Comparative Analysis of the Chemical Composition and Microstructure Conformation Between Different Dental Implant Bone Drills

Abstract

:1. Introduction

2. Materials and Methods

- Straumann (Institut Straumann AG, Basel, Switzerland) 2.2 mm in diameter

- NobelBiocare (NobelBiocare AB, Gothenburg, Sweden) 2.0 mm in diameter

- Xive Implant System (Desplay Friadent GmbH, Mannheim, Germany,) 2.0 mm in diameter

- Global D (In-Kone GlobalD Universal, Brignais, France) 2.0 mm in diameter

- Sweden & Martina (Sweden & Martina, Due Carrare, Italy) 2.0 mm in diameter

3. Results

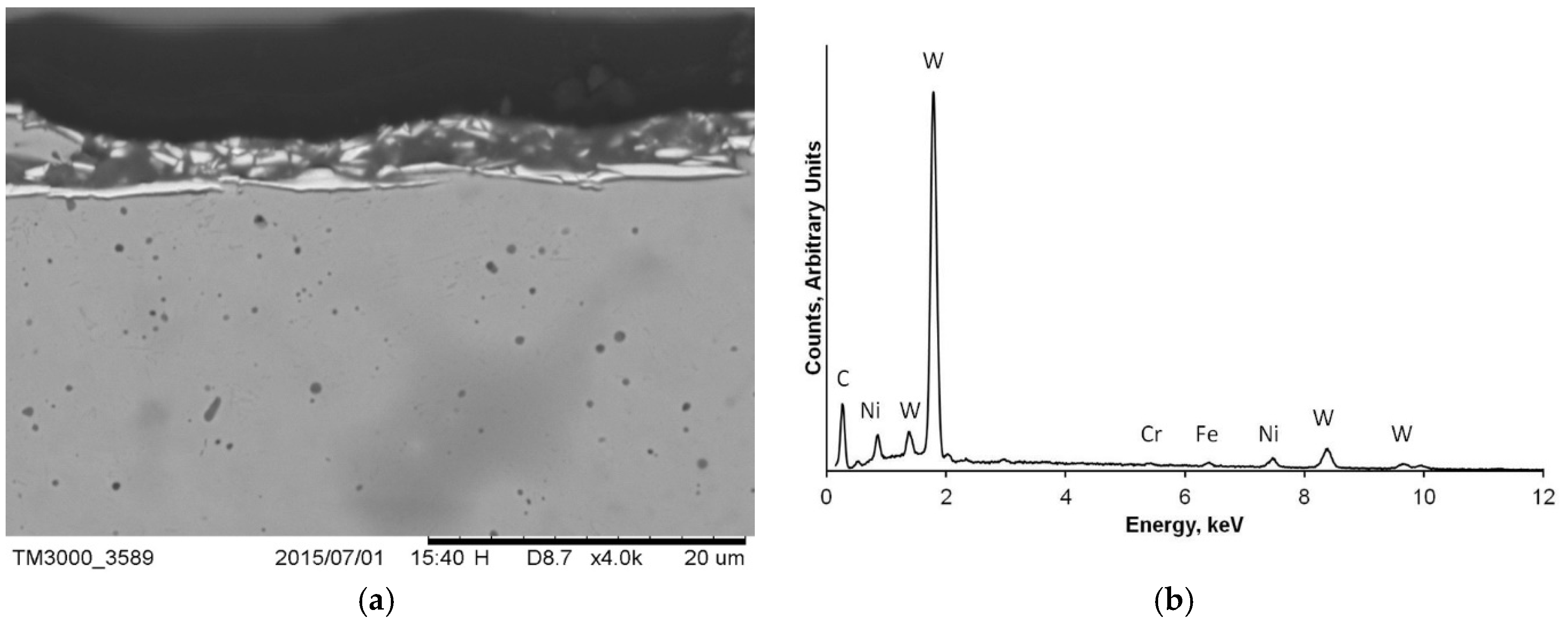

3.1. Chemical Composition

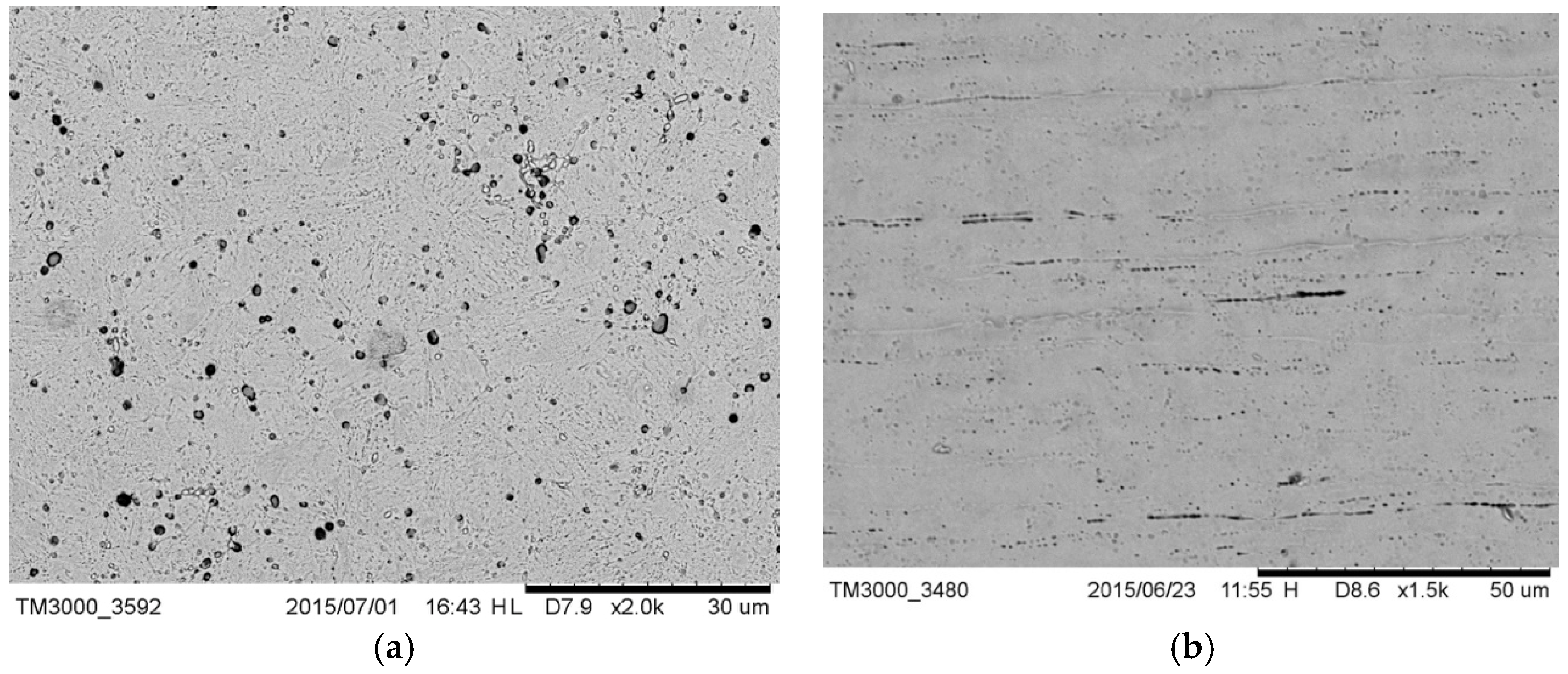

3.1.1. Microstructural Conformation

