The Effect of Substrate Biasing during DC Magnetron Sputtering on the Quality of VO2 Thin Films and Their Insulator–Metal Transition Behavior

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure Characterization by Raman

3.2. Surface Morphology Characterization by SEM

3.3. Chemical States Characterization by XPS

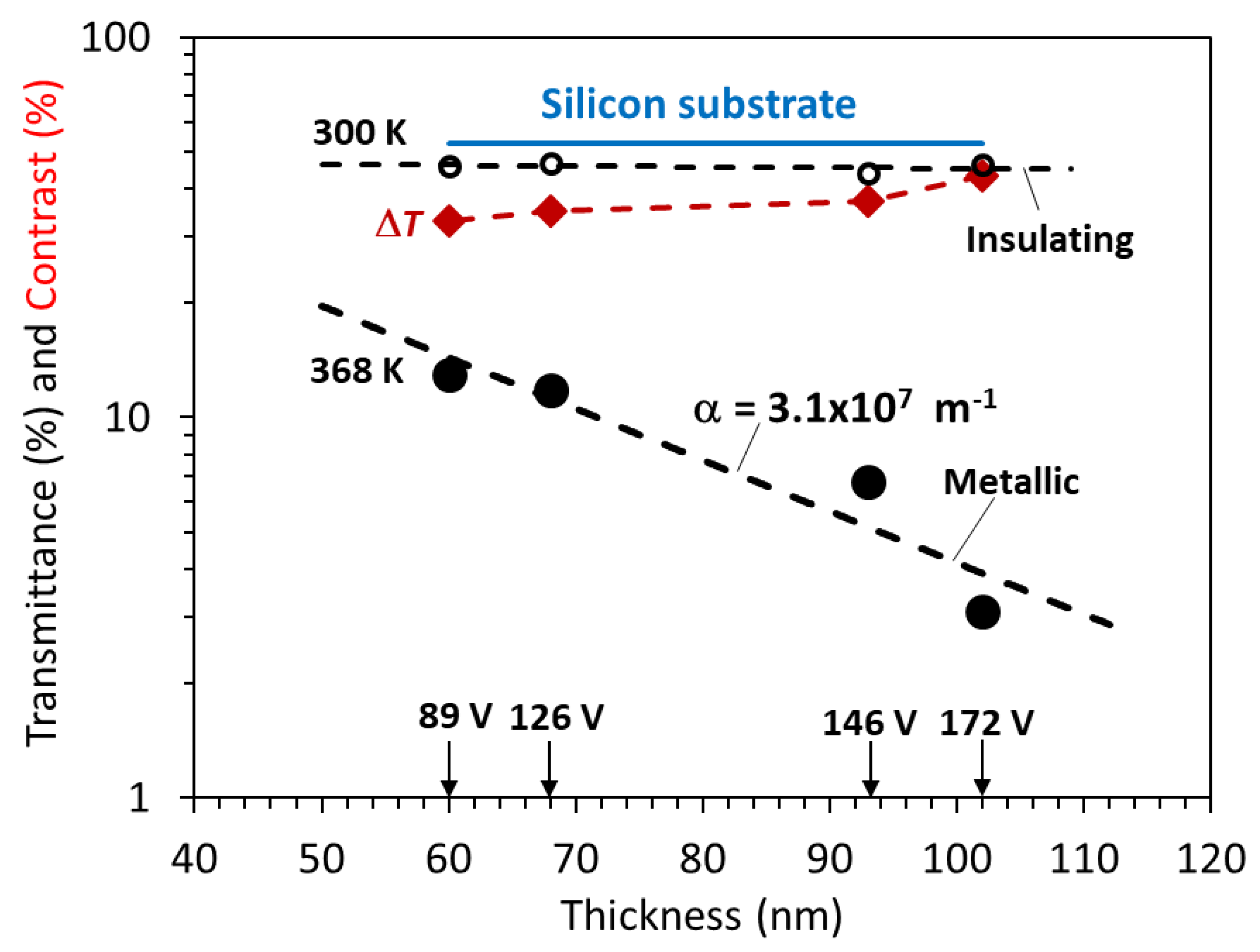

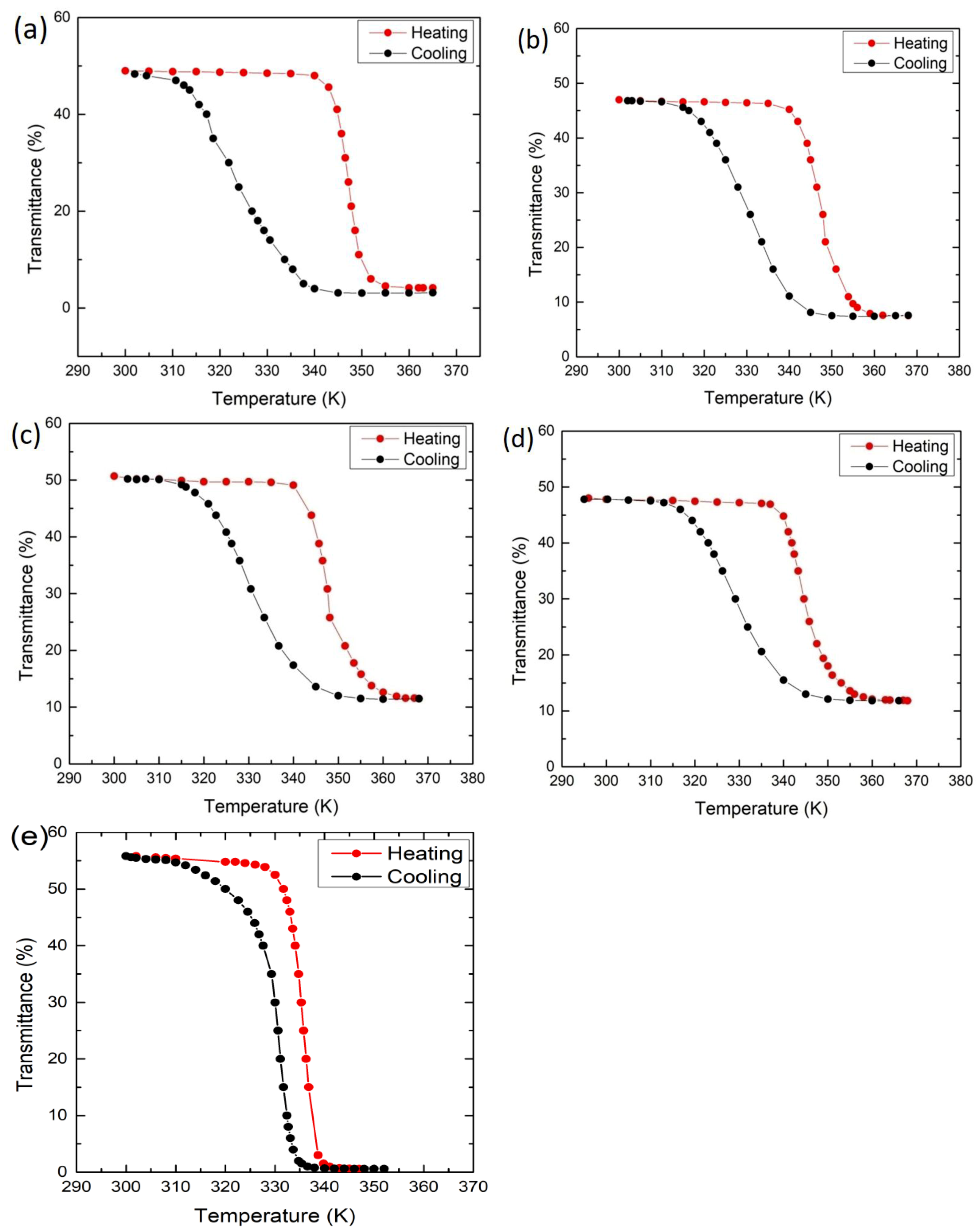

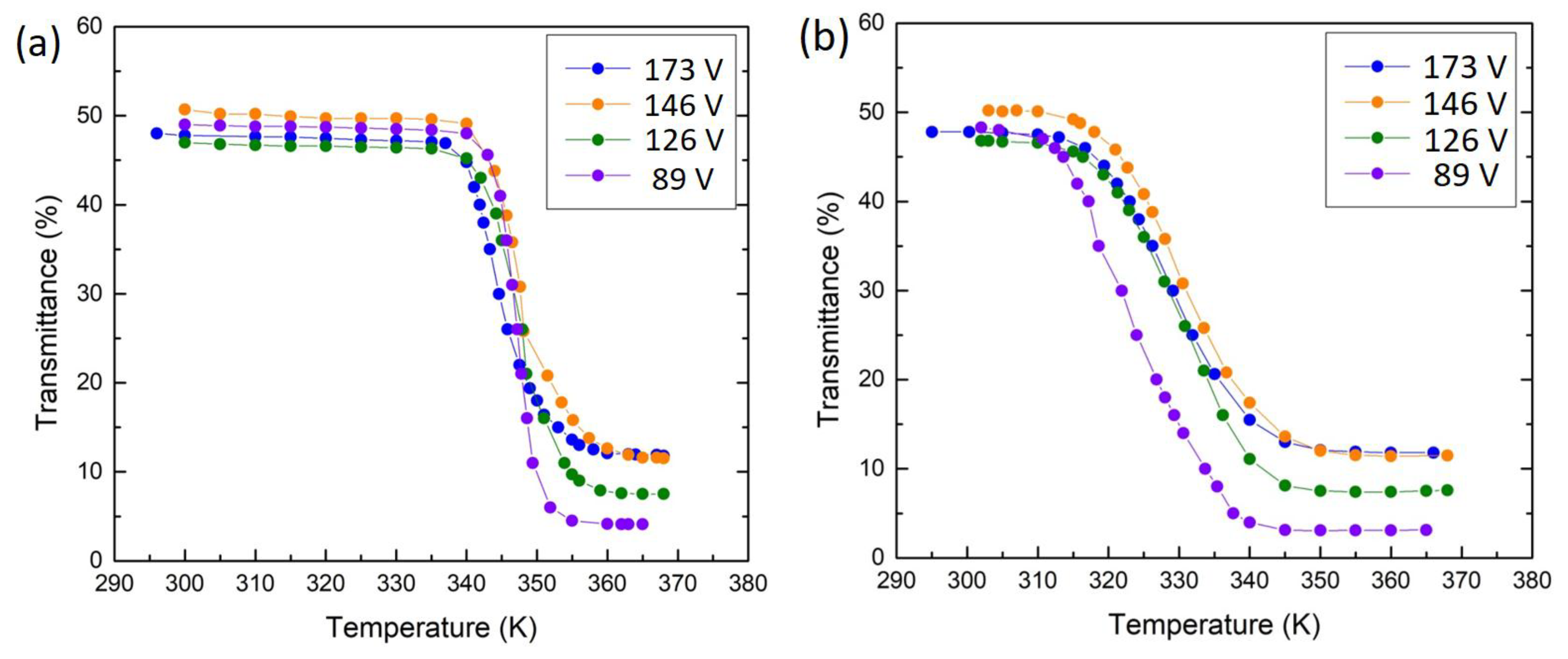

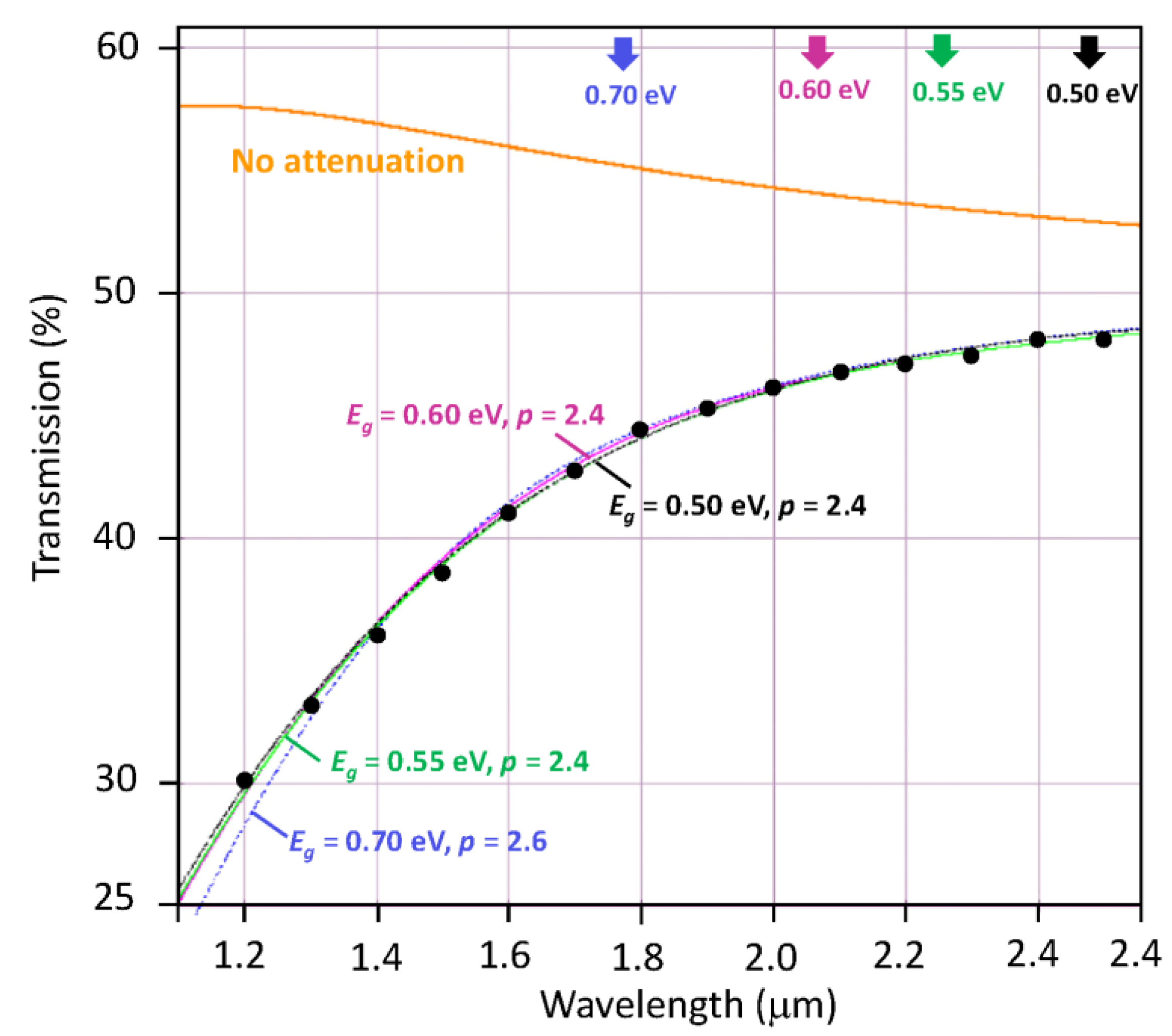

