Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses

Abstract

:1. Introduction

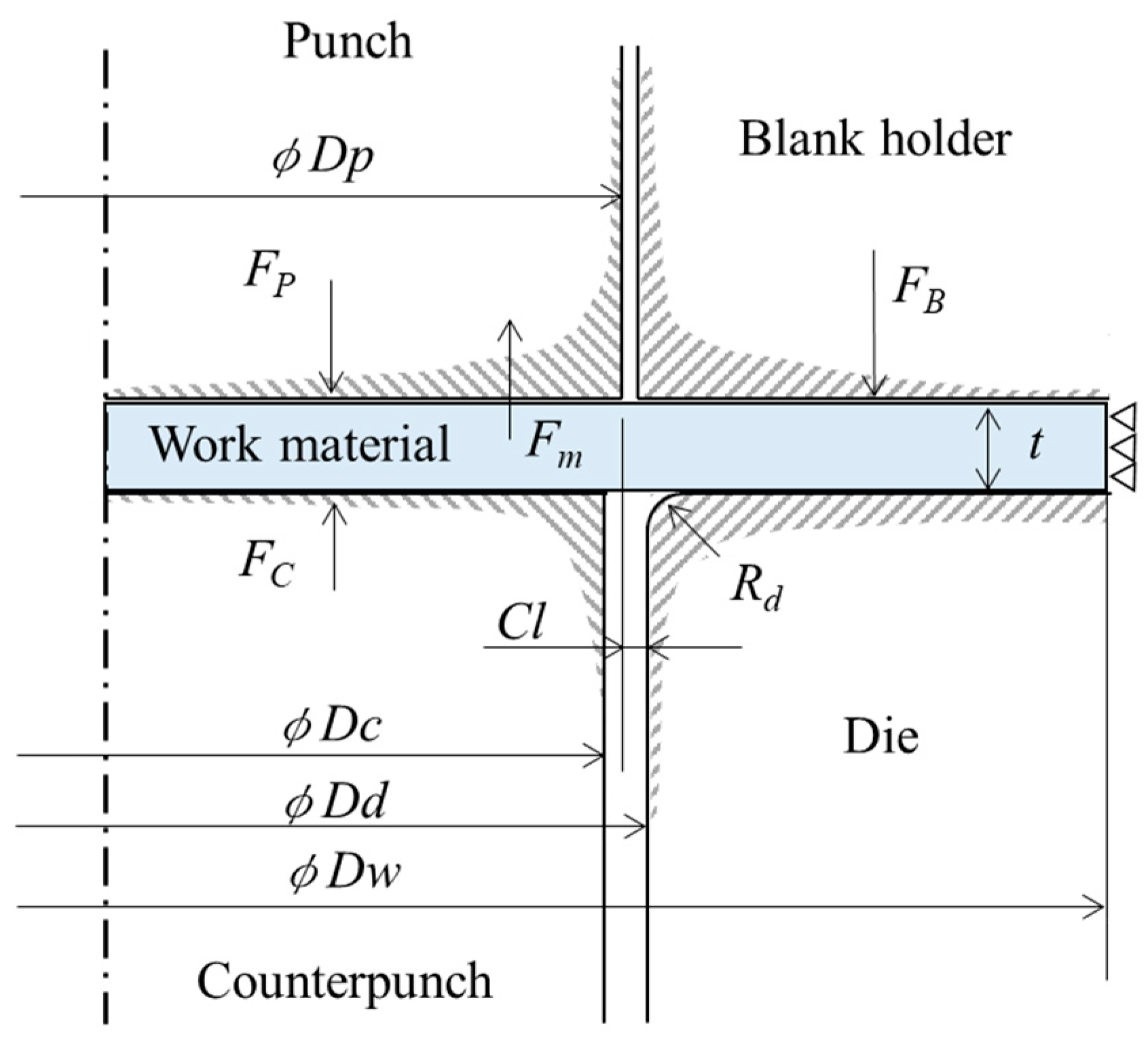

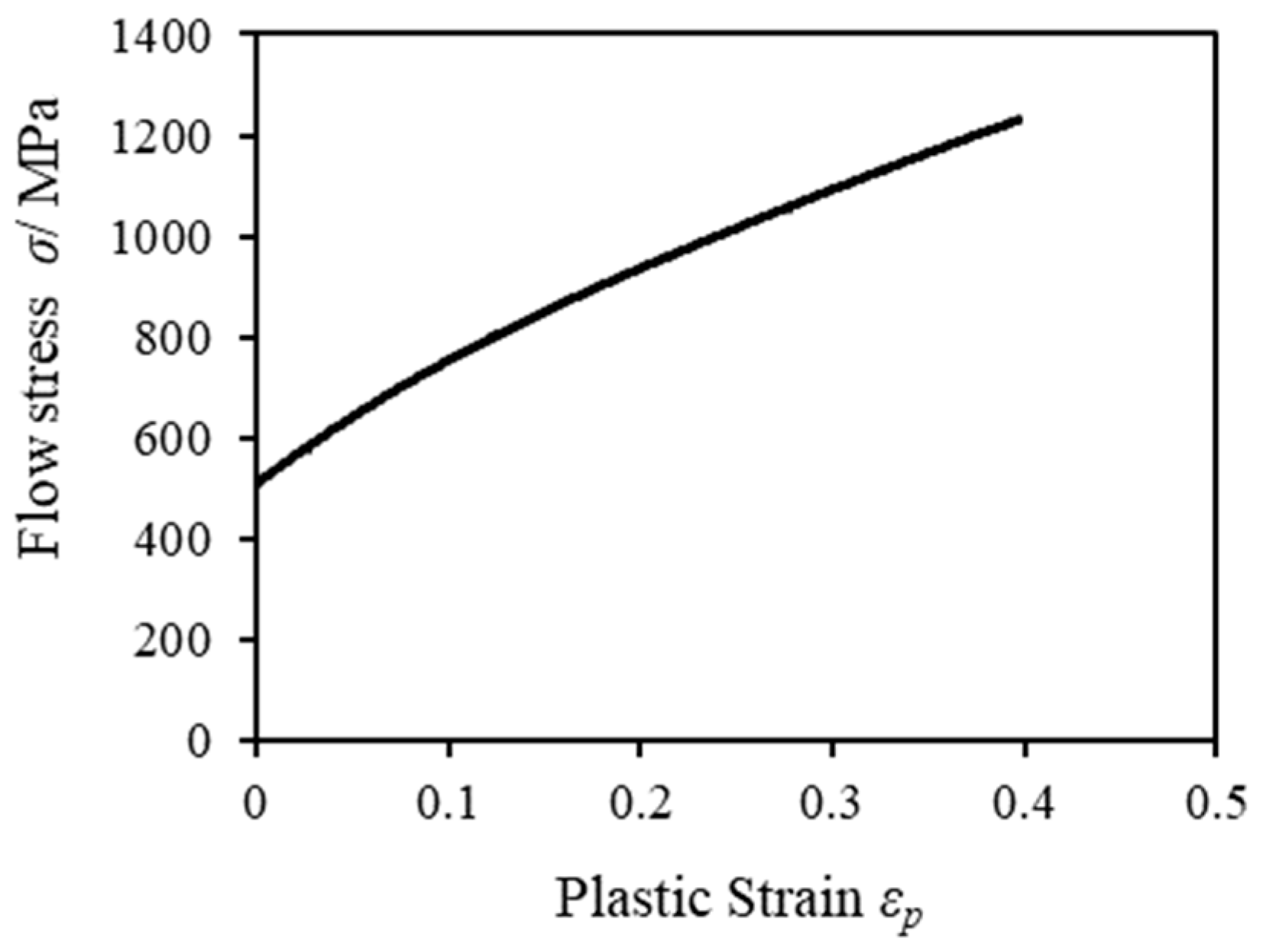

2. FEM Simulation Model and Conditions

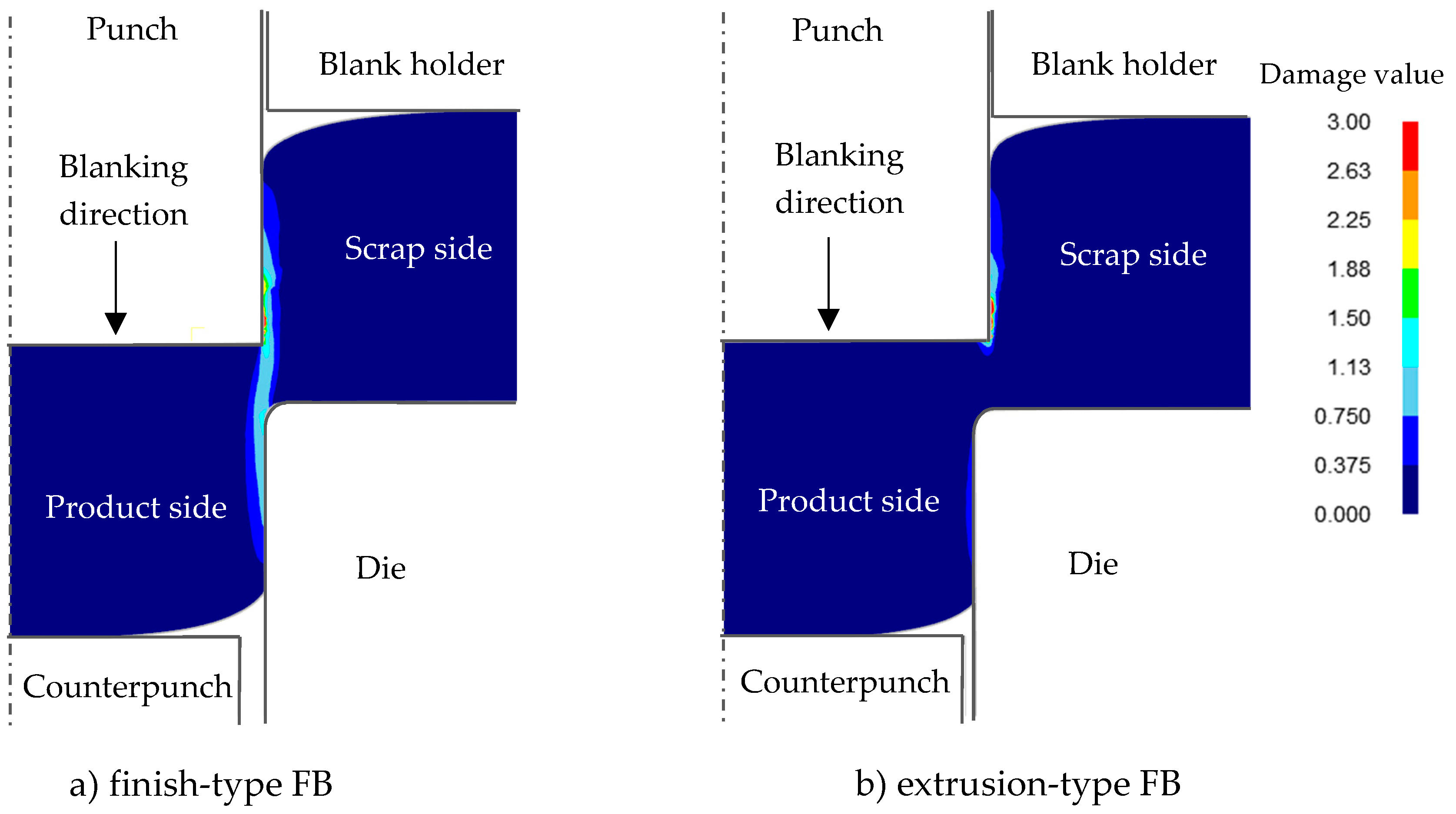

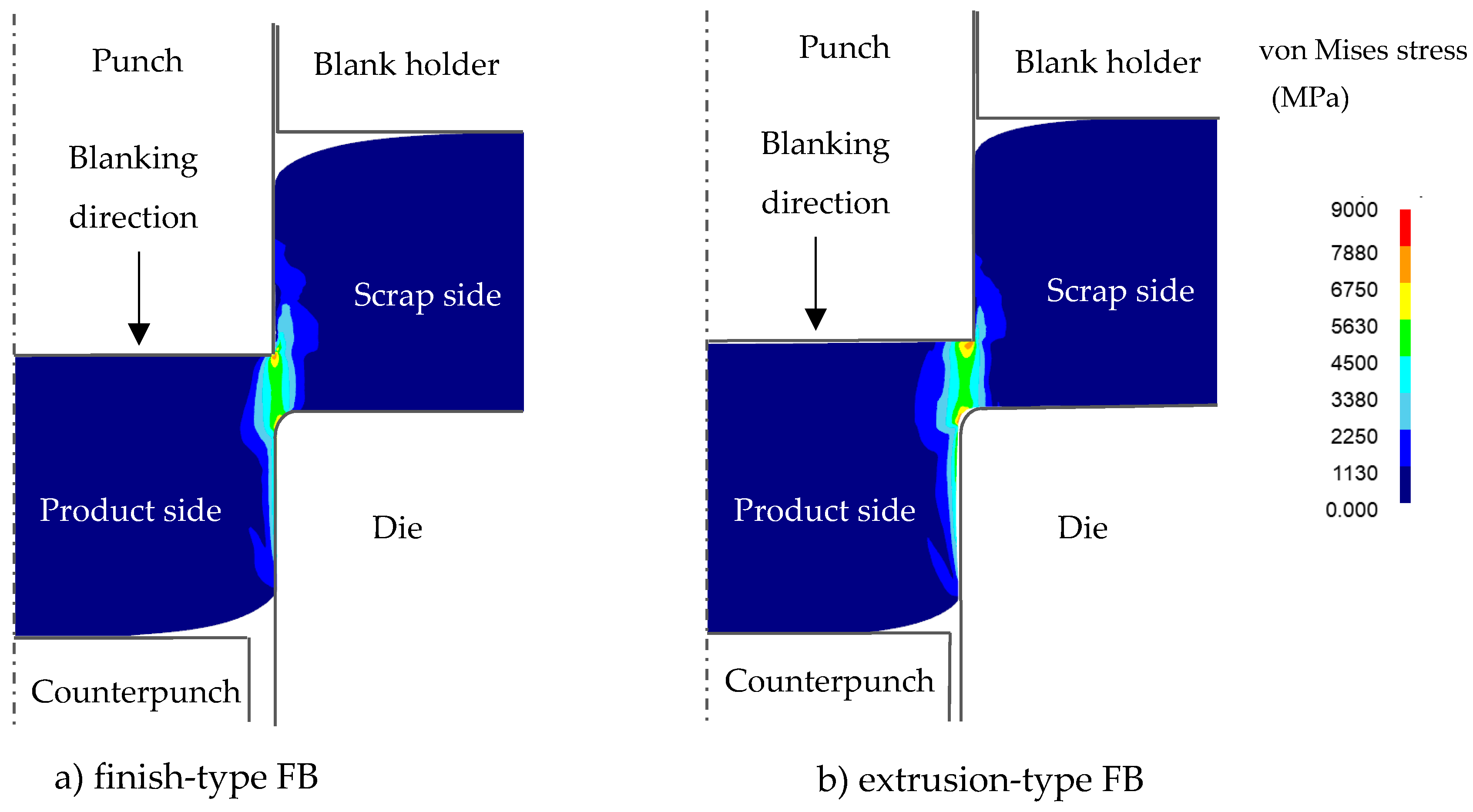