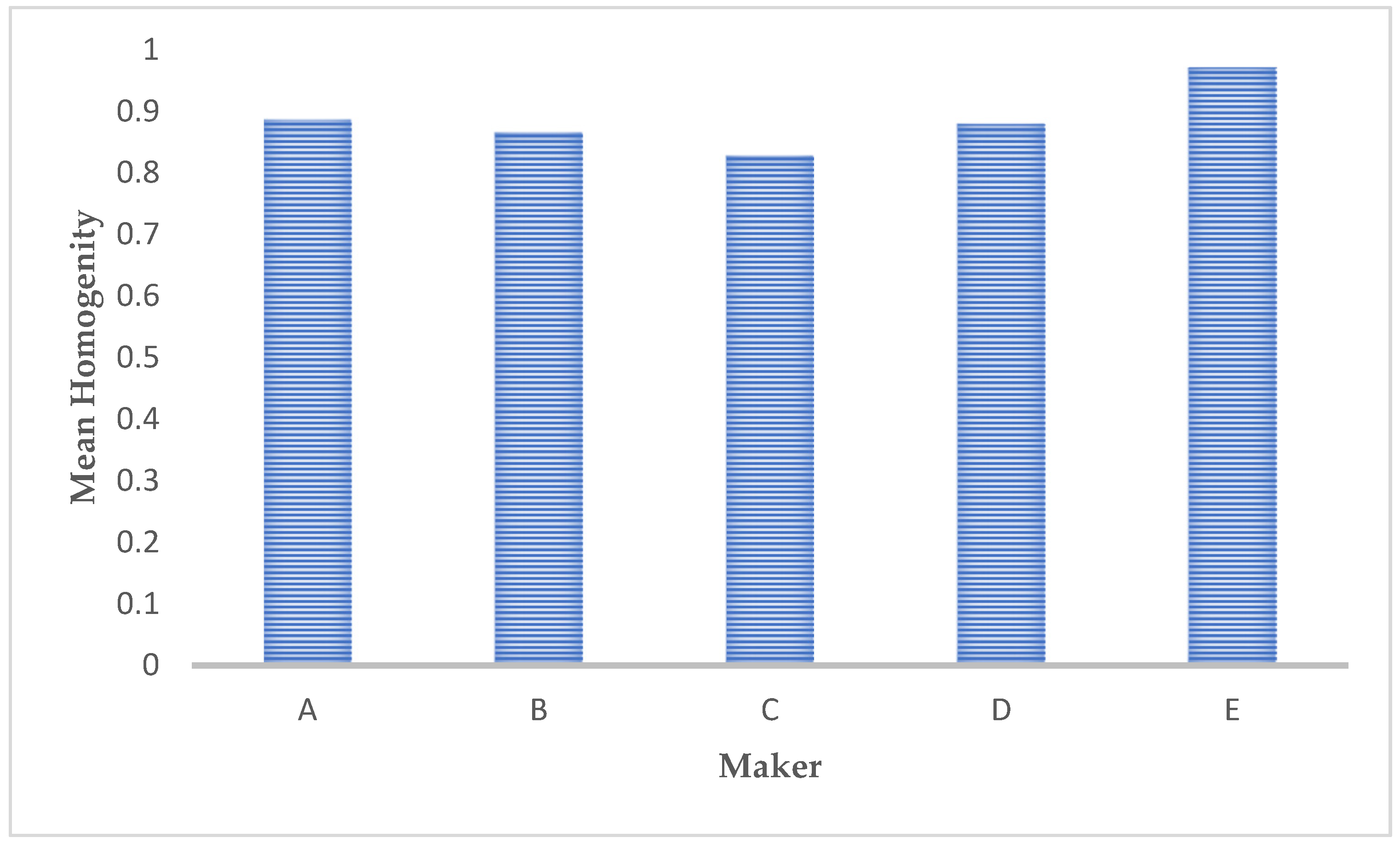

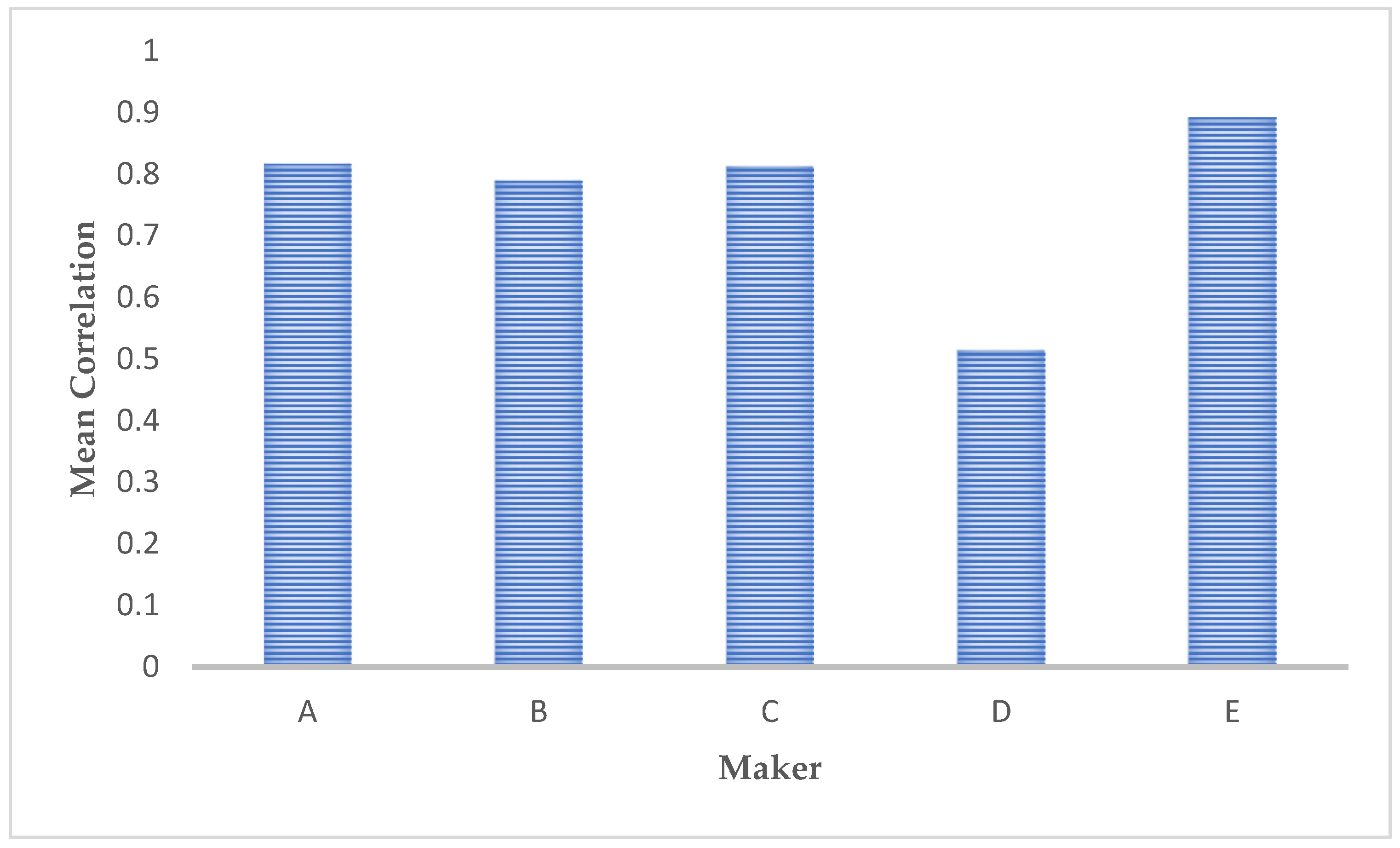

3.1.2. Microstructure Obtained by Fourier Descriptors (FD)

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Ting, M.; Tenaglia, M.S.; Jones, G.H.; Suzuki, J.B. Surgical and Patient Factors Affecting Marginal Bone Levels Around Dental Implants: A Comprehensive Overview of Systematic Reviews. Implant Dent. 2017, 26, 303–315. [Google Scholar] [CrossRef]

- Falisi, G.; Severino, M.; Rastelli, C.; Bernardi, S.; Caruso, S.; Galli, M.; Lamazza, L.; Di Paolo, C. The effects of surgical preparation techniques and implant macro-geometry on primary stability: An in vitro study. Med. Oral Patol. Oral Cir. Bucal. 2017, 22, 201–206. [Google Scholar] [CrossRef]