3.4. Optical Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morin, F.J. Oxides Which Show a Metal-to-Insulator Transition at the Neel Temperature. Phys. Rev. Lett. 1959, 3, 34–36. [Google Scholar] [CrossRef]

- Chen, S.; Ma, H.; Yi, X.; Wang, H.; Tao, X.; Chen, M.; Li, X.; Ke, C. Optical switch based on vanadium dioxide thin films. Infrared Phys. Technol. 2004, 45, 239–242. [Google Scholar] [CrossRef]

- Cheng, C.; Guo, H.; Amini, A.; Liu, K.; Fu, D.; Zou, J.; Song, H. Self-assembly and horizontal orientation growth of VO2 nanowires. Sci. Rep. 2014, 4, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Pellegrino, L.; Manca, N.; Kanki, T.; Tanaka, H.; Biasotti, M.; Bellingeri, E.; Siri, A.S.; Marré, D. Multistate memory devices based on free-standing VO2/TiO2 microstructures driven by Joule self-heating. Adv. Mater. 2012, 24, 2929–2934. [Google Scholar] [CrossRef] [PubMed]

- Srirodpai, O.; Wootthikanokkhan, J.; Nawalertpanya, S.; Yuwawech, K.; Meeyoo, V. Preparation, Characterization and Thermo-Chromic Properties of EVA/VO2 Laminate Films for Smart Window Applications and Energy Efficiency in Building. Materials 2017, 10, 53. [Google Scholar] [CrossRef] [PubMed]

- Fu, D.; Liu, K.; Tao, T.; Lo, K.; Cheng, C.; Liu, B.; Zhang, R.; Bechtel, H.A.; Wu, J. Comprehensive study of the metal-insulator transition in pulsed laser deposited epitaxial VO2 thin films. J. Appl. Phys. 2013, 113, 043707. [Google Scholar] [CrossRef]

