Modeling and Experimental Validation with an Orientation Distribution Function for Ti-7Al Alloy. Metals 2017, 7, 459. [Google Scholar] [CrossRef]

- Acar, P. Crystal Plasticity Model Calibration for Ti-7Al Alloy with a Multi-Fidelity Computational Scheme. Integr. Mater. Manuf. Innov. 2018, 7, 186–194. [Google Scholar] [CrossRef]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acar, P. Uncertainty Quantification for Ti-7Al Alloy Microstructure with an Inverse Analytical Model (AUQLin). Materials 2019, 12, 1773. https://doi.org/10.3390/ma12111773

Acar P. Uncertainty Quantification for Ti-7Al Alloy Microstructure with an Inverse Analytical Model (AUQLin). Materials. 2019; 12(11):1773. https://doi.org/10.3390/ma12111773

Chicago/Turabian StyleAcar, Pınar. 2019. "Uncertainty Quantification for Ti-7Al Alloy Microstructure with an Inverse Analytical Model (AUQLin)" Materials 12, no. 11: 1773. https://doi.org/10.3390/ma12111773