- Busenlechner, D.; Fürhauser, R.; Haas, R.; Watzek, G.; Mailath, G.; Pommer, B. Long-term implant success at the Academy for Oral Implantology: 8-year follow-up and risk factor analysis. J. Periodontal Implant Sci. 2014, 44, 102–108. [Google Scholar] [CrossRef] [PubMed]

- Pandey, R.K.; Panda, S.S. Drilling bone: A comprehensive review. J. Clin. Orthop. Trauma 2013, 4, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Batista Mendes, G.C.; Padovan, L.E.; Ribeiro-Júnior, P.D.; Sartori, E.M.; Valgas, L.; Claudino, M. Influence of implant drill materials on wear, deformation, and roughness after repeated drilling and sterilization. Implant Dent. 2014, 23, 188–194. [Google Scholar] [CrossRef] [PubMed]

- Ercoli, C.; Funkenbusch, P.D.; Lee, H.J.; Moss, M.E.; Graser, G.N. The influence of drill wear on cutting efficiency and heat production during osteotomy preparation for dental implant: A study of drill durability. Int. J. Oral Maxillofac. Implant. 2004, 19, 335–349. [Google Scholar]

- Tehemar, S.H. Factors affecting heat generation during implant site preparation: A review of biologic observation and future consideration. Int. J. Oral Maxillofac. Implant. 1999, 14, 127–136. [Google Scholar]

- Chacon, G.E.; Bower, D.L.; Larsen, P.E.; McGlumphy, E.A.; Beck, F.M. Heat production by 3 implant drill systems after repeated drilling and sterilization. J. Oral Maxillofac. Surg. 2006, 64, 265–269. [Google Scholar] [CrossRef]