- Kim, I.S.; Lauhon, L.J. Increased yield and uniformity of vanadium dioxide nanobeam growth via two-step physical vapor transport process. Cryst. Growth Des. 2012, 12, 1383–1387. [Google Scholar] [CrossRef]

- Fan, L.L.; Chen, S.; Luo, Z.L.; Liu, Q.H.; Wu, Y.F.; Song, L.; Ji, D.X.; Wang, P.; Chu, W.S.; Gao, C.; et al. Strain dynamics of ultrathin VO2 film grown on TiO2(001) and the associated phase transition modulation. Nano Lett. 2004, 14, 4036–4043. [Google Scholar] [CrossRef] [PubMed]

- Miller, M.J.; Wang, J. Influence of grain size on transition temperature of thermochromic VO2. J. Appl. Phys. 2015, 117, 034307. [Google Scholar] [CrossRef]

- Luo, Z.; Wu, Z.; Wang, T.; Xu, X.; Li, W.; Li, W.; Jiang, Y. Comparison of the optical responses of O-poor and O-rich thermochromic VOX films during semiconductor-to-metal transition. J. Phys. Chem. Solids 2012, 73, 1122–1126. [Google Scholar] [CrossRef]

- Drosos, C.; Vernardou, D. Advancements, Challenges and Prospects of Chemical Vapour Pressure at Atmospheric Pressure on Vanadium Dioxide Structures. Materials 2018, 11, 384. [Google Scholar] [CrossRef] [PubMed]

- Chen, E.E. The influence of deposition temperature on the structure and optical properties of vanadium oxide films. J. Vac. Sci. Technol. 1986, A4, 432–435. [Google Scholar] [CrossRef]

- Yang, Y.; Yao, Y.; Zhang, B.; Lin, H.; Luo, Z.; Gao, C.; Zhang, C.; Kang, C. Investigating Metal–Insulator Transition and Structural Phase Transformation in the (010)-VO2/(001)-YSZ Epitaxial Thin Films. Materials 2018, 11, 1713. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Ramanathan, S. Heteroepitaxial VO2 thin films on GaN: Structure and metal-insulator transition characteristics. J. Appl. Phys. 2012, 112, 74114. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, H.-J.; Wang, M.-H.; Miao, L.-H.; Liu, H.-Z.; Zhang, Y.-Z.; Bian, J.-M. VO2 Thermochromic Films on Quartz Glass Substrate Grown by RF-Plasma-Assisted Oxide Molecular Beam Epitaxy. Materials 2017, 10, 314. [Google Scholar] [CrossRef] [PubMed]

- Fu, G.; Polity, A.; Volbers, N.; Meyer, B.K. Annealing effects on VO2 thin films deposited by reactive sputtering. Thin Solid Films 2006, 515, 2519–2522. [Google Scholar] [CrossRef]

- Zhu, M.-D.; Shan, C.; Li, C.; Wang, H.; Qi, H.-J.; Zhang, D.-P.; Lv, W.Z. Thermochromic and Femtosecond-Laser-Induced Damage Performance of Tungsten-Doped Vanadium Dioxide Films Prepared Using an Alloy Target. Materials 2018, 11, 1724. [Google Scholar] [CrossRef]

- Mai, L.Q.; Hu, B.; Hu, T.; Chen, W.; Gu, E.D.; Mai, L. Electrical Property of Mo-Doped VO2Nanowire Array Film by Melting−Quenching Sol−Gel Method. J. Phys. Chem. B 2006, 110, 19083–19086. [Google Scholar] [CrossRef]

- Burkhardt, W.; Christmann, T.; Franke, S.; Kriegseis, W.; Meister, D.; Meyer, B.; Niessner, W.; Schalch, D.; Scharmann, A. Tungsten and fluorine co-doping of VO2 films. Thin Solid Films 2002, 402, 226–231. [Google Scholar] [CrossRef]

- Béteille, F.; Livage, J. Optical Switching in VO2 Thin Films. J. Sol-Gel Sci. Technol. 1998, 13, 915–921. [Google Scholar] [CrossRef]

