Debonding Detection and Monitoring for CFRP Reinforced Concrete Beams Using Pizeoceramic Sensors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Samples

2.2. Test Setup of 3-Point Bending

2.3. Ultrasonic Measurements

2.3.1. Beam 1 for Debonding Detection after Failure

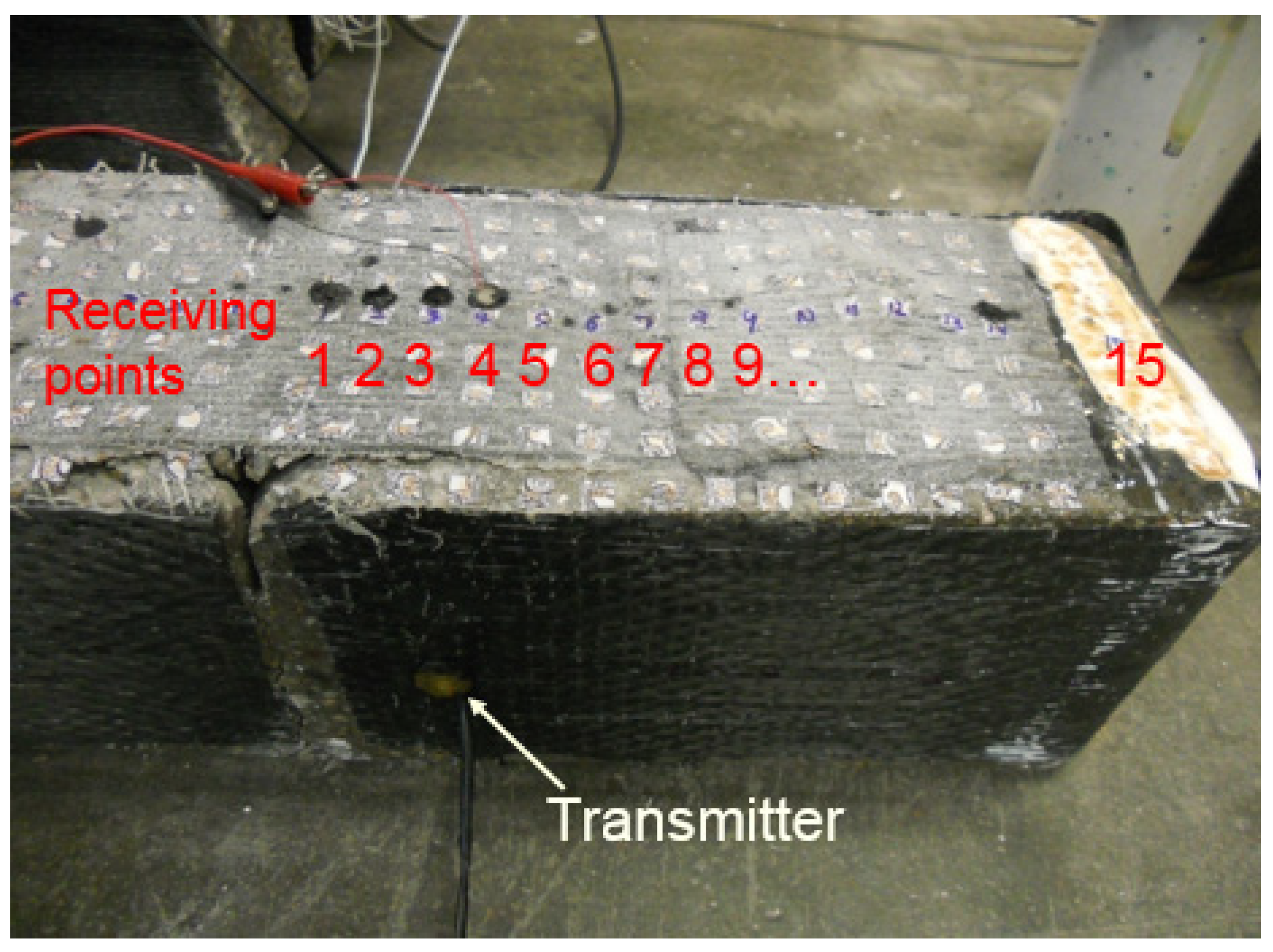

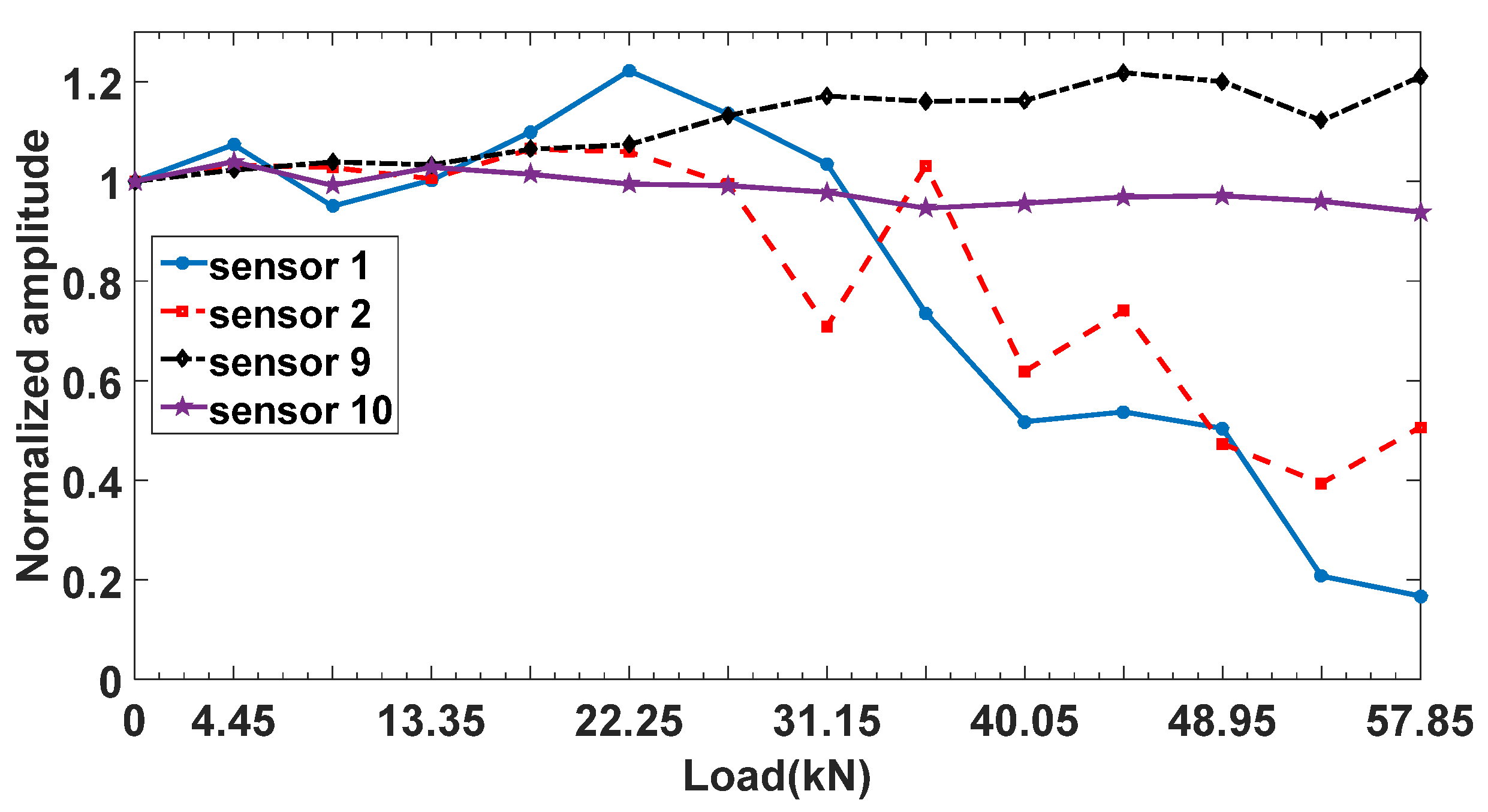

2.3.2. Beam 2 for Debonding Monitoring during Loading

3. Results and Discussion

3.1. Debonding Detecion after Failure

3.2. Debonding Monitoring during Loading

4. Conclusions

- (1)

- In the debonding detection test, the signal amplitude obtained in the debonding area is less than 20% of the amplitude obtained from the sensor attached to the concrete surface, and a 12.7 cm debonding length was estimated. The results were compared and verified by the strain measurement results from the vision-based strain testing system. The ultrasonic pitch–catch method using piezoceramic sensors showed feasibilities for locating the existing debonding between CFRP sheet and concrete substrate.

- (2)

- In the debonding monitoring test, at 57.85 kN of load, the amplitudes of sensors 1 to 4 were 40% less than the amplitudes before loaded. Other than this amplitude drop, a first arrival delay phenomenon was also observed. The debonding process of CFRP-reinforced concrete beam during loading could be successfully monitored by piezoceramic sensors in situ.

Author Contributions

Funding

Conflicts of Interest

References

- Peng, H.; Hao, H.; Zhang, J.; Liu, Y.; Cai, C.S. Experimental investigation of the bond behavior of the interface between near-surface-mounted CFRP strips and concrete. Constr. Build. Mater. 2015, 96, 11–19. [Google Scholar] [CrossRef]

- Sakar, G.; Tanarslan, H.M. Prestressed CFRP Fabrics for Flexural Strengthening of Concrete Beams with an Easy Prestressing Technique. Mech. Compos. Mater. 2014, 50, 537–542. [Google Scholar] [CrossRef]

- Xie, J.-H.; Guo, Y.-C.; Liu, Y.-F.; Chen, G.-F. Experimental Study on Flexural Behaviour of Pre-damaged Reinforced Concrete Beams Strengthened with CFRP. Mater. Plast. 2014, 51, 370–375. [Google Scholar]