- Sener, B.C.; Dergin, G.; Gursoy, B.; Kelesoglu, E.; Slih, I. Effects of irrigation temperature on heat control in vitro at different drilling depths. Clin. Oral Implant. Res. 2009, 20, 294–298. [Google Scholar] [CrossRef]

- Reingewirtz, Y.; Szmukler-Moncler, S.; Senger, B. Influence of different parameters on bone heating and drilling time in implantology. Clin. Oral Implant. Res. 1997, 8, 189–197. [Google Scholar] [CrossRef]

- Oliveira, N.; Alaejos-Algarra, F.; Mareque-Bueno, J.; Ferrés-Padró, E.; Hernández-Alfaro, F. Thermal changes and drill wear in bovine bone during implant site preparation. A comparative in vitro study: Twisted stainless steel and ceramic drill. Clin. Oral Implant. Res. 2012, 23, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Piattelli, A.; Assenza, B.; Carinci, F.; Di Donato, L.; Romani, G.L.; Merla, A. Infrared thermographic evaluation of temperature modifications induced during implant site preparation with cylindrical versus conical drills. Clin. Implant Dent. Relat. Res. 2011, 13, 319–323. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, F.; Tawada, Y.; Komatsu, S.; Hata, Y. Heat distribution in bone during preparation of implant sites: Heat analysis by real-time thermography. Int. J. Oral Maxillofac. Implant. 1992, 7, 212–219. [Google Scholar]

- Strbac, G.D.; Unger, E.; Donner, R.; Bijak, M.; Watzek, G.; Zechner, W. Thermal effects of a combined irrigation method during implant site drilling. A standardized in vitro study using a bovine rib model. Clin. Oral Implant. Res. 2014, 25, 665–674. [Google Scholar] [CrossRef] [PubMed]

- Bullon, B.; Bueno, E.F.; Herrero, M.; Fernandez-Palacin, A.; Rios, J.V.; Bullon, P.; Gil, F.J. Effect of irrigation and stainless steel drills on dental implant bed heat generation. J. Mater. Sci. Mater. Med. 2015, 26, 75. [Google Scholar] [CrossRef] [PubMed]

- Oh, H.J.; Kim, B.I.; Kim, H.Y.; Yeo, I.S.; Wikesjö, U.M.; Koo, K.T. Implant Drill Characteristics: Thermal and Mechanical Effects of Two-, Three-, and Four-Fluted Drills. Int. J. Oral Maxillofac. Implant. 2017, 32, 483–488. [Google Scholar] [CrossRef] [PubMed]

- Koo, K.T.; Kim, M.H.; Kim, H.Y.; Wikesjö, U.M.; Yang, J.H.; Yeo, I.S. Effect of implant drill wear, irrigation and drill materials on heat generation in osteotomy sites. J. Oral Implant. 2015, 41, 19–23. [Google Scholar] [CrossRef] [PubMed]

- Sannino, G.; Capparé, P.; Gherlone, E.F.; Barlattani, A. Influence of the implant drill design and sequence on temperature changes during site preparation. Int. J. Oral Maxillofac. Implant. 2015, 30, 351–358. [Google Scholar] [CrossRef]

- Gholampour, S.; Shakouri, E.; Deh, H.H.H. Effect of drilling direction and depth on thermal necrosis during tibia drilling: An in vitro study. Technol. Health Care 2018, 26, 687–697. [Google Scholar] [CrossRef]

- Sumer, M.; Misir, A.F.; Telcioglu, N.T.; Guler, A.U.; Yenisey, M. Comparison of heat generation during implant drilling using stainless steel and ceramic drills. J. Oral Maxillofac. Surg. 2011, 69, 1350–1354. [Google Scholar] [CrossRef]

- Er, N.; Alkan, A.; Ilday, S.; Bengu, E. Improved Dental Implant Drill Durability and Performance Using Heat and Wear Resistant Protective Coatings. J. Oral Implantol. 2018, 44, 168–175. [Google Scholar] [CrossRef] [PubMed]

- Sartori, E.M.; Shinohara, E.H.; Ponzoni, D.; Padovan, L.E.; Valgas, L.; Golin, A.L. Evaluation of deformation, mass loss, and roughness of different metal burs after osteotomy for osseointegrated implants. J. Oral Maxillofac. Surg. 2012, 70, 608–621. [Google Scholar] [CrossRef] [PubMed]

- Pires, L.F.; Tandler, B.; Bissada, N.; Duarte, S., Jr. Comparison of heat generated by alumina-toughened zirconia and stainless steel burs for implant placement. Int. J. Oral Maxillofac. Implant. 2012, 27, 1023–1028. [Google Scholar]