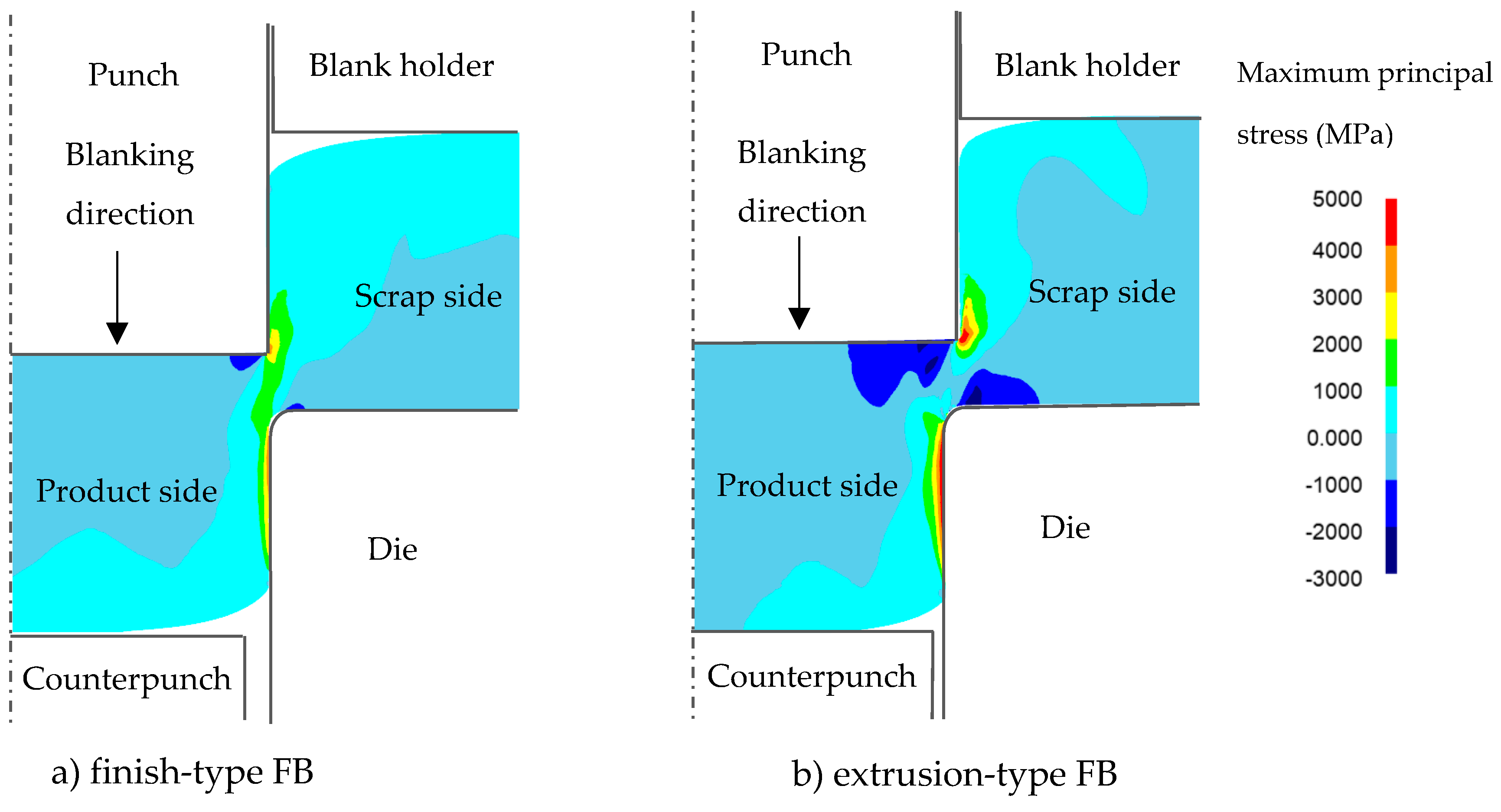

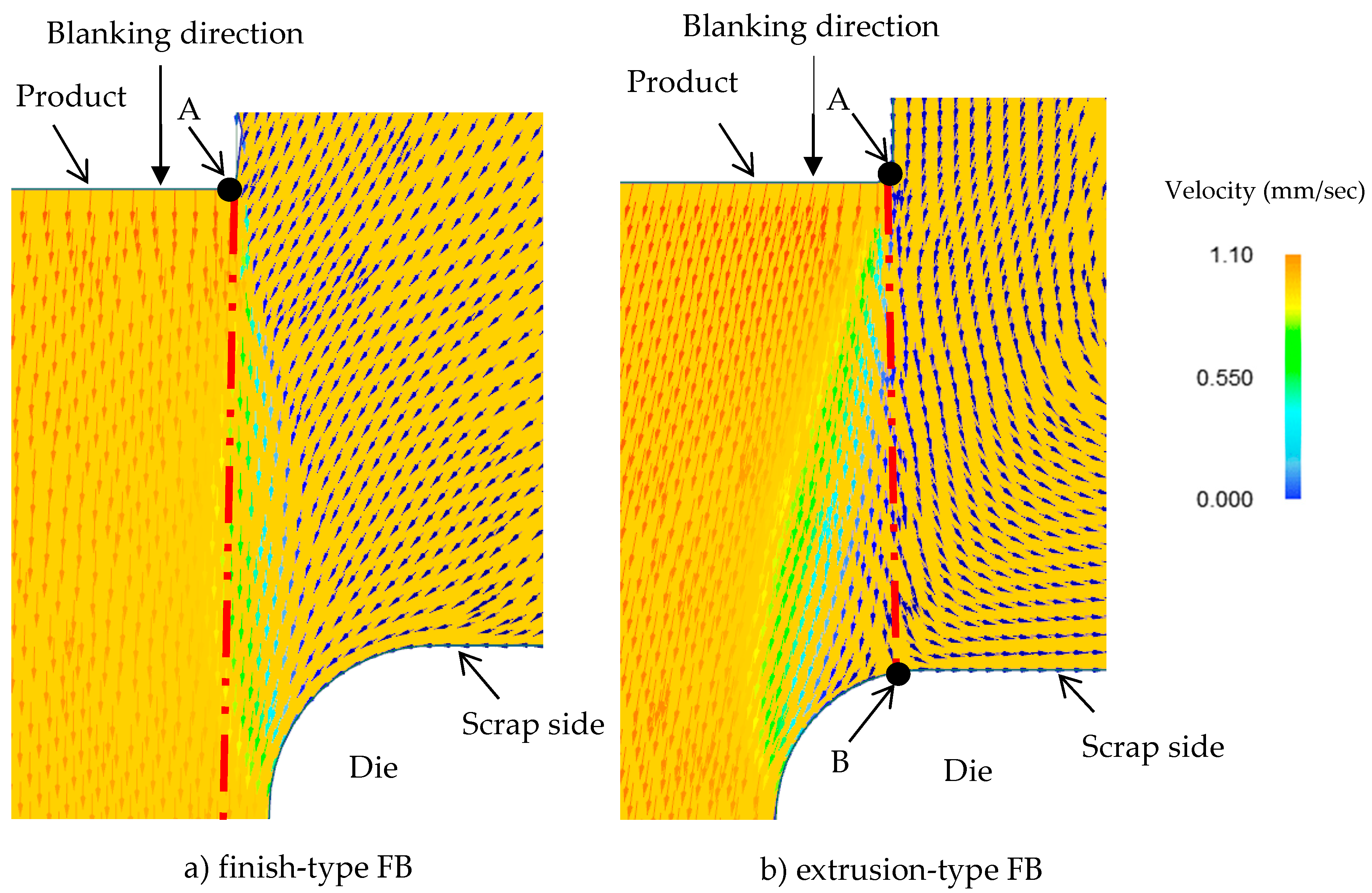

3. FEM Simulation Results and Discussion

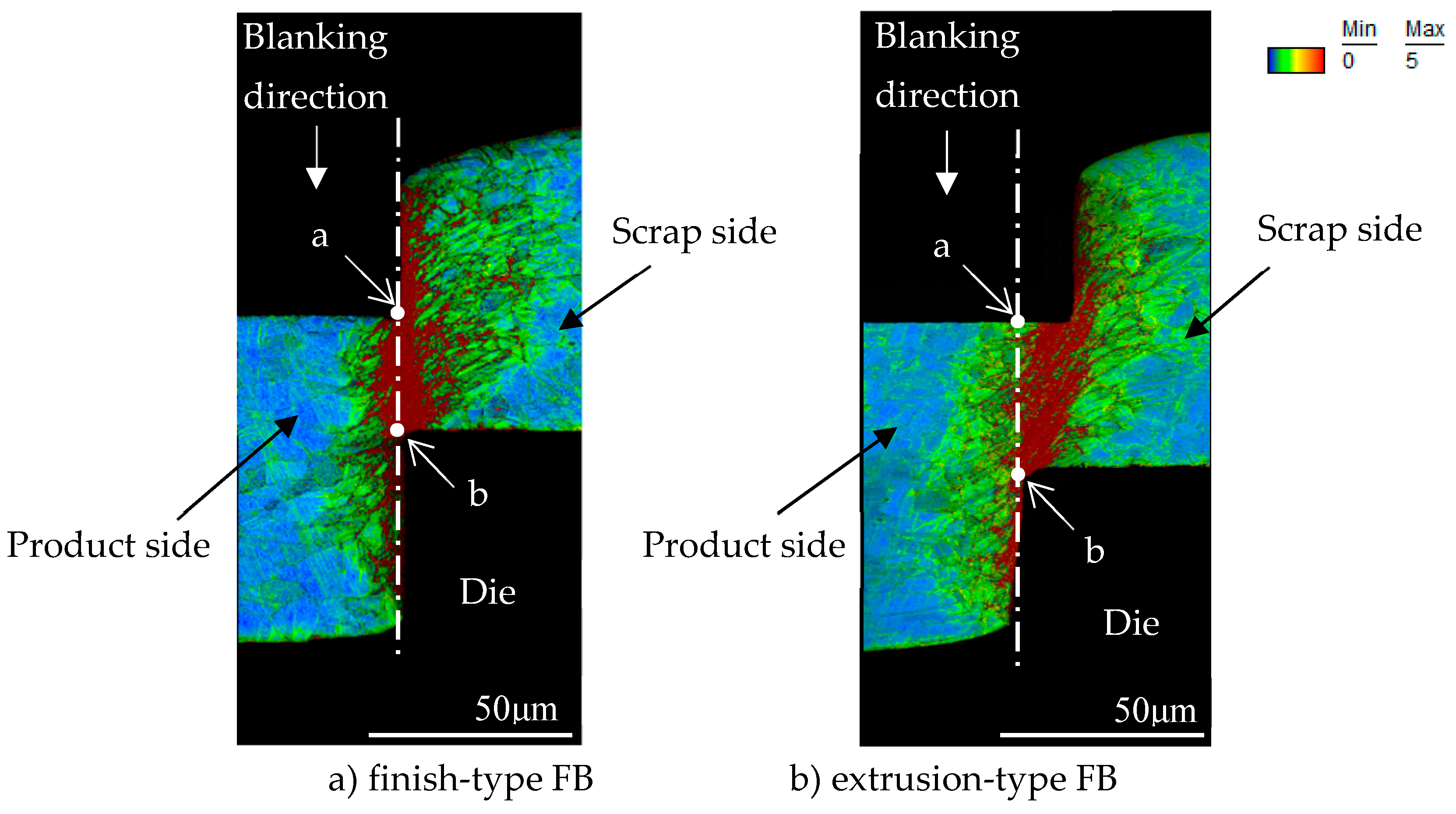

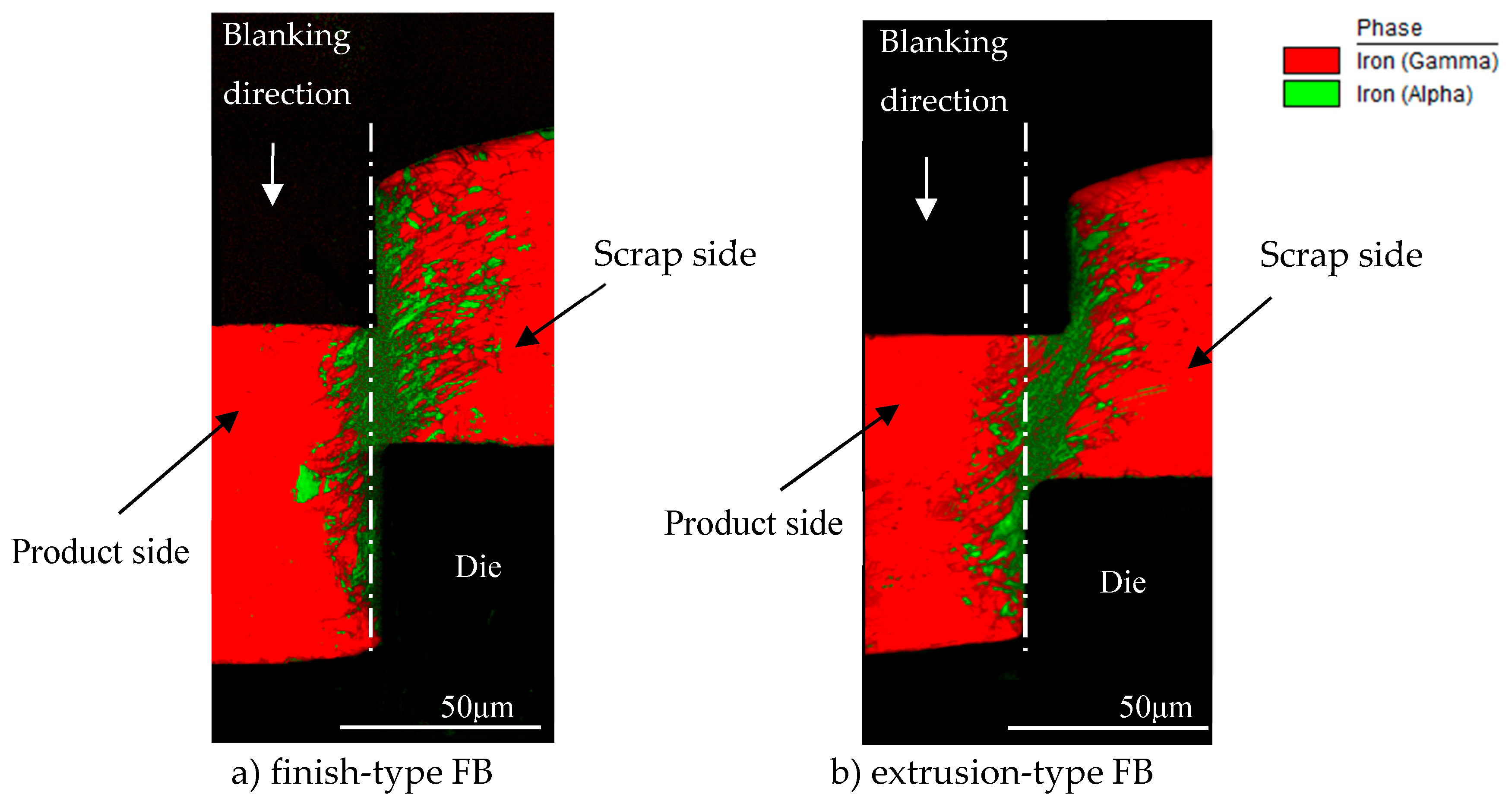

4. Discussion Based on