- Peng, H.; Zhang, J.; Cai, C.S.; Liu, Y. An experimental study on reinforced concrete beams strengthened with prestressed near surface mounted CFRP strips. Eng. Struct. 2014, 79, 222–233. [Google Scholar] [CrossRef]

- Attari, N.; Amziane, S.; Chemrouk, M. Flexural strengthening of concrete beams using CFRP, GFRP and hybrid FRP sheets. Constr. Build. Mater. 2012, 37, 746–757. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Dias, S.J.E.; Lima, J.L.T. Efficacy of CFRP-based techniques for the flexural and shear strengthening of concrete beams. Cem. Concr. Compos. 2007, 29, 203–217. [Google Scholar] [CrossRef]

- Lou, T.; Lopes, S.M.R.; Lopes, A.V. Effect of linear transformation on nonlinear behavior of continuous prestressed beams with external FRP cables. Eng. Struct. 2017, 147, 410–424. [Google Scholar] [CrossRef]

- Lou, T.; Karavasilis, T.L. Time-dependent assessment and deflection prediction of prestressed concrete beams with unbonded CFRP tendons. Compos. Struct. 2018, 194, 365–376. [Google Scholar] [CrossRef] [Green Version]

- Lou, T.; Liu, M.; Lopes, S.M.R.; Lopes, A.V. Effect of bond on flexure of concrete beams prestressed with FRP tendons. Compos. Struct. 2017, 173, 168–176. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Chastre, C.; Silva, M.A.G. Estimations of the debonding process of aged joints through a new analytical method. Compos. Struct. 2019, 211, 577–595. [Google Scholar] [CrossRef]

- Kim, J.-W.; Lee, C.; Park, S. Damage Localization for CFRP-Debonding Defects Using Piezoelectric SHM Techniques. Res. Nondestruct. Eval. 2012, 23, 183–196. [Google Scholar] [CrossRef]

- Brown, J.R.; Hamilton, H.R. Quantitative infrared thermography inspection for FRP applied to concrete using single pixel analysis. Constr. Build. Mater. 2013, 38, 1292–1302. [Google Scholar] [CrossRef]

- Tashan, J.; Al-Mahaidi, R. Bond defect detection using PTT IRT in concrete structures strengthened with different CFRP systems. Compos. Struct. 2014, 111, 13–19. [Google Scholar] [CrossRef]

- Xu, B.; Li, B.; Song, G. Active Debonding Detection for Large Rectangular CFSTs Based on Wavelet Packet Energy Spectrum with Piezoceramics. J. Struct. Eng. 2013, 139, 1435–1443. [Google Scholar] [CrossRef]

- Sikdar, S.; Ostachowicz, W. Ultrasonic Lamb wave-based debonding monitoring of advanced honeycomb sandwich composite structures. Strain 2018, 1–15. [Google Scholar] [CrossRef]

- Deng, H.; He, Z.; Chen, L. Ultrasonic guided wave-based detection of composite insulator debonding. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3583–3593. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Lin, Y. Detecting debonding flaws at the epoxy-concrete interfaces in near-surface mounted CFRP strengthening beams using the impact-echo method. NDT E Int. 2016, 83, 1–13. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, R.; Liu, Z.; Shao, C. An acoustic-optical fiber NDE technique for interfacial debonding detection in FRP-retrofitted structures. NDT E Int. 2015, 72, 50–57. [Google Scholar] [CrossRef]

- Sun, W. Behavior of Carbon Fiber Reinforced Polymer (CFRP) Anchors Strengthening Reinforced Concrete Structures. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2014. [Google Scholar]

- ASTM International. ASTM C293/C293M-16 Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Jirsa, J.O.; Shekarchi, W.A.; Pudleiner, D.K.; Wang, H. Use of Carbon Fiber Reinforced Polymer (CFRP) with CFRP Anchors for Shear-Strengthening and Design Recommendations/Quality Control Procedures for CFRP Anchors. No. FHWA/TX-16/0-6783-1; University of Texas at Austin: Austin, TX, USA, 2017. [Google Scholar]

- ACI Committee 440. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures (ACI 440.2R-08); American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Sun, W.; Jing, H.; Dong, Z. Debonding Detection and Monitoring for CFRP Reinforced Concrete Beams Using Pizeoceramic Sensors. Materials 2019, 12, 2150. https://doi.org/10.3390/ma12132150

Liu S, Sun W, Jing H, Dong Z. Debonding Detection and Monitoring for CFRP Reinforced Concrete Beams Using Pizeoceramic Sensors. Materials. 2019; 12(13):2150. https://doi.org/10.3390/ma12132150

Chicago/Turabian StyleLiu, Shukui, Wei Sun, Hongwen Jing, and Zhaoxing Dong. 2019. "Debonding Detection and Monitoring for CFRP Reinforced Concrete Beams Using Pizeoceramic Sensors" Materials 12, no. 13: 2150. https://doi.org/10.3390/ma12132150