- Allan, W.; Williams, E.D.; Kerawala, C.J. Effects of repeated drill use on temperature of bone during preparation for osteosynthesis self-tapping screws. Br. J. Oral Maxillofac. Surg. 2005, 43, 314–319. [Google Scholar] [CrossRef] [PubMed]

- Möhlhenrich, S.C.; Modabber, A.; Steiner, T.; Mitchell, D.A.; Hölzle, F. Heat generation and drill wear during dental implant site preparation: Systematic review. Br. J. Oral Maxillofac. Surg. 2015, 53, 679–689. [Google Scholar] [CrossRef] [PubMed]

- ASTM E3—11(2017) Gabb, T. Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 2017.

- Jain, A.K. Fundamentals of Digital Image Processing; Prentice-Hall: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Granlund, G.H. Fourier Pre-processing for hand print character recognition. IEEE Trans. Comput. 1972, 21, 195–201. [Google Scholar] [CrossRef]

- Mallat, S.G. A theory for multiresolution signal decomposition: The wavelet representation. IEEE Trans. Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Haralick, R. Statistical and Structural Approaches to Texture. Proc. IEEE 1979, 67, 786–804. [Google Scholar] [CrossRef]

- Haralick, R.; Shamnugam, S. Textural Features for Image Classification. IEEE Trans. Cybern. 1973, 3, 2. [Google Scholar] [CrossRef]

- Jamovi Project 2018. Jamovi (Version 0.9). Available online: https://www.jamovi.org (accessed on 25 February 2019).

- ISO 6507-1:2005(E). Metallic Materials—Vickers Hardness Test—Part 1: Test Method; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- Brook, C.R. Heat Treatment of Ferrous Alloy; Hemisfere Pub. Corp.: Washinton, DC, USA, 1979. [Google Scholar]

- Allsobrook, O.F.; Leichter, J.; Holborrow, D.; Swain, M. Descriptive study of the longevity of dental implant surgery drills. Clin. Implant Dent. Relat. Res. 2011, 13, 244–254. [Google Scholar] [CrossRef]

- Vander Voort, G.F. Martensitic Structure; Metallography and Microstructure; ASN: Materials Park, OH, USA, 2004; Volume 9, pp. 165–178. [Google Scholar]

- Marenzi, G.; Sammartino, J.C.; Quaremba, G.; Graziano, V.; El Hassanin, A.; Qorri, M.E.; Sammartino, G.; Iorio-Siciliano, V. Clinical Influence of Micromorphological Structure of Dental Implant Bone Drills. BioMed Res. Int. 2018, 6, 2018. [Google Scholar] [CrossRef] [PubMed]

- Shironita, S.; Souma, K.; Umeda, M. Effect of chromium content on the corrosion resistance of ferritic stainless steels in sulfuric acid solution. Heliyon 2018, 22, 00958. [Google Scholar]

- Oh, H.J.; Wikesjö, U.M.; Kang, H.S.; Ku, Y.; Eom, T.G.; Koo, K.T. Effect of implant drill characteristics on heat generation in osteotomy sites: A pilot study. Clin. Oral Implant. Res. 2011, 22, 722–726. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.K.; Chowdhary, R. Heat generated by dental implant drills during osteotomy-a review: Heat generated by dental implant drills. J. Indian Prosthodont. Soc. 2014, 14, 131–143. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Aghvami, M.; Brunski, J.; Helms, J. Biophysical regulation of osteotomy healing: An animal study. Clin. Implant Dent. Relat. Res. 2017, 19, 590–599. [Google Scholar] [CrossRef] [PubMed]

- Takabi, B.; Tai, B.L. A review of cutting mechanics and modeling techniques for biological materials. Med. Eng. Phys. 2017, 45, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Rongo, R.; Valletta, R.; Bucci, R.; Rivieccio, V.; Galeotti, A.; Michelotti, A.; D’Antò, V. In vitro biocompatibility of nickel-titanium esthetic orthodontic archwires. Angle Orthod. 2016, 86, 789. [Google Scholar] [CrossRef]

- Albrektsson, T.; Eriksson, A. Thermally induced bone necrosis in rabbits: Relation to implant failure in humans. Clin. Orthop. Relat. Res. 1985, 195, 311–312. [Google Scholar] [CrossRef]

- Misic, T.; Markovic, A.; Todorovic, A.; Colic, S.; Miodrag, S.; Milicic, B. An in vitro study of temperature changes in type 4 bone during implant placement: Bone condensing versus bone drilling. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod 2011, 112, 28–33. [Google Scholar] [CrossRef]