EBSD Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, M. Micro integral forming technology in press die. J. Jpn. Soc. Technol. Plast. 2006, 47, 558–563. [Google Scholar] [CrossRef]

- Nakagawa, T. Fine Blanking; The Nikkan Kogyo Shimbun: Tokyo, Japan, 1998; pp. 1–162. [Google Scholar]

- Maeda, T. Design of punching die. J. Jpn. Soc. Technol. Plast. 1960, 1, 309–316. [Google Scholar]

- Maeda, T. Experimental investigation on fine blanking 2nd Report. J. Jpn. Soc. Technol. Plast. 1968, 9, 627–636. [Google Scholar]

- Nakano, S.; Suzuki, Y.; Aihara, T.; Shiratori, T. Visualization technology and nanometric positioning die system for micropiercing. J. Jpn. Soc. Technol. Plast. 2015, 56, 213–218. [Google Scholar] [CrossRef]

- Xu, Z.T.; Peng, L.F.; Lai, X.M.; Fu, M.W. Geometry and grain size effects on the forming limit of sheet metals in micro-scaled plastic deformation. Mater. Sci. Eng. A 2014, 611, 345–353. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Guo, Y.Z.; Wei, Q.; Topping, T.D.; Dangelewicz, A.M.; Zhu, Y.T.; Langdon, T.G.; Lavernia, E.J. Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves. Mater. Sci. Eng. A 2009, 525, 68–77. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Guo, Y.Z.; Wie, Q.; Dangelewicz, A.M.; Xu, C.; Zhu, Y.T.; Langdon, T.G.; Zhou, Y.Z.; Lavernia, E.J. Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scr. Mater. 2008, 59, 627–630. [Google Scholar] [CrossRef]