- Du, J.; Gao, Y.; Luo, H.; Kang, L.; Zhang, Z.; Chen, Z.; Cao, C. Significant changes in phase-transition hysteresis for Ti-doped VO2 films prepared by polymer-assisted deposition. Sol. Energy Mater. Sol. Cells 2011, 95, 469–475. [Google Scholar] [CrossRef]

- Liu, M.K.; Wagner, M.; Abreu, E.; Kittiwatanakul, S.; McLeod, A.; Fei, Z.; Goldflam, M.; Dai, S.; Fogler, M.; Lu, J.; et al. Anisotropic Electronic State via Spontaneous Phase Separation in Strained Vanadium Dioxide Films. Phys. Rev. Lett. 2013, 111, 096602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.; Koughia, C.; Li, Y.; Cui, X.; Ye, F.; Shiri, S.; Sanayei, M.; Wen, S.-J.; Yang, Q.; Kasap, S. Near-zero IR transmission of VO2 thin films deposited on Si substrate. Appl. Surf. Sci. 2018, 440, 415–420. [Google Scholar] [CrossRef]

- Bobyak, L.; Fallon, P.; Razavi, A. The effects of biasing and annealing on the optical properties of radio-frequency sputtered VO2. J. Vac. Sci. Technol. A 1990, 8, 1391–1394. [Google Scholar]

- Azhan, N.H.; Okimura, K.; Ohtsubo, Y.; Kimura, S.-I.; Zaghrioui, M.; Sakai, J. Large modification in insulator-metal transition of VO2 films grown on Al2O3 (001) by high energy ion irradiation in biased reactive sputtering. J. Appl. Phys. 2016, 119, 055308. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Q.; Koughia, C.; Ye, F.; Sanayei, M.; Wen, S.-J.; Kasap, S. Characterization of vanadium oxide thin films with different stoichiometry using Raman spectroscopy. Thin Solid Films 2016, 620, 64–69. [Google Scholar] [CrossRef]

- Li, B.; Yu, D.; Zhang, S.-L. Raman spectral study of silicon nanowires. Phys. Rev. B 1999, 59, 1645–1648. [Google Scholar] [CrossRef]

- De Natale, J.F.; Hood, P.J.; Harker, A.B. Formation and characterization of grain-oriented VO2 thin films. J. Appl. Phys. 1989, 66, 5844–5850. [Google Scholar] [CrossRef]

- Mihailescu, C.N.; Symeou, E.; Svoukis, E.; Negrea, R.F.; Ghica, C.; Teodorescu, V.S.; Tanase, L.C.; Negrilă, C.; Giapintzakis, J. Ambiguous Role of Growth-Induced Defects on the Semiconductor-to-Metal Characteristics in Epitaxial VO2/TiO2 Thin Films. ACS Appl. Mater. Interfaces 2018, 10, 14132–14144. [Google Scholar] [CrossRef]

- Bull, S.J.; Jones, A.M.; MacCabe, A.R. Residual stress in ion-assisted coatings. Surf. Coat. Technol. 1992, 54/55, 173–179. [Google Scholar] [CrossRef]

- Kasap, S.O. Principles of Electronic Materials and Devices, 4th ed.; McGraw-Hill: New York, NY, USA, 2018; p. 896. [Google Scholar]

- Chain, E.A. Optical properties of vanadium dioxide and vanadium pentoxide thin films. Appl. Opt. 1991, 30, 2782. [Google Scholar] [CrossRef] [PubMed]

- Rosevear, W.H.; Paul, W. Hall effect in VO2 near the Semiconductor-To-Metal transition. Phys. Rev. B 1973, 7, 2109. [Google Scholar] [CrossRef]

- Kivaisi, R.; Samiji, M. Optical and electrical properties of vanadium dioxide films prepared under optimized RF sputtering conditions. Sol. Energy Mater. Sol. Cells 1999, 57, 141–152. [Google Scholar] [CrossRef]

- Hensler, D.H. Transport Properties of Sputtered Vanadium Dioxide Thin Films. J. Appl. Phys. 1968, 39, 2354. [Google Scholar] [CrossRef]

- Kasap, S.O. Optoelectronics and Photonics: Principles and Practices, 2nd ed.; Pearson: Upper Saddle River, NJ, USA, 2013; p. 73. [Google Scholar]