- Hochscheidt, C.J.; Shimizu, R.H.; Andrighetto, A.R.; Pierezan, R.; Thomé, G.; Salatti, R. Thermal Variation During Osteotomy With Different Dental Implant Drills: A Standardized Study in Bovine Ribs. Implant Dent. 2017, 26, 73–79. [Google Scholar] [CrossRef]

- Majeed, F.A.; Karki, H.; Karkoub, M.; Magid, Y.L.A. Experimental verification of drill string vibration suppression using an adaptive self-tuning controller. Int. J. Acoust. Vib. 2013, 18, 20–26. [Google Scholar]

- Baroiu, N.; Teodor, V.G.; Berbinschi, S. New sharpening method and behavior of multi-flute twist drill with curved cutting edge in machining operations. Indian J. Eng. Mater. Sci. 2016, 23, 357–369. [Google Scholar]

- Lo Giudice, R.; Puleio, F.; Rizzo, D.; Alibrandi, A.; Lo Giudice, G.; Centofanti, A.; Fiorillo, L.; Di Mauro, D.; Nicita, F. Comparative investigation of cutting devices on bone blocks: An SEM morphological analysis. Appl. Sci. 2019, 9, 351. [Google Scholar] [CrossRef]

- Kliemann, W. Nonlinear Dynamics and Stochastic Mechanics; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