- Wang, J.L.; Fu, M.W.; Shi, S.Q. Influences of size effect and stress condition on ductile fracture behavior in micro-scaled plastic deformation. Mater. Des. 2017, 131, 69–80. [Google Scholar] [CrossRef]

- Suzuki, Y.; Shiratori, T.; Yang, M.; Murakawa, M. Processing of metal microgear tooth profile by finish blanking and extrusion blanking and evaluation of cut-surface shape. J. Jpn. Soc. Technol. Plast. 2018, 60, 64–69. [Google Scholar] [CrossRef]

- Yoshida, Y. Finite element method analysis of shearing process. J. Jpn. Soc. Technol. Plast. 2012, 53, 800–804. [Google Scholar] [CrossRef]

- Tanaka, T.; Hagihara, S.; Tadano, Y.; Inada, T.; Mori, T.; Fuchiwaki, K. Application of finite element method to analysis of ductile fracture criteria for punched cutting surfaces. Mater. Trans. 2013, 43, 1697–1702. [Google Scholar] [CrossRef]

- Thipprakmas, S.; Jin, M.; Kanaizuka, T.; Yamamoto, K.; Murakawa, M. Prediction of Fineblanking surface characteristics using the finite element method (FEM). J. Mater. Process. Technol. 2008, 198, 391–398. [Google Scholar] [CrossRef]

- Cockcroft, M.G.; Latham, D.J. Ductility and the workability of metals. J. Inst. Met. 1968, 96, 33–39. [Google Scholar]

- Sasada, M.; Shimura, K.; Aoki, I. Study on coefficient of friction between tool and material in Shearing. Trans. Jpn. Soc. Mech. Eng. Ser. C 2005, 71, 249–255. [Google Scholar] [CrossRef]

- Maeda, T.; Nakagawa, T. Experimental investigation on fine blanking 1st Report. J. Jpn. Soc. Technol. Plast. 1968, 9, 618–626. [Google Scholar]

- Huang, X.; Xiang, H.; Zhuang, X.; Zhao, Z. Improvement of die-roll quality in compound fine-blanking forming process. Adv. Mater. Res. 2011, 337, 236–241. [Google Scholar] [CrossRef]

- Thipprakmas, S.; Jin, M.; Murakawa, M. An investigation of material flow analysis in fineblanking process. J. Mater. Process. Technol. 2007, 192, 237–242. [Google Scholar] [CrossRef]

- Kimura, H.; Wang, Y.; Akiniwa, Y.; Tanaka, K. Misorientation analysis of plastic deformation of autenitic srainless steel by EBSD and X-ray diffraction methods. Trans. Jpn. Soc. Mech. Eng. 2005, 71, 118–124. [Google Scholar] [CrossRef]

- Shiratori, T. Effects of Grain Size and Process Condition on Stability of Sheared Surface in Micropunching at SUS304. Ph.D. Thesis, Tokyo Metropolitan University, Tokyo, Japan, 2017. [Google Scholar]

| Simulation Model Type | Axisymmetric Model |

|---|---|

| Object type | Workpiece: elasto-plastic (φDw:3.5 mm) |

| Punch /Die: rigid (φDp:1.748 mm, φDd1:1.752 mm, φDd2:1.732 mm) | |

| Blank holder /Stripper: rigid | |

| Counterpunch: rigid (φDc:1.720 mm) | |

| Clearance (Cl) | Finish-type FB: 2 μm |

| Extrusion-type FB: −8 μm | |

| Blank holder force (FB) | 1000 N (50% of maximum blanking force) |

| Counterpunch force (FC) | 400 N (20% of maximum blanking force) |

| Blanking force (FP) | Non-constant value |

| Radii of tool cutting edges | Rp = 0.00 mm, Rd = 0.01 mm |

| Work material (Workpiece) | SUS304 t = 0.178 mm Young’s modulus: 193 GPa Poisson’s ratio: 0.3 |

| Fracture criterion equation | Cockcroft and Latham |

| Friction coefficient (μ) | 0.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, Y.; Shiratori, T.; Yang, M.; Murakawa, M. Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses. Materials 2019, 12, 2143. https://doi.org/10.3390/ma12132143

Suzuki Y, Shiratori T, Yang M, Murakawa M. Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses. Materials. 2019; 12(13):2143. https://doi.org/10.3390/ma12132143

Chicago/Turabian StyleSuzuki, Yohei, Tomomi Shiratori, Ming Yang, and Masao Murakawa. 2019. "Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses" Materials 12, no. 13: 2143. https://doi.org/10.3390/ma12132143