- Swanepoel, R. Determination of the thickness and optical constants of amorphous silicon. J. Phys. E Sci. Instrum. 1983, 16, 1214–1222. [Google Scholar] [CrossRef]

- Wan, C.; Zhang, Z.; Woolf, D.; Hessel, C.M.; Rensberg, J.; Hensley, J.M.; Xiao, Y.; Shahsafi, A.; Salman, J.; Richter, S.; et al. Optical properties of thin-film vanadium oxide from the visible to the far infrared. arXiv preprint 2019. [Google Scholar]

- Swann, J.T.; De Smet, D.J. Ellipsometric investigation of vanadium dioxide films. J. Appl. Phys. 1985, 58, 1335–1338. [Google Scholar] [CrossRef]

- Parker, J.C.; Geiser, U.W.; lam, D.J.; Xu, Y.; Ching, W.Y. Optical properties of the vanadium oxides VO2 and V2O5. J. Am. Ceram. Soc. 1990, 73, 3206–3208. [Google Scholar] [CrossRef]

- Lin, T.; Wang, J.; Liu, G.; Wang, L.; Wang, X.; Zhang, Y. Influence of Discharge Current on Phase Transition Properties of High Quality Polycrystalline VO2 Thin Film Fabricated by HiPIMS. Materials 2017, 10, 633. [Google Scholar] [CrossRef]

- Shin, S.; Suga, S.; Taniguchi, M.; Fujisawa, M.; Kanzaki, H.; Fujimori, A.; Daimon, H.; Ueda, Y.; Kosuge, K.; Kachi, S. Vacuum-ultraviolet reflectance and photoemission study of the metal-insulator phase transitions in VO2, V6O13, and V2O3. Phys. Rev. B Condens. Matter 1990, 41, 4993–5009. [Google Scholar] [CrossRef]

| Sample # | Biasing Power (W) | Biasing Voltage (V) | Average Grain Size (nm) | Thickness (nm) |

|---|---|---|---|---|

| A | 15 | 89 | 58.8 ± 0.6 | 102 ± 1 |

| B | 25 | 126 | 67.2 ± 1.0 | 93 ± 2 |

| C | 35 | 146 | 88.6 ± 1.2 | 68 ± 1 |

| D | 45 | 173 | 75.1 ± 0.5 | 60 ± 2 |

| Sample # | Thickness (nm) | Average Grain Size (nm) | p | As (nmp−1) | αsL at 2000 nm |

|---|---|---|---|---|---|

| A | 102 ± 1 | 58.8 ± 0.6 | 2.4 | 1.30 × 105 | 0.16 |

| B | 93 ± 2 | 67.2 ± 1.0 | 1.6 | 4.05 × 102 | 0.20 |

| C | 68 ± 1 | 88.6 ± 1.2 | 2.0 | 6.70 × 103 | 0.11 |

| D | 60 ± 2 | 75.1 ± 0.5 | 2.2 | 3.65 × 104 | 0.12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Gunes, O.; Li, Y.; Cui, X.; Mohammadtaheri, M.; Wen, S.-J.; Wong, R.; Yang, Q.; Kasap, S. The Effect of Substrate Biasing during DC Magnetron Sputtering on the Quality of VO2 Thin Films and Their Insulator–Metal Transition Behavior. Materials 2019, 12, 2160. https://doi.org/10.3390/ma12132160

Zhang C, Gunes O, Li Y, Cui X, Mohammadtaheri M, Wen S-J, Wong R, Yang Q, Kasap S. The Effect of Substrate Biasing during DC Magnetron Sputtering on the Quality of VO2 Thin Films and Their Insulator–Metal Transition Behavior. Materials. 2019; 12(13):2160. https://doi.org/10.3390/ma12132160

Chicago/Turabian StyleZhang, Chunzi, Ozan Gunes, Yuanshi Li, Xiaoyu Cui, Masoud Mohammadtaheri, Shi-Jie Wen, Rick Wong, Qiaoqin Yang, and Safa Kasap. 2019. "The Effect of Substrate Biasing during DC Magnetron Sputtering on the Quality of VO2 Thin Films and Their Insulator–Metal Transition Behavior" Materials 12, no. 13: 2160. https://doi.org/10.3390/ma12132160