| Implant Drill | Fe (wt %) | Cr (wt %) | Mn (wt %) | Si (wt %) | Mo (wt %) |

|---|---|---|---|---|---|

| A | Balance | 17.0 | 0.6 | 0.6 | 0.7 |

| B | Balance | 13.4 | 1.4 | 0.4 | 0.4 |

| C | Balance | 13.7 | 1.2 | 0.6 | 0.4 |

| D | Balance | 17.1 | 0.8 | 0.5 | 0.6 |

| E | Balance | 13.1 | 1.2 | 0.5 | 0.5 |

| Implant Drill | Hardness |

|---|---|

| A | 600.3 |

| B | 466.6 |

| C | 530.2 |

| D | 674.8 |

| E | 589.1 |

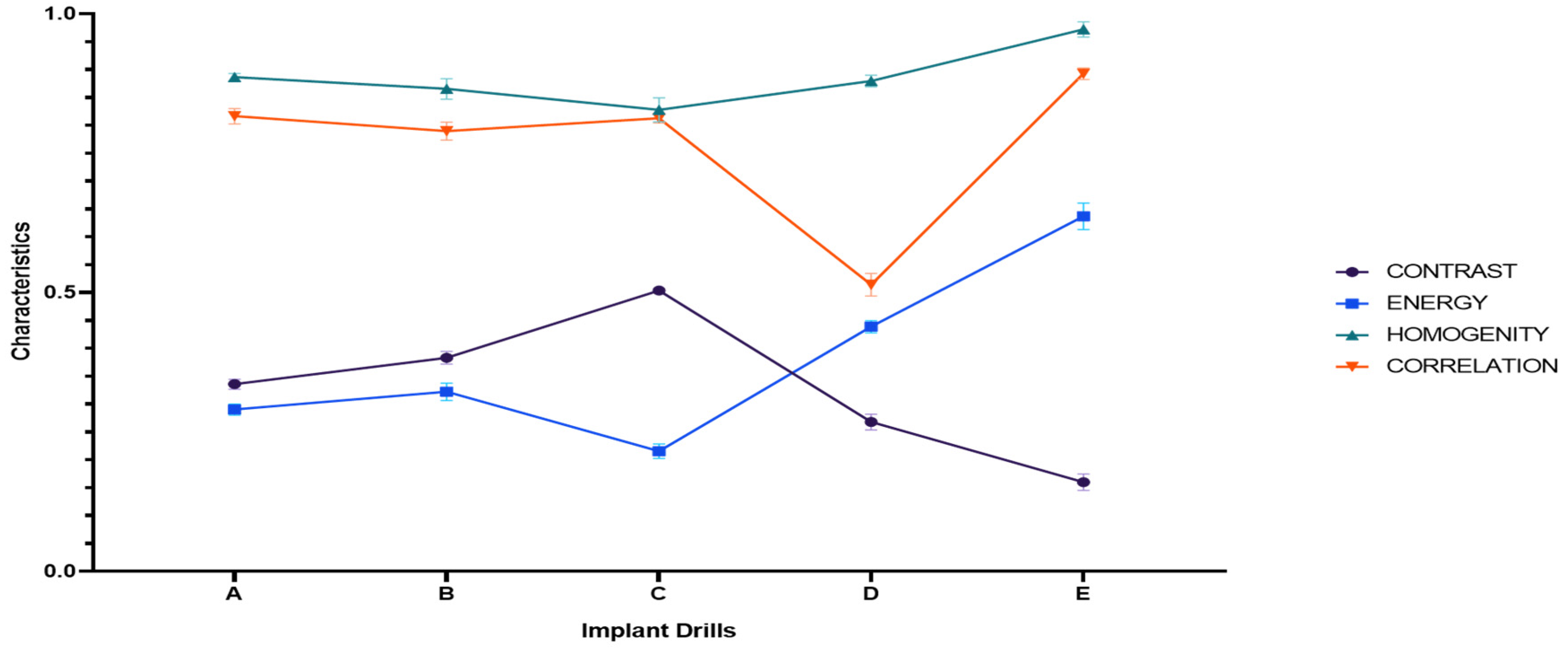

| Group Descriptives | |||||

|---|---|---|---|---|---|

| Implant Drills | N | Mean | SD | SE | |

| Contrast | A | 5 | 0.336 | 0.00890 | 0.00398 |

| B | 5 | 0.383 | 0.01123 | 0.00502 | |

| C | 5 | 0.504 | 0.00509 | 0.00227 | |

| D | 5 | 0.268 | 0.01411 | 0.00631 | |

| E | 5 | 0.160 | 0.01456 | 0.00651 | |

| Energy | A | 5 | 0.290 | 0.00990 | 0.00443 |

| B | 5 | 0.322 | 0.01545 | 0.00691 | |

| C | 5 | 0.216 | 0.01303 | 0.00583 | |

| D | 5 | 0.439 | 0.01106 | 0.00495 | |

| E | 5 | 0.637 | 0.02369 | 0.01059 | |

| Homogeneity | A | 5 | 0.886 | 0.00677 | 0.00303 |

| B | 5 | 0.865 | 0.01826 | 0.00817 | |

| C | 5 | 0.828 | 0.02141 | 0.00957 | |

| D | 5 | 0.880 | 0.01040 | 0.00465 | |

| E | 5 | 0.972 | 0.01360 | 0.00608 | |

| Correlation | A | 5 | 0.817 | 0.01390 | 0.00622 |

| B | 5 | 0.790 | 0.01615 | 0.00722 | |

| C | 5 | 0.813 | 0.00837 | 0.00374 | |

| D | 5 | 0.514 | 0.02034 | 0.00910 | |

| E | 5 | 0.893 | 0.01031 | 0.00461 | |

| Within Subjects Effects (WSE) | ||||||

| Sum of Squares | N | df | Mean Square | F | p | |

| Implant Drills characteristics | 57.446 | 4 | 3 | 19.149 | 9311 | <0.001 |

| Implant Drills characteristics * Implant Drills | 11.499 | 25 | 12 | 0.0958 | 466 | <0.001 |

| Residual | 0.0123 | 100 | 60 | 2.06 × 10−4 | ||

| Between Subjects Effects (BSE) | ||||||

| Implant Drills | 0.19926 | 5 | 4 | 0.0498 | 270 | <0.001 |

| Residual | 0.00369 | 25 | 20 | 1.84 × 10−4 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marenzi, G.; Sammartino, J.C.; Scherillo, F.; Rengo, C.; De Rosa, A.; Graziano, V.; Spagnuolo, G. Comparative Analysis of the Chemical Composition and Microstructure Conformation Between Different Dental Implant Bone Drills. Materials 2019, 12, 1866. https://doi.org/10.3390/ma12111866

Marenzi G, Sammartino JC, Scherillo F, Rengo C, De Rosa A, Graziano V, Spagnuolo G. Comparative Analysis of the Chemical Composition and Microstructure Conformation Between Different Dental Implant Bone Drills. Materials. 2019; 12(11):1866. https://doi.org/10.3390/ma12111866

Chicago/Turabian StyleMarenzi, Gaetano, Josè Camilla Sammartino, Fabio Scherillo, Carlo Rengo, Alfredo De Rosa, Vincenzo Graziano, and Gianrico Spagnuolo. 2019. "Comparative Analysis of the Chemical Composition and Microstructure Conformation Between Different Dental Implant Bone Drills" Materials 12, no. 11: 1866. https://doi.org/10.3390/